The evolution of automotive technology has brought forth specialized systems designed to enhance performance and driver engagement. The XShift Sequential Gearbox Plus Evolution 10 represents a cutting-edge solution in this realm, integrating advanced gear mechanisms with electronic controls. Business owners in the automotive industry must grasp the intricacies of this product, from its customization options and mechanical workings to its wiring configurations and advanced display systems. Each chapter of this article elaborates on these aspects, providing a comprehensive understanding essential for informed decision-making and product development.

Sequential Gearbox Evolution 10: Customization, Lever Wiring, and Display in Modern High-Performance Drivetrains

The realm of high-performance drivetrains has long revolved around precision, speed, and a driver’s intimate connection with the machine. In this space, the most compelling evolutions are not merely faster gears or stronger components; they are systems designed to listen to the driver’s intent and translate it into instantaneous, repeatable action. The notion of a Sequential Gearbox Evolution 10, seen through the lens of customization, lever wiring, and on-vehicle displays, invites a holistic view of how modern race-ready transmissions are engineered, tuned, and deployed. It is a story of modularity, of electronic and mechanical collaboration, and of the painstaking craft that turns a sophisticated concept into a reliable tool on the track. What makes Evolution 10 compelling is less its raw capability than the way it embodies a philosophy: that performance comes from a harmonized ecosystem where every interface—mechanical, electrical, and human—speaks the same language and shares a single goal: rapid, controlled power delivery under all track conditions.

At its core, a sequential gearbox is built to change gears in a linear sequence, one at a time, rather than through a traditional H-pattern. This design accelerates gear changes and minimizes the opportunity for mis-shifts, a critical advantage when hundreds of milliseconds can decide a lap or a stage. Yet the practical value of such a system hinges on a precise orchestration of control strategies, calibration, and feedback that keep the driver and the car in sync. The Evolution 10 concept foregrounds customization as the enabling force. Teams and builders are not simply choosing a gearbox; they are shaping an entire transmission ecosystem to fit a vehicle’s weight distribution, power profile, tire characteristics, and the specific demands of a race discipline. The emphasis on customization begins with the gearbox itself but extends outward to the lever interface, the wiring harness, the control software, and the driver display. Each element must be capable of adjustment, because the most marginal gains on a race weekend often come from small, repeatable refinements rather than a single dramatic upgrade.

The sequential gearbox operates with a linear shift pattern. In practice, this means the driver’s input acts as a clean signal to the control system, which then commands the actuators to engage the appropriate gear. The path from pedal or lever to the road is short and tightly controlled: a rapid, smooth engagement that preserves grip, torque, and momentum through every corner. The speed of the shift is not just a function of the mechanical actuation; it is the result of careful tuning of shift timing, clutch or hydro-mechanical engagement, and the electronics that coordinate engine mapping with drivetrain dynamics. Evolution 10’s sense of performance thus rests on how precisely these timings can be adjusted to align with engine torque curves, turbo response, or, in an electrified configuration, motor torque delivery. The goal is not simply to shift faster; it is to deliver the right amount of torque at the right moment, so the car remains planted, predictable, and responsive to driver inputs.

A defining feature of the system discussed here is its integration of lever wiring and a dedicated display, elements that connect the human operator to the machine with clarity and reliability. The shifter lever is more than a mechanical input; it is a sensor-rich interface that translates a discrete gesture into a sequence command. The wiring harness has to survive brutal environments: high vibration, heat cycling, EMI from power electronics, and the constant demands of on-track operation. Practitioners emphasize robust connectors, shielded cables, and redundancy pathways so that a single misfire or a damaged wire cannot derail a race. The display, meanwhile, provides real-time feedback that is essential during a high-stakes maneuver. It may show the current gear, RPM band, shift advisories, and diagnostic cues. The driver’s situational awareness is enhanced when the display communicates clearly, without ambiguity, so decisions—such as whether to prepare for a late-braking shift or to engage a launch control sequence—can be made with confidence.

To realize the full potential of customization, engineers lean on a configuration workflow that connects mechanical design with electrical and software tuning. The gearbox configuration can be tailored to a vehicle platform by adjusting gear ratios to match engine torque delivery and vehicle performance targets for a given race discipline. Shorter ratios might suit a sprint format with rapid accelerations and frequent corner exits, while longer ratios can optimize top-end speed and fuel efficiency for endurance events. A modular internal approach enables teams to replace or reconfigure internal components to suit evolving performance goals or chassis changes, preserving the core control philosophy while adapting to new hardware. The shift timing is not a single scalar value but a set of parameters that define how quickly the system responds to a shift request, how it synchronizes with engine and clutch behavior, and how it handles transitional states during downshifts where engine braking and vehicle dynamics must be carefully managed. Data-driven methods underpin these decisions: telemetry and data logs illuminate how shifts perform under load, how clutch heat evolves, and how drive-train angles wobble through rapid changes in traction. This data-informed loop makes customization practical, not theoretical, enabling repeatable outcomes rather than ad hoc improvements.

The integration with electronic control units is a cornerstone of the Evolution 10 vision. The gearbox is designed to present clean, interpretable signals to the vehicle’s control architecture, allowing traction control, launch control, and stability algorithms to harmonize with gear selection. The software layer can support customized logic, including safety interlocks and fault handling that keep the system safe when pushed to the edge. In practice, this means engineers can script particular responses to extreme steering angles, wheel slip, or abrupt throttle transitions, ensuring the drivetrain acts in a predictable manner even when the driver is operating near the car’s limits. The result is not a single feature but a coordinated suite of capabilities that makes the entire drivetrain more predictable and more responsive in the hands of a skilled driver.

From a broader perspective, Evolution 10 also embodies an industry-wide tension between customization and standardization. The market tends to reward systems that can be tailored to a wide range of chassis and powertrains while still maintaining a robust, repeatable interface. This dual demand—customization without sacrificing reliability—drives a design philosophy centered on modularity and openness of interfaces. It is common to see standardized mounting patterns and sensor interfaces that facilitate compatibility with a spectrum of chassis builders, even as the software and electronic controls are tuned to reflect the idiosyncrasies of a particular race program. The practical upshot is a platform that can be adapted quickly, with software-defined behaviors that can be tuned parallel to physical revisions in the hardware. In this light, the change from one race weekend to the next may be as much about software calibration and sensor reconfiguration as it is about swapping mountings or gears.

The chapter’s focus shifts naturally to how these systems talk to the rest of the vehicle. The lever input must be robust against the vibration and thermal environment of a race car, yet it must also be intuitive for the driver. A well-designed lever wiring harness ensures that a pull or push is interpreted consistently, every time, regardless of the track’s demands. The display becomes the bridge to the driver’s cognitive load: it should present essential information without creating distraction. A clean gear indicator, a precise RPM readout, and clear shift advisories can reduce the cognitive burden, enabling the driver to maintain focus on throttle modulation, braking points, and line choice. The ultimate aim is for the driver to feel an immediate translation from intention to action, with the system sustaining that loop without fatigue across hours of competition.

In practice, implementing Evolution 10 within a race program involves a disciplined development cycle. Bench testing validates electrical integrity, signal timing, and actuator response in a controlled environment before anything is installed in a car. On-vehicle calibration then begins, with incremental changes to shift timing and gear ratios while the car sits on a lift and then on the track. Engineers rely on calibrated data logging to observe the system’s behavior under real load, including how the clutch and transmission temperatures evolve during a session. A key milestone is achieving a stable shift cadence under varying throttle, braking, and cornering loads, a state that often requires tuning the synchronizing logic between engine maps and chassis dynamics. The result is not simply faster shifts but a coordinated, repeatable system that preserves grip and balance as the car moves through each gear.

Another layer of nuance lies in the brand-specific aspects of such systems. In practice, customization becomes a question of ecosystem compatibility. The same fundamental concept—sequential shifting controlled by software and hardware interfaces—must coexist with different chassis conventions, sensor suites, and body configurations. This is where brand-specific considerations emerge: mounting interfaces, sensor connectors, and software protocols that respect the expectations of a given engineering culture and service network. The premium in this context is the assurance that teams can rely on a complete support chain, including maintenance, parts availability, and software updates, as their programs evolve. Yet it is essential to recognize that extensive customization can also introduce vendor lock-in or a dependency on specialized support channels. For some teams, the trade-off is worthwhile for the sake of performance parity and a predictable upgrade path; for others, it might steer them toward platforms that prioritize broader interoperability.

Looking ahead, the trajectory of Evolution 10 and its peers likely includes deeper integration with vehicle dynamics and predictive control. Artificial intelligence and advanced data analytics hold promise for automatic fine-tuning of shift strategies based on track conditions, tire wear, and driver style. In such a future, the gearbox becomes not just a passive actuator but an active participant in a closed-loop system that constantly optimizes performance within safety boundaries. The human role remains crucial—the driver provides the strategic intent, while engineers supply the calibration discipline and the software engineers supply the adaptive logic. The essence of this evolution is not merely more gears or faster shifts; it is the maturation of a system that can learn from every outing and translate that learning into reliable, repeatable performance on the next race day.

For readers seeking a broader context on how these systems evolve and the design principles behind them, a comprehensive external resource on sequential gearbox architecture and applications offers valuable insights. A complete guide to custom sequential gearbox: specifications, types, and applications provides a foundation for understanding the tradeoffs, tuning strategies, and integration challenges that suppliers and teams navigate when pursuing this class of technology.

If you are looking for a concrete, context-rich exemplar of how a full sequential gearbox upgrade can be approached on a real car platform, the industry ecosystem often references modular, plug-and-play interfaces and flexible software stacks. A useful internal reference that readers can explore for a tangible sense of how a complete system components fit together is the full-sequential-gearbox page. This page outlines how the gearbox, lever input, and electronics can come as a coordinated package, with attention to robustness, serviceability, and track-side support. For those who prefer concise pointers, think of it as a blueprint for a cohesive upgrade path rather than a single, isolated component.

In sum, Evolution 10 embodies a mature approach to high-performance transmissions: a design that foregrounds customization as the engine of capability, while ensuring the human-machine interface remains transparent and trustworthy. The lever wiring and the driver display are not merely accessories; they are essential channels through which performance is captured, translated, and delivered. When these channels are well designed, the race car performs with a calm decisiveness that translates into faster laps, more consistent handling, and a driver who can exploit the car’s full potential with confidence. The integration of mechanical precision, electrical reliability, and software intelligence underpins a new standard for how we conceive and deploy sequential gearboxes on the track, a standard that continues to push the boundaries of what is possible in modern performance engineering.

External reference for further reading: A Complete Guide to Custom Sequential Gearbox: Specifications, Types, and Applications.https://www.racecarperformance.com/custom-sequential-gearbox-guide

Internal context note: for a concise, tech-forward look at how these systems can be integrated into a specific chassis family, explore the full-sequential-gearbox page. full-sequential-gearbox page

Mechanical and Electronic Anatomy of a Sequential Gear Mechanism (Lever, Wiring and Display Integration)

Mechanical and Electronic Anatomy of a Sequential Gear Mechanism

A sequential gearbox system unites precise mechanical parts with deterministic electronic controls. This chapter follows how the lever, the wiring harness and the display work together to deliver fast, repeatable shifts. It explains the essential components, functional relationships, and practical considerations when integrating a sequential system into a performance or track-focused vehicle.

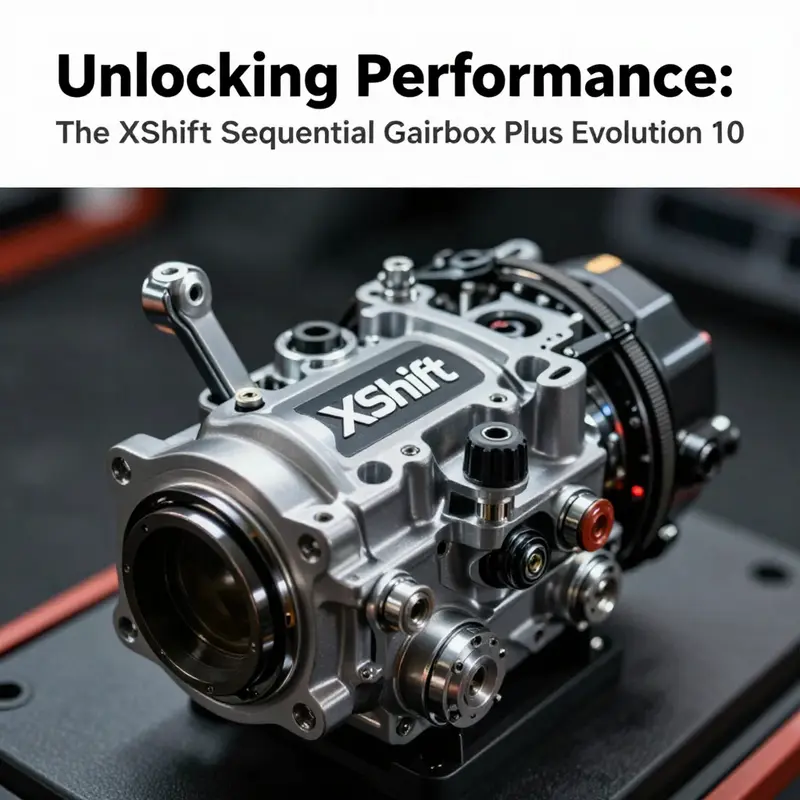

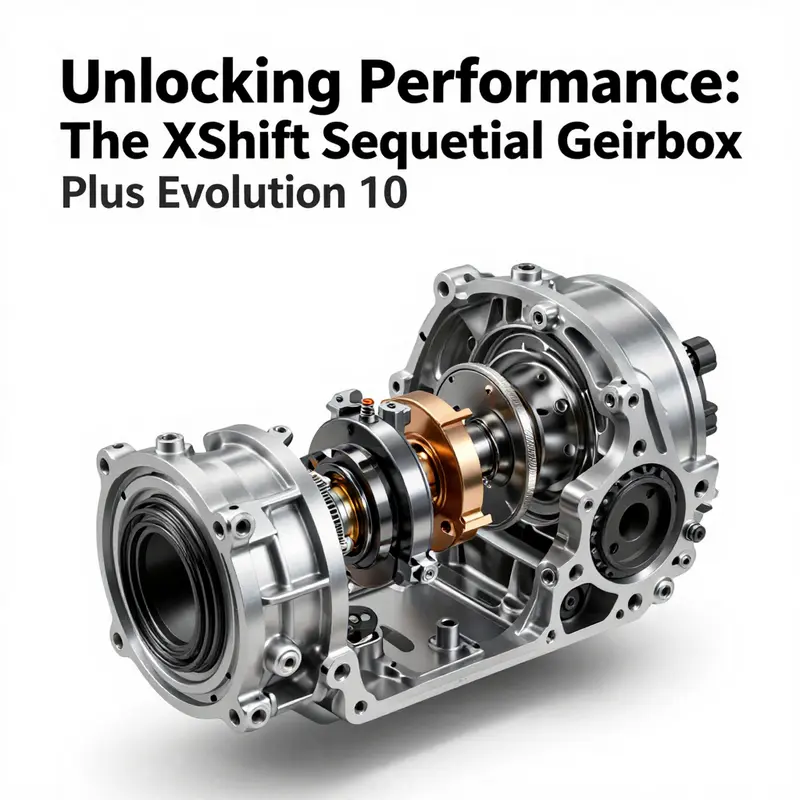

At the mechanical core is the selector mechanism. Traditional sequential designs rely on a selector drum or a linear selector with dog engagement. The selector drum converts rotary motion into axial movement of shift forks. Those forks push dog rings or sliding collars to engage or disengage gearsets in sequence. Alternatively, some modern systems use a cam-and-follower or straight rail selector, providing shorter travel and faster engagement. The geometry of the selector, the stiffness of shift forks, and the fit of dogs or sync-less collars determine shift time, reliability and noise.

The physical act of commanding a shift can be accomplished by a lever or paddles. A mechanical lever attaches to a linkage that turns the selector drum or moves the selector rail. Its benefit is direct feel and a simple failure mode. In contrast, an electronic lever — an e-shifter — detects lever movement with sensors and commands actuators to perform the shift. Electronic actuation removes bulky linkages, allows programmable shift characteristics, and supports multiple shift strategies. A crucial mechanical requirement for both approaches is low compliance in the actuated path; play or elasticity in linkages increases shift time and can create incomplete engagements that damage gears.

Actuation may be hydraulic, pneumatic or electric. Hydraulic actuation uses a compact cylinder and retains excellent force density. Pneumatic systems are lighter and faster but need a reliable air supply and mitigation against condensation. Electric actuators offer modular installation and simpler plumbing, but require careful control of current and thermal management under repeated high-rate shifts. Each method interfaces with the selector via an actuator arm or a direct push/pull rod. The actuator response must be synchronized to clutch management and ignition cut systems for seamless shifts.

The wiring harness is the nervous system linking sensors, actuators and a controlling ECU or shift controller. A well-designed harness groups power, sensor, and communication lines separately to reduce interference. Power feeds for actuators should be fused and routed with adequate gauge to avoid voltage drop. Sensor lines — including gear position, lever position, rev signal, and temperature sensors — often use shielded pairs to reduce electromagnetic interference. Where multiple actuators are present, bus architectures such as CAN or LIN allow distributed control modules to share telemetry while minimizing wiring bulk.

Connectors are a frequent failure point. Locking automotive-grade connectors with seals resist vibration and moisture. Strain relief is essential where the harness meets moving parts, such as lever mounts or actuators. In motorsport applications, quick-disconnect plugs facilitate component swaps and rapid servicing. Grounding strategy is equally important; a single high-quality ground point for the gearbox controller and a dedicated return for high-current actuators prevents ground loops and unexpected resets.

Sensors provide the data necessary for deterministic shifting. A gear position sensor verifies the engaged gear using a rotary encoder or reed/sensor on the selector drum. A lever or paddle position sensor can be a Hall-effect device or optical encoder, offering high resolution with no contact wear. Engine speed is typically derived from a crank or camshaft sensor. Clutch position and pedal travel sensors support automated clutch modulation. Temperature sensors on the gearbox housing and actuators allow the controller to apply temperature-dependent limits to protect components.

The controller ties the mechanical system and harnessed sensors into a coherent logic. In a simple setup, the controller reads lever commands and commands an actuator to move to a target selector position. More advanced strategies include rev-matching, throttle blips, ignition retard, or torque cut. The controller’s software implements safety checks: inhibits a shift above certain engine speed thresholds, prevents engagement when vehicle speed is inconsistent with selected gear, and enforces neutral safeguards. Shift mapping is often user-tunable, enabling customization of shift aggression and clutch behavior for street, track, or drag applications.

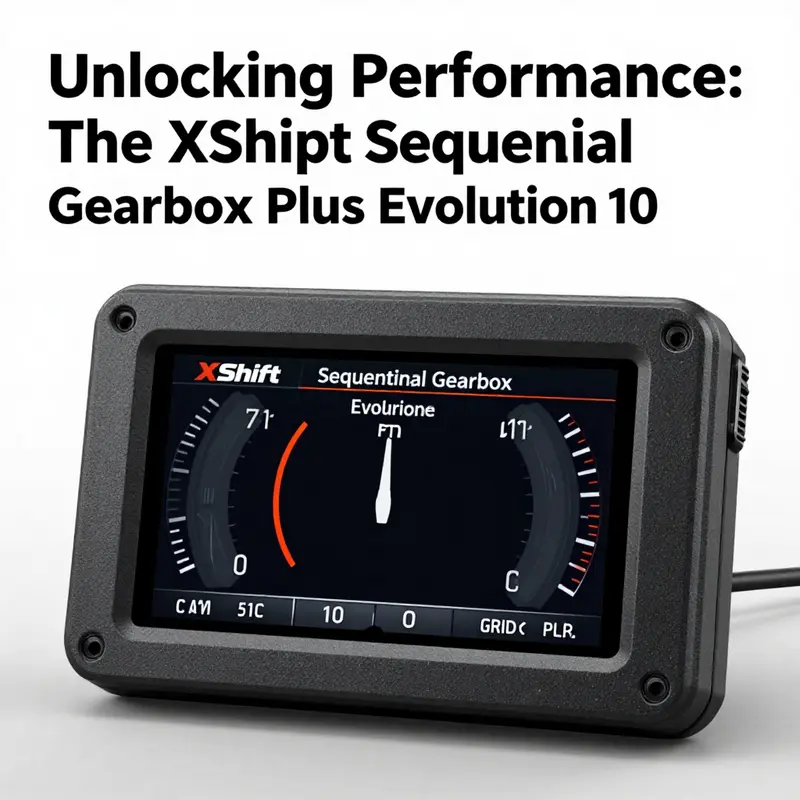

A visible and immediate feedback channel is the display. Displays vary from small single-purpose gear indicators to rich, configurable units showing engine RPM, gear, shift lights, lap times and diagnostic codes. A dedicated shift display is most effective when it prioritizes clarity under load and in sunlight: high-contrast LEDs or OLEDs, large numerals for current gear, and programmable shift lights for optimal upshift RPM. Some units offer shift history, logging each shift event with time and rpm to aid setup and troubleshooting.

Integration between display and controller follows either a direct serial link or a shared vehicle bus. A display that receives raw CAN messages can show not only the current gear but also actuator position, error codes, and temperature warnings. Mapping visual cues to driver ergonomics matters: placing the primary indicators within the driver’s natural sight line reduces distraction, while tactile feedback on the lever or paddle confirms the command without forcing the driver to look down.

Installation and packaging present real-world challenges. The gearbox housing must provide mounting points for sensors and actuators without weakening the casing. Routing the harness through bulkheads requires grommets and fire-retardant sleeves. Heat management matters: actuators and controllers should be located away from exhaust and turbochargers, and if placed nearby, should be thermally shielded. Vibration mounts for the controller reduce mechanical stress on solder joints and connectors.

Calibration is iterative. Initial bench testing ensures the selector cycle covers the entire gear range and that sensors produce clean signals under simulated loads. Next, integrate with the engine control system to coordinate torque management during shifts. On-vehicle testing begins with low-speed shifts to verify physical engagement and progressively extends to high-speed operation. Data logging is indispensable: record actuator current draw, position traces, and engine revs to identify sluggish actuators, misalignments or clutch slip.

Reliability practices borrowed from motorsport improve longevity. Use redundancies where failure could cause safety risks: dual sensors for gear position or a limp-home mode that defaults to neutral if inconsistent signals arise. Employ conformal coatings on PCBs and use braided sleeve protection on the harness to guard against abrasion. Replace mechanical wear items such as shift forks and dogs at scheduled intervals rather than waiting for catastrophic failure.

Human factors play a significant role. The lever must offer a positive detent feel and a clear neutral position. Paddles should be easy to reach and require consistent force for actuation. The display should allow drivers to set shift points quickly between sessions without complex menus. Training drivers to interpret subtle cues from the gearbox — small vibrations, slight delays or changes in shift sound — helps detect early issues.

For teams considering a conversion or upgrade, compatibility with the vehicle’s driveline is critical. The gearbox input spline, bellhousing alignment and clutch assembly must match the engine. Custom adapter plates or bellhousings are often necessary. Evaluate drivetrain torque capacity and match gear ratios to the intended use; sequential systems sometimes pair with close-ratio gear sets to maximize the advantage of rapid shifting.

Finally, modern sequential implementations increasingly lean on software flexibility. A single hardware platform can serve varied roles: a stripped-down race unit for minimal weight, or a feature-rich system for mixed street and track use. The software should allow mapping different shift curves and clutch profiles to selectable modes. This flexibility reduces the need for hardware changes during development while delivering tailored behavior when required.

For a deeper technical foundation on custom sequential gearbox design, specifications and applications, consult a technical guide that outlines the core principles and electronic upgrade paths: https://www.racecarperformance.com/custom-sequential-gearbox-guide

If you need a practical example of a purpose-built sequential installation for common performance platforms, see the documentation for a full sequential gearbox adapted to Evo chassis platforms: full sequential gearbox for mitsubishi evo 4-9 and x.

Lever Wiring in the Next-Generation Sequential Gearbox: Technical Insights, Configurations, and Display Interfaces

The shift lever, once a purely mechanical interface, has become a crucial conduit between human intention and rapid, precise gear changes in the latest electronic sequential gearboxes. In high-performance contexts, where even a few milliseconds can influence lap times or rally-stage results, the interface between the driver and the gear train must be both intimate and robust. Modern sequential systems strip away the long linkage and H-pattern of old, replacing it with a compact, wired dialogue that travels along a carefully engineered path from hand to actuator. The result is a transmission that responds with immediacy, yet remains forgiving enough to preserve driver confidence in the middle of a contested corner. The lever is no longer simply a lever; it is the first touchpoint in a closed-loop communication channel that couples human intent with machine logic. This channel relies on a delicate balance of mechanical tolerance, electrical fidelity, and software calibration, all of which must cohere to deliver predictable shifts under extreme loads, when the throttle is pinned, and the tire contact patch is what separates success from misfortune.

The heart of the system lies in the lever wiring harness, a compact but essential bundle that bridges the driver’s input, the vehicle’s engine control architecture, and the sequential gearbox’s actuator. The wiring harness is not just a bundle of wires; it is a designed network that must carry fast, clean signals in a hostile environment. In high-performance applications, the communication typically travels via a high-speed CAN protocol. This choice is not incidental. CAN provides deterministic messaging with a resilience that suits racing environments where ignition noise, EMI from high-torque events, and vibration could otherwise corrupt critical data streams. The harness routes signals from the shift lever position sensor to the ECU and from there to the gearbox actuator, ensuring that a deliberate movement of the lever translates to an exact, timely gear command. The driver feels the immediate translation of intent, but behind that sensation lies a layer of protective engineering meant to preserve performance even when conditions degrade. The harness is designed with shielding and robust grounds; the shielding helps mitigate electromagnetic interference from motors, spark events, and the rapid current surges that occur when a clutch is engaged or released in quick succession. Grounding strategies are not afterthoughts but core design decisions, because a single ground fault can propagate through the CAN network and cause misreads on gear position or timing—precisely what a race car cannot tolerate.

Beyond shielding and routing, the physical construction of the lever wiring harness is tuned for reliability under vibration and temperature extremes. Connectors are selected for high mating cycles and resistance to corrosion from sweat, fuel, or oil traces that accumulate on the cockpit floor. The internal layout of the wiring must also minimize crosstalk between sensor lines and power leads. The result is a predictable, repeatable signal chain that preserves the perceived “feel” of the lever while delivering the electronic speed and precision that modern gearboxes demand. For a driver, that translates to a sense that the lever movement is faithfully mirrored by the gearbox action, with minimal delay, occasional audible confirmations from the system, and a tactile sense of confidence even under heavy braking or on a bumpy surface.

The lever wiring is intimately connected to three principal actors in the gearbox architecture: the shift lever sensor, the ECU, and the actuator. The shift lever sensor translates the angular or linear position of the lever into a digital or analog signal that encodes the driver’s intended shift sequence. This information must be read with minimal latency and with a degree of redundancy so that a momentary sensor glitch does not misinterpret the driver’s intention. The ECU then interprets this input, applying a calibrated logic that can include hysteresis, bounds checks, and safety interlocks. The actuator, often a compact electric motor or a hydraulic/electro-hydraulic device, receives the command and executes the shift with precise timing. In this triad, the CAN network functions as the nervous system, carrying status updates, fault codes, and calibration data between components at speeds that keep the system responsive.

Calibration is the next tier of this intricate web. Achieving optimal shift timing involves refining when the gearbox engages a new gear relative to the engine speed, vehicle speed, and load conditions. The timing does not occur in a vacuum; it is constrained by clutch engagement points, friction material behavior, and the mechanical geometry of the shift system. Engineers adjust shift maps so that a planned upshift occurs at a point where the engine can maintain torque without overrev or lug. Likewise, downshifts must occur with a balance of throttle response and engine braking so that the car remains stable through entry and corner exit. This calibration process often begins with a baseline map derived from controlled dyno tests and chassis data. It then evolves through on-track testing, where the driver’s input, vehicle attitude, and tire behavior feed back into the mapping. In practice, calibration is iterative: a small change in the shift timing or clutch engagement point can ripple through the whole drivetrain, affecting throttle response, stability control, and even steering feel as the driver learns a new response envelope.

The display interfaces accompanying these electronic shifters play a critical role in conveying information without overwhelming the driver. A well-designed display shows the current gear, the predicted next gear, engine speed, and possibly the shift light status or a visual cue indicating a recommended shift point. The driver’s attention is a precious resource; a display that is too busy can distract, while one that is too sparse can leave the driver guessing. The challenge is to present information that is immediately interpretable, using color coding, typography, and a minimal amount of flashing indicators to communicate urgency without artificial distraction. The integration of display data with the ECU’s feedback loop creates a sense of continuity: the driver sees a live readout that matches the car’s behavior, while the system uses that same data stream to refine its behavior in real time. The ultimate goal is clarity under pressure, so the driver can focus on line, brake points, and tire management rather than deciphering ambiguous signals.

A crucial part of integrating the lever wiring, sensors, and display is the physical and software layout of the system within the cockpit and the car’s electrical architecture. The cockpit must accommodate the lever with ergonomic reach and predictable travel, while the harness is tucked away to minimize exposure to heat sources, moisture, and spray from the road or track. The software side must manage timing constraints, data integrity, and fault handling in a way that preserves performance, yet protects against unsafe situations. For example, if the system detects a loss of reliable gear position sensing, it can enter a safe mode that prevents inadvertent gear engagement or a double-trigger scenario that could cause mechanical stress or safety concerns. The design philosophy here blends performance with resilience: the most radical shift performance is hollow if the system cannot be trusted in the heat of competition.

To illustrate the practical dimension of these concepts, consider how teams approach the question of vendor specificity and customization. Many teams adopt modular architectures that can accommodate different sensor families, harness configurations, and actuator variants. The leverage of modularity is not just about swapping components; it is about reconfiguring the control logic to align with each track’s demands and each driver’s preference. The wiring harness is the physical thread that binds these choices into a coherent whole. It must remain serviceable, with connectors that can be easily diagnosed and replaced in the paddock or pit lane, yet robust enough to withstand repeated removal and reinstallation during a race weekend. The interplay between hardware robustness and software flexibility defines the real-world viability of a modern sequential gearbox system with electronic shift. A practical retrofit example—described in detail in a dedicated installation guide—demonstrates how a complete electronic shift solution can be integrated and validated in a high-performance chassis. See the resource linked here for a deeper technical walkthrough: full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x. The guide walks through signal routing, pin assignments, and diagnostic procedures that echo the broader principles discussed here, providing a concrete template for practitioners who want to translate theory into reliable practice.

As with any high-performance electrical system, diagnostics and troubleshooting are not afterthoughts but daily disciplines. A misbehaving shift signal—whether due to a degraded sensor, a loose connector, or an EMI-induced error—can manifest as slow, hesitant shifts or, conversely, unexpected gear commands. The diagnostics workflow emphasizes continuity testing of the lever sensor, verification of CAN messages with known-good IDs, and careful inspection of shield continuity and grounding. Since the CAN bus carries critical state information, even a single compromised node can cascade into misalignment between the driver’s intent and the gearbox action. A practical diagnostic approach involves back-tracing the signal path from lever to ECU, verifying the integrity of each connection, and cross-checking with logged data during a test run. Maintaining good practice means documenting harness routes, connector pinouts, and shield terminations so that maintenance teams can replicate the checks across sessions and across different vehicles.

All these considerations—lever interface, wiring, ECU integration, calibration, display strategy, and diagnostic discipline—collectively shape how a modern sequential gearbox performs under pressure. The lever wiring harness, in particular, stands as a linchpin between human skill and machine timing. It is the quiet enabler of precision shifts, the conduit that makes a driver’s deliberate action translate into a precise, repeatable change in the powertrain’s state. When well executed, the system provides the driver with a coherent, tactile sense of control, a stable platform for aggressive corner entries, and the confidence to push harder without compromising safety or reliability. When mismanaged, the same harness can become a source of erratic shifts, spurious fault codes, or degraded driver confidence. The difference often comes down to careful design choices, thorough calibration, and a disciplined maintenance routine that treats the wiring as a dynamic part of the car rather than a mere accessory.

In the broader arc of geartrain evolution, the lever wiring and its associated display interfaces epitomize a shift from passive mechanical reliability to active electronic intelligence. The core ideas remain straightforward: capture driver intention with accurate sensing, deliver commands with low latency and high reliability, and present information in a way that supports quick, informed decision-making. Yet the implementation requires a systems-thinking approach that respects the physics of the vehicle, the electrical environment, and the human factors at play in a race or rally environment. As designers explore the next generation of sequential gearboxes, the guiding principle is clear: the best systems feel seamless, almost invisible in operation, yet are underpinned by a network of carefully engineered signals, power distribution, and software that anticipate rather than react to the unpredictable curveballs of competition.

External context matters for practitioners who want to deepen their understanding. For a broader technical context on how custom sequential gearboxes integrate electronics, sensors, and control logic, see the external resource here: https://www.racecarperformance.com/custom-sequential-gearbox-guide. This guide outlines the design principles, component choices, and applications that illuminate the engineering trade-offs involved in modern electronic shift systems. The chapter’s core ideas—reliably capturing driver input, transmitting it through a robust high-speed network, and translating it into precise mechanical action—are echoed across race vehicles and high-performance builds alike, making the lever wiring harness a focal point for both performance and reliability in today’s sequential gearboxes.

null

null

Final thoughts

Understanding the XShift Sequential Gearbox Plus Evolution 10 equips business owners with crucial insights into a product that marries technological sophistication with practical application in high-performance environments. The customization options, detailed mechanics, effective wiring, and sophisticated display systems enhance both vehicular performance and user experience. By embracing these advancements, businesses can remain competitive within the evolving automotive landscape, ensuring they meet the demands of performance-oriented customers.