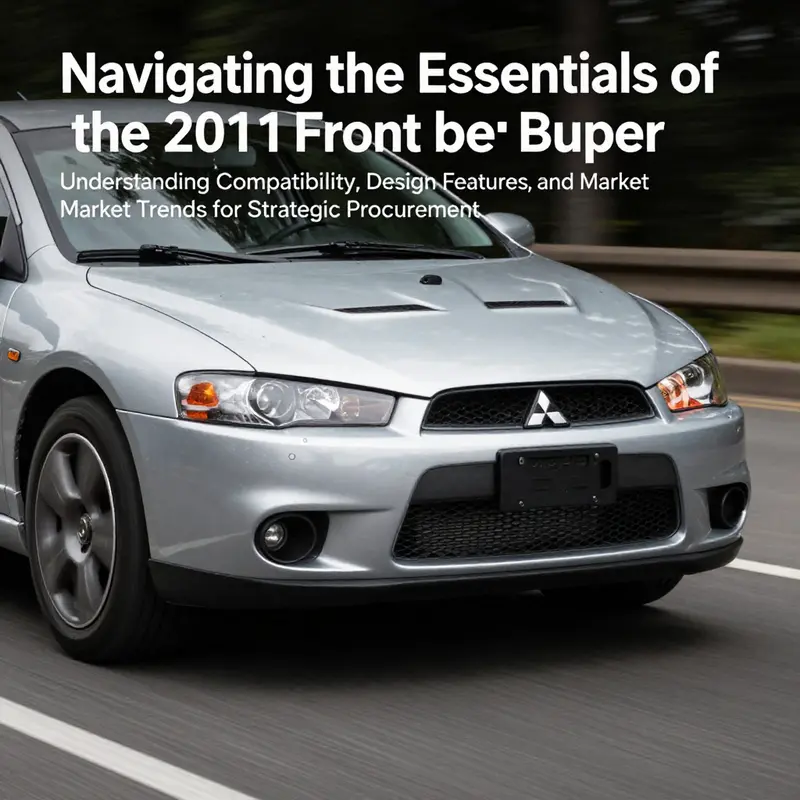

For business owners involved in automotive sales or repair, recognizing the significance of the 2011 Mitsubishi Eclipse front bumper is crucial. This component not only influences vehicle aesthetics but also impacts safety and functionality. In this article, the first chapter will delve into compatibility and specifications, highlighting the importance of proper fitment for optimal performance. The second chapter will explore the design features and safety integrations of the front bumper, which are essential for modern vehicles. Finally, the third chapter will analyze market trends and provide effective procurement strategies, ensuring that business owners can source quality parts efficiently and economically.

Shaping Safety and Style: Compatibility, Construction, and the 2011 Mitsubishi Eclipse Front Bumper

The front end of a car is more than a greeting to the road; it is a carefully tuned system that blends form, function, and safety into a single statement. For the 2011 Mitsubishi Eclipse, the front bumper is a critical node in energy absorption, sensor alignment, and overall vehicle integrity. This chapter explains how the bumper anchors a network of systems that shape daily driving and the response to impacts, while remaining the interface between the car and its environment. It covers construction, fitment, sensor integration, and the practical realities of sourcing and installation, emphasizing the importance of precise geometry and correct calibration for safety features to operate as designed. It also considers aftermarket versus OEM options, warranty implications, and the balance between aesthetics and function when choosing a replacement or upgrade for the 2011 Eclipse front bumper.

Edge of Aesthetics and Armor: The 2011 Mitsubishi Eclipse Front Bumper as a Nexus of Design, Safety, and Sensor-Ready Engineering

The front bumper of a car is often perceived as a purely cosmetic shield, a painted shield that frames the grille and headlights. But on the 2011 Mitsubishi Eclipse, the bumper is far more than a surface treatment. It is a carefully engineered frontier where styling meets safety, where every contour and material choice is weighed for impact energy, sensor alignment, and aerodynamic balance. In this sense, the 2011 Eclipse front bumper becomes a living example of how a component that sits at the very edge of the car must perform multiple roles at once. It must look right, protect crucial components, and tolerate the realities of daily driving—stone chips, minor collisions, and the relentless push and pull of modern driver-assistance systems that watch from behind the plastic shield.

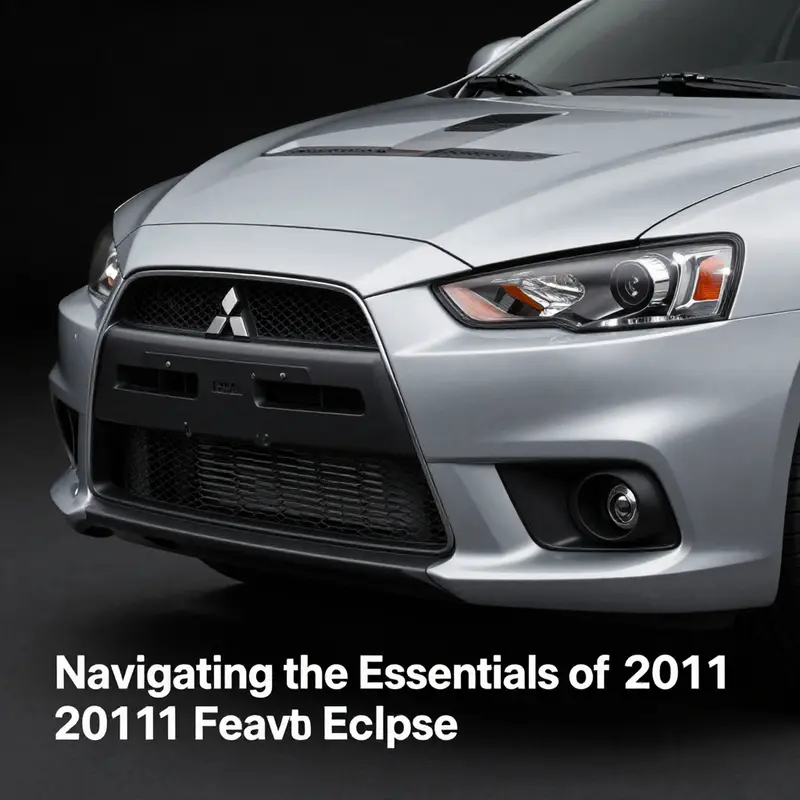

From the outset, the bumper’s design speaks to a philosophy that blends visual aggression with functional resilience. Its corners are reinforced, not just for the sake of a more chiseled appearance but to improve durability during low-speed impacts, a common scenario in city driving and parking-lot scrapes where the worst damage is often concentrated at the edges. Those reinforced corners are more than decorative accents; they are structural features that distribute impact forces away from the radiator and surrounding modules. Along the entire front, energy-absorbing structures are woven into the bumper’s architecture. These structures, a combination of tightly engineered lattice forms and crush zones, are purpose-built to absorb and dissipate kinetic energy during a collision. The result is a bumper that can deform in a controlled manner, reducing peak forces transmitted to the engine bay and other sensitive components.

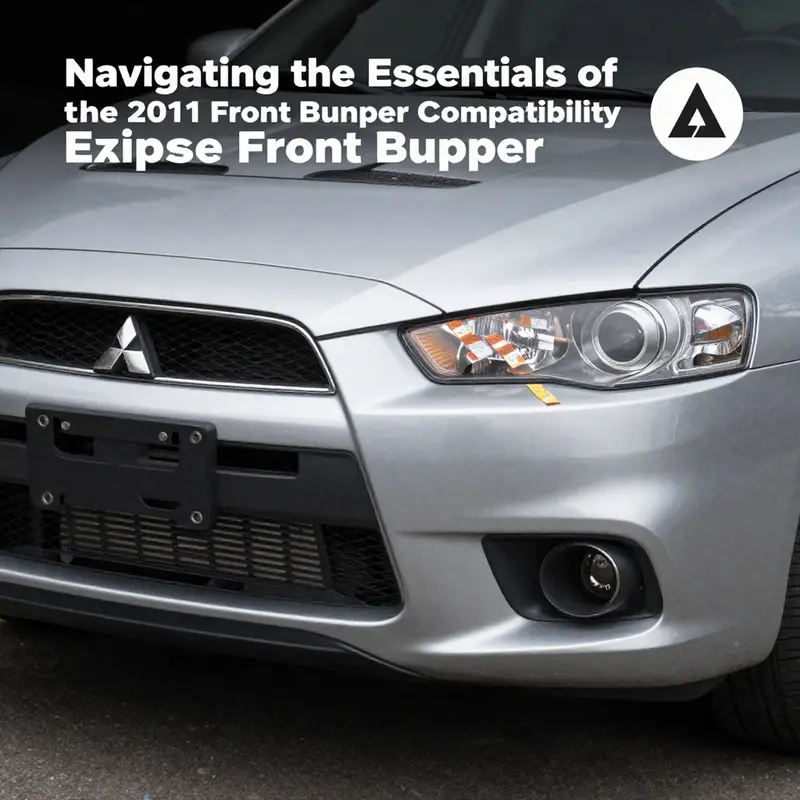

The material choices further illuminate the bumper’s dual mandate of sportiness and toughness. The Eclipse’s front bumper is typically constructed from high-grade ABS plastic or composite polymers. These materials offer a balance of rigidity and resilience, resisting cracks from road debris while remaining pliable enough to crumple in a controlled way when necessary. The surface finish is designed to resist environmental challenges—from salt and moisture to UV exposure—so that the visual stride of the vehicle remains sharp for years. The bumper’s surface is not merely a canvas for paint; it is a component with a defined role in aerodynamics. Integrated mounting points ensure precise alignment of the headlights, fog lights, and other front-end devices, contributing to the overall flow of air around the vehicle. This attention to mounting accuracy helps prevent misalignment that could degrade light distribution or disrupt sensor fields of view.

Within the design, the bumper also houses a sophisticated system of energy management that anticipates how the car will behave in a real-world incident. Foam inserts or crushable cores are built into the bumper’s inner layers. These inserts act as first responders, absorbing energy and converting it into a more distributed deformation. The goal is to protect vital components that live just behind the bumper face—the radiator and cooling assembly, the engine, and other critical systems—while maintaining a high level of occupant protection. The energy-absorbing strategy is particularly important given the Eclipse’s sporty intent; it must withstand the unpredictable nature of urban crashes as well as the more forgiving dynamics of highway travel.

A central thread in the bumper’s design is its compatibility with the vehicle’s active safety ecosystem. As sensing technologies migrate from a luxury feature to a standard expectation, the bumper must align with sensors and cameras that enable adaptive cruise control, forward collision warning, and other front-end warning and assistance functions. The 2011 Eclipse front bumper is therefore conceived with sensor geometry in mind. The bumpers of this era are designed to preserve the integrity of radar emitters, camera housings, and other front-mounted sensing devices. Even minor deformations from a fender bender should not throw the system’s readings off, so the bumper’s geometry is crafted to maintain sensor spacing and line-of-sight. In other words, the bumper is not just a cover; it is a calibration-friendly interface with the car’s safety brain.

The integration of permissions around lighting is another facet of its design. The Eclipse line in this period sometimes featured integrated fog light housings as part of the bumper assembly. This arrangement supports both improved low-visibility performance and a clean, coherent front-end silhouette. The lighting integration is not purely cosmetic; it interacts with the bumper’s geometry to guarantee that light beams project where they are intended and that the fog lights remain within easy reach of maintenance while preserving the bumper’s aerodynamic profile.

The 2011 bumper’s design language also aligns with a broader family of bumpers produced for the model during the period. This lineage emphasizes uniformity in fitment and structural behavior, which is critical for consumers who replace a bumper after minor damage or who purchase an aftermarket piece. A representative reference to the bumper family can be found in the “2006-2012 Mitsubishi Eclipse front bumper” category, which illustrates how manufacturers synchronized dimensions, mounting points, and sensor interfaces across a span of model years. The continuity within this family fosters predictable fitment and standardized safety performance across years, reducing the likelihood of misfit issues that could complicate sensor calibration or structural integrity after replacement. For readers exploring the broader design and compatibility narrative, this reference offers a tangible sense of how the 2011 bumper sits within a wider engineering framework.

The bumper’s capacity to accommodate a precise alignment of components is a practical outcome of its engineering process. Integrated mounting points are not merely convenience features; they are the keystones that enable correct assembly and reliable performance. The headlights, fog lights, and upper air intakes must align with exacting tolerances to maintain the intended airflow and lighting performance. A misalignment, even by a fraction of a millimeter, can ripple outward into aerodynamic drag changes, lighting scatter, and sensor misreads. The bumper’s geometry is therefore a careful balance of cosmetic contour and mechanical precision. The result is a front end that preserves its visual identity while supporting the mechanical and electronic ecosystems that modern vehicles demand.

The production side of this design story is equally telling. The Eclipse’s front bumper is a post-manufacture asset in the aftermarket ecosystem, with a supply chain that reflects the global nature of modern automotive parts. In the late 2000s and early 2010s, Asia—especially regions with advanced plastics processing and injection-molding capabilities—emerged as a core hub for bumper production. The front bumper for the Eclipse family often travels from manufacturing centers in the Asia-Pacific region to markets around the world, where replacement parts must meet strict safety standards and fitment specifications. This global supply architecture makes the bumper not merely a local component but part of a broader trade network. For business buyers and shops, understanding this ecosystem clarifies why lead times, pricing, and quality control vary across sources. It also explains why robust supplier relationships and clear acceptance criteria become essential when selecting a bumper for repair or upgrade.

In the practical realm of replacement, buyers face a meaningful choice between OEM bumpers and aftermarket versions. OEM components are designed to the exact factory specifications, ensuring a known fit and a level of crashworthiness that mirrors the original. Aftermarket bumpers, on the other hand, can offer stylistic variations or cost benefits, but they demand careful verification of safety standards and proper calibration support for sensor systems. The decision is not simply about appearance; it is about preserving the bumper’s role in energy management, sensor alignment, and overall vehicle integrity. A responsible approach to replacement starts with verifying that any replacement piece, whether OEM or aftermarket, adheres to robust industry testing and that the installation process includes proper reassembly procedures and, where applicable, sensor calibration.

The chapter’s examination of the 2011 Eclipse front bumper thus reveals a design that is at once expressive and protective. Its lines contribute to the car’s aggressive stance while its internal architecture shields critical components from damage and helps sustain the performance of safety and driver-assistance features. In the context of the wider article on the 2011 Mitsubishi Eclipse front bumper, this chapter’s emphasis on design features, safety integration, and replacement considerations provides a cohesive voice that ties aesthetics to engineering reality. It is a reminder that the front bumper is not simply a peripheral element—it is a strategic component that shapes the car’s behavior in emergencies, its reliability in routine use, and its visual identity on the road.

For readers who want to explore the broader bumper family and see how similar front-end assemblies were implemented across years, a practical entry point is the reference to the 2006-2012 bumper family. This reference highlights the shared geometry and mounting strategies that help ensure compatibility across model years and trim levels, while still allowing for necessary adaptations to accommodate evolving sensor layouts and lighting configurations. The idea is that a well-designed bumper in one year should still fit, align, and function in another, provided the replacement adheres to the same core principles and tolerances. This perspective reinforces the importance of careful selection, precise installation, and informed expectations when approaching bumper replacement projects.

Beyond the immediate hardware, the Eclipse bumper embodies a philosophy about vehicle safety that extends to the entire front-end package. It reinforces a core truth in modern automotive design: safety systems are not standalone gadgets but integrated elements whose performance depends on the integrity of surrounding structures. The bumper’s foam inserts, its energy-absorbing architecture, and its sensor-friendly geometry all contribute to a crash energy management strategy that aims to protect vital components while preserving the vehicle’s ability to warn and assist the driver. This alignment is not a luxury feature; it is a baseline expectation for vehicles in this era, where multiple safety functions rely on accurate sensor inputs and stable front-end geometry.

In the end, examining the 2011 Eclipse front bumper offers more than a record of materials and attachments. It provides a lens into how design choices translate into real-world outcomes: better energy management in a collision, clearer sensor readings for driver-assistance technology, and a front end that remains visually coherent and aerodynamically efficient even after a repair. The bumper acts as a living interface between form and function, a boundary where aesthetics meet engineering discipline. It is a reminder that even the edge of a car—the very part that greets the world first and takes the brunt of impact—deserves the same attention to detail as the heart of the machine.

For readers who wish to delve further into the evolution of the Eclipse’s front-end family, the broader reference to the 2006-2012 bumper range is a useful map. It contextualizes the 2011 bumper as part of a continuity that emphasizes fit, safety, and sensor compatibility across multiple years. The link to that broader family serves not as a promotional prompt but as a technical breadcrumb pointing to a coherent design philosophy that underpins the model’s entire front-end hardware strategy. Understanding this continuity helps explain why certain dimensions and mounting interfaces appear consistent across years, and why replacement options—whether OEM or aftermarket—often follow recognizable patterns that promote safer, more predictable outcomes on the road.

External resource for practical context: https://www.aliexpress.com/item/1005005467938532.html

Shaping Safety, Fit, and Supply: The 2011 Mitsubishi Eclipse Front Bumper Market, Materials, and Procurement Pathways

The front bumper of a 2011 Mitsubishi Eclipse is more than a cosmetic panel; it is a critical nexus where safety, performance, and procurement converge. For a model so closely tied to its era’s design language and safety technology, the bumper must align with the entire front-end architecture. Replacing or repairing it is not a simple swap of shell and paint. It requires an understanding of fitment accuracy, attachment geometry, and the way the bumper interacts with sensors, radar units, and cameras that may form the vehicle’s active safety network. When a bumper is replaced, even minor misalignments can cascade into misreadings from forward collision alerts, adaptive cruise controls, or parking assistance systems. The Eclipse, with its 2011 specification, sits at a crossroads of older, well-understood mechanical standards and newer emphasis on integrated safety features. The choice of bumper—whether original equipment or aftermarket—shapes not only the vehicle’s appearance but its safety integrity and the long-term reliability of its front-end systems. Consequently, the decision becomes a balance between fit, function, and the realities of a global supply chain that now serves a broad aftermarket ecosystem as much as it does the factory floor.

Market dynamics for the Eclipse front bumper reflect broader shifts in how automakers and aftermarket manufacturers approach strength, weight, and crash performance. Materials science has moved beyond the era of rigid, heavy plastics toward smarter composites. Polypropylene and thermoplastic olefins (TPO) have gained ground due to their resilience and forgiving energy absorption profiles. These materials offer a more favorable strength-to-weight ratio, which translates into improved fuel efficiency and handling—attributes that resonate with manufacturers aiming to meet tightening regulatory expectations for vehicle efficiency. For owners and fleets, the promise of better impact resistance without a heavy penalty in weight translates into lower lifecycle costs, fewer panel repairs after minor incidents, and less downtime when parts are needed. The Eclipse’s 2011 bumper is thus part of a global trend where the front-end structure is treated as an engineered system rather than a simple cover piece. It must withstand stone strikes, weather-induced wear, and the daily stresses of urban driving while maintaining aesthetic integrity and coordinated alignment with adjacent panels and lighting systems.

Embedded in this material evolution is the constant push to improve energy absorption characteristics. In practice, the bumper component has to work in concert with a surrounding structure that includes impact beams, foam cushions, and, increasingly, sensor housings that accommodate driver-assist features. The shift toward sensor-enabled bumpers means that replacing the bumper now entails more than restoring a physical shell. It requires consideration of how the housing will interact with radar reflectors, camera fields of view, and mounting points that anchor the front fascia to the vehicle’s frame. If a bumper is swapped without proper attention to these interfaces, the calibration of forward-looking sensors can drift, producing false alerts, delayed braking responses, or degraded parking assist performance. The 2011 Eclipse sits in a transitional space where many vehicles still relied on established mechanical designs, yet the safety ecosystem around them began to rely more heavily on sensor data and precise geometries. This convergence makes the procurement decision complex: a bumper must align with the car’s trim level, sensor configurations, and the maintenance capabilities of the shop performing the replacement.

For buyers and shop owners navigating this landscape, the installation process emphasizes precision. The mounting points on the frame must align within millimeter tolerances to ensure the bumper’s lower lip line and upper edge sit flush with adjacent body panels. Modern front bumpers sometimes feature integrated fog light housings or openings that must align with lighting modules. In models where fog lamps are part of the bumper assembly, a mismatch in the electrical harnesses, connectors, or sealant channels can lead to moisture ingress or uneven illumination. The Eclipse’s 2011 front bumper, in its various aftermarket iterations, may incorporate these features or provide the mounting geometry to accommodate them, depending on whether the replacement is an OEM part, an OEM-equivalent, or an aftermarket design. A diligent installer will verify gasket integrity, confirm the clearance around the wheel arch, and check for any deviation in the bumper’s radial alignment that could affect wheel shot clearance or pedestrian impact performance. All of these checks are essential to preserve the vehicle’s overall safety profile and to ensure that the repair or replacement does not undermine the integrity of the front-end architecture.

As a focal point of procurement strategy, the Eclipse bumper market illustrates how procurement decisions are shaped by a mix of technical requirements and market realities. If the bumper is sourced from a regional supplier with deep engineering controls, it is more likely to offer fitment guides, testing data, and a clear bill of materials that maps directly to the Eclipse’s front-end architecture. Fitment guides are invaluable because they translate a part’s geometry into actionable steps for the installer. They help ensure that the bumper’s volume, curvature, and attachment points align with the car’s nose panel, fenders, and hood. Third-party certifications act as a proxy for reliability, signaling that a supplier adheres to recognized quality management systems and process controls. For buyers, these certifications reduce the risk of misfit and early part failure, especially when a bumper must withstand repeated minor impacts, weather exposure, and chemical exposure from road salts. In this context, the Eclipse’s 2011 front bumper market becomes a case study in balancing engineering precision with practical procurement discipline.

From a geographic and industrial perspective, the post-2008 automotive aftermarket matured into a globally distributed ecosystem. The majority of front-bumper manufacturing and assembly activities for popular models has gravitated toward established hubs in Asia, with Zhejiang Province’s Ningbo and Wenzhou standing out for their lean manufacturing practices and robust supplier networks. These regions have built up sophisticated supply chains that can produce high volumes with consistent quality while maintaining cost competitiveness. For a buyer, this means access to a wide range of options—from OEM-equivalent parts to more economical aftermarket designs that still meet strict fitment criteria. The trade-off often centers on performance guarantees and long-term durability. A supplier that invests in process controls, joint testing, and transparent material specifications can offer parts that perform reliably under a broad range of conditions, from coastal fog to winter road salt. The Eclipse’s front bumper procurement path, therefore, becomes a reflection of how manufacturing ecosystems in Zhejiang support not just regional demand but a global aftermarket. It also underscores the importance of selecting suppliers who can demonstrate traceability, consistent process capability, and clear documentation that links the bumper to the vehicle’s trim-specific requirements.

With these market dynamics in mind, procurement strategies must also address the realities of immediate availability. For a buyer who needs a solution quickly, aftermarket options on regional marketplaces provide a practical path to minimize downtime. Yet speed cannot come at the expense of fitment and safety integrity. In practice, buyers weigh two primary questions: Will the bumper align with the Eclipse’s specific trim (GS, GT, or base models), and will the part preserve the vehicle’s sensor alignments and functional interfaces? The answer depends on the supplier’s ability to provide a fitment guide, mounting diagrams, and, ideally, third-party verification of the part’s dimensions and material properties. It is not enough to have a bumper that looks right; it must also align with the front-end sensors and the car’s structural elements. In this sense, the Eclipse’s bumper becomes a testbed for the maturity of the aftermarket supply chain, revealing how well the market has translated engineering constraints into reliable, install-ready products.

To illustrate the practicalities of choosing a bumper that meets these standards, consider the value of a consolidated fitment reference. A generic but precise resource that captures the Eclipse’s bumper fitment across model years can be a helpful compass for buyers and shop technicians alike. The reference point can be accessed via a dedicated page that compiles the essential mounting geometry and alignment considerations, providing a reliable baseline for comparison across OEM-equivalent and aftermarket options. For those who want to explore fitment without committing to a specific brand or design, this resource becomes a practical starting point. See 2006-2012-mitsubishi-eclipse-front-bumper for an overview of fitment considerations and mounting geometry that relate directly to the Eclipse’s front-end architecture. This page helps bridge the gap between design intent and actual installation reality, guiding buyers toward parts that respect the vehicle’s structural interfaces while meeting the expectations of modern safety and comfort.

Another dimension of procurement strategy is the balance between cost and long-term durability. Cheaper options often appear appealing, especially for fleets or hobbyists who undertake DIY repairs. However, lower price points may correspond with thinner wall sections, reduced corrosion resistance, or less robust mounting hardware. Over time, these shortcuts can manifest as increased maintenance costs, more frequent replacements, or misalignment that triggers sensor recalibration or warning indicators. A more deliberate approach emphasizes suppliers who provide warranties, robust material specifications, and documented evidence of crash-test performance or real-world testing. Even if a bumper is sourced as a generic part, the supplier with transparent testing results and a clear return policy offers greater protection against repeat repair cycles and unexpected downtime. In the Eclipse market, where optional features such as fog lamps and sensor housings influence the complexity of the installation, the value of a well-documented part becomes even more pronounced. A purchase decision grounded in technical transparency reduces the risk that a later adjustment or recalibration will be necessary, and it improves the probability that the replacement will preserve the intended level of safety performance.

From a practical standpoint, the installation workflow also affects procurement planning. Shops often begin by confirming the bumper’s compatibility with the car’s subcomponents, including the radar module, camera assembly, and any forward-looking sensors. If these components are integrated into the bumper or require precise reattachment, the installer must ensure that sealants, fasteners, and mounting brackets match the vehicle’s frame and plate geometry. Calibrating sensors after a bumper replacement can be a delicate process. Many modern systems require a correct reference frame to avoid misinterpretation of sensor data. In some cases, calibration can be performed with the vehicle on a specific diagnostic tool and under controlled environmental conditions. In others, it may require a dedicated service procedure at a dealership or a qualified shop with access to the right equipment. The essential takeaway for procurement is that the bumper is not a stand-alone part; it is a component of an integrated safety network. As such, the procurement strategy must account for post-purchase serviceability, documentation, and the potential need for calibration workflows that preserve the full functionality of the Eclipse’s front-end systems.

The Eclipse market also reflects a broader consumer preference for bumpers that can accommodate modern upgrades while maintaining compatibility with legacy features. Many owners now expect the potential for wireless connectivity enhancements or integration with upgraded sensors and camera modules. A bumper that provides a flexible mounting framework and clearly defined channels for wiring and sensor housing becomes a valuable platform for such upgrades. This trend underscores the importance of clear engineering documentation from suppliers, especially for parts sourced from the Asia-Pacific manufacturing corridor. Buyers seeking long-term value will favor suppliers who can show a track record of consistent part dimensions, material property data, and performance evidence from testing. In turn, manufacturers and distributors can build stronger relationships with customers by providing transparent material specifications, packaging that resists moisture ingress, and serviceable instructions that facilitate proper installation and calibration.

The global supply chain narrative that surrounds the Eclipse’s front bumper is not just about parts; it is about the reliability and predictability of supply. For a fleet operator or a repair shop, the ability to source multiple part numbers from a limited set of trusted suppliers can simplify inventory management, reduce lead times, and ensure consistent quality. It also reduces the risk of counterfeit components, which can be challenging to detect without proper traceability and documentation. The procurement strategy, therefore, is as much about choosing the right supplier network as it is about selecting the right bumper design. The best choices balance cost with the assurance that the part will perform within the car’s safety framework, fit precisely, and stand up to the environmental rigors of daily use.

In summarizing the current climate for the 2011 Mitsubishi Eclipse front bumper, it is clear that the market is not static. Advances in materials science, growing emphasis on sensor integration, and a mature yet still global supply chain all shape what buyers can expect in terms of availability, performance, and value. The Eclipse front bumper serves as a microcosm of a wider automotive aftermarket movement toward parts that are lighter, stronger, and more capable of supporting safety systems without compromising on fit and installation practicality. For practitioners, the path forward involves a disciplined approach to supplier selection, a clear understanding of fitment and sensor interfaces, and a willingness to embrace parts that come with robust testing and documentation. This approach reduces risk, shortens downtime, and helps ensure that every replacement preserves the vehicle’s safety and performance promise.

External resource: https://www.ebay.com/itm/2006-2012-Mitsubishi-Eclipse-Duraflex-Demon-Front-Bumper-1-Piece-Fits-All-Models/353876248477

Final thoughts

Understanding the intricacies of the 2011 Mitsubishi Eclipse front bumper—from its compatibility and design features to market procurement strategies—is vital for business owners in the automotive industry. This knowledge not only aids in providing quality service but also enhances the overall customer experience. By staying informed about these aspects, businesses can improve their operations and ensure they meet the evolving demands of the market.