The front bumper of the 2012 Mitsubishi Eclipse plays a pivotal role in ensuring safety and functionality on the road. This component is designed not only to absorb impacts during collisions but also to enhance the vehicle’s aesthetic appeal and aerodynamics. For business owners involved in the automotive aftermarket or fleet management, understanding the intricacies of the front bumper design, maintenance requirements, and sourcing options is crucial. This holistic approach equips you with the knowledge needed to make informed decisions, ensuring not only the longevity of the vehicles but also the satisfaction of your clients. Each chapter will unpack these elements, leading you from understanding its features to ensuring proper maintenance and finding reliable suppliers.

Sculpted Shield: The Design and Features of the 2012 Eclipse Front Bumper

The front end of a car is more than a decorative fascia. It is a careful balance of form and function, a sculpted shield that blends airflow, impact protection, and the potential for advanced sensing. In the 2012 model’s nose, the bumper plays a central role in how the vehicle meets the road and the weather, how it moves through air, and how it communicates with the driver through modern safety aids. This chapter follows the thread that ties aesthetics to engineering, showing how the bumper’s shape, materials, and integration with sensors and lighting come together to influence performance, safety, and maintenance across the life of the vehicle. It is not merely about replacement parts; it is about understanding a design choice that affects efficiency, handling, visibility, and the reliability of driver-assist features in everyday driving conditions.

At the core of the bumper’s function is its aerodynamic intent. The Italian-sculpted language that characterizes this generation’s front end is not accidental. The contours around the air intake and the smooth transitions along the sides are crafted to channel air efficiently around the vehicle. The goal is to reduce drag while guiding air to cooling channels and underbody surfaces that manage lift and stability at speed. When air is allowed to flow predictably around the car, the overall drag coefficient drops, and the vehicle requires less energy to push through the air. The result is a small but meaningful gain in fuel efficiency and a steadier feel at higher speeds, especially as road surfaces become uneven or when crosswinds challenge the nose of the car. The bumper’s geometry interacts with the grille opening, the lower spoiler, and the front lip to form a cohesive boundary layer. The way these elements meet the hood line and the fenders also influences how the car sits visually: a purposeful, planted look that signals performance without sacrificing comfort and everyday usability.

The bumper is not just an aero piece; it also acts as a structural cradle for the front of the vehicle. In this generation, the bumper is designed to absorb and dissipate minor impacts that might occur in urban traffic or parking mishaps. The construction uses reinforced plastics and composite materials that offer a favorable mix of stiffness and resilience. The objective is to provide a protective layer that can deflect small debris, absorb low-speed collisions, and shield critical components beneath the nose from road hazards. The balance between stiffness and weight is key. A bumper that is too rigid can crack or transfer more force into the structure during a low-speed impact, while one that is too soft may not offer adequate protection or alignment with the other body panels. The chosen materials aim to strike a middle ground that preserves energy absorption, keeps weight down, and maintains consistent fitment with the rest of the front end.

Within this framework, the bumper also houses lighting and sensor integrations that are essential for visibility and safety systems. The integrated fog light housings are a clear example of how the bumper serves multiple roles. Fog lights extend the driver’s field of view in rain, fog, or snow by projecting a low, wide beam that reduces glare and increases proximity lighting. The housings are designed to accommodate these lamps in a manner that preserves the vehicle’s profile while ensuring optimal light distribution. The configuration can vary with trim levels and market specifications, but the principle remains the same: the bumper must provide secure mounting points, proper heat management, and a clean optical path for the lamps. In some variants, the housings are set into the bumper’s face in a way that minimizes stray light leakage and protects the lenses from road debris, while still allowing for straightforward replacement if lenses crack or seals fail.

Beyond lighting, the bumper’s surface and attachment points are calibrated to accommodate sensors that are part of the vehicle’s assistance systems. In modern front ends, collision warning systems and adaptive cruise control rely on sensors and cameras positioned near or within the bumper area. The alignment of these components is not a afterthought; it must be precise to maintain detection range, calibration accuracy, and reliable object recognition. A misaligned bumper can throw off sensor geometry, leading to degraded performance or unintended system activations. Because the sensing suite sometimes shares data with the vehicle’s braking and steering dynamics, even small variations in position or angle can ripple into performance differences. This underlines a practical truth for owners and technicians: when replacing or modifying the front bumper, a careful re-calibration of affected sensors and cameras is often required to preserve the integrity of driver assistance features. It is not merely a cosmetic step but a safety-critical procedure that ensures the car’s electronic safety suite remains synchronized with the physical geometry of the front end.

From a maintenance perspective, the 2012 bumper is designed with serviceability in mind, but not at the expense of precision. If the bumper is damaged in a collision, the replacement process is rarely a simple swap. The bumper assembly may include or be closely integrated with electronic modules, brackets, and alignment references that tie into the vehicle’s body structure and safety systems. Replacing it involves ensuring the new unit matches the original mounting points, rechecking panel gaps, and confirming that the sensor housings align with their reference targets. In practice, this means technicians follow detailed installation specifications and perform calibration procedures that restore the vehicle to factory-specified geometry. The work is a reminder that even a seemingly straightforward bumper swap can ripple into the vehicle’s perception of its surroundings and its response to real-world driving hazards.

From a procurement standpoint, the front bumper for this generation rises to a twin-track reality: there is abundant aftermarket diversity, but the fit and finish, as well as sensor integration, require careful selection. OEM-style replacements are marketed to match the original design cues and attachment interfaces, offering a straightforward path for drivers who want a direct replacement that preserves the car’s lines and alignment with adjacent panels. On the other hand, aftermarket options can broaden personal expression or meet budget constraints, with materials ranging from reinforced plastics to composite blends that aim to balance weight, rigidity, and cost. When choosing aftermarket options, attention to fitment accuracy and surface finish becomes a priority because small deviations in contour or mounting points can cascade into misalignments of adjacent panels or interference with the sensor modules embedded in the bumper area.

The regional dimension of the supply chain is an important backdrop to the replacement decision. In the global aftermarket ecosystem, suppliers from major manufacturing hubs have long supplied both OEM and aftermarket front bumpers. Regions with well-developed manufacturing infrastructure tend to offer shorter lead times, consistent quality, and easier returns or warranty coverage. For buyers seeking replacements, there is a spectrum of access: from local workshops with access to standard kits to global distributors that provide a broader catalog and guaranteed compatibility services. The provisioning landscape emphasizes two practical considerations: first, the importance of ensuring that the chosen part is designed to cooperate with the vehicle’s safety and sensor packages; second, the need to confirm alignment references and mounting hardware are included so the installation does not become a puzzle of missing pieces.

For readers evaluating options, it helps to anchor decisions in a few concrete questions. Does the replacement part align with the vehicle’s body lines and grille geometry? Are the mounting points and brackets designed to align with the existing structure without forcing misfits? Will the sensor and camera housings align with the vehicle’s reference targets after installation? And crucially, will the chosen piece sustain the hood line and wheel arch transitions that contribute to the car’s overall stance? Answering these questions often dictates whether a buyer leans toward OEM-style replacements that promise a straightforward fit or toward aftermarket pieces that require more meticulous fitment checks and, in some cases, professional calibration services.

From a stylistic perspective, the bumper’s design cadence complements the broader silhouette of the front end. The lines are engineered to echo the vehicle’s fenders and hood, drawing the eye toward a coherent face that communicates speed and control even when the car is at rest. This harmony matters because it reinforces the impression of a well-balanced vehicle, where the nose communicates competence and restraint rather than aggression. The integration of fog light housings, the careful handling of air intakes, and the subtle wrap of the bumper into the sides all contribute to a perception of purpose. For enthusiasts, the bumper’s detailing presents opportunities for tasteful upgrades that do not disrupt the original geometry, including refinements to the lower lip or the addition of cosmetic edges that subtly intensify the car’s stance without compromising safety-critical interfaces.

In practice, the decision-makers—owners, technicians, and retailers—often turn to one of two paths. They may pursue OEM-style replacements that preserve the original fit and finish, ensuring a predictable installation and a proven compatibility record with the vehicle’s other components. Or they may explore aftermarket upgrades that promise a new look or incremental aerodynamic tweaks, but with the caveat that the installation may demand more careful calibration and alignment checks. If a driver leans into the latter route, it is essential to select a supplier that provides explicit fitment guidance and, ideally, a warranty that covers alignment and sensor recalibration if needed. The goal is to keep the car performing as it did before the bumper was damaged or replaced, so the safety systems retain their accuracy and reliability. A thoughtful approach to procurement, installation, and post-installation checks lays the groundwork for a bumper that not only protects the front of the vehicle but continues to support the advanced systems that many drivers have come to rely on.

To illustrate the practical journey, consider the path a typical owner might take when replacing the front bumper on this generation. First, they identify the desired outcome: preserve the car’s lines, reestablish precise gaps with adjacent panels, and maintain the alignment of all sensor and lighting elements. Then they evaluate the trade-offs between OEM and aftermarket options, weighing the price delta against the certainty of fit and the projected service life. The next step involves verifying that the chosen part includes attachment hardware and that the mounting points align with the vehicle’s body structure. If the replacement touches on sensor housings or camera interfaces, the owner should factor in the calibration steps and potential downtime required to restore full safety system functionality. This is not merely a shopping choice; it is a decision with safety implications and a direct bearing on long-term maintenance costs.

A practical reminder emerges from the literature surrounding front bumper replacements: precision in installation matters nearly as much as the component itself. The more integrated the bumper is with the vehicle’s safety architecture and the more dependent the performance of driver-assistance features is on exact geometry, the more essential it becomes to involve trained technicians for alignment and recalibration. In many cases, technicians will reference official installation guidelines or reliable industry standards from parts suppliers to ensure consistency with the vehicle’s design tolerances. The result is a safer, more predictable outcome that respects the car’s intended behavior under varying driving conditions. When a bumper is correctly installed and the sensors properly recalibrated, the vehicle can resume its typical response patterns—the braking system operates as expected in response to a detected obstacle, and the adaptive cruise control maintains appropriate following distances. The interplay between a physical front-end component and the digital safety ecosystem is a reminder that automotive design remains a synthesis of mechanical engineering and software-driven perception.

For readers seeking a concrete point of reference on fitment and OEM-style alignment for this generation, there is value in reviewing dedicated pages that map the interface between the bumper and the car’s bodywork. Such resources highlight how the bumper’s contours conform to the fender line, how the hood meets the top edge, and how the lower edge interacts with the splitter or undertray—if present—on higher-spec configurations. This information is particularly valuable when evaluating aftermarket alternatives, as it clarifies the expectations for how close a non-OEM part must come to the original geometry to remain visually seamless and functionally compatible with the vehicle’s safety systems. A careful reading of fitment guides can spare a lot of trial-and-error during installation and reduce the risk of misalignment that could compromise sensor accuracy or lighting performance. It is through this lens that the bumper emerges as a practical engineering component rather than a simple cosmetic surface.

From a consumer education perspective, it is helpful to recognize that the bumper system is part of an integrated front-end architecture. The bumper supports, brackets, and fasteners must be matched to the vehicle’s frame geometry and structural points. Skipping steps or selecting a part without confirming compatibility can lead to gaps, misaligned lights, or worse, the mispositioning of sensor housings. In such scenarios, the car’s safety systems may not perform optimally when it matters most. The chapter has pursued a nuanced view of how the 2012 model’s bumper design weaves together aerodynamics, protection, and sensor integration. It is a reminder that even the most visually striking front ends conceal a network of careful choices—choices that affect everything from gas mileage to the trust a driver places in the car’s protective features during inclement weather or busy highways.

When considering the broader article arc, this chapter connects with the theme that the modern bumper is a convergent piece of engineering. It is shaped by wind tunnel insights, by the need to protect critical components, and by the reality that electronics in the bumper region are increasingly central to the car’s safety and convenience features. The chapter’s narrative lines up with the idea that the front bumper is a dynamic interface—a boundary between the road and the vehicle’s internal world of sensors and controls. The practical takeaway for readers is clear: knowledge of how the bumper is designed, manufactured, and installed helps drivers make informed choices that preserve safety, performance, and the vehicle’s aesthetic integrity as it ages. In this sense, the bumper is not an afterthought but a carefully engineered frontline component that deserves attention in any discussion about the 2012 model’s front end.

For readers who want a deeper dive into the OEM-style rearward compatibility of front bumpers and the alignment references that come with factory specifications, a dedicated resource exists that presents the exact fitment expectations for the 2006–2012 era. The page offers a straightforward guide to installation and highlights how precise alignment with adjacent panels and sensor targets is essential for maintaining the vehicle’s safety profile. This resource can be a useful companion for technicians who need a reliable reference point when working on this generation. The content reinforces the message that the bumper is part of a larger system and that each interaction—from the paint finish to the sensor housing alignment—has been considered in the design and manufacturing process. In the end, the bumper’s function is to protect, streamline, and connect the car to the technologies that modern drivers rely on every time they turn the key and head out onto the road.

Internal link for further reference: 2006-2012 Mitsubishi Eclipse Front Bumper.

External resource for detailed specifications and listings: For a broader sense of the part’s specifications and availability, consult the following listing. Alibaba listing for 2012 Mitsubishi Eclipse Front Bumper.

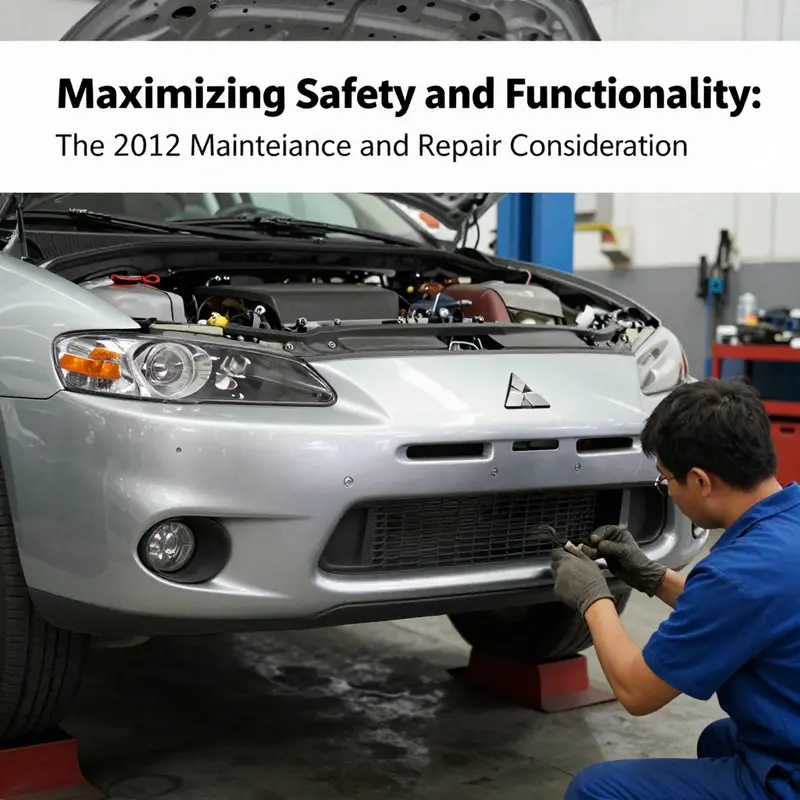

Guarding the Frontline: Maintenance and Repair Realities of the 2012 Mitsubishi Eclipse Front Bumper

The front bumper is more than a cosmetic shield; it is a vital safeguard that absorbs the first blows of road life and helps keep the engine bay, headlights, and cooling system intact under a variety of conditions. For the 2012 Mitsubishi Eclipse, this frontline component carries the weight of function, safety, and appearance in a delicate balance. When one considers the overall architecture of the vehicle, the bumper is not a standalone shell but part of an integrated system that includes impact absorption panels, reinforcement bars, and, increasingly, sensors and cameras that feed into driver-assistance systems. In this light, maintenance and repair of the bumper demand a holistic view that blends practical repair techniques with an appreciation for the vehicle’s electronic backbone. The narrative that follows threads together how this bumper performs in everyday driving, the kinds of damage it most commonly endures, the repair versus replace decision, and the careful part selection that preserves both form and function. It is a narrative about keeping the front of the Eclipse resilient and reliable, even as the road throws its everyday challenges at it.

The 2012 Eclipse front bumper, designed with urban and variable weather realities in mind, emphasizes two intertwined purposes: protection and perception. On the protection side, the bumper acts as a sacrificial shield for the engine compartment and critical components behind it. It is engineered to manage the energy from low-speed collisions or encounters with road debris that would otherwise damage the radiator, headlights, or even the cooling system’s integrity. In this sense, the bumper’s outer face and its internal reinforcement framework share a common objective: to distribute impact forces over a broader area and to preserve the structural elements behind them. The bumper also houses and visually integrates auxiliary components like fog light housings, which are not mere aesthetic add-ons. They contribute to visibility in inclement weather, making the front end more capable when rain, mist, or snow reduce forward sightlines. The integration of sensors and camera systems into the bumper area, a trend that continues to grow across many model years, adds another layer of complexity. The front bumper becomes part of a sensing ecosystem, where misalignment or distortion can ripple into calibration challenges for parking assist, collision detection, and lane-keeping assistance. Small misalignments can cascade into misreadings, triggering the need for recalibration that goes beyond repainting or reinstallation. In this sense, the bumper’s role is not merely to bear impact but to ensure the smooth operation of the vehicle’s safety net.

From a materials and structural standpoint, the Eclipse’ front bumper is a composite of outer shells, impact-absorbing foams, and reinforcement bars designed to work in concert. The practical consequence is that repairs require attention to both surface aesthetics and internal integrity. When damage occurs, one must distinguish between cosmetic scuffs and more serious structural concerns. A minor scrape along the bumper’s lip might be addressed with professional detailing and careful repainting, restoring a surface the eye perceives as flawless. Yet even such cosmetic work carries implications. Repainting isn’t simply about color; it can influence finish durability, fade resistance, and the seamless match of the bumper to adjacent body panels. A more substantial dent, crack, or deformation may indicate that the bumper’s reinforcement components have sustained compromised integrity. In such cases, replacing the bumper assembly or, at minimum, its reinforcing subassemblies becomes a prudent path to restore safety margins and aerodynamic alignment. In other words, the distinction between repair and replacement hinges on the depth of structural compromise and the bumper’s role in sensor calibration and lighting alignment.

The decision between repairing versus replacing is not purely a function of cost. It also hinges on the bumper’s long-term performance and the maintenance burden that accompanies a repaired piece. Small repairs can be compatible with high-quality detailing and paint work, but if the bumper’s inner reinforcements are bent or cracked, patching may only delay the inevitable. A damaged reinforcement member can alter energy absorption characteristics, shifting the crash dynamics in the event of another collision. If the energy-absorbing elements have deformed, their ability to dampen future impacts diminishes, increasing the risk to the engine bay and the vehicle’s most vulnerable front-end components. In such scenarios, replacement of the bumper assembly or its internal reinforcement is often the safer and wiser course. This is especially true when sensors or cameras are integrated into the bumper, because misalignment or calibration drift can undermine driver-assistance functions and parking aids that rely on precise geometry.

For those seeking to maintain the Eclipse bumper with a mind toward longevity, the distinction between OEM (original equipment manufacturer) parts and aftermarket options becomes a central theme. OEM components are designed to fit, align, and function in concert with the vehicle’s broader safety and electrical systems. Aftermarket bumpers, while offering potential cost savings or styling variations, may require additional attention to fitment and calibration. The alignment of the bumper—its height, its angle, and its precise interface with the fenders and grille—directly influences aerodynamics, cooling airflow, and even the performance of adjacent lighting. When alignment is off, the visual continuity of the front end suffers, and the risk of rattling, premature wear, and sensor misreads increases. Thus, the repair or replacement workflow must consider how the bumper interacts with the vehicle’s sensors, cameras, and lighting systems. Any work in this area should be approached with meticulous attention to re-calibration needs and test fits before final fastening.

A practical, often-understated facet of bumper maintenance concerns the grille and its surrounding architecture. The grille isn’t just a cosmetic feature; it contributes to engine cooling by shaping airflow into the radiator and helps define the front-end silhouette that customers notice first. A damaged grille can alter airflow patterns enough to influence cooling performance and may force an earlier replacement of the bumper assembly to restore both form and function. In the realm of parts selection, it remains essential to prioritize high-quality components that resist corrosion and wear. Corrosion resistance is particularly important for urban driving scenarios where road salts, moisture, and humidity can foster degradation in exposed metal and mounting points. Engaging with a bumper replacement that includes corrosion-resistant materials and sealed mounting points contributes to consistent fitment and reduces the risk of future misalignment caused by rust and material fatigue.

Repair options for the Eclipse bumper are not monolithic. Minor damages can often be resolved through professional detailing that includes careful sanding, color-matched repainting, and protective clear coats. The goal is to produce a surface that looks and feels like new and to restore the seamless transition between the bumper and adjacent panels. Several media demonstrations show that with skilled workmanship, a repaired bumper can look nearly indistinguishable from a factory part. But it is important to manage expectations. Surface restoration does not always capture the bumper’s original energy-absorbing characteristics if internal components have been compromised. When the damage extends beyond the surface and into the bumper’s structural core or its reinforcement framework, more involved procedures become necessary.

Structural damage often necessitates more than cosmetic remedies. If the bumper’s reinforcement support—as designed to absorb energy during a collision—has bent or fractured, replacing the bumper assembly or critical interior members becomes a safer route. In such cases, the alignment of the bumper relative to the vehicle’s frame and to adjacent components becomes a matter of precision, not guesswork. Modern bumpers frequently house sensors or housings for security and safety features; improper installation can hinder after-market or factory-calibrated safety systems. Therefore, any repair plan that touches electronic components must include a recalibration step to restore sensor accuracy and maintain full functionality of parking assist and related features.

Part selection, then, emerges as a central axis of this maintenance philosophy. When opting for replacement, the aim is to preserve the Eclipse’s visual identity and aerodynamic profile, while ensuring the structural integrity that safeguards passengers and critical components. OEM or high-quality aftermarket parts should be evaluated on several criteria: precise fit, robust mounting points, compatibility with any integrated sensors or cameras, and the degree to which the part preserves the original kerf lines and gaps that define the car’s front-end appearance. The bumper, after all, frames the vehicle’s face, and even small deviations can affect perceived quality and resale value. For readers who are actively pursuing a replacement, the navigation toward a compatible bumper page within the same generation of Eclipse parts is a practical starting point. For readers seeking a direct source for a bumper assembly compatible with this generation, see the dedicated product page 2006-2012-mitsubishi-eclipse-front-bumper.

In the realm of aftermarket considerations, a note about installation accuracy and sensor calibration must be kept in mind. Aftermarket hitches or auxiliary devices, though occasionally marketed as compatible with a range of models, can inadvertently limit ground clearance or interfere with bumper structure and the sensors integrated into the bumper. When such components are introduced, installation requires careful measurements and, in some cases, professional alignment procedures to ensure that nothing reverberates with the bumper’s mounting points or sensor housings. It is easy to underestimate how a slight misalignment can alter how the bumper lips interact with the fenders and grille, potentially creating unwanted gaps or contact with adjacent panels during operation. A meticulous installation protocol minimizes these risks, protecting the vehicle’s front-end geometry and preserving the car’s original aesthetics.

Maintenance and inspection routines form the backbone of longevity for the Eclipse’s front bumper. Regular inspections should focus on the bumper’s surface integrity, the condition of mounting brackets, and the alignment of the bumper with the surrounding body panels. Look for cracks, dents, or chips that could propagate into larger fractures if left untreated. Misalignment signs—such as gaps that are wider on one side, or a pull in the bumper relative to the headlight line—should be addressed promptly, because small misalignments can worsen with road vibrations and temperature fluctuations. In addition, inspect the fog light housings and the grille area for damage that could affect airflow or lighting performance. When sensors or cameras are involved, regular functional checks help identify calibration drift early. Even seemingly minor misalignments can lead to inaccurate sensing, which, in turn, can degrade the performance of safety features that users rely on daily.

If you are navigating the supply chain for replacement parts, there are two broad strategies to consider: OEM replacement parts from authorized channels, and high-quality aftermarket options that aim to replicate the original fit and finish. Both pathways share the same objective—to maintain the Eclipse’s front-end integrity and prolong its service life. The choice between the two is often determined by budget, availability, and the user’s tolerance for potential calibration nuances. In any case, the integrity of the bumper’s fixtures—bolts, brackets, and mounting points—must be verified during installation. Neglecting these can lead to future misalignment, rattling, or more costly repairs down the line. A careful, staged approach—careful removal, inspection of mounting hardware, controlled alignment checks, and cautious reattachment—helps ensure the job stands the test of time.

For readers who want a direct source for bumper assemblies or reinforcement components, the broader supply ecosystem for this generation of Eclipse front-end parts offers a range of options. The maintenance and repair path selected should be accompanied by a plan for future serviceability. That means not only selecting the right parts but also establishing a workflow for periodic inspections, re-painting when needed, and sensor recalibration when the bumper is removed and reinstalled. In this sense, bumper maintenance becomes a running thread in the vehicle’s overall care, woven together with wheel, suspension, and engine cooling system upkeep. It is a reminder that the front bumper is not a stand-alone accessory but a functional interface that engages with many facets of the vehicle’s design and operation.

In closing, the 2012 Eclipse front bumper embodies a philosophy of prudent maintenance and thoughtful repair. It highlights how a single component serves as a nexus between safety, aesthetics, and technology. The path from a minor scratch to a full front-end replacement is narrower than it might appear, once one factors in sensor calibration, air flow, and the continuity of the vehicle’s visual language. A well-executed maintenance and repair plan respects this complexity and preserves the bumper’s role as both guardian and face of the Eclipse. For readers who want to explore a direct source for bumper assemblies compatible with this generation, the dedicated product page linked above offers a starting point that aligns with the car’s original design intent. The journey from minor blemish to renewed front-end is less about replacing a panel and more about restoring a carefully engineered system that protects, guides, and inspires confidence in every drive.

External reference: For additional context on reinforcement components and genuine parts, see the widely cited reinforcement kit resource at https://www.ebay.com/itm/175352976775. This external source provides a tangible reference point for the kinds of reinforcement structures discussed, helping readers understand how a robust front-end assembly contributes to long-term safety and performance.

From Factory Floor to Global Market: The 2012 Mitsubishi Eclipse Front Bumper and Its Sourcing Journey

The front bumper of a car is often taken as a mere outer shell, a shield painted to match the body and to hide the more utilitarian elements of the vehicle. Yet for a model like the 2012 Mitsubishi Eclipse, the bumper is a carefully engineered interface. It mediates crash energy, protects vital components behind it, and houses the evolving sensor and camera arrays that anchor the car’s safety and driver-assistance features. In the broader context of the automotive aftermarket, the Eclipse’s front bumper reveals how a component designed for one market becomes a global commodity, dispersed through a network that spans continents, factory floors, and repair bays. To understand its sourcing is to trace a lineage that begins with design intent, passes through the realities of mass production, and ends in the hands of buyers who must balance fit, function, and cost when a bumper finally arrives at a repair shop or a garage shelf. The journey of the 2012 Eclipse front bumper is not merely about replacement parts; it is about the way a vehicle’s safety envelope is preserved in a rapidly globalized market, where the precision of installation and the integrity of materials matter as much as the appearance of gloss and color match.

In the design language of the Eclipse, the bumper is more than a protective plate. It is a structural interface that helps dissipate impact energy and serves as a mounting plane for fog light housings, aerodynamic features, and, increasingly, sensors and cameras. The integrated fog lamp housings, noted in contemporary discussions of the era’s front-end design, reflect an emphasis on visibility under adverse weather—rain, fog, or snow. This relates not only to driver comfort but to the broader safety ecosystem that modern vehicles increasingly rely on. The bumper’s geometry must accommodate air intakes, radiator access, and the precise alignment required by adjacent panels. When you look at a 2012 Eclipse bumper, you are looking at a component that has to perform in a wide range of climates and road conditions, while also providing a predictable surface for sensor calibration and for paint repair after a collision. The engineering challenge is not only to make a bumper that fits, but one that can support an array of electronic components without impeding their function.

From a sourcing perspective, the global market for this specific bumper variant is deeply anchored in Asia, with a pronounced concentration in China. This regional dominance is not accidental. It reflects a mature ecosystem that has evolved over decades to produce high-volume auto parts with consistent quality and rapid turnaround times. Within China, two provinces stand out as production and supply powerhouses: Guangdong and Zhejiang. Guangdong, especially around Guangzhou, has developed integrated production pipelines that cover injection molding, fiberglass fabrication, painting, and tooling. These capabilities are essential for producing bumpers that not only meet structural standards but also achieve a finish that can pass OEM color-matching tests and withstand the wear and tear of daily use. Zhejiang, by contrast, is renowned for lean production and cost optimization. Factories here frequently emphasize efficiency improvements, process standardization, and competitive pricing—without compromising the bumper’s structural integrity or its ability to hold up under impact. Taken together, these provinces offer a two-pronged advantage: Guangdong supplies scale and robust finishing capabilities, while Zhejiang contributes cost efficiency across the supply chain. The result is a robust, diversified supply base that can respond to both large OEM-style orders and aftermarket demand that demands quick replenishment cycles.

The materials that dominate this bumper market are largely ABS plastics, chosen for their balance of toughness, chemical resistance, and ease of molding. ABS provides the kind of resilience that a front bumper needs when faced with road debris and minor impacts, while offering a surface that can be painted to match exact color codes. The choice of material is not incidental; it is a core factor in paint adhesion, long-term appearance, and the ease with which a bumper can be repaired or repainted after a collision. For aftermarket suppliers, achieving OEM-like tolerances in thickness, curvature, and surface finish is essential to ensure a consistent fit. This is particularly important for a model such as the Eclipse, where the bumper interfaces with energy-absorbing structures behind it, as well as with a suite of sensors and cameras whose alignment is critical for the correct operation of safety features.

Beneath the surface, construction practices in Guangdong and Zhejiang converge on a philosophy of compatibility and repeatability. Injection molding lines must produce parts that consistently meet dimensional tolerances, while painting lines must deliver a layer of color that aligns with the vehicle’s original finish and withstands the rigors of sun exposure, temperature fluctuations, and everyday wear. Fiberglass components are sometimes used to reinforce certain bumper sections, adding a layer of rigidity where needed without significantly increasing weight. All of this is orchestrated to deliver a bumper that can be installed with predictable fitment, reducing the risk of misalignment that would necessitate additional adjustments after installation. This is particularly important for the Eclipse, a vehicle whose front-end geometry is linked to aerodynamic performance and pedestrian safety considerations. A bumper that deviates even slightly from its intended contour can alter airflow around the nose, affecting both cooling and stability at highway speeds, as well as the accuracy of any forward-facing sensors that rely on a clear, unobstructed field of view.

For buyers navigating the aftermarket, the procurement process becomes a test of due diligence and supplier reliability. The best practice is to verify certifications that reflect a factory’s quality management and production discipline. ISO/TS 16949, for example, has historically signaled a level of process maturity in the automotive supply chain. While standards evolve and new frameworks emerge, the underlying principle remains constant: a supplier’s capability to produce parts that meet consistent quality, withstand test cycles, and deliver on time is the bedrock of a trustworthy relationship. Buyers should seek evidence of a supplier’s defect rates, on-time delivery performance, and their capacity to sustain long-term partnerships. In a market where a bumper must align precisely with the vehicle’s mounting points and with adjacent panels, even small variances in plastic thickness or fixture tolerances can cascade into fitment problems. A supplier that communicates openly about tolerance ranges and provides robust post-sale support is often a more reliable partner than one that offers aggressive pricing with opaque quality assurances.

The human element of sourcing is equally important. In Guangdong and Zhejiang, generations of manufacturers have refined their practical crafts. Workers who assemble, finish, and inspect bumpers bring a tacit knowledge about how plastic behaves during molding, how paint coats adhere to surfaces, and how minor imperfections in a finish can be corrected without sacrificing the overall look. This experiential knowledge is often as important as formal certifications. It shapes the way a bumper arrives at a repair facility, where technicians must rely on a consistent surface for reattachment, precise alignment, and accurate color matching. The aftermarket world frequently involves orders that range from single units to large batches, and the capacity to scale production while maintaining consistent quality is a hallmark of the Guangdong and Zhejiang ecosystems. The same ecosystems that deliver a color-matched, fit-for-purpose bumper also enable efficient reordering when a replacement is needed after an accident or when a model-year update requires an updated shell with minor trim adjustments.

The sourcing journey for the 2012 Eclipse front bumper also intertwines with consumer-facing marketplaces that facilitate both bulk procurement and individual purchases. In the global aftermarket, platforms that offer guaranteed fit and compatibility have gained traction. They provide a bridge between the sophistication of factory production and the accessibility demanded by individual car owners who need replacements quickly and affordably. A key dynamic here is the balance between authenticity and price. Buyers may encounter genuine OEM parts that reflect the exact engineering of the original, alongside high-quality aftermarket options that reproduce the same fit and finish at a lower cost. The risk, of course, is variability in color matching, surface texture, and durability over time. This is where the due diligence process becomes essential: checking for proper documentation, confirming compatibility with the specific Eclipse trim and bumper reinforcement, and understanding the return and warranty policies that accompany aftermarket purchases.

In exploring specific sourcing channels, it is useful to consider how the market aggregates supply chains across regions. Guangdong’s manufacturing clusters feed into rapid distribution networks that span Asia and beyond. From there, the parts travel through ports and logistics hubs to reach markets in Europe, the Americas, and Africa. Zhejiang’s emphasis on lean production supports competitive pricing and shorter lead times, which can be decisive for buyers who need to replenish inventory quickly after a batch of repairs. The result is a mosaic: a bumper that is engineered for performance, produced in a region famed for its scale and efficiency, and distributed through channels that aim to minimize downtime for clients who depend on fast, reliable replacements. The 2012 Eclipse front bumper thus serves as a microcosm of the modern automotive aftermarket, where design, manufacturing discipline, and supply chain efficiency come together to deliver a product that is more than a shell—it is a carefully calibrated interface to a car’s safety technology and to the continuity of repair work.

For practitioners who want a concrete onboarding path to this market, reference to a specific, representative product page can be instructive. A widely used entry point is the 2006-2012 Mitsubishi Eclipse Front Bumper page, which consolidates key specifications, compatibility notes, and purchase options in one place. This page acts as a practical touchstone for technicians and buyers who need to confirm fit and overview the expected materials and construction practices that underpin the bumper. It serves not only as a catalog entry but also as a portal into a broader conversation about how such parts are manufactured, tested, and distributed across the global market. You can visit the internal product page here: 2006-2012 Mitsubishi Eclipse Front Bumper.

The chapter on sourcing would be incomplete without acknowledging the broader literature on global procurement strategies for automotive parts. A comprehensive external resource that frames supplier evaluation, performance metrics, and long-term partnerships provides a useful backdrop for applying the lessons of the Eclipse bumper case. For readers seeking a structured approach to vetting suppliers and managing risk in a global supply chain, this external guide offers foundational insights and practical checklists. See the external resource for deeper context: https://www.autoparts-sourcing.com/mitsubishi-eclipse-front-bumper-supplier-guide.

In the end, the story of the 2012 Mitsubishi Eclipse front bumper is a story about how a seemingly everyday component embodies a network of decisions. Design intent, material science, and the geometry of the bumper must align with the realities of manufacturing precision, supply chain reliability, and the needs of repair professionals who rely on predictable fit and finish. It is a story that transcends a single model year or a single marketplace. It is about the global flow of parts that keeps vehicles on the road and keeps safety systems functioning as intended. As the Eclipse’s front bumper travels from a Guangdong or Zhejiang factory floor to a repair shop in a distant city, it carries with it the careful balance of engineering, quality control, and logistics that defines modern automotive aftermarket practice. This balance is what makes the bumper not just a protective shell, but a reliable link in a complex system that safeguards people, preserves vehicle performance, and supports the ongoing lifecycle of a car long after it leaves the showroom.

The deeper takeaway for practitioners is clarity about where to begin in sourcing: confirm compatibility with the specific model and trim, verify the supplier’s quality credentials and delivery performance, and align procurement decisions with a partner that can sustain reliability across the product’s lifecycle. The Eclipse bumper represents a case study in how global supply chains optimize for scale while still acknowledging the essential human factors—the technicians who install parts, the customers who rely on accurate fit, and the shops that must manage pricing and inventory with discipline. In this sense, the chapter on sourcing is not merely about procurement; it is about how the automotive industry maintains safety, consistency, and resilience through careful, transparent, and collaborative practices across borders.

Final thoughts

Understanding the 2012 Mitsubishi Eclipse front bumper in terms of its design, maintenance needs, and sourcing options empowers business owners in the automotive sector. By recognizing the importance of this vital component, you can ensure your fleet remains safe and functional, while also benefiting from effective supply chain management. This knowledge not only aids in maximizing the profitability of your business but also ensures customer satisfaction through reliable, high-quality parts. Invest in your understanding of automotive components today and stay ahead in the competitive market.