The 4G69 engine, a robust 2.4L inline four-cylinder engine developed by Mitsubishi, has gained significant traction in the automotive market due to its reliable performance and adaptable features. Business owners in the automotive sector, particularly those involved in vehicle maintenance or manufacturing, will find the engine’s attributes compelling. This article delves into the engine’s power and performance characteristics, highlights its technical innovations and reliability, and examines its applications across various market segments, providing a thorough understanding of what makes the 4G69 a trusted choice for numerous vehicle manufacturers and owners alike.

Balanced Pulse: Unlocking the Practical Power and Quiet Durability of the 4G69 Engine

In Mitsubishi’s broader engine story, the 4G69 is less a headline-grabbing sports powerplant and more a steady workhorse that blends usable power with enduring reliability. It sits at the heart of a family of vehicles that emphasized practicality, space, and confidence behind the wheel. The 4G69 began life as a 2.4-liter inline-four engine that could be pressed into a range of body styles and markets, from compact family SUVs to mid-size crossovers and rugged sport utilities. The spirit of the engine is straightforward: deliver a tractable, livable driving experience with a balance of low-end response, mid-range punch, and reasonably refined highway behavior. It is not the most flamboyant engine in Mitsubishi’s stable, but it is one of the most approachable for daily use, and that accessibility has helped the 4G69 endure across generations and different brands through collaboration and localization. This chapter delves into the mechanics that give the 4G69 its characteristic balance, the performance profile that makes it suitable for city commutes and highway stretches alike, and the design choices that foster durability without sacrificing everyday practicality. It is a narrative about the virtue of well-executed engineering, where the goal is not extreme raw numbers but a dependable, versatile engine that remains relevant as technology and needs evolve.

At the core, the 4G69 is a 2.4-liter inline-four with natural aspiration and a valve train that has seen evolution across variants. The engine family is notable for adopting Mitsubishi’s MIVEC—an electronic control system that times the intake and exhaust valves to optimize performance across different speeds and loads. MIVEC is the kind of technology that changes how the engine feels in the real world, translating to crisper throttle response in the mid-range and better combustion efficiency at part-throttle. The result is a tractable engine that behaves predictably in urban traffic and feels willing enough to deliver steady acceleration when you need to merge onto a highway or climb a slope. In many trims and in several generations, the 4G69 uses a Single Overhead Camshaft (SOHC) configuration, with MIVEC integration. There are variants that sport more advanced configurations, including a DOHC version, which typically enhances high-RPM performance. The DOHC variant broadens the engine’s appetite for revs, appealing to drivers who value a more energetic top end. Yet even in its SOHC form, the 4G69’s design supports a broad torque curve and a reliable, durable performance that suits family vehicles and long-distance travel. The engine’s architecture—relatively simple, with accessible components—also helps with serviceability. For owners, easier access to service intervals and routine maintenance translates into lower running costs and less downtime, a practical benefit that compounds over years of ownership.

Performance, when looked at through the lens of real-world use, is a study in balance rather than outright peak numbers. The 4G69 typically delivers around 125 to 160 horsepower, depending on the exact model year and vehicle installation. The torque figure—roughly 219 to 220 Nm—lands in a sweet spot for city driving and mid-range overtaking. This torque is most often available in the mid-RPM range, which means a driver can feel confident when passing on rural roads or maintaining a steady pace on a grades. The power band is broad enough to avoid excessive gear hunting, which reduces stress in daily use and contributes to a more relaxed driving experience. In practical terms, the engine pulls smoothly from low to moderate engine speeds, without the abruptness that can plague some older naturally aspirated four-cylinders. In contexts like the Outlander, Lancer, Pajero, and other Mitsubishi models, that mid-range flexibility translates into confident throttle response without requiring constant revving. In more spirited applications that push toward higher revs, a DOHC variant can demonstrate improved high-RPM efficiency, offering a more linear power delivery when the throttle is opened wide and the engine revs into the upper ranges. The versatility of the 4G69 becomes apparent as you compare city streets to open highways; it does not demand aggressive driving to feel alive, yet it is capable of meaningful performance when the road demands it.

An important design decision lies in the engine’s construction. The 4G69 uses an aluminum block in many configurations, which helps reduce overall weight and improve heat dissipation. Lightening the block reduces the unsprung mass and can contribute to slightly better fuel economy and handling steadiness, especially when paired with a drivetrain tuned for efficiency. The aluminum block also supports a stiffer, more durable base for long-term operation, particularly in applications with varying load demands, such as all-wheel-drive variants or family SUVs carrying passengers and cargo. Coupled with MIVEC, the valve-timing system actively manages intake and exhaust flow to optimize combustion under different conditions. The result is a broad, usable torque curve that remains reliable across a range of temperatures and driving scenarios. The engine’s durability is aided by Mitsubishi’s long history of engineering consolidation and a supply chain that, through partnerships and localization, has kept parts and service accessible in many markets. This accessibility matters in the daily life of owners who rely on predictable maintenance and timely part availability to keep their vehicles on the road.

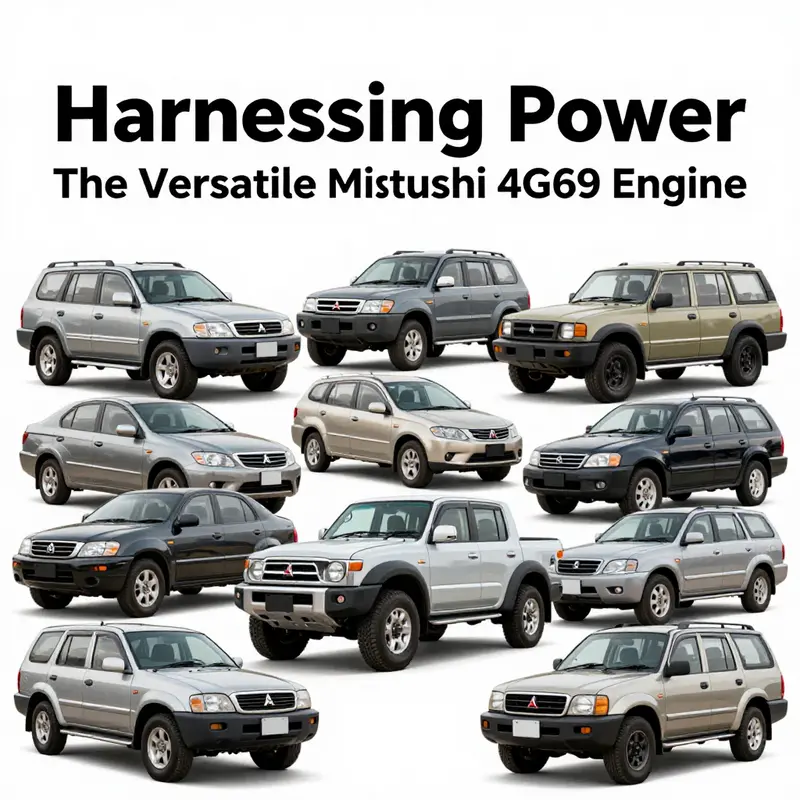

The 4G69’s applications reflect a design philosophy that favors wide-market practicality. It has found its way into several well-known Mitsubishi models, including SUVs and sedans, where the need for dependable torque and smooth operation is strong. The engine’s reputation for reliability is reinforced by its relatively simple architecture and the maturity of the parts supply chain. In markets where the 4G69 was produced under license or through joint ventures, it has benefited from a broad service ecosystem. The consequence for owners is not just a factory warranty but a long tail of parts and knowledge you can lean on as the vehicle ages. The engine’s broad use across various platforms has also helped keep maintenance costs reasonable, with common wear items available from multiple suppliers and service intervals that align with standard automotive maintenance practices. This ecosystem reduces ownership friction and makes the 4G69 a practical choice for drivers who value predictable running costs and ease of maintenance over the long term.

From a driving perspective, the 4G69 emphasizes refinement without forfeiting practicality. The torque available in the mid-range is particularly helpful when the engine operates at lower speeds, such as during city stop-and-go traffic. The character of that mid-range torque means throttle response is immediate enough to make brisk merges and lane changes feel secure, while at the same time avoiding the peaky power delivery that can lead to abrupt shifts in torque and less refined acceleration. The MIVEC system contributes to this behavior by optimizing valve timing so that combustion remains efficient across a spectrum of speeds. In practical terms, that means better fuel economy under typical daily driving and an engine that remains responsive when the road demands a more assertive pace. The engine’s natural aspiration means there is no turbo lag to contend with, which can be a real advantage for drivers who prefer a predictable throttle map and straightforward engine behavior. And while the 4G69 may not deliver the high-end adrenaline of a turbocharged unit, its combination of mid-range strength, easy throttle response, and quiet operation in everyday use makes it a comfortable partner for family travel, daily commutes, and long highway cruises.

Fuel economy, a perennial consideration for many buyers, is another area where the 4G69 earns its keep. In mixed driving scenarios, the engine typically records a fuel consumption in the ballpark of roughly 9 to 11 liters per 100 kilometers. This range places it in the middle of the pack for its class, which is a sensible trade-off for the level of performance and reliability it offers. The MIVEC valve-timing optimization plays a crucial role here by maximizing combustion efficiency, reducing fuel consumption at part throttle, and smoothing the transition between low and mid-range operation. In urban use, the engine’s torque helps avoid excessive downshifting, contributing to steady fuel use and a calm driving experience. On highways, the engine can maintain speed with modest revs, further aiding efficiency. The real-world numbers will vary based on vehicle weight, transmission choice, drivetrain layout, and the overall efficiency tuning of the model, but the overarching message is clear: the 4G69 is designed to deliver a balanced mix of usable power and reasonable economy, rather than chasing extreme performance figures.

Maintenance and long-term durability form an essential part of the 4G69’s story. A mature engineering platform benefits from established service procedures, abundant parts availability, and a broad base of technicians familiar with the engine family. With proper maintenance—regular oil and filter changes, timely attention to cooling system maintenance, and routine checks on belts, tensioners, and air intake systems—these engines have demonstrated the potential to cover substantial mileages with minimal intrusion from major failures. The practical takeaway for owners is that the 4G69 rewards regular care with steady performance and fewer interruptions to daily life. Its simple, robust design means repair costs tend to stay within reasonable limits, which is a compelling consideration when total ownership cost enters the discussion. The engine’s durability is not just about raw strength; it is also about predictable behavior over time. The engine remains stable under load, maintains its response characteristics as components wear, and does not exhibit sudden, dramatic changes in performance as it ages, provided routine maintenance is kept up.

The 4G69’s broad adoption and ongoing relevance owe much to its adaptable nature. In vehicle lineups that required a dependable powerplant capable of moving families and cargo without demanding constant attention, the 4G69 offered a compelling package. Its weight profile, aided by the aluminum block in various configurations, contributed to the overall balance of acceleration, handling, and efficiency. The induction system, enhanced by MIVEC, allows the engine to breathe efficiently at different rpm ranges, maintaining a steady flow of air and fuel that supports smooth acceleration and steady cruising. In vehicles designed for longer trips or frequent highway use, the ability to sustain comfortable performance with modest fuel consumption becomes a meaningful differentiator. And for markets where after-sales support is critical, the 4G69’s presence in multiple brands and its localization through joint ventures have ensured a robust supply chain, reducing downtime for maintenance and repairs. This ecosystem matters as much as the engine’s technical specifications because, in many real-world scenarios, the value of a powertrain is measured by how readily it can be serviced, how widely parts are available, and how easily the knowledge to maintain it can be accessed by technicians and enthusiasts alike.

For readers who want to dive deeper into technical specifics or explore variants in more detail, a dedicated resource on the 4G69’s design and performance is available. You can explore this resource for a focused look at the engine’s 2.4-liter displacement, its MIVEC integration, and how the configurations differ between SOHC and DOHC implementations. 4G69 engine details. This internal link points to a page that consolidates information about the engine’s production context and its presence in a range of vehicles, providing a practical reference for readers who want to connect the theory of performance with the realities of service and maintenance. The engine’s story, after all, is as much about how it is supported and serviced as it is about horsepower and torque. It is this combination of accessible design, reliable performance, and broad applicability that keeps the 4G69 relevant even as newer powerplants appear in the market.

For readers seeking official, in-depth specifications and service procedures, the manufacturer maintains a technical service resource that covers the 4G69 and related powerplants. This external resource provides verifiable procedures, maintenance intervals, and updates that reflect changes across model years and regional implementations. Manufacturer Technical Service Manual.

In sum, the 4G69 embodies a philosophy of sensible engineering: a compact, naturally aspirated 2.4-liter inline-four built for everyday life. Its combination of practical power, broad torque, and a mature, durable design makes it a reliable partner for a wide range of Mitsubishi vehicles and a dependable choice for owners who value steady, predictable performance over flashy peak figures. The engine’s longevity is backed by a robust ecosystem of service and parts, a factor that is often as important as the specs themselves when a car becomes a long-term companion on roads and highways alike.

Engineering Resilience and Rampant Innovation: The 4G69 Engine’s Blend of MIVEC Precision and Proven Longevity

The Mitsubishi 4G69 engine stands as a quiet exemplar of how a modern powerplant can marry advanced control with enduring reliability. It is a 2.4-liter inline-four, naturally aspirated, that has found its place not just in Mitsubishi’s own models but in a broader ecosystem of partnerships and localization efforts. Its story is less about flashy horsepower numbers and more about a harmonized approach to engineering where every choice—weight, breathing, timing, and thermal management—works in concert to deliver robust daily performance, respectable efficiency, and long-term durability. In markets around the world, this engine has earned trust not because it shouts about its technology, but because it quietly proves its mettle over tens of thousands of miles, often with routine maintenance and sensible operating habits. The 4G69’s lineage traces back to the 4G64 family, yet it carries its own refinements. It demonstrates that a well-tuned natural aspiration engine can stay relevant in an era where turbocharged power often grabs headlines. What gives the 4G69 its staying power is a philosophy of reliable engineering that does not chase peak power at the expense of long-run durability. Instead, it seeks a balance—a broad, usable torque curve, steady fuel delivery, and a mechanical layout that minimizes the chances of unexpected failure, even after many years of service. To appreciate what makes this engine distinctive, one can begin with the core technologies that define it and then trace how those technologies interact with real-world driving and vehicle design choices. The centerpiece is Mitsubishi’s MIVEC system, the variable valve timing electronic control that adjusts intake and exhaust timing in response to speed and load. This system is not a one-trick feature, but a dynamic, bidirectional tool that shapes how the engine breathes through its entire RPM range. When the engine is below peak torque, MIVEC can optimize valve overlap to improve low-end pulling power, enabling confident acceleration from a stop or while negotiating city traffic. As the revs climb, MIVEC shifts to favor higher lift and more precise timing, allowing more air and exhaust to move in and out of the combustion chamber. The net effect is a broader, more usable power band with smoother transitions and better fuel efficiency. The result is not only stronger off-idle response but also more stable mid-range performance. In everyday terms, that translates to day-to-day drivability—less throttle fiddling at low speeds, quicker overtakes on the highway when needed, and an engine that does not feel out of breath as it climbs through gears. The 4G69’s design reinforces these motor-skill characteristics with a high-quality breathing system. It uses a multi-point electronic fuel injection system to deliver precise fuel metering, ensuring a careful air-to-fuel ratio across varying loads. Precision in fuel delivery is crucial because it underpins both performance and emissions. In a naturally aspirated engine, maintaining efficient combustion across a wide range of conditions is the difference between a sluggish idle and a responsive throttle. The 4G69’s approach—careful injector timing, matched to the air flow and the valve timing set by MIVEC—helps minimize fuel waste and reduce emissions while preserving power. The engine’s architecture also highlights material choices that matter for long-term reliability. The block and cylinder head are built from aluminum alloy, a choice that lightens the rotating assembly and improves heat dissipation. Lighter mass means less inertial stress during acceleration and braking cycles, while better heat transfer helps maintain consistent combustion and reduces thermal fatigue in critical components. The aluminum construction also supports the engine’s overall packaging, allowing for reasonable rigidity and reduced vibration. The result is a compact, rigid core that can endure the rigors of daily driving and occasional more demanding conditions without demanding extraordinary maintenance. The four-valve-per-cylinder arrangement, paired with a dual-overhead camshaft (DOHC) configuration, ensures efficient breathing. Four valves per cylinder provide a broad flow path for both intake and exhaust, enabling greater volumetric efficiency. In practice, this translates to smoother idle, improved throttle response, and a more resilient torque curve as the engine spins up and down. The architecture also supports a robust manufacturing story. A mature platform means engineers have had the chance to refine tolerances, reduce assembly risk, and build a supply chain that can deliver reliable parts at scale. This is not merely theoretical. Real-world ownership experiences reflect a history of dependable service, with many vehicles attributed to 4G69 powertrains delivering well into the 100,000-200,000-kilometer range when owners follow conventional maintenance plans. The engine’s reliability is reinforced by a combination of straightforward mechanical design and a history of proven components. Its lineage through the 4G64 offers a conservative, well-tested foundation, while its refinements address the needs of modern emissions standards and average driving patterns. The result is a durable power unit that can be expected to endure the daily grind of commuting, school runs, and weekend trips with a degree of peace of mind that is prized in family-friendly applications. One of the more compelling aspects of the 4G69 is how it has found a home across a spectrum of Mitsubishi models, and even beyond the brand’s own badge. It’s appeared in the Outlander and Pajero Sport, both as practical, mid-sized SUVs where reliable torque and steady highway performance matter. It has also been fitted in the Lancer and Eclipse models, where a balance of weight and power supports agile handling and confident acceleration without resorting to aggressive turbocharging. The engine’s adaptability is further illustrated by its localization in various markets through joint ventures and domestic production efforts. By becoming a familiar, accessible powerplant, it has supported a broader ecosystem of parts availability and service networks that make ownership more convenient for a wider range of customers. In practical terms, the reliability the 4G69 offers rests partially on how well it is supported by maintenance. Regular oil changes with quality lubricants, timely replacement of filters, and attention to cooling system health contribute significantly to longevity. Because the aluminum engine core is efficient at shedding heat, owners who monitor coolant condition and address overheating early tend to see fewer warps, warping, or thermal fatigue in components that influence the engine’s long life. The MIVEC system, while a technical highlight, is also a maintenance consideration. Like any variable valve timing technology, it benefits from a clean oil supply and an intact electronic control system. When oil quality degrades or the oil becomes dirty, the valves can experience sticky timing or inconsistent behavior, reducing the smoothness of transitions and potentially diminishing the fuel economy gains that MIVEC provides. In this sense, the 4G69’s reliability is closely tied to routine maintenance habits rather than a purely mechanical guarantee. The broader reliability profile is also shaped by the engine’s operational envelope. Because it is naturally aspirated, it relies on efficient intake and exhaust flow rather than forced induction to achieve its power. This tends to translate into fewer high-stress situations compared with turbocharged engines that chase peak horsepower. The result is calmer engine operation under typical driving conditions, with fewer abrupt transients that can stress ancillary systems over time. Yet the 4G69 is not merely a sum of its parts. It is a carefully engineered blend where every piece—from the timing strategy to the intake-exhaust choreography—works in concert. When a driver presses the throttle, the MIVEC system responds to RPM, load, and even temperature, ensuring that the engine is breathing optimally as it moves from city streets into open highways. The integrated approach to torque delivery also means that the engine can deliver confidence in overtaking and passing maneuvers without requiring constant gear changes or high RPM labor. The driving experience becomes more predictable, particularly for family-based applications where a predictable response adds a sense of safety and control. In terms of maintenance and repair, the 4G69 benefits from the extensive parts availability that comes with its long service life and widespread deployment. Because many vehicles used the same core engine, the aftermarket ecosystem has grown to support belts, timing components, sensors, and actuators with a broad range of options. This contributes to lower total ownership costs, a factor that endears the engine to both users and service providers. The reliability story is further reinforced by the ease of diagnosis. The engine’s architecture is straightforward enough that routine troubleshooting can identify most issues without complex disassembly. The DOHC design, for example, has well-documented service procedures, and the MIVEC system, while sophisticated, is supported by abundant diagnostic resources. In practical terms, this translates to shorter repair times and more predictable costs, which again underscores the engine’s lifelong value proposition. A nuanced aspect of the 4G69’s appeal is its compatibility with a broad range of vehicle applications and driving demands. For many owners, this means that the engine can be a tactical choice for a used vehicle stack, or a reliable base powerplant for a model that remains popular in used-car markets. The balance of torque, smoothness, and mid-range accessibility means that even as fuel economy standards tighten in various regions, the 4G69 remains relevant. Its efficiency is not primarily a result of forced induction or tiny turbochargers, but rather a thoughtful alignment of air intake, valve timing, and precise fuel delivery that permits efficient combustion under real-world driving conditions. The engine’s role in Mitsubishi’s broader strategy also bears noting. By offering a powertrain that is easy to maintain, widely supported, and capable of meeting everyday demands with quiet competence, Mitsubishi could keep model lines appealing to families and practical buyers. The use of aluminum in the engine core, the DOHC configuration, and MIVEC timing are all part of a package that emphasizes practical performance over sensational bragging rights. In the end, what makes the 4G69 a lasting point of reference is not a single feature, but the integration of technologies and design choices that deliver consistent everyday value. It demonstrates how a modern engine can be thoroughly engineered around the realities of real-world use: varying loads, temperature swings, and the long arc of ownership. It is an artifact of reliable engineering that continues to inspire confidence in both drivers and technicians alike. For readers who want to explore this engine further in practical terms, a good starting point is the 4G69’s identity as a 2.4L JDM-powered unit that has traveled far beyond its origin. The model range that carries the 4G69 badge often benefits from the engine’s simplicity and robust performance, making it a durable option in a world where vehicle lifespans are extended and maintenance expectations are higher than ever. The internal balance of high-quality materials, careful valve timing, and precise fuel delivery underpins a powertrain that can cope with the daily demands of modern travel while still delivering the kind of long-term reliability that owners count on year after year. As the automotive landscape continues to evolve with tighter emission regulations and shifting consumer priorities, the 4G69 serves as a reminder that elegance in engineering can be found in the steady, repeatable performance of a well-executed design. Its combination of MIVEC-driven valve timing, aluminum construction, DOHC architecture, and multi-point fuel injection offers a compelling blueprint for reliability without sacrificing the kind of driveability that makes everyday use enjoyable. Internal link: for readers curious about specific variant details, see the page on the 4G69 2.4L JDM engine. 4G69 2.4L JDM made in japan. External reference: https://www.motor1.com/uk/news/358475/mitsubishi-4g69-engine-review/

Enduring Footprint: The Market Journey and Global Reach of the 4G69 Engine

The 4G69 engine stands as a quiet workhorse in the automotive landscape, a 2.4-liter inline-four that has carved out a surprisingly broad and durable niche across continents. Its story is not merely one of horsepower figures or torque numbers; it is a narrative about steady reliability, thoughtful engineering, and a market strategy that recognized early on how a well-rounded powerplant can outlive fashion and trend. The engine’s core appeal—smooth urban manners paired with enduring capability—has carried it from the early days of its release into the hands of families, fleets, and drivers who prize predictable performance and easy maintenance as much as frugality at the pump. In this sense, the 4G69 became less a provincial engine tied to a single model line and more a platform for mobility across a wide spectrum of vehicles, brands, and markets. It is difficult to discuss the engine without noticing how often it appears in places where value and dependability are the decisive factors for buyers and operators alike, especially in Asia and other emerging economies where practical economics often shape the long-term viability of a vehicle choice.\n\nThe engine’s enduring appeal is rooted in a blend of power, reliability, and efficiency that translates well into real-world driving patterns. Naturally aspirated and designed with a straightforward architecture, the 4G69 delivers usable torque across mid-range RPMs, ensuring steady acceleration in city traffic and confident highway cruising without the complexity—and cost—of more technologically dense powerplants. The official numbers, often summarized as a maximum around the mid- to upper-twenties kilowownages in horsepower equivalent and a torque peak in the vicinity of two hundred plus newton-meters, only begin to describe the daily reality of ownership: gratifying tractability in stop-and-go urban driving, predictable response when load increases on a hill, and tolerable, not excessive, fuel consumption when driven with a measured pace. The cited fuel economy figures, typically in the nine to eleven liters per hundred kilometers range under综合工况 (mixed conditions), reflect a balance that suits families and fleets alike—where the goal is not sprinting to a redline but sustained, sensible performance over thousands of kilometers between services.\n\nOne of the engine’s most influential attributes is the integration of Mitsubishi’s MIVEC variable valve timing system. This technology, which modulates valve timing in response to engine speed and load, helps the 4G69 breathe more efficiently at different operating points. On the lower end of the rev range, MIVEC can smooth idle and improve low-end torque, which translates into easier city driving and better responsiveness for everyday errands. As RPM climbs, the system shifts to preserve or even enhance top-end breathing, supporting a more confident mid-range performance without sacrificing the economical benefits that made the engine attractive in the first place. The result is a powertrain that remains composed across a broad spectrum of driving conditions, a factor that strengthens its reputation for reliability over the long term. This reputation is not merely anecdotal; it has been reinforced over decades by fleets and private buyers who have logged tens of thousands of kilometers with minimal disruption when routine maintenance is kept on schedule. The engine’s mechanical simplicity—an asset that reduces maintenance complexity and parts cost—often translates into a lower total cost of ownership, a consideration that resonates in budget-conscious markets.\n\nThe market presence of the 4G69 extends beyond Mitsubishi’s own lineup. Its rugged, adaptable character made it a natural candidate for licensing arrangements and OEM partnerships that allowed other brands and model families to adopt the engine in a variety of form factors. In practice, this meant that the 4G69 powered not just SUVs and crossovers from Mitsubishi but also a diverse set of vehicles from other manufacturers, including those developed through joint ventures or local manufacturing programs. The engine’s compatibility with a range of platforms—coupled with the availability of widely distributed parts and service networks—made it a practical choice for manufacturers seeking a proven, cost-effective, and low-risk powerplant. This widespread adoption is telling; it reveals a manufacturing and product strategy that valued not only performance but also supply chain resilience and ease of maintenance for end users. The engine’s footprint across Asia and into emerging markets illustrates how a well-calibrated, mid-range engine can become a backbone for affordable mobility, enabling families to own reliable vehicles with serviceable parts and straightforward repairs.\n\nWithin Mitsubishi’s broader ecosystem, the 4G69 has powered flagship and near-flagship models that defined traction in the SUV sector, such as the Outlander and Pajero variants. These platforms showcased the engine’s ability to perform in traditional, rugged environments while maintaining a level of refinement expected of modern engines. The powertrain’s robust operational envelope—its ability to deliver smooth operation without producing excessive heat or noise relative to similar-class engines—contributed to its long service life, even as other technologies evolved around it. The durable construction, aided by a natural aspiration design, reduces the risk of turbocharger-related complexity and potential failure modes, a factor appreciated by drivers who rely on consistent performance rather than sudden surges. For buyers who value a vehicle as a store of value, the engine’s reputation for reliability offers reassurance: with reasonable maintenance, many examples can easily surpass the 10- or 20-year milestones, a fact that helps explain why the 4G69 remains prevalent in markets where vehicles tend to move into second or third ownership cycles rather than being retired after a few years.\n\nAnother dimension of the engine’s market success is its role in cross-brand collaborations and localized manufacturing. The engine’s presence in aftermarket and OEM contexts across a variety of markets is a testament to its resilience in the face of shifting regulatory and consumer demands. Several regional partnerships supported local production and assembly, ensuring that spare parts remained accessible and affordable for end users. This is crucial in markets where supply chain disruptions or currency fluctuations can influence the ongoing cost of ownership. As production and assembly moved into joint ventures and locally sourced configurations, the 4G69 gained a kind of market eligibility that transcended a single geographic or brand identity. Domestic production and licensing helped foster a broad network of service centers and authorized repair facilities, and in many places, that network became as important as the engine’s actual performance. The ability to source parts quickly, obtain familiar service procedures, and draw on trained technicians reduces downtime and makes routine maintenance less intimidating for everyday drivers. The practical reality is that when a motor is supported by a robust ecosystem of parts and expertise, ownership feels less like a gamble and more like a stable, long-term investment.\n\nThe engine’s compatibility with a wide array of vehicle segments further underscores its adaptability. SUVs, MPVs, and passenger cars have all leveraged the 4G69, each with its own set of demands. In SUVs where reliance on durability and consistent torque matters for off-road or semi-urban use, the 4G69’s torque characteristics and robust mechanicals provide confidence. In MPVs intended for family transport, the engine’s smoothness and reliability support comfortable long-distance travel and steady daily commutes. For compact or mid-size sedans, the balance of power and efficiency helps keep running costs manageable while preserving adequate performance for overtaking and highway merging. This versatility is especially valuable in markets where buyers exchange a single vehicle for multiple roles within a family or small business, creating a need for one engine that can competently fit into several body styles without exorbitant customization costs. The 4G69’s ability to serve in these varied applications without sacrificing reliability or serviceability contributes to its long life in the market.\n\nIn addition to mechanical robustness, the engine’s emissions profile mattered in its market life. As many regions tightened emissions standards toward Euro 3 and Euro 4 levels, the 4G69 demonstrated its adaptability to stricter regulatory regimes. Its natural-aspirated configuration and mature combustion strategy could be tuned to meet current emissions expectations without the complexity of more modern turbocharged or high-strung engines. That flexibility helped the engine remain relevant during periods of environmental regulation tightening, when automakers sought engines that could be readily calibrated for compliance while still delivering practical performance. This capacity to meet evolving standards, combined with the engine’s maintainability and cost efficiency, reinforced the 4G69’s appeal in price-sensitive segments and in markets where regulatory continuity was valued as a predictor of long-term ownership costs.\n\nThe engine’s journey is also a reminder about how a single powerplant can become a standard bearer for regional automotive narratives. In many Asia-Pacific markets, where consumer expectations are shaped by reliability, affordability, and straightforward maintenance, the 4G69 emerged as a benchmark for mid-range engines. Its story intersects with broader questions about how automakers balance performance, durability, and production economics in a rapidly developing automotive landscape. The engine’s longevity reflects deliberate choices: to offer a design that could scale across models, to partner with manufacturers who could leverage established supply chains, and to provide a unit that remained economical to service even as new technologies emerged. These choices created a steady, cumulative impact: a ready supply of spare parts, a broad network of technicians familiar with the engine’s idiosyncrasies, and a reputation for dependable operation in a wide range of conditions and climates.\n\nFor readers who wish to explore the engine’s lineage in more technical detail, a dedicated technical note and overview can be accessed on a page that documents the 4G69’s development and deployment across different markets. This resource highlights how the engine’s core architecture supported its broad adoption and how its features—such as MIVEC timing and a robust block design—contributed to its enduring presence. The link provides a gateway to understanding how the 4G69’s engineering decisions translated into practical advantages for operators around the world. https://mitsubishiautopartsshop.com/mitsubishi-4g69-2-4l-jdm-made-in-japan/

Final thoughts

The Mitsubishi 4G69 engine represents a perfect blend of power, reliability, and versatility, making it a sound choice for various manufacturers and applications. Its innovative features such as the MIVEC system enhance fuel efficiency and engine performance, while its reputation for durability ensures low maintenance costs over time. For business owners in the automotive sector, understanding these dynamics provides valuable insights into customer preferences and potential market opportunities revolving around the 4G69 engine. Embracing this knowledge can lead to improved service offerings, better vehicle selections, and sustained growth within a competitive automotive landscape.