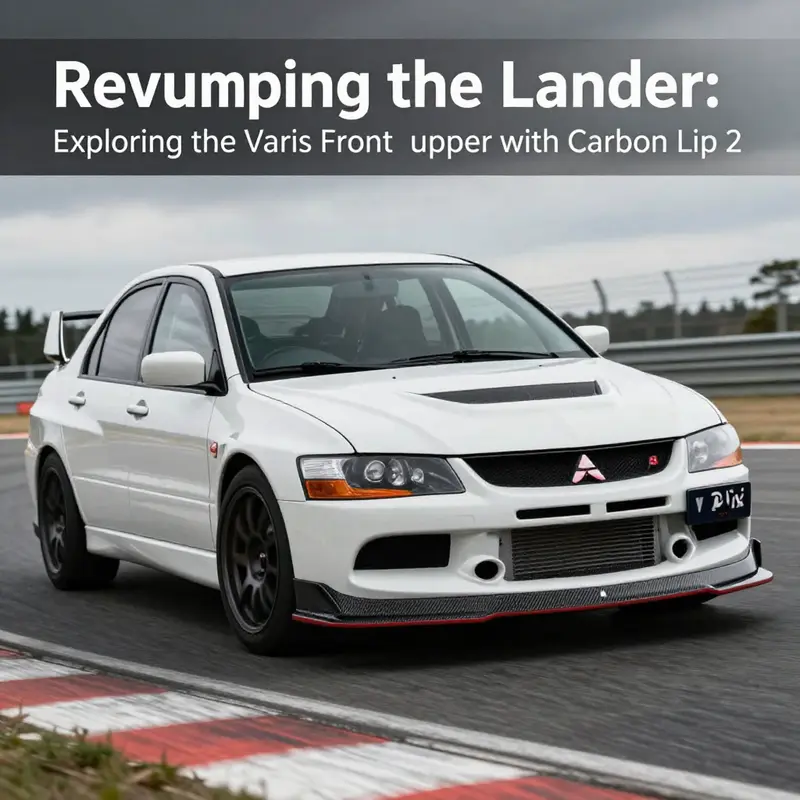

The Mitsubishi Lancer Evolution VIII and IX models have long been revered in the automotive community, particularly among performance enthusiasts. At the forefront of modifications for these vehicles is the Varis front bumper, particularly its striking carbon lip addition—commonly referred to as Carbon Lip 2. This unique component not only elevates the vehicle’s aesthetic appeal but also enhances its aerodynamic performance, enriching the driving experience. In the following chapters, we will delve into the key features that define this front bumper, outline the installation process to ensure a seamless fit, discuss the performance enhancements it offers, and finally, examine the market considerations that come into play for business owners seeking to tap into this niche segment.

Aeroalchemy on the Evo 8/9: The Carbon Lip Front Bumper That Refines Downforce, Heat Management, and Street Presence

Aerodynamics rarely reveals its true power at rest. On the Evo 8 and Evo 9, where engineering heritage meets a crowd of tuned rivals, the front end becomes a stage for precision, balance, and a dash of drama. The carbon lip front bumper accompanying the newer styling package is more than a cosmetic upgrade; it is an integrated aero solution that channels airflow with intent, trims unsprung weight at the nose, and threads aesthetics to performance so the car feels tighter and keener at speed. The use of genuine carbon fiber reduces mass and improves rigidity, contributing to more responsive steering and a more stable front end during high-speed runs or aggressive corner entries. The lip acts like a small wing at the lower edge, shaping the boundary layer and reducing flow separation while preserving a clean, linear front silhouette. Larger intake openings further aid engine cooling and intercooler efficiency under sustained load, translating to steadier power delivery and less thermal degradation on track or spirited mountain passes. The design balances downforce with drag, keeping the nose planted without punishing efficiency, and it harmonizes with the car’s lines so the stance remains purposeful rather than abrupt. Fitment for Evo 8/9 is precise, designed to align with factory mounting points so installation is straightforward and durable, and carbon fiber’s resilience helps it endure the rigors of daily driving and occasional track sessions. Beyond the hardware, the upgrade communicates a philosophy of weight-conscious performance, where form and function reinforce each other. It invites a broader aero strategy with compatible components—cooling, suspension tuning, chassis bracing—so the overall package feels cohesive, confident, and capable of repeatable, controlled reactions at speed. In short, the carbon lip front bumper on the Evo 8/9 is not merely a visual upgrade; it is a measured step toward improved downforce management, heat handling, and street presence that remains forgiving in real-world driving while elevating the vehicle’s demeanor when the road or the track demands it.

Contours in Motion: Installing the Front Bumper with a Carbon Lip on the Evo 8/9 Platform

The front end of a performance-oriented car speaks before the driver does. It is where the geometry of airflow, the weight balance, and the tactile relationship between road and chassis converge. When the bumpers of the Evo VIII and IX era are upgraded with a carbon lip, the effect is not merely cosmetic. The lip adds a precision edge to the aerodynamics, a featherweight surface that can influence how the downforce distributes across the lower fascia, and how the vehicle sits at the curb and on the highway. The objective behind integrating a front bumper with a carbon lip is not just to sharpen the silhouette; it is to tune the car’s front end so it breathes more efficiently, reduces drag where necessary, and maintains structural integrity under load. This chapter follows a continuous narrative of fitment, alignment, and testing that binds the aesthetic upgrade to its functional purpose, without losing sight of the safety and torque discipline required by high-performance assemblies. The process is meticulous and demands respect for the sequence, the torque values, and the clean interfaces between metal, composite, and the vehicle’s electrical system. Throughout, the goal remains clear: a seamless, secure installation that preserves the car’s dynamics while elevating its visual impact. For readers curious about the exact product framework that underpins this upgrade, there is a direct reference point in the linked product entry that demonstrates how the carbon lip integrates with the bumper cross-section and the mounting points along the frame rails. See the integrated presentation at evo-8-9-varis-front-bumper-with-carbon-lip. The discussion that follows treats the installation as a continuum rather than a checklist: each step informs the next, and each decision traces to a larger objective of performance, longevity, and daily drivability.

The preparation phase begins long before the bumper ever touches the car. The vehicle is positioned on a lift or a stable jack stands setup that provides unfettered access to the front end. This is not a cosmetic exercise; it is a mechanical operation that hinges on stable access to fasteners and clip points that anchor the bumper to the vehicle’s structure. Safety cannot be overstated. The battery is disconnected to eliminate the risk of short circuits or inadvertent airbag system interactions during the disassembly and reassembly process. While some may be tempted to rush the transition, the most durable results come from deliberate, uncluttered workspaces. A prepared environment also means you have a clear view of the factory mounting surfaces, the weathered edges of the radiator shroud, and the fender flange where the bumper will eventually seat. The toolkit should include wrenches, screwdrivers, plastic trim tools, a torque wrench, and protective gear. These items are not mere conveniences; they are the guardians of a clean installation that avoids gouges, scuffs, or misrouted wiring harnesses.

The removal of the old bumper is where many lessons crystallize. Access points are typically located at the outer edges, under the hood seam, and along the inner fender wells. Clips and fasteners must be released with care to avoid snapping the plastic or bending the mounting points. Plastic trim tools are the friend here, allowing leverage with minimal resistance. There is a quiet art to prying without damage: long, smooth motions and sequential release rather than a forceful, all-at-once approach. It is common to encounter wiring harnesses connected to fog lights or sensors that trace along the bumper’s backside. These connections demand careful unplugging and labeling so that reassembly occurs in the correct orientation. The moment the old bumper comes free, the mounting surfaces reveal their condition: some areas show residual adhesive, some have minor corrosion on metal brackets, and others carry the faint imprint of the bumper’s previous contour. A thorough cleaning of these surfaces sets the stage for a flush, even fit of the new component. The carbon lip that accompanies the bumper is not an add-on to be attached after the fact; it is part of the continuous aerodynamic profile and must be aligned with the factory contours to maintain the intended airflow path over the lower edge of the bumper. The lip’s precision fit depends on the exactness of the bumper’s own geometry, so attention to both parts in concert is essential from the outset.

With the old assembly removed and the surfaces cleaned, the installation of the new bumper begins. The first step is an alignment check. The new piece should sit level, with minimal gaps along the top edge and no twist in the lower fascia that would betray a misaligned mounting bracket. If the body lines don’t align with the fender flanges or the fog light housings, a gentle adjustment of the mounting brackets is required. This is where the torque specifications come into play: the technician tightens bolts to the exact values prescribed by the manufacturer, ensuring structural integrity while avoiding over-torquing that could crack the composite or stress the mounting points. The central support bracket and side brackets represent the core of the installation’s rigidity. Their alignment must be coaxial with the vehicle’s frame and in line with the bumper’s mounting holes. Any misalignment here will become evident through visible gaps, a parallaxed front face, or a sensation of looseness during a test move.

The carbon lip introduces an additional dimension to the alignment process. It is not merely a decorative edge; it defines the aerodynamic boundary layer along the bumper’s lower edge and interacts with the splitter or chin geometry to shape the underbody airflow. The lip must be cleaned and dry to prevent adhesive or mounting inconsistencies. Its fit is checked against the bumper’s lower contours and the vehicle’s valance line. When the lip aligns perfectly, the bonding or mechanical fasteners that secure it to the bumper can be engaged. The installation sequence often involves working progressively from the center outward, ensuring that the lip’s centerline intersects the bumper’s midline, and that the edges sit flush against the cutouts near the wheel wells. Any deviation in this stage can create a stress concentration that translates into a micro-crack in the carbon fiber under high-load conditions or at speed over uneven pavement. The goal is to preserve the carbon lip’s aesthetic while preserving the bumper’s loaded performance under aerodynamic stress.

Electrical connections are a quiet but crucial part of the process. If the bumper includes integrated radar or camera systems, their connectors must be reconnected to the vehicle harness with the same care as the mechanical fasteners. Signals, sensors, and power lines require correct routing to avoid pinching or interference with the bumper’s movement or the wheels. It is a good time to recheck the harness routing, labeling, and loom protection, especially near the edges where the bumper moves during parking or high-speed runs. A final electrical test is prudent: the system should power up without faults, and cameras or parking sensors should respond in their usual cadence. The neatness of the wiring is more than cosmetic; it prevents fatigue, chafing, or short circuits that could arise as the car traverses potholes or speed bumps at speed or under load.

Once the mechanical and electrical assemblies are in place, the next phase is the inspection and testing cycle. A visual sweep ensures the bumper sits flush against the body with no noticeable gaps that would catch airflow irregularities or collect dirt. Fasteners are rechecked for proper torque, ensuring no looseness that could cause a rattle at speed. A test drive follows, with the goal of verifying that the bumper does not rattle, rub, or contact any suspension components, and that the carbon lip remains in its intended alignment even as the vehicle is driven through varying road conditions. During the drive, the driver pays particular attention to wind noise, a sensation of vibration, and any perceived change in steering feel that might imply altered front-end weight distribution. The lip’s position must remain consistent, and no loose edge should flutter or contact the undercarriage. The vehicle’s dynamics should feel coherent with the new aero profile: steering response should stay predictable, and braking should remain stable as the lip’s interaction with airflow evolves with speed.

The alignment check is not a one-off moment. It relies on both a static assessment and a dynamic validation: at a minimum, you recheck the fitment after a short drive to ensure no unexpected movement occurred. A second pass at the torque values ensures the final safety margin is achieved. At this stage, the installation is largely complete, but the process remains mindful of the broader guidelines that govern high-performance exterior components. Manufacturer guidelines deserve strict adherence. The installation sequence, torque values, and inspection steps must align with the official manual supplied by the component maker. This standard ensures the installation supports not only immediate performance gains but also long-term durability and safety, especially under the demanding conditions of track days or spirited street driving. In practice, this means that any owner who is considering an upgrade of this nature should seek and follow the exact installation instructions as published by the manufacturer or its official distributors. The attention to detail in these guidelines is what converts a cosmetic upgrade into a confident, high-performance upgrade.

As a final note on the installation narrative, the reader should view this upgrade as an integrated system rather than a single protruding lip. The carbon lip and the bumper together define a near-sculptural profile that interacts with the car’s overall stance, weight balance, and front-end airflow. Even minor adjustments to the lip’s alignment or the bumper’s mount points can alter the way air splits across the radiator, the intercooler, and the lower intakes. The result should be a more balanced front-end behavior at a broad range of speeds, with a visible enhancement to the car’s silhouette that still communicates its performance intent. Documentation and a careful reproduction of the torque specifications are essential to combat any warping of the composite or loosening under vibration. If there is a need to revisit the installation later, the same methodical approach should apply: recheck alignment, confirm torque, ensure electrical integrity, and verify that the lip remains true to its intended position during dynamic testing.

For readers who wish to explore the exact configuration and read more about the practicalities of this specific bumper-and-lip combination, the linked product page provides a detailed snapshot of how the carbon lip integrates with the bumper’s geometry and mounting points. This reference is not intended to replace manufacturer manuals, but it serves as a practical companion for understanding how the pieces come together in a workshop setting. In addition to the product-level documentation, the broader engineering literature on aerodynamics reinforces the importance of clean interfaces, symmetrical mounting, and controlled mass distribution. The carbon lip, as a concept, embodies the idea that small, carefully considered design choices can produce meaningful, measurable outcomes in handling and stability.

To close the loop, the installation narrative emphasizes that the project is as much about discipline as ambition. The satisfaction of a clean, flush fit, the confidence in the bumper’s secure attachment, and the smooth operation of any integrated systems all emerge from a process that respects both the art and the science of automotive bodywork. When done correctly, the upgrade yields a front end that is not merely aggressive in appearance but accurate in function. It is a testament to how thoughtful engineering, precise execution, and careful validation can elevate a car’s personality while preserving, and even enhancing, its performance envelope. External resources can offer further context on the imperative of alignment and surface preparation, and readers are encouraged to consult the official guidance to maximize safety and longevity. For those seeking a definitive, externally hosted reference on the topic, the official site of the component maker provides comprehensive installation resources that complement the hands-on experience described here. External resource: Varis official site.

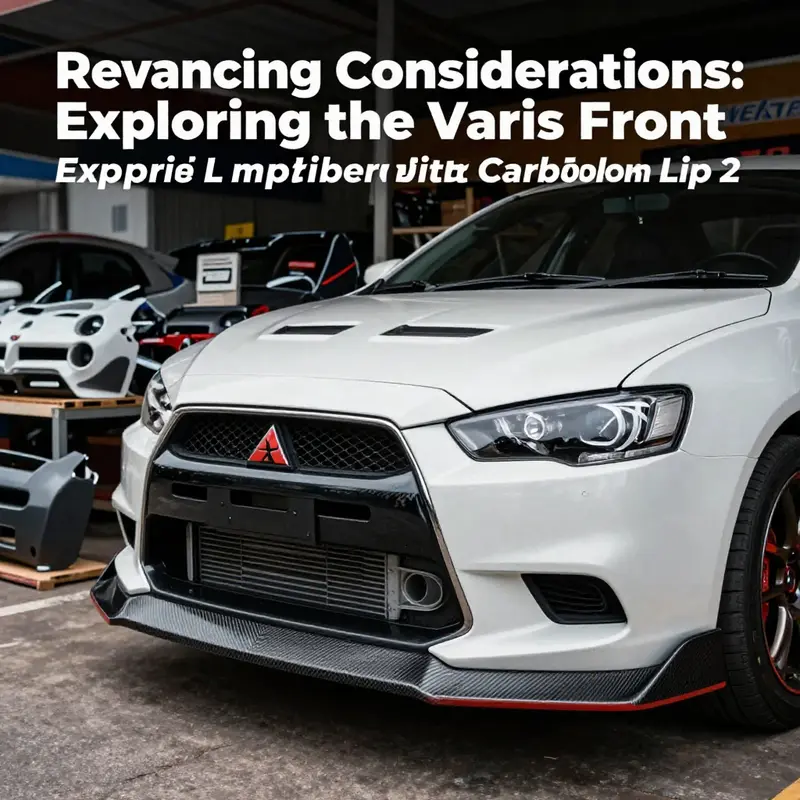

Carbon Velocity: Reassessing the Evo 8/9 Varis Front Bumper with Carbon Lip

The front end of a performance machine tells a story about intent. It speaks to a driver who values precision, cadence, and the way a car commits to a line as it leaves a corner. In the world of modern tuning, the Varis-style front bumper paired with a carbon lip marks a purposeful shift toward carbon efficiency and aerodynamic intent. This is not merely about sportiness or a dramatic visual statement; it is a carefully considered integration of weight, airflow, and grip. When a vehicle like the Evo eight and nine platform wears a carbon lip as part of a Varis-inspired front bumper, the outcome is a front end that feels lighter, crisper, and more responsive to driver input. The choice to adopt carbon fiber for the bumper and its lip follows a logic that enthusiasts understand intimately: if you can shave weight without sacrificing stiffness or impact resistance, you gain in every facet of performance from steering response to tire load management. The result is a chassis that communicates more clearly with the road, a sensation that is especially palpable on a windy track or a twisting canyon road where the line matters as much as the speed.

Carbon fiber has long been the material of choice when the goal is to trade bulk for strength. In this particular application, the bumper’s carbon fiber construction serves multiple roles. First, there is the obvious benefit of reduced mass. The front end, already a load-bearing area during acceleration and cornering, becomes lighter to rotate, which translates into quicker steering feel and a more immediate response to steering inputs. This is not about making the car feel faster in a straight line alone; it is about shaping the dynamic balance so that the front wheels respond with less inertia and more fidelity. When a front end is lighter, the rest of the car—the suspension geometry, the chassis flex, and the tire contact patch—works with greater ease, allowing the driver to place the car more precisely on exit from corners or on the approach to a braking zone. In track work, that translates into fewer microadjustments required from the driver to maintain the intended line.

Beyond weight, the structural integrity of carbon fiber remains a centerpiece of this design. The bumper lip, integrated into the overall front fascia, contributes not only to a slimming silhouette but also to stiffness at the leading edge. A stiffer front end resists unwanted deflection during high-speed runs, which in turn helps maintain a predictable airflow pattern across the vehicle’s nose. Predictability is a precious asset on track days, where small inconsistencies in aero behavior can become major performance penalties at the apex. The rigidity of carbon fiber supports a shaping of the air that reduces drag while preserving lift characteristics where downforce is advantageous. In practice, the combination of a lightweight bumper and a lip that doubles as a structural element makes the whole front end feel more united—a critical factor when the track demands exacting throttle modulation and precise steering input at elevated speeds.

The aerodynamic story of this front-end setup centers on a profile that embraces both efficient laminar flow and targeted disturbance management. The bumper’s contours are not arbitrary; they are crafted to guide air through strategically placed channels and vents. These features do a handful of things at once. They help reduce parasitic drag, which is the unseen energy drain that robs acceleration and top-end stability. They also foster higher-speed downforce, a concept many drivers feel as the car’s nose plants a touch more firmly into the tarmac as speed climbs. The effect is not just about a higher cornering limit; it is about a more confident high-speed line where gusts and crosswinds can otherwise buffet the front end. The integrated air intakes play a dual role as both cooling pathways and aerodynamic elements. They serve the engine bay and intercooler components while maintaining a clean, efficient airflow that complements the engine’s cooling demand during hard driving. The channels are designed to pull air through the radiator and intercooler with minimal interference, reducing the chance of hot spots or local stagnation that could sap performance or reduce power during sustained sessions.

In practical terms, the high-speed stability delivered by this combination is not an abstract benefit. It translates to a front end that maintains directional integrity as the speedometer climbs toward the track’s upper limits. Drivers report that the car feels more planted and more communicative through a sweeper where the line matters more than outright horsepower. When the front remains predictable under load, braking zones can be approached with a steadier hand, and throttle modulation through the exit can be more aggressively managed. This is especially meaningful for cars built for track days, where the cadence between entry, apex, and exit defines lap times. The Varis-inspired bumper with carbon lip does more than merely reduce weight; it aligns the vehicle’s aerodynamic footprint with the driver’s intention, enabling more precise wrist and foot control that translates into faster, more repeatable laps.

Cooling management is another pillar of the system’s performance logic. The Evo platform’s turbocharged architecture benefits from clean, well-directed airflow that reaches radiators, intercoolers, and oil coolers with minimal turbulence. The front bumper’s venting pattern and lip geometry aid in funneling air through designed routes, opening up pathways that help heat bleed away from hot zones. When a car works at the edge of its thermal envelope, such attention to airflow can be a differentiator. The carbon lip’s contribution extends to this thermal equation: it stabilizes the nose’s contact with the air, smoothing the boundary layer and reducing the tendency for turbulent separation at high speed. In everyday terms, that translates to more consistent performance as temperatures rise and the pace quickens. For drivers who push their machines on track days, such stability matters, because it preserves power delivery and the car’s overall balance when the pace demands sustained effort.

The performance package of a front bumper like this culminates in what many enthusiasts describe as a track-focused philosophy. The synergy of reduced front-end mass, robust stiffness, and clean aero flow creates a platform where the driver’s inputs are rewarded with quicker, more accurate mechanical feedback. The car’s steering feels lighter and more precise, the front tires are offered a predictable load path, and the chassis reacts with a degree of immediacy that fosters confident corner entry. These are not purely theoretical gains; they show up in real-world driving where time on the clock matters more than the static appeal of a shaved profile. The track environment rewards this kind of integrated approach, where every gram saved and every channel shaped in service of airflow can translate into milliseconds shaved off a lap. In street contexts, this same ethos translates into improved handling responses, a more planted feel through mid-c weaves, and a general sense of refinement that comes from a carefully engineered marriage of form and function.

Despite the aggressive look and the performance edge, the front bumper with its carbon lip also weaves a narrative of elegance. Carbon fiber wasn’t chosen as a purely aesthetic statement; it is a material that embodies the idea of lean, efficient engineering. The lip’s geometry complements the bumper’s lines, and together they contribute to a visual impression of speed even when the car is stationary. This is not to say aesthetics alone dominate the decision; rather, the appearance serves as an indicator of the deeper engineering choices at work. The carbon lip adds a subtle glare-free sheen under sun and a matte, factory-compatible tone in overcast conditions, helping the front end maintain a purposeful presence without appearing overdone. Enthusiasts value this synergy between visual drama and functional clarity, because it supports a broader philosophy that performance modifications should feel earned rather than ornamental.

A practical note for owners and builders is the importance of fitment and compatibility. Any front-end modification demands careful alignment with fenders, headlights, and the vehicle’s bumper cover architecture. In the context of a Varis-inspired piece with a carbon lip, this alignment matters even more because the aero features rely on precise tolerances to achieve their intended effect. When installation is executed with proper attention to mounting points, fasteners, and cosmetic gaps, the result is a front end that remains secure under high-speed loads and is resilient to road hazards without compromising the aero performance. The engineering discipline applied here—balancing weight savings, stiffness, aero shaping, and cooling pathways—echoes across the entire vehicle. It means step-by-step attention to the mounting hardware, the seals at the edges, and the way the lip integrates with the lower apron. The broader takeaway is that performance gains accrue through a comprehensive approach, not a single change in isolation. And in that sense, the front bumper with carbon lip becomes a focal point for a larger program of weight reduction, aero refinement, and chassis precision that enthusiasts pursue in tandem with suspension upgrades, brake tuning, and wheel-and-t tire choices. The result is a cohesive package that respects the heritage of the Evo platform while enabling a new level of control and expressiveness on the road and on the track.

For readers who want a direct reference to this exact configuration and its placement within the broader ecosystem of performance components, the Evo 8-9 Varis Front Bumper with Carbon Lip is presented as a deliberate, well-integrated option. The design brief centers on delivering meaningful gains in weight efficiency, aero efficiency, cooling efficacy, and driving confidence at speed. It invites a holistic evaluation of the car’s overall balance: weight distribution, aero loading, tire grip, and the driver’s sense of control through the wheel. The chapter’s exploration of these points is not an invitation to embrace a single metric or a hard-and-fast rule; instead, it is a framework for understanding how a carbon lip and a Varis-inspired bumper can change the experiential qualities of the car. In other words, it is a narrative about how form and function come together to create a more compelling, capable vehicle that responds to a driver’s decisions with greater fidelity.

If you are considering adopting this specific setup, the practical path begins with a clear understanding of the intended use. On track days, where downforce and stall management matter, the combination offers tangible benefits in turn-in response, mid-corner stability, and exit acceleration. On the street, it translates to a sharper front-end sensation, a more linear steering response, and a look that communicates a performance-first mindset. The choice to integrate carbon fiber in both the bumper and its lip is a message about the kind of driving experiences you want to chase: one that rewards precision, consistency, and a refined sense of balance. While aesthetics are part of the package, the enduring value lies in how the system influences the vehicle’s dynamics and the driver’s interaction with it over a long weekend at the track or a spirited drive through back-to-back corners. The result is a front-end treatment that feels less like a modifier and more like a harmonized element of the car’s overall performance architecture.

For further details about the specific configuration and its official specification, you can explore the dedicated product page. Evo 8-9 Varis Front Bumper with Carbon Lip. This resource provides an accessible entry point for builders who want to understand fitment notes, finish options, and potential compatibility considerations with related components in the aero and chassis upgrade family. As with any high-performance modification, the path from concept to track-ready reality involves careful planning, professional installation when needed, and a willingness to tune the rest of the car to complement the new aero characteristics.

External specs and data can also be consulted to ground decisions in empirical context. For a detailed listing of the product’s specifications and real-world data, see the external resource here: https://www.alibaba.com/product-detail/Evo-8-Varis-Front-Bumper-Carbon1600742384943.html?spm=a2700.1.xxf1oF&productId=1600742384943&source=productdetail

Edge, Aerodynamics, and Authenticity: Navigating the Evo 8/9 Front Bumper with Carbon Lip

The fascination with a car’s silhouette and its performance envelope often begins on the street and shifts toward the track in the mind of an enthusiast. In that space, the front end is not merely a visual statement but a precise interface between air, cooling, weight, and the way a chassis breathes at speed. For owners of the Evo 8 and Evo 9, the choice to add a front bumper with a carbon lip sits at the intersection of form and function, engineering nuance and sentimental value, craftsmanship and cost. The decision rarely rests on a single factor; it unfolds as a narrative of how a vehicle meets a philosophy of speed. The front bumper becomes a platform where aesthetics are not separate from aerodynamics, where the lip is not just decoration but a carefully tuned edge that shapes how the car behaves as it slices through the air. This is the broader context in which the Evo 8/9 front bumper with a carbon lip is evaluated by a market that values both appearance and performance with equal seriousness.

In the aftermarket ecosystem, carbon fiber parts carry a promise and a price tag. The carbon lip attached to a front bumper is a classic case study in weight reduction and stiffness-to-weight efficiency. Carbon fiber’s high strength-to-weight ratio means the lip can contribute to downforce and improved aero balance without adding bulk. Yet, the practical realities of this material are often illuminated by the number next to the price tag. Enthusiasts who understand the physics—how a splitter, lip, and bumper work together with the car’s undertray and radiator intake—also understand that carbon fiber costs reflect the complexity of layup, resin systems, curing processes, and the meticulous quality control required to maintain structural integrity in real-world conditions. The market seeking these parts recognizes that a carbon lip is not a mere cosmetic upgrade; it is a performance accessory that has to survive high-speed airflow, road obstacles, and the occasional track session while still delivering a premium tactile impression when touched.

Authenticity and fitment are inseparable from performance in this segment. The Evo 8 and Evo 9 each have their own design language and mounting geometry, and the front end is not a forgiving canvas for trial-and-error experimentation. The value of an authentic, OEM-compliant bumper component lies in precise fitment, verified safety margins, and confirmed compatibility with the vehicle’s crashworthiness standards. When a kit is designed to integrate with the car’s grille, sensors, and crash structure, every edge and mounting point matters. The market rewards parts that arrive ready to install with minimum modification and maximum assurance that the vehicle’s integrity remains intact. The risk of misalignment, interference with parking sensors, or compromised crash zones is not merely a nuisance; it is a performance and safety concern that can affect handling, braking, and the integrity of the overall crash structure under impact.

From a performance perspective, aerodynamic gains are rarely limited to horsepower alone. The front bumper’s shape—especially with an integrated carbon lip—affects how air splits around the car, how the radiator inlet operates, and how the compression of air under the vehicle interacts with the front diffuser and side skirts. In a thoughtful setup, the lip helps redirect high-velocity air to reduce front-end lift and improve high-speed stability. The bumper’s larger air intakes can facilitate cooler intake air by shortening the path that hot air must travel from the engine bay to the radiator after a long corner or a straightaway infusion of speed. These aerodynamic improvements often translate into more predictable steering feel, better cornering trust, and a chassis that remains composed under abrupt throttle application. However, the precise outcome depends on a holistic approach: the bumper must be integrated with the car’s existing aero components, the underbody, and the cooling system. In some installations, adapting mounting points or modifying adjacent panels becomes necessary, potentially raising installation costs but yielding aerodynamic gains that are meaningful both on the street and on the track.

Model compatibility sits at the heart of purchase decisions. The Evo 8 and Evo 9 represent two generations with distinct bodywork cues and mounting frameworks. A bumper kit that is marketed as compatible with both models must be vetted for exact fitment across year ranges, bumper reinforcement locations, and hood gaps. Even small misalignments can cascade into sensor misreads, improper bumper alignment, or panels that refuse to sit flush. The market understands the importance of compatibility not as a burden but as a safeguard for performance and longevity. In practice, owners often consult installation guides or rely on professional shops to confirm fitment before committing to a high-cost upgrade. The peace of mind that comes from knowing the part will align with the car’s geometry and that the crash structures will cooperate in the unlikely event of a collision is part of what motivates the more discerning buyers to invest in parts that come with verified specifications and documented fitment details.

The economics of upgrading are notable in a market where demand for high-end body kits continues to grow. Collectors and builders who seek a race-inspired silhouette find that the allure of a carbon lip combined with a precisely sculpted bumper speaks to something deeper than mere looks. It signals a commitment to precision, to a clean transition from showroom to high-performance persona. Still, the cost calculus remains central. Carbon fiber parts carry a premium over alternatives such as fiberglass or standard plastic composites. For budget-conscious builders, this means prioritizing what truly matters: the perceived premium feel of the finish, the weight savings, and the aerodynamic behavior under load. For others, the premium is a badge of authenticity, a signal that the vehicle is calibrated for serious performance while maintaining an elevated aesthetic. The market response mirrors this duality: a robust aftermarket ecosystem that supports both the functional pursuit of speed and the personal satisfaction of owning a uniquely styled, well-crafted front end.

In parallel, the global nature of the aftermarket marketplace expands the conversation beyond local shops. Platforms that connect buyers with suppliers enable a broader set of options, including cross-border sourcing for those who want to compare finishes, resin systems, and layup consistency. This international reach broadens the spectrum of available configurations and price points, but it also raises questions about quality control and after-sales support. Buyers are increasingly savvy about supplier credibility, warranty terms, and the availability of replacement parts or color-matched components if a finish needs refinement after installation. The emphasis on safety and certification remains a guiding principle in this ecosystem. Reputable suppliers that document testing, adhere to safety standards, and provide clear installation guidance tend to win the trust of a market that treats a bumper and lip kit as both an investment and a statement.

The practical realities of installing a carbon lip on a front bumper go beyond the theoretical. Even with a high-quality kit, the real-world process can involve prep work that influences the final result. Surface preparation, adhesive choices, and climate conditions during installation all play a role in ensuring a durable, aesthetically pleasing finish. Some setups may require adjustments to the bumper reinforcement or to the car’s fascia, and the labor involved must be factored into the total cost. This is not just about a bolt-on upgrade; it is about orchestrating a sequence of steps that preserves the vehicle’s structural integrity while delivering the performance and look the owner expects. Seasoned installers weigh the benefits of additional protective coatings, UV stabilization for exposed carbon fiber, and careful inspection of sealing joints to prevent moisture intrusion that could compromise both appearance and performance over time.

Within this context, the decision to purchase becomes a balancing act. On the one hand, the appeal of a carbon lip and a refined front bumper is undeniable: a leaner, stiffer face that communicates speed and precision, with a surface that catches light and attention in equal measure. On the other hand, the realities of a finite budget, the potential need for supplementary modifications, and the possibility of fluctuating maintenance costs temper enthusiasm. The market’s strongest participants understand this balance: they plan for the total cost of ownership, which includes not just the initial purchase but the installation, possible adjustments to fitment, and the long-term upkeep that preserves the part’s luster and performance. In many cases, this thoughtful budgeting translates into a decision to upgrade in stages, layering aero improvements with supporting components such as upgraded intercooling, reinforced mounting points, or improved cooling ducting. The result is a tailored package where the front end becomes a coherent element of a broader performance strategy rather than a standalone enhancement.

Of course, a chapter in any market narrative would be incomplete without acknowledging how education and transparency shape buyer trust. The best suppliers invest in documentation that clarifies what users can reasonably expect from a carbon lip and bumper combination. This includes technical drawings showing mounting interfaces, data on weight savings, and notes about potential clearance issues with particular wheel and tire packages. Buyers who read these details gain confidence that the upgrade will align with their vehicle’s handling goals, that the aero effects are not accidental, and that the overall package will work harmoniously with the car’s existing systems. In this sense, the market rewards clarity and honest representation as much as it does performance metrics. When a kit comes with a clearly defined installation window, a realistic assessment of fitment, and a straightforward warranty path, it stands out in a crowded field where the allure of carbon fiber can sometimes overshadow practical considerations.

The evolving marketplace for high-performance body components like the Evo 8/9 front bumper with carbon lip reflects a broader trajectory in modern automotive culture. Enthusiasts increasingly view their cars as platforms for experimentation, storytelling, and personal craftsmanship. The front end—once a weathervane for style and prestige—now serves as a measurable arena where engineering discipline and aesthetic ambition meet. The carbon lip, once a bold novelty, is becoming a standard touchstone for those who value weight savings and downforce without compromising the car’s classic lines. Yet even as demand grows, buyers exercise discernment, seeking authentic parts with verifiable fitment, optimal aero balance, and a realistic understanding of the total cost involved. This maturity signals a market that is not merely about accumulating parts but about composing a coherent, high-performance identity for a vehicle that has long symbolized rally-inspired passion.

For readers who want to explore this space further while keeping the discussion grounded in practical realities, the product page that details the Evo 8/9 front bumper with carbon lip offers a concrete reference point for fitment diagrams, mounting hardware, and finish options. evo-8-9 varis front bumper with carbon lip product page. This page can serve as a starting point for understanding how a genuine, properly engineered kit aligns with the car’s geometry and safety requirements, and it helps frame the broader considerations discussed here—how performance, aesthetics, and value converge in the aftermarket landscape around these classic Mitsubishi models.

In the end, the decision to invest in a front bumper with a carbon lip for the Evo 8 and Evo 9 is a statement about priorities. It is about choosing a crafted combination of lightness and stiffness, about selecting a design that actively contributes to stability at speed and a balance that resonates with a car’s driving personality. It is also about choosing a source of parts that supports reliable fitment and safety, trusted by a community that values both performance and provenance. The market rewards buyers who approach the upgrade with a holistic mindset: one that weighs aerodynamics against practicality, aesthetics against cost, and the thrill of speed against the responsibility of maintaining a car that can be driven confidently on public roads and pushed hard on closed courses alike. As this ecosystem continues to evolve, enthusiasts will remain drawn to the compelling blend of engineering precision and personal expression that defines the Evo 8/9 front bumper with carbon lip, a modern emblem of how the pursuit of speed can be rendered in carbon fiber, composite engineering, and careful craftsmanship.

External reference: https://www.alibaba.com/product-detail/Varis-Front-Bumper-Carbon-Fiber-815_1600523746197.html

Final thoughts

The Varis front bumper with Carbon Lip 2 is a testament to the fusion of aesthetic appeal and high-performance engineering for the Mitsubishi Lancer Evolution VIII and IX models. As business owners, recognizing the value this component adds can strategically align your offerings with the desires of performance car enthusiasts seeking to enhance both the look and handling of their vehicles. Leveraging the features, dedicated installation insights, and performance enhancements discussed throughout this article can help capitalize on a growing market opportunity. Ensuring your trade practices align with trends and needs will empower you to effectively serve this passionate community.