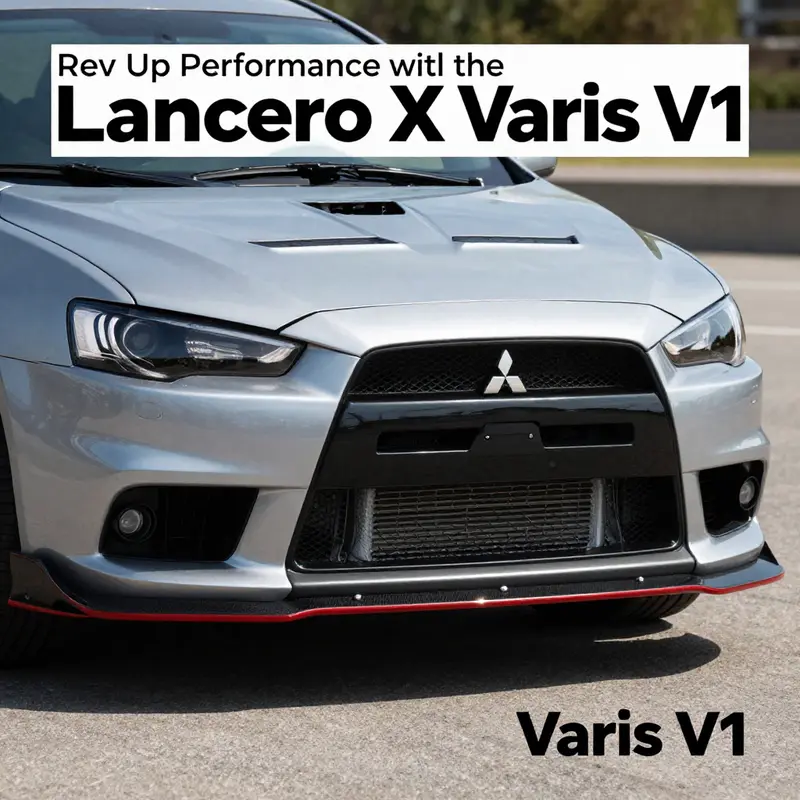

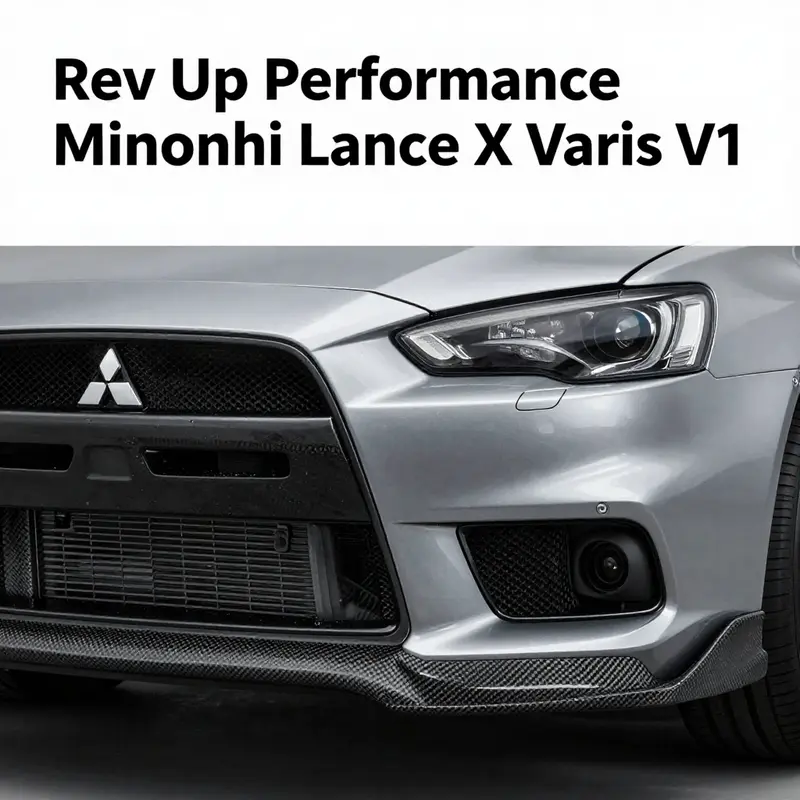

The Mitsubishi Lancer Evo X Varis V1 front bumper stands out as an essential component for enthusiasts seeking to enhance both aesthetics and performance. Designed specifically for the Evo X, it embodies a unique blend of aggressive styling and advanced aerodynamics, appealing to business owners in the automotive aftermarket. This article will dissect the value of the Varis V1 front bumper by exploring its design intricacies and aerodynamic benefits, high-quality construction materials, current market trends and pricing, and potential customizations that drive performance enhancements. Each chapter will build upon this foundation, offering insights for businesses looking to cater to the high-performance automotive sector.

Engineering the Evo X Front End: Design, Aerodynamics, and the Allure of a Wide-Body Front Bumper

The Mitsubishi Lancer Evolution X has always carried a sense of purpose in its silhouette, a look forged in rally stages and tuned for high-speed duels with the clock and the wind. When a front bumper is treated not merely as a protective shield but as a decisive aerodynamic element, the entire character of the car shifts. The piece in focus—an advanced carbon-fiber front bumper kit developed for the Evo X—reads the road before the first wheel touches it. It is a culmination of precise engineering that combines aggressive aesthetics with purposeful airflow management. This is not just a cosmetic upgrade; it is a carefully integrated system designed to modulate pressure, reduce lift, and invite the underbody to work in harmony with the air streaming around the rest of the chassis. In this frame, the front end becomes a theater where form and function perform in unison, and the car’s line, stance, and stance’s intent all align with a single mission: to press the air down and push the cornering envelope outward with confidence.

At the heart of the design is a prominent splitter that sits along the bottom edge of the bumper, a deliberate horizontal extension that channels air beneath the car rather than letting it slip past unnoticed. The splitter acts like a low damper against lift, trapping high-pressure air beneath the chassis and guiding it outward in a controlled fashion. The result is more than mere downforce; it is a stability platform that matters most at the speeds and forces encountered on winding mountain roads or fast highway sweeps. The air that slips under the car is not allowed to detach into a chaotic wake. Instead, it zips along a path sculpted by the splitter, reducing turbulence, smoothing the flow, and contributing to a more planted, confident ride feel through corners. In practical terms, this translates to improved grip when the throttle is coaxed toward the apex and a more predictable response when the car is driven hard out of a bend. It is the subtle balance of pressure and velocity, the same balance that keeps a car from dancing on its suspension in violent gusts yet lets it breathe when straight-line acceleration is the goal.

The visual language of the bumper complements its aerodynamic logic. The integrated lip, the sheer geometry of the lower edge, and the sculpted lines that run into the fender profile all contribute to a look that is at once aggressive and purposeful. The Evo X was already a bold design, a machine that embraced its rally-bred roots with a body that spoke of speed and precision. The bumper amplifies that heritage rather than clashing with it. Its form locks in with the car’s existing lines, emphasizing width and stance without appearing bulky or incongruent. The result is a front end that signals intent before the engine even turns over. In this sense, the bumper is as much a statement piece as it is a functional component. Its presence tells observers that the car is built to harness airflow, to slice through air with minimal resistance, and to leverage that air into measurable grip and control at high speeds.

Among the functional refinements, the bumper is designed for seamless integration with the Evo X’s body lines. Enthusiasts who favor a factory-like fit—one that does not demand a repaint or heavy modification—appreciate the approach taken here. The engineering team emphasizes compatibility and a smooth transition from the bumper to the adjacent panels, so the overall look remains clean and cohesive. This is not a case of a separate piece slapped on the front; it is a unified skin that matches the curvature of the nose and flows into the wheel arches with minimal gaps. The goal is to preserve the car’s visual integrity while extending its aerodynamic capability. Because the bumper is shaped to align with the existing body geometry, installers can often achieve a professional, paint-free finish when the color matches the factory or desired exterior shade. The desire for a pristine, factory-like appearance without a labor-intensive paint job is a recurring theme among modern aero kits, and this front end adheres to that preference while delivering real-world aerodynamic benefits.

In concert with the bumper’s own geometry, the broader aerodynamic package surrounding the Evo X—side skirts, a rear diffuser, and, where relevant, a front lip—is designed to work as a system. The bumper’s splitter, canards, and flow channels are not isolated features; they are elements of a carefully choreographed airflow strategy. The side skirts extend the clean lines of the front end toward the rear, reducing the amount of disturbed air that can seep along the underbody and around the wheel wells. The rear diffuser then acts as the counterpart to the front’s momentum, managing the wake and pulling the flow outward and downward, which translates to improved overall downforce distribution along the car’s length. When all these pieces are matched to a wide-body setup—whether the owner is pursuing an aggressive track-inspired stance or a more restrained yet performance-oriented appearance—the package gains a visual and functional coherence that makes the Evo X instantly recognizable while also more capable in high-speed conditions.

As the narrative around this front bumper grows, so too does the sense of community that surrounds it. The ecosystem of enthusiasts and builders who gravitate toward high-performance aero is drawn to the idea that appearance and performance can be married without compromise. Social media posts and builds often showcase Evo X iterations that juxtapose the bumper with different fenders, rear bumpers, and diffuser configurations to illustrate the car’s capacity to transform its behavior in response to changes in the aero suite. The emphasis on both aesthetics and function has helped broaden the appeal of carbon-fiber front-end kits, turning them into recognizable signifiers of a car that values purposeful engineering as much as eye-catching looks. The aesthetic impact is not incidental; it’s a signal to fellow car people that the owner is aiming for a complete, performance-focused platform rather than a mere cosmetic upgrade.

From a practical perspective, the bumper’s carbon-fiber construction is more than a stylistic choice. Carbon fiber’s high stiffness-to-weight ratio contributes to a stiffer front end, enhancing throttle response and steering feel through the car’s mid-corner transitions. While weight reduction can be a goal in itself, the structural stiffness of the material also translates into more predictable suspension behavior over rough pavement and after aggressive wheel-load changes during cornering. The experience for the driver, especially on track or canyon roads, can be calmer and more controlled when the front end remains composed under load. In real-world terms, that means less chassis flex, more direct feedback through the steering wheel, and a more linear relationship between the driver’s inputs and the car’s response. All of this compounds the feeling that the Evo X is a machine designed to be driven with intent and confidence rather than a car relegated to smooth highway driving.

For those who want to explore the practical side of ownership, market activity around similar performance front-end components provides some context. A recent listing on a popular online marketplace shows a Varis-branded carbon-fiber front bumper lip for the Evo X—listed as a second-hand item, priced at a mid-range figure and offering free local pickup in the United States. The presence of such listings underscores ongoing interest in high-quality, performance-oriented front-end components. It also hints at the broader ecosystem in which these parts exist: a market where carbon-fiber upgrades are valued for their weight savings, their aesthetic appeal, and their potential to contribute to a cohesive aero package when paired with compatible wings, side skirts, and diffusers. The fact that buyers consider these parts viable enough to invest in—even used—speaks to the lasting appeal of aero-focused customization in this platform.

Yet the practicalities of installation and integration matter as much as the look and the air. The bumper kit is intended to work with a wide-body configuration that requires careful measurement and alignment to ensure proper gaps and surface continuity. When a kit is designed for a factory-fit concept, it can simplify installation because the mounting points, tab positions, and structural interfaces are planned to mirror the factory geometry as closely as possible. The process can still require precise trimming and some surface finishing, but the goal is to minimize the need for paint or major bodywork. This aligns with the desire for a clean, professional result that preserves the car’s visual coherence while enabling the aerodynamic improvements the owner seeks. The best outcomes come from collaboration between the kit manufacturer and an experienced installer who can verify fitment, trim any necessary edges, and ensure that all fasteners sit flush and secure against the mounting surfaces. In the end, the result is not only a sharper front end but a robust integration that can handle the rigors of spirited driving and track sessions alike.

Behind the scenes, the decision to pursue a front bumper kit of this nature often rests on a balance between appearance, performance, and versatility. Enthusiasts may be drawn by the idea of an aggressive stance and a measurable uptick in downforce, but they also want a unit that remains compatible with other upgrades. A well-conceived bumper kit surfaces as part of a broader plan: to equip the Evo X with a complete aero ensemble that includes wider fenders to accommodate wider wheels, a tailored front lip for additional forward projection, and a diffuser that can manage the rear wake. The goal is to create a coherent silhouette in which each element complements the others. When done well, the front bumper does more than simply sharpen the car’s expression; it accelerates a holistic transformation that touches handling, balance, and the very way the vehicle communicates through its steering and throttle inputs.

To ground this exploration in a practical frame, consider the broader ecosystem of documentation and resources that accompany these parts. Official technical documentation often emphasizes the kit’s intended use scenarios, care instructions for carbon-fiber components, and recommended companion parts that best realize the aero package’s potential. While the aesthetic impact is visible in photos and videos, the aerodynamic gains are measurable in wind tunnel data and in-road testing, where even small changes in underbody flow can affect drag, lift, and downforce distribution. This balance of data and design is what makes the front bumper a focal point of a wider performance project rather than a standalone upgrade. In that light, the Evo X front-end upgrade becomes a catalyst for a broader rethinking of the car’s dynamics—how weight is distributed, how air completes its path around the car, and how the driver experiences the vehicle when pushing toward the limit.

For readers who want to dive deeper into the customization options and the exact fitment details, one path is to consult product documentation that outlines the Evo X aero kits in a structured way. These resources help set expectations for fit, finish, and compatibility with other components in the same family. In the meantime, the practical story remains clear: a well-engineered carbon-fiber front bumper kit can transform the Evo X’s front-end presence while delivering tangible aerodynamic benefits that bolster high-speed stability and cornering confidence. The kit’s design philosophy—the fusion of aggressive, rally-inspired styling with a precise airflow management strategy—speaks to a broader culture of performance-oriented modification. It resonates with drivers who see the car not only as a means of transportation, but as a platform for experimentation, tuning, and the pursuit of a more immersive, confident driving experience.

For readers seeking a touchpoint outside the immediate narrative of the front bumper, a related avenue is to explore genuine aftermarket options that align with the Evo X’s styling and engineering language. The Evo X front-end ecosystem includes components that can be combined with the bumper to achieve a balanced, cohesive look and performance profile. This approach allows builders to craft a complete aero package that respects the car’s proportions while expanding its capabilities. When paired with proper alignment and a thoughtful selection of supporting parts, the result is a vehicle that looks, feels, and performs as a unified system rather than a collection of individual upgrades. The appeal lies not just in the immediate visual impact but in the quiet assurance that the car is tuned to respond predictably and decisively to the driver’s control inputs.

In summation, the Evo X front bumper is more than a protective fascia or a styling cue. It is a performance-oriented design that captures the essence of the car’s rally-inspired heritage while elevating its dynamic performance through a carefully crafted aerodynamic package. The splitters, the lip, and the integrated lines work in concert with the car’s wider body architecture to deliver stability, grip, and a sense of composure at speed. The visual aggression communicates intent, but the engineering speaks in the language of downforce and handling, which is arguably more compelling to the true enthusiast. As community conversations continue to evolve around aero-focused builds, the Evo X front bumper stands as a reminder that the most effective upgrades are those that respect the vehicle’s existing design DNA while extending its capabilities in a coherent, purposeful way.

Internal link reference (for readers seeking a closely related OEM-compatible option): evo-x-front-bumper-genuine

External resource for official specifications and documentation: For official specifications and documentation about aero kit options and Evolution X compatibility, visit the maker’s product documentation: https://www.varis.co.jp/en/products/evolution/x/.

Aero-Grade Framing: Material, Craft, and Fit of the Evo X Varis V1 Front Bumper

The front end of a high-performance Lancer Evolution X is more than a visual statement; it is a carefully engineered system where material choices, manufacturing discipline, and precise fit converge to shape airflow, cooling, and the car’s on-road behavior. The Varis V1 front bumper, conceived for this chassis, embodies a philosophy that blends aggressive aesthetics with functional aerodynamics. It is a piece that invites the eye to travel along its lines and then forces the gaze to acknowledge the engineering that underpins them. In this context, the bumper’s material and construction quality become not merely a matter of durability or weight, but a fundamental contributor to how the entire vehicle breathes at speed. The story of this component begins with the choice of fiber-reinforced plastic as its core, a material family long cherished in performance circles for its balance of strength, resilience, and relative lightness compared to metal. The exact formulation of FRP used in this bumper is described as delivering structural integrity that remains resilient under the duress of aggressive driving, while contributing to a lighter overall vehicle mass that translates into reduced inertia, quicker responses, and better dynamic balance during high-speed cornering and braking. The claim is not simply about being light; it is about maintaining stiffness where stiffness matters most: at the impact-prone periphery that also carries the brunt of aerodynamic loads. In that sense, the Varis V1 bumper positions itself as a performance component that performs as it looks, with material science backing its aggressive silhouette.

The construction ethos rests on a foundational assertion that the bumper should fit precisely without extensive bodywork or repainting. The so-called “Perfect Fitting Without Paint” specification asserts that the component is engineered to align with the car’s original mounting points and geometry with a tolerance that minimizes the need for additional sanding, reshaping, or color work. This is not a statement of cosmetic passivity but a claim about production discipline. The manufacturing process, from mold design to resin infusion, is tuned to produce a bumper whose geometry mirrors the OEM fitment philosophy while adding the extra inches of width and the sculpted contours that give the Evo X its distinctive stance. The result, for a builder or enthusiast, is a more straightforward installation that reduces assembly time and the risk of misalignment, a benefit when time at the shop is valuable and the buildup is intended for track-ready performance rather than showroom polish alone. In practical terms, this means that people who invest in this bumper can expect a product that can be mounted with standard hardware and factory supports, provided the rest of the chassis is prepared to receive such a widening and the associated aero components that complete the look and function.

From a materials perspective, FRP offers a suite of advantages that align with the performance goals of a widebody stance. The reinforced-plastic matrix, typically incorporating fiberglass or similar fibers, creates a composite that resists impact and holds its shape under load without the degree of flex that might compromise aero performance at high speeds. The bumper’s surface finish, while not inherently as glossy as carbon fiber, is designed to accept paint or clear coats without excessive prep work, depending on the build preferences of the owner. There is a practical elegance to this approach: a panel that can endure daily driving, endure some track days, and still be compatible with the gloss or matte aesthetics chosen by the car’s owner. In the case of the Varis V1, the emphasis is on a clean, integrated profile. The lines flow from the leading edge into the sides with a continuity that makes the entire front fascia read as a single, coherent plane rather than a collection of pieces bolted together. This is not happenstance but the product of careful mold development and a finished surface that has been tuned to minimize gaps and misalignments, ensuring a seamless transition from bumper to fenders and beyond.

If there is a note of caution in this material-centric narrative, it lies in understanding the nuances of FRP as a performance material. While FRP can deliver impressive strength-to-weight ratios, its long-term behavior under UV exposure and varying climate conditions can differ from more exotic composites. The resin system and fiber orientation influence crack resistance, impact absorption, and glass transition behavior. The Varis V1’s construction, however, is designed to mitigate these realities through a robust resin saturation and a fiber layout that prioritizes stiffness where the shell must resist deformation. The result is a bumper that remains visually and structurally coherent across a broad swath of temperatures and driving scenarios. And inside the chassis, the bumper does not merely sit as a cover for the core structure. Its mounting points align with the reinforcement framework of the vehicle, and the integration with the bumper’s undertray and chin lip helps to channel air in a controlled pattern that complements the car’s broader aero strategy. The lip and ducts, integrated as part of the bumper’s design, are not decorative add-ons but functional elements that contribute to cold-air delivery to the radiator and intercooler, as well as to the management of boundary-layer separation at the car’s nose.

In the conversation about fit, the term “Perfect Fitting Without Paint” reaches beyond a simple convenience. It signals the bumper’s compatibility with a host of common aftermarket and OEM parts, including the front fenders and side skirts that make up the widebody aesthetic. The compatibility is more than cosmetic alignment; it is about ensuring that the vertical lines of the bumper, the curves of the radiator housing, and the angles of the headlights track with the body panels as if they were designed in one continuous process. A well-made FRP bumper like this one is sculpted with that continuity in mind. It is not about forcing the car to wear a new face; it is about enhancing the existing silhouette with a precise blink of aerodynamic intent. The bumper’s architecture acknowledges that a wide front end does more than look aggressive; it creates a broader contact patch with the air as the car advances through the air, shaping how that air presses against the car and how it reattaches along the sides. In a performance context, that matters when stability is the currency of speed.

The front end’s aero intent is complemented by the silhouette’s integration with other elements of a broad, performance-oriented build. Enthusiasts who pair the Varis V1 bumper with matching wide-body front fenders or a front diffuser typically seek a cohesive front-end narrative. The bumper’s lines flow into the fenders and into the undertray in ways that reduce drag while narrowly guiding air to crucial cooling channels and brake rotors. In such combinations, the bumper acts as a keystone piece of the overall aero package, its material properties contributing to a robust, predictable front-end response under high-G cornering or mid-range track speeds. It is a deliberate balance: the bumper must be rigid enough to resist deformations and to maintain its intended airflow cues, yet not so heavy that the car’s dynamic balance shifts unfavorably. The Varis V1’s FRP construction appears to strike this balance by offering a relatively light, stiff shell that can endure the kind of repeated stresses typical in spirited street driving and competitive events without demanding unreasonable reinforcement or maintenance.

Market realities also shape how this bumper is perceived and used. In the broader ecosystem of Evo X customization, this component sits among a range of options intended to realize a wide, aggressive stance. A used Varis carbon-fiber front bumper lip from a secondary market listing, for example, demonstrates ongoing demand for carbon-based street performance accents that can be combined with FRP main bodies to achieve a layered aero look. The existence of such listings underscores that, for many owners, the front end is a focal point for both cosmetic identity and aerodynamic improvement. The conversation around value is not solely about a price tag; it is about how the part integrates with the rest of the car’s performance architecture and how it endures over time in the hands of different drivers. A bumpers’ market footprint, including second-hand offerings, signals its perceived value in the tuning community and hints at how the front end can form the centerpiece for a broader build project that includes upgraded wings, side skirts, and a reworked rear end for a truly cohesive wide-body appearance.

In the context of installation and ongoing maintenance, the bumper’s FRP construction and the Perfect Fitting Without Paint standard translate into a straightforward, repeatable process for a competent shop or DIY enthusiast. The install involves removing the stock bumper and its mounting points, ensuring the hood latch and radiator cover clearances are respected, and then aligning the new bumper with the factory crash-bar support and bumper brackets. Because the panel is designed to fit without needing paint as a first step, owners can rely on the raw surface to provide a clean, uniform look if they opt for factory color match or a matte finish. If paint is desired, prep becomes a focused activity on the bumper’s surface—scuffing, priming, and finishing—without forcing additional corrective work elsewhere on the front fascia. The advantages here are tangible: shorter downtime, fewer aesthetic discrepancies between panels, and a front end that reads as a single, purpose-built piece rather than a combination of aftermarket elements bolted together.

Beyond fit and finish, the material’s behavior under impact and during routine maintenance is part of the narrative of quality. FRP, when correctly manufactured, offers a degree of resilience that dampens vibrations and reduces the likelihood of noise generation associated with misaligned edges or gaps. The crack resistance and the long-term stability of the fiberglass matrix are, in practice, linked to how well the bumper has been cured and how it has been protected from environmental stressors. While carbon fiber remains the benchmark for ultimate stiffness-to-weight, FRP presents a pragmatic balance for enthusiasts who value performance without breaking the bank. The Varis V1 is positioned as a part that can support track-inspired driving without demanding the same level of bespoke fabrication and cost that a full carbon-fiber front end would typically require. In that sense, the material and construction quality of the bumper become a decisive factor when a builder assesses the overall project scope, budget, and the desired level of performance.

The broader narrative of this bumper therefore spans not just a single component but a philosophy of integration. It is about recognizing that an aero part is a system, not an isolated shell, and that the material choice informs how that system behaves in real-world conditions. It is about knowing that a precise fit reduces the friction of the build, facilitating better alignment with the rest of the vehicle and ensuring that the lines of the car’s front end communicate a consistent message of performance. It is about acknowledging the market realities—where used components can indicate ongoing interest and where a genuine, OEM-analog front bumper may sit alongside aftermarket variants that share the same design language. For a builder, the result is a front-end expression that is as coherent in its aesthetics as it is in its mechanical function; a statement that a car in motion, with this bumper on, is not merely fast, but intelligently engineered to manage speed and stability.

Internal link note: enthusiasts who want to understand the spectrum of genuine front-end options for this chassis can consult a representative listing that provides a direct view into OEM-fitment front bumper options. mitsubishi-cz4a-lancer-evolution-x-front-bumper-genuine

External resource for further detail on material specifications and consumer feedback can be found at CarParts.com, which offers verified information on aftermarket components like these and related performance upgrades. External resource: CarParts.com.

Aero-Edge Economics: Pricing, Value, and Buyer Signals in Premium Carbon Front Bumper Upgrades

The market for premium carbon-fiber front bumper upgrades mirrors how performance buyers weigh aerodynamics, aesthetics, and install practicality. Buyers seek parts that deliver measured gains in airflow and downforce while maintaining street usability, and the price tag often reflects the complexity of integration as much as the material quality.

Pricing hinges on three core factors. First, the scope of the kit matters: a complete aero package that includes the bumper, a carbon lip or splitter, canards, and the necessary hardware generally commands a higher price than a single lip or a partial component. Second, material and finish drive the premium: true carbon fiber with a high-end weave, resin system, UV coating, and surface finish adds cost but also consistency in fit and durability. Third, the distribution path and warranty influence perceived value: authorized dealers with warranties tend to carry higher list prices but offer stronger post-purchase assurance.

Used parts complicate the equation but are common in this space. A used carbon-fiber lip with canards may trade around the six- to nine-hundred-dollar range, depending on condition, visibility of wear, and local demand. Location, shipping, and the potential need for refinishing or reworking mounting hardware can shift that value, sometimes making local pickup a meaningful savings.

From the buyer’s perspective, value is best understood through a three-tier lens: performance, fitment, and longevity. Performance covers actual airflow gains and stability at speed; fitment ensures the part aligns with factory lines and all sensors and guards remain functional; longevity reflects the remaining service life of the carbon fiber and the robustness of the warranty or support structure. When these pillars align, the upgrade becomes less about sticker price and more about long‑term vehicle capability and confidence during high‑speed driving.

In practice, many buyers prefer purchasing through reputable channels that provide clear provenance and professional installation guidance. Authorized distributors tend to offer reliable warranty coverage and a seamless integration with the car’s body, while reputable importers may broaden the option set but vary in after‑sales support. The smartest approach is to verify compatibility for the specific sub-model year, confirm professional installation, and balance upfront cost against the expected reliability and resale value of a cohesive aero package.

Aero Craft and Aggressive Stance: Evo X Varis V1 Front Bumper

Designed for the Evo X, the Varis V1 front bumper combines aggressive styling with purposeful aerodynamics. It shapes airflow around the nose to improve cooling, feed the intercooler and radiator, and direct air toward brake ducts, while the integrated canards create front end downforce and stability at speed. Extended Fender flares accommodate wider tires, enhancing mechanical grip and balance with the wider kit. The bumper is engineered to work with Varis V1 widebody components for a cohesive front end, and installation emphasizes precise fit and alignment to preserve aero performance. While the bumper itself does not add horsepower, it optimizes air handling and cooling so that any engine upgrades or track focused packages can perform more consistently. Overall, it is part of a complete aero strategy rather than a standalone cosmetic upgrade.

Final thoughts

The Mitsubishi Lancer Evo X Varis V1 front bumper serves as a powerful tool for automotive enthusiasts and businesses alike that aim to enhance vehicle aesthetics while optimizing performance. This direct connection between design and functionality not only elevates the Evo X’s style but also its aptitude in dynamic driving scenarios. Understanding the material quality, market trends, and customization options related to the Varis V1 front bumper can provide businesses with an advantageous edge in the lucrative aftermarket sector. By investing in high-quality performance parts, you can help shape the aspirations of car enthusiasts worldwide.