The front bumper of the 2014 Mitsubishi Lancer is more than just a design element; it’s a key component designed for both aesthetics and functionality. For business owners, ensuring this part is in optimal condition means maintaining vehicular protection while reflecting the vehicle’s modern image. In the chapters that follow, we will delve into its design and functionality, explore replacement and customization options, and cover installation and maintenance best practices to keep your Lancer looking and performing at its best.

Edge and Endurance: The Design and Function of the 2014 Mitsubishi Lancer Front Bumper

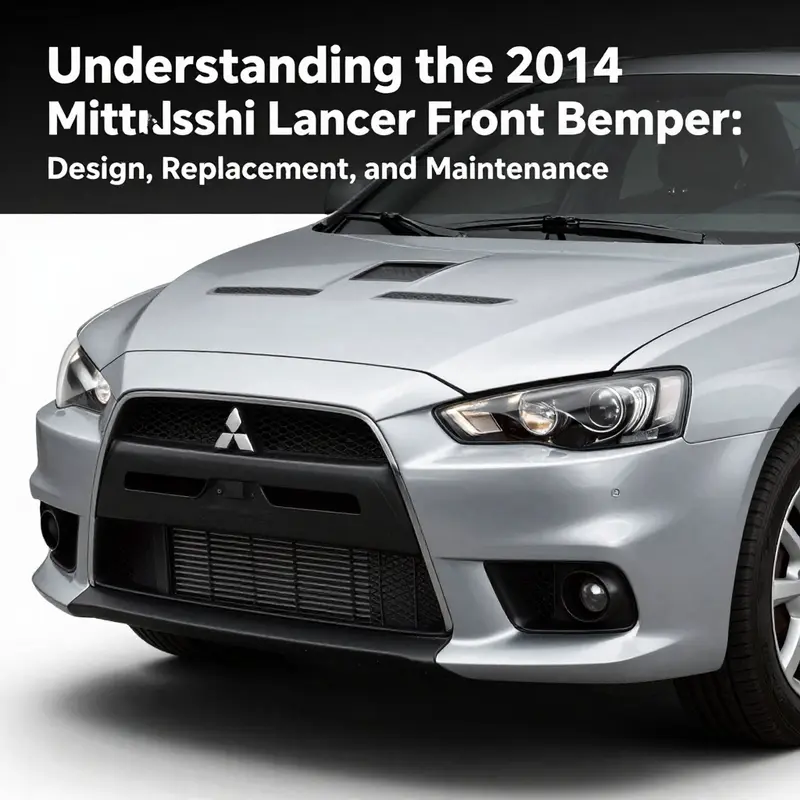

The front bumper of a car is often seen as a face that communicates intent and character at a glance, yet in the 2014 Mitsubishi Lancer it is also a carefully engineered shield, a conduit for air, and a precision component that anchors the entire front-end architecture. The bumper is more than a cosmetic panel; it is a fusion of form and function that supports performance, safety, and the wearer’s sense of identity behind the wheel. When one considers the 2014 Lancer as a package—the crisp lines, the slightly sharpened profile, the compact yet confident stance—the bumper plays a pivotal role in translating those design cues into a practical, real-world experience. Its shape, its materials, and its mounting logic are all tuned to a single aim: to protect, to perform, and to please, across the varied demands of city streets, long highway trips, and the occasional track-day excursion that a sportier driver might imagine in a weekend setting. In this way, the bumper becomes a continuous thread through which aesthetics and engineering meet, shaping the car’s behavior while reinforcing the visual language that made the Lancer recognizable on the road.

From the outset, the 2014 bumper is designed with aerodynamics in mind. A carefully engineered silhouette exists not merely to reduce drag for the sake of speed, but to stabilize the car at higher velocities, improve fuel efficiency, and manage the way air flows around the front corners during cornering and braking. The bumper’s lower lip, its integrated scrapes or diffusers, and the surrounding fascia together form a pathway for air that minimizes turbulence. The result is a measurable, practical effect: less lift at speed, steadier steering feedback, and reduced resistance that translates into marginal gains in efficiency without compromising the Lancer’s nimble handling traits. The visual language of the bumper—its contoured brow, the subtle aggression of the lower intake, and the way it hugs the grille line—also communicates a modern, high-performance intent that appeals to drivers who want the car to look awake and ready for action as soon as they pull into a lot or leave one behind on a back road.

The aggressive appearance that many owners crave is not accidental. It reflects an evolution in the Lancer’s design philosophy, where the front end acts as a focal point for the car’s personality. The bumper’s shape contributes to a sense of forward momentum. The lines are crisp, the angles deliberate, and the overall stance is one of purpose rather than mere ornament. Yet the same lines are engineered to avoid over-sculpting that would hamper airflow or create noise and vibration in the cabin. In other words, the bumper is optimized for both external impact management and the internal experience of the vehicle’s occupants. When you look at the Lancer’s front end as a whole, you notice how the bumper’s geometry aligns with the grille, the headlights, and the hood—each element reinforcing a coherent, performance-oriented silhouette. This harmony is not luck; it is the result of iterative testing and engineering discipline that seeks to balance beauty with resilience.

Material choice is central to achieving the bumper’s dual goals of lightness and durability. The 2014 bumper commonly employs materials such as thermoplastic olefin (TPO) composites or fiberglass, which provide a productive combination of stiffness, light weight, and impact resistance. These materials absorb energy when a low-speed impact occurs, protecting the underlying frame and critical sensors, while also resisting cracking or permanent deformation under UV exposure and temperature cycling. Some performance-oriented configurations may utilize polyurethane, known for its elasticity and resilience. Polyurethane can rebound after minor dings, reducing the chance of cosmetic cracking and offering a forgiving response to small shoves from a parking lot collision or a low-speed bump. Each material choice comes with trade-offs: TPO typically delivers excellent chemical resistance and formability at a reasonable weight, while fiberglass can offer stiffness and a distinct finishing quality, though it might require more careful attention to resin finish and impact resistance in certain climate conditions. Regardless of the exact composition, the bumper’s internal structure is built to distribute energy away from the most vulnerable points, redirecting force toward the bumper’s designed collapse zones so that the impact energy is managed predictably and repair bills stay within sensible bounds.

The interplay between materials and architecture extends to how the bumper integrates with other front-end systems. Sensor housings, fog light pockets, and daytime running light provisions are all factored into the bumper’s design. A modern Lancer of this era expects a clean alignment with those components, preserving their functions while maintaining a flush, factory look. When a bumper is replaced or upgraded, this compatibility becomes the decisive factor in achieving a correct fit without invasive tweaks. OEM-compliant replacements are engineered to meet Mitsubishi’s safety and fitment specifications, ensuring precise alignment with mounting points and safe integration with sensors and lighting if those options exist on a given trim. Aftermarket options continue this thread of compatibility by aiming to reproduce the original geometry and mounting geometry, but with a broader range of materials and finishes. The result is a marketplace that can satisfy a range of preferences—from a faithful, factory-like appearance to a more aggressive, performance-oriented look—without sacrificing the essential interface that connects the bumper to the car’s underlying safety and structural systems.

Of course, the bumper’s role extends beyond aesthetics and energy management. Its ability to withstand repetitive minor impacts translates into meaningful cost savings over the vehicle’s life. For daily drivers, a bumper that resists cracking, warping, and paint peeling reduces the frequency and expense of cosmetic repairs after parking lot bumps or grocery-store misjudgments. For enthusiasts who use the Lancer on back roads or at weekend events, the bumper’s resilience helps preserve the car’s overall geometry, preserving alignment, wheel tracking, and the accuracy of grille and fog-light positioning that can matter for performance and style alike. A well-chosen bumper, especially when paired with a matching front bumper cover and related trim pieces, can preserve the car’s silhouette and maintain the integrity of the front-end crash structure, which is designed to absorb energy in a controlled manner and to minimize the chance of more serious damage in a subsequent, more severe impact.

In the realm of customization and personalization, the bumper becomes a gateway to a broader conversation about how a Lancer owner chooses to express the car’s character while maintaining its functional core. Aftermarket bumpers are often designed to mirror factory geometry so they can accept the same mounting points, fasteners, and sensor interfaces. They also offer options for integrated features—such as fog lights or air intakes—that may align with a driver’s preferred trim or aesthetic. The trade-off here is that while some aftermarket choices promise a factory-derived fit, others lean into a more aggressive profile that demands careful attention to alignment, paint color matching, and potential recalibration of sensors or cameras. The notion of paint code compatibility emerges as a key detail in this landscape. A bumper that matches the vehicle’s original color code ensures a seamless surface, reducing the visibility of seams and the chance of shade mismatch. It also helps maintain a cohesive finish that preserves the car’s overall presence when viewed from any angle. In practice, whether choosing an OEM-compliant replacement or an aftermarket variant, the priority remains simple: the bumper should sit square with the rest of the front fascia, stay aligned with the grille openings and headlamps, and support the precise snap-in and bolt-on connection that keeps the entire assembly secure through the car’s service life.

To locate compatible front bumper options for a 2014 Lancer, drivers commonly explore catalogs from vehicle-specific parts retailers and online marketplaces that curate parts by year, make, model, and trim. The process begins with confirming the exact model year and trim level—whether SE, GT, or Ralliart—as well as whether the replacement includes specific features such as integrated fog lights or sensor modules. The trim-specific fitment ensures that the bumper aligns with the surrounding panels, preserves the intended aerodynamics, and maintains proper clearance with the frame rails and underbody components. Additionally, a careful check of part numbers and engineering standards is prudent. Official Mitsubishi resources and vehicle-specific parts lookups remain reliable tools for verifying compatibility and safety compliance. Such diligence helps maintain warranty considerations and ensures that any replacement adheres to the vehicle’s designed tolerances for energy absorption and mounting geometry. It is also worth noting that reliable suppliers typically provide documentation about weight, material composition, and expected load-bearing performance, along with installation notes that guide the user through fastener removal and reattachment, clip alignment, and torque specifications for critical mounting points.

For enthusiasts who choose to source a bumper from beyond the traditional channels, the landscape often widens into specialized catalogs and international suppliers. Some vendors offer universal-fit fiberglass options or CF skin touches that can be painted to match the car’s color. While these choices can broaden the range of styling options and potentially reduce cost, they also place greater emphasis on fitment accuracy, paint-matching integrity, and the careful handling of mounting hardware. In this context, caution and due diligence become essential. The process of replacement shares a common backbone: first, remove the existing bumper by accessing the fasteners along the wheel arches, under the bumper, and at the corners near the fenders; second, disconnect any electrical connectors for sensors or lights; third, align and bolt the new bumper into place, ensuring that all mounting points engage cleanly and that fasteners are torqued to specification; finally, reattach lights, sensors, and trim pieces. A service manual or professional mechanic’s guidance is invaluable during this sequence, helping to avoid misalignment that could compromise the system’s protective function or the front-end’s precise geometry.

The broader conversation about the 2014 Lancer’s front bumper also touches on how this component integrates with the car’s overall design language. This generation emphasized a sharper, more contemporary look while preserving the Lancer’s reputation for agile handling and everyday practicality. The bumper’s lines echo the hood curvature and the angular, confident stance of the headlights, producing a cohesive, street-ready appearance. The design’s success is measured not only in how it looks when the car is parked but also in how it behaves when the vehicle is moving. A bumper with effective energy dispersion and minimal drag can contribute to steadier high-speed performance, improved fuel economy, and a more satisfying driving experience for those who value both form and function. The chapter’s exploration of materials, compatibility, and sourcing underscores the reality that a bumper is a vehicle’s first line of defense and a visible statement of intent. It is the interface where engineering meets aesthetics, and where a driver’s personal taste meets the car’s built-in capacity for resilience.

In practice, choosing between OEM and aftermarket options often comes down to a balance of fit, finish, cost, and the intended use of the vehicle. For a daily driver who wants the front end to look right and protect the frame with predictable performance, an OEM-compliant replacement that preserves the original geometry and sensor alignment may be the most sensible choice. On the other hand, a project car or a weekend warrior might benefit from a purpose-built alternative that emphasizes a more aggressive profile or lighter weight. The key is to approach the selection with a clear understanding of what matters most for the owner: paint compatibility to maintain a seamless exterior or the ability to customize the bumper’s presence to reflect a personal sense of speed and style. Each path has its merits, and both hinge on careful evaluation of fitment, finish, and the role the bumper is expected to play in the car’s daily life and occasional performance use.

The 2014 Mitsubishi Lancer’s front bumper thus stands as a microcosm of automotive design: a single component that embodies aerodynamic intent, material science, safety engineering, and aesthetic expression. It is a reminder that a car’s appearance and its protective envelope are not separate topics but a single, integrated system. As technology advances and new materials offer even greater degrees of flexibility and resilience, the bumper will continue to be a focal point for those who seek to balance the practical realities of daily driving with the excitement of personal customization. This is the essence of the 2014 Lancer’s front-end philosophy: a construct that makes the car feel both capable and inviting, ready to face the road ahead with poise, efficiency, and a touch of assertive style.

For readers who want to explore related details or dive into specific replacement pathways, a representative example in the broader landscape of Lancer parts and customization can be found through targeted resources focused on year-specific and trim-specific components. In the context of the model year discussed here, one practical path is to consult a dedicated parts listing that aligns with the vehicle’s unique fitment. An example of such a resource is available through a dedicated parts catalog that emphasizes the Evo X-era Lancer family and its various front-end components, including those associated with the 08-15 generation. This link provides a concrete reference to the broader ecosystem of front-end parts and how they relate to the 2014 model’s bumper design and mounting framework. 08-15 Mitsubishi Lancer Evolution Evo X hood phantom black OEM U02

For readers who want to extend their research beyond the immediate ecosystem of OEM and aftermarket bumpers, the marketplace offers a spectrum of options, including specialized composites and paint-ready covers designed to fit the 2014 Lancer’s front end. In this context, the discussion broadens to emphasize not only the parts themselves but also the service pathways, such as installation guidance and calibration considerations for sensor-equipped variants. The goal remains to preserve the integrity of the car’s front structure while enabling the owner to realize a preferred aesthetic that aligns with the vehicle’s performance personality. By keeping in mind the bumper’s dual mandate—protection and appearance—drivers can approach replacements with confidence, ensuring a smooth process from the moment they order a new piece to the moment the last fastener is snug and the vehicle is returned to the road with its front-end geometry intact.

External research resources can further illuminate the practical dimensions of this topic. A widely accessible reference in the broader automotive parts marketplace provides examples of front bumper offerings and related components with a focus on the 2014 lancer’s front-end geometry and installation considerations. This external resource presents a useful context for understanding how suppliers interpret OEM specifications, how paint-matching challenges are addressed, and how the safety standards embedded in the original design are preserved in replacement parts. For those who want to explore external options online, the following listing offers a glimpse into the kinds of front bumper configurations available in the global market: https://www.alibaba.com/product-detail/2014-Lancer-Front-Bumper_1600378955248.html?spm=a2700.18921132.0.0.1c9b4e95dHnLZw. This reference provides a practical sense of the market’s range, material choices, and the trade-offs involved in choosing a non-OEM front bumper that still aligns with the Lancer’s front-end requirements.

In sum, the 2014 Mitsubishi Lancer front bumper stands as a thoughtful embodiment of the vehicle’s design priorities: a front end that is aerodynamic, visually assertive, and robust enough to withstand the everyday minor impacts that define daily driving. Its construction, materials, and mounting logic reveal a careful balance between lightness and toughness, between the demands of a modern aerodynamic profile and the realities of real-world use. The bumper’s significance is not limited to the moment of purchase or the ease of installation; it resonates through the car’s daily operation, influencing how the vehicle moves through air, how it absorbs energy in a collision, and how it presents itself to the world each time it sits in a parking lot or takes to the highway. As with any modern car that blends performance with practicality, the bumper is a key chapter in the ongoing story of the Lancer’s design language and its enduring appeal to drivers who demand both style and substance from their everyday performance machine.

External reference note: For readers seeking broader context about available bumper options and associated front-end components in the market, an external listing provides a practical snapshot of materials, fitment approaches, and potential customization paths that align with the 2014 Lancer’s front end. https://www.alibaba.com/product-detail/2014-Lancer-Front-Bumper_1600378955248.html?spm=a2700.18921132.0.0.1c9b4e95dHnLZw

Face Reimagined: Replacement and Personalization of the 2014 Mitsubishi Lancer Front Bumper

The front bumper of the 2014 Mitsubishi Lancer is more than a protective shield for the nose of the car; it is a carefully sculpted element of the vehicle’s identity. When owners think about replacing or customizing this panel, they are often balancing three intertwined goals: preserve or restore original protection, refine performance or styling, and manage cost without compromising structural integrity. The 2014 Lancer sits at a point in its lifecycle where the design language of the model year blends a cleaner, more aggressive stance with practical engineering. The bumper, as part of that face, carries the weight of that aesthetic while also absorbing minor impacts and channeling airflow toward cooling systems and brakes. Understanding this dual role helps frame any replacement or customization project as more than a swap of plastic; it becomes a chance to reassert the car’s personality while maintaining the protective envelope that keeps critical components aligned and shielded from road hazards.

The practical considerations of replacement begin with compatibility. The 2014 Lancer front fascia was tuned to a particular silhouette, and the bumper that fits this year’s model is designed to align with adjacent panels, the grille, headlights, fog-light assemblies (where applicable), and the lower air intake. For owners who drive a higher-performance or sport-oriented variant of the Lancer, such as trims that historically integrated fog lamps or sport mesh designs, choosing a bumper with the right cutouts and mounting points is essential. Mismatches in mounting holes or sensor housings can complicate installation and degrade fit, making it worthwhile to confirm part numbers through official resources or a vehicle-specific parts lookup tool. In the absence of access to official catalogs, an experienced mechanic or parts specialist can cross-check shapes, attachment points, and air-flow features to ensure a proper match with the 2014 model’s dimensions.

From there, the decision between OEM quality and aftermarket options shapes both the tracking path and the final look. OEM or high-quality replacement bumpers are engineered to mirror the exact tolerances of the original piece. They slot into the car’s architecture with minimal fuss, preserving alignment with adjoining panels and maintaining the factory line across the front end. Materials in this category are typically engineering plastics such as polypropylene, selected for their balance of stiffness, impact resistance, and recyclability. A well-made OEM-level bumper is UV-stabilized to resist sun-induced degradation and is intended to retain its color and shape through years of exposure. For owners who want to keep the integrity of the factory finish without repainting, these options are attractive because they minimize the risk of shade mismatches and fitment issues that sometimes accompany cheaper aftermarket parts.

On the other hand, aftermarket or performance-oriented components widen the range of choices and often introduce advances in material science that appeal to enthusiasts chasing durability, weight savings, or a more aggressive aesthetic. Polyurethane bumpers, for example, blend toughness and resilience. They tend to absorb impacts with a level of flexibility that helps in preventing cracking under minor hits. In certain climates with high heat and rapid temperature swings, polyurethane can offer superior resistance to micro-cracking and stress. Some builders also consider polycarbonate bumpers for their exceptional impact resistance and rigidity, which can matter for those prioritizing durability in track days or rough road conditions. Each material carries its own handling and finishing requirements; polyurethane might demand professional or at least careful repainting to attain a factory-like gloss and color, while polycarbonate components may demand precise mounting to prevent alignment drift under stress. The choice of material is not merely a matter of length of service but also a reflection of the owner’s intent—whether to maintain the factory stance, push toward a more aggressive posture, or reduce weight for performance gains.

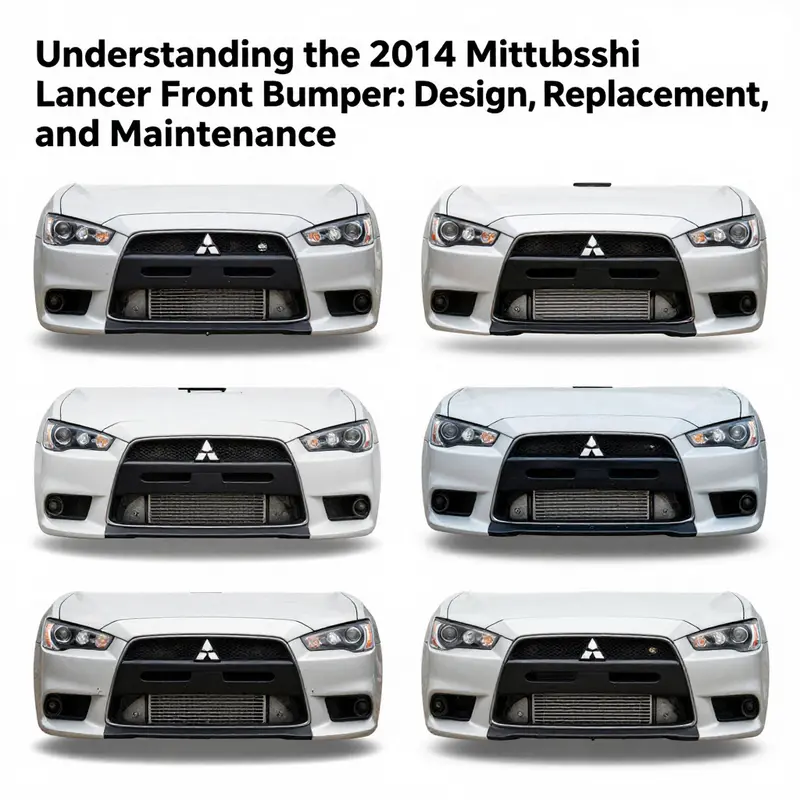

Styling choices underpin much of the customization discussion. The Lancer’s front end presents opportunities to alter the visual weight and air-intake character through grille designs, lower lip configurations, and the proportions of the bumper itself. A bumper’s silhouette can influence perceived width, height, and even the car’s stance on the road. For fans of a modern, refined look, a bumper that preserves the existing geometry while incorporating subtle chrome accents or a refined mesh insert can elevate the car without screaming for attention. For those seeking a more aggressive, performance-inspired appearance, mesh patterns, larger air intakes, and a pronounced lip can dramatically shift the front fascia, creating a sense of motion even when the vehicle is stationary. The choice of finish—glossy, matte, or satin—also affects light reflection and the way the bumper reads against other panels. Importantly, any aesthetic modification should respect the overall proportion of the Lancer’s front profile; a bumper that looks right in isolation can appear out of scale when paired with a changed grille, headlight treatment, or fog-light housing.

Part of the customization journey is the confidence that the replacement piece will work with the car’s existing trim and features. Different trims may feature integrated fog lights, sensors for advanced driver-assistance systems, or specific curvature in the lower air intake. A bumper that includes fog-light cutouts, for instance, should be matched to the car’s lighting configuration to avoid gaps or misaligned mounting surfaces. If a bumper is sourced without fog-light provisions, owners may need to adapt the wiring harness or switchgear, which can complicate installation and require professional electrical work. Conversely, bumpers that include integrated fog-light housings can streamline the upgrade path for drivers who want to maintain or improve illumination without adding separate housings or brackets. These considerations extend to the bumper’s weight distribution and mounting geometry. A well-fitting bumper keeps the vehicle’s crumple zones intact and ensures the bumper reroutes energy away from vital components during minor impacts while protecting the face of the engine and cooling systems from road debris.

A practical mindset for any replacement project is to align the choice with the owner’s budget and driving style. If the aim is a pristine, factory-like outcome with no risk to the vehicle’s warranty, an OEM-grade option is a logical starting point. It reduces uncertainties in fitment and color matching, and it typically comes with a straightforward return policy if the part fails to meet expectations. For drivers who enjoy a hands-on approach and want to push the envelope on aesthetics or performance, a performance-oriented bumper provides the opportunity to experiment with materials and design. It is essential, however, to factor in the additional steps often required by these parts, such as more involved surface finishing, primer and paint, and, in some cases, professional alignment to guarantee the panel sits perfectly with the fenders and hood. The paint process itself is a small but critical detail in a successful replacement. The bumper must be color-matched to the vehicle’s factory shade and then clear-coated to resist UV aging and yellowing. Inaccurate color matching can quickly reveal a mismatch at certain lighting angles, undermining the overall appearance of the front end.

For those who want a balanced approach—retaining a factory-like fit while enabling some visual updates—the use of a bumper with unobtrusive styling tweaks becomes appealing. A subtle change such as a more tightly woven mesh pattern in the grille, or a refined lip that does not overwhelm the bumper’s lines, can deliver a modern look that remains faithful to the car’s original design intent. Such choices also simplify the installation process: maintaining standard attachment points, avoiding custom brackets, and ensuring that the replacement aligns with the factory seam lines. This balance of function and form emphasizes how carefully chosen front-end parts can influence the car’s resale value and daily usability. A well-chosen bumper, despite its apparent simplicity, informs the vehicle’s first impression and can dramatically shape how observers perceive the Lancer’s age, care, and purpose on the road.

In the practical realm of installation, the process is a combination of methodical disassembly of the existing assembly and careful reassembly of the new piece. The typical workflow begins with safely disconnecting the battery to mitigate any potential electrical issues, especially if the bumper houses sensors or lighting components. Next, fasteners—ranging from visible bolts to hidden clips—are removed. The lower splash shield may need to come off to reveal additional mounting points. Some models require detaching the radiator grille or removing the headlights to access certain screws, while others allow direct access to standard mounting holes. It is common to encounter stubborn clips that resist removal, and working slowly is essential to avoid tearing the mounting tabs or damaging adjacent bodywork. The bumper cover itself is then separated from the vehicle with careful prying and unhooking of brackets. The new bumper is positioned and aligned with reference to the fenders, hood line, and chin spoiler if applicable. A careful sequence of bolts and clips reaffirms the connection points and ensures structural integrity. If sensors or assistive devices exist, their harnesses must be reconnected exactly as they were before. The final checks focus on alignment, panel gaps, and the way the bumper meets the bumper cover’s edge along the fender and the hood line. A staged test drive in a controlled environment is prudent to confirm that no panel is binding, and that the new piece does not pose any interference with wheel travel or steering components.

In this context, the role of reference materials cannot be overstated. Vehicle-specific documentation, such as service manuals or parts lookup guides, provides the exact torque specifications, clip types, and sequence for removing a front bumper on the 2014 Lancer. For enthusiasts who prefer to perform the job themselves, these resources can be the difference between a smooth installation and frustration from misaligned parts or missing fasteners. Yet even with meticulous preparation, many owners find that having a professional handle the process yields a more consistent fit, particularly when paint matching or sensor integration is involved. A shop with experience in Mitsubishi models can bring an extra layer of confidence to the project, ensuring that the bumper sits in harmony with the rest of the bodywork and that the finish withstands the test of time.

The conversation about replacement and customization naturally loops back to the broader ecosystem of parts access. The modern consumer benefit lies in the availability of OEM-compatible or aftermarket options across online marketplaces and parts retailers, which helps keep the Lancer’s front end both protected and expressive. When selecting a part, it is prudent to verify that the bumper is designed for the 2014 model year and compatible with the owner’s trim level and any features such as fog lights or sensors. Matching the trim and feature set reduces the likelihood of post-purchase surprises and ensures that the installation remains straightforward. With the right part in hand, the project becomes less about improvisation and more about precise adaptation, alignment, and finish work that respects the car’s original lines while allowing a personal touch to emerge in the final presentation.

For readers seeking a broader context on how bumpers fit into the Lancer’s broader lineup and its varied bumper configurations, consider the dedicated page that surveys 2016-era bumper options across the Lancer family. This resource, while focusing on a稍 later model year, helps illuminate how mounting points, grille interfaces, and lip treatments can differ across generations and trims, and it can guide a shopper’s expectations when evaluating a 2014 bumper’s compatibility with other front-end components. Such cross-year awareness underscores the value of a careful parts lookup approach and highlights how even small differences in the bumper assembly can influence the overall look and function of the vehicle.

In practice, whether a driver chooses OEM-right fit, a high-performance fabrication, or a styling-focused upgrade, the process remains anchored in thoughtful measurement, careful selection, and disciplined installation. The bumper’s role in protecting the air intake, cooling system, and bumper beams is foundational, yet its silhouette also communicates the owner’s expectations about the car’s use—whether daily driver, weekend racer, or showpiece. The 2014 Lancer front bumper embodies this dual purpose: it is a protective element engineered for durability, and it is the most visible piece of the car’s first impression. A replacement or customization that respects both these roles can extend the car’s usable life, maintain or elevate its aesthetic, and preserve the integrity of the ownership experience across seasons and kilometers.

To summarize the practical path forward, owners should start with a compatibility check, then decide on OEM authenticity versus a performance-minded or styling-minded aftermarket route. In either case, attention to mounting points, sensor integration, and the finish will help ensure that the investment yields a front end that not only protects but also speaks to the Lancer’s confident stance. The 2014 front bumper, with its characteristic lines and functional features, remains a fertile ground for personalization without sacrificing the core protections that keep the car’s front end aligned, efficient, and ready for the road ahead. For those who wish to explore a broader set of bumper configurations that fit the Lancer family, see the page dedicated to the 2016 Mitsubishi Lancer front and rear bumpers. 2016-mitsubishi-lancer-front-and-rear-bumpers.

External reference for practical examples of aftermarket options can be found here: https://www.ebay.com/itm/375652588432

Between Fit and Finish: Installing, Aligning, and Maintaining the 2014 Mitsubishi Lancer Front Bumper

The front bumper of a 2014 Mitsubishi Lancer is more than a cosmetic shell. It is a carefully engineered interface between the road and the car’s most vulnerable point, shaping airflow, guiding energy away from the engine bay, and anchoring a host of sensors, lights, and mounting points that keep the vehicle functioning in daily use and during the occasional bounce of a minor collision. In the 2014 Lancer, the front fascia presents a sharper, more modern stance than earlier generations, and that bold look depends on a bumper that fits precisely, mirrors the body lines, and integrates seamlessly with the surrounding panels. This is why installation, alignment, and ongoing maintenance are not afterthoughts but essential components of preserving both safety and style. When the bumper is installed correctly, it sits flush with the fenders, aligns with the hood line, and forms a continuous silhouette that communicates the car’s intent as much as its function. When it isn’t, gaps widen, sensors misread, and the overall impression of quality can be lost in an instant. The conversation about the bumper, therefore, begins with fit and ends with finish, tying together the mechanical, aesthetic, and protective roles that this part performs on a modern compact sedan.

From a practical standpoint, owners will encounter two broad paths when replacing or upgrading the bumper. One option is an OEM-specification bumper, designed to match exactly the factory pieces in both geometry and finish. The other path is the aftermarket route, where materials and styling can vary significantly. Polypropylene and other plastics remain common, prized for their light weight and resilience against impact in everyday driving. But there are aftermarket materials—such as high-strength fiberglass or polyurethane—that trade some rigidity for design flexibility or enhanced impact resistance. Each material brings its own considerations for mounting, alignment, and finish. The key is to understand how each choice affects the car’s original warranties, sensor alignment, and paint compatibility. A bumper in true OEM spec will generally offer the least friction with factory mounting points, wiring harnesses, and seal interfaces. An aftermarket option can broaden style choices or price points, but it may demand additional steps: reshaping mounting brackets, reworking edge contours, or even repainting to achieve a perfect color match. The careful eye of a shop that understands the Lancer’s geometry can turn these choices into a result that not only looks right but behaves predictably at speed and in the glare of the sun.

The moment of installation hinges on alignment. The Lancer’s front end is a composite of panels that must converge at exact tolerances. The bumper’s primary role is to shield the car’s front structure while letting the headlamps, fog lights (where equipped), and any proximity or adaptive-sensor systems work in concert. This means the process starts with a clear plan for how the new bumper will mate with the surrounding pieces. A precise fit means fewer adjustments later, reduced risk of rattles, and a more stable finish after painting. For those who choose OEM or OEM-style pieces, professional installation is often strongly advised to ensure the bumper sits at the factory reference gaps and remains in harmony with the vehicle’s sensors and lighting system. The precision required is not merely cosmetic; it is about maintaining the integrity of the front-end assembly and the way it communicates with the rest of the car’s systems. When a bumper is installed without attention to these details, the result can be misalignment that leads to repeated vibrations, gaps that collect dirt and moisture, or misaligned lights that reduce nighttime visibility.

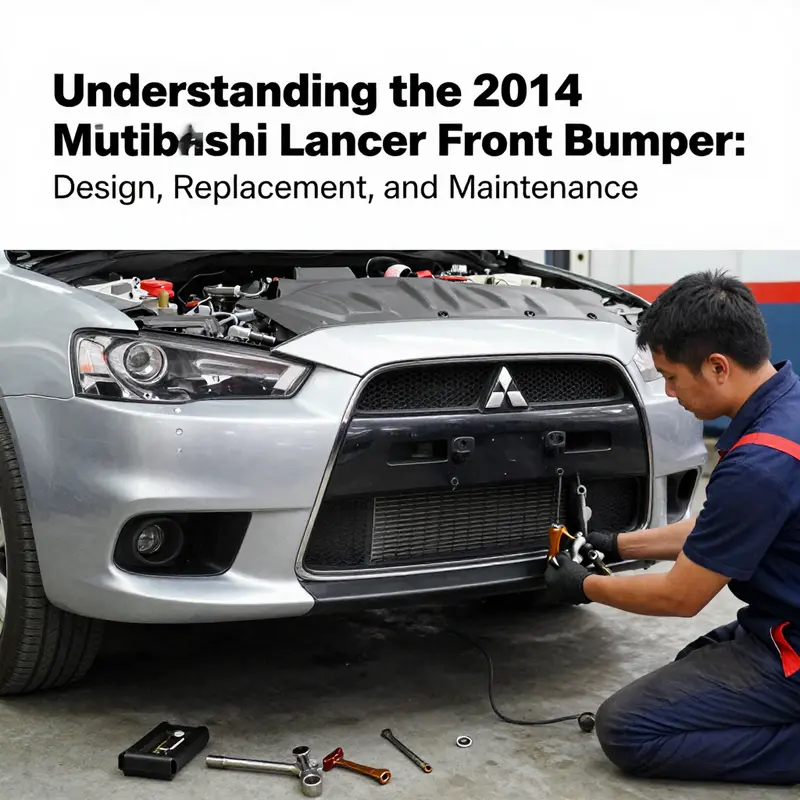

In practical terms, the installation begins with a careful preparation of the vehicle. The process asks for a methodical approach: gather the right tools, confirm the bumper part matches the specific trim of the Lancer, and have a plan for any integrated features such as fog lights or sensors. Even with an OEM bumper, the mounting hardware may differ slightly between production runs or trim variations. Therefore, technicians often verify the fit by aligning the bumper with the first mounting points before tightening any fasteners. This prevents over-tightening or forceful bending that could distort the bumper’s geometry and, in turn, disturb the alignment of adjacent panels. The vehicle is parked on a level surface, the parking brake is engaged, and the battery is disconnected to avoid any electrical mishaps with sensors or lights during the process. These steps, though simple, form the foundation of a successful installation, and they echo the carmaker’s emphasis on precision for every front-end component.

The actual removal of the old bumper is an exercise in attentiveness. Screws and clips secure the bumper to the framework and to the radiator support. It is a sequence that rewards patience: start at the outer edges, peel back the clips, and work toward the center while supporting the bumper so nothing catches on the grille, sensors, or wiring harnesses. If fog lights or sensors are present, their connectors must be carefully unplugged, the wiring routed to avoid pinching, and the entire harness checked for routing clearances as the new bumper begins to settle. The goal is to unburden the vehicle’s front end from the old geometry without inflicting new scrapes or damage to nearby components. The removal phase is exactly where a professional approach can save time and prevent incidental damage, especially when sensors or connectors interact with the bumper’s inner structure.

Installing the new bumper follows a complementary cadence. The alignment is the central challenge, and it is achieved by first mounting the bumper loosely to confirm the correct engagement with the fenders, the grille, and the hood edge. The process often requires fine-tuning of the bumper height and angle so that the top edge sits flush with the line of the hood and the bottom edge doesn’t interfere with the splash shield or the lower air intake opening. Reconnecting any fog-lamp or sensor wiring comes next, followed by the reinstallation of clips or screws. The torque applied to each fastener should reflect the manufacturer’s guidance as found in the service manual, ensuring that the bumper is secure without over-stressing any mounting tabs. Once the physical attachment is set, a final check confirms the proper seating against all adjacent panels and the absence of gaps that might trapeze the airflow, collect debris, or trap moisture.

Beyond the physical fit, the bumper’s functional integration matters. If the vehicle uses fog lights, parking sensors, or forward-collision sensors, the installer must verify that these systems are calibrated to the new bumper geometry. This calibration ensures that the lights illuminate the intended area and that sensors read the correct distances for safety systems. In some cases, a sensor calibration or alignment procedure requires a scan tool or a service procedure from the vehicle’s manual. When a bumper includes a notable contour change, such as a painted lip or a ribbed lower section for aerodynamics, the installer may also check for interference with the undercarriage components. A bumper that is too tight can rub on the radiator support or the splash shield; one that is too loose can flutter at highway speeds and produce noise or even wear down the paint. The professional’s eye balances these variables, delivering a completed installation that feels integrated rather than bolted on.

After installation, the vehicle should be tested comprehensively. The battery is reconnected, and all electrical features—headlights, daytime running lights, fog lamps, and any parking sensors—should be tested for continuity and proper operation. The alignment should be re-evaluated with the car on a level surface, ensuring that windshields’ glare and the sun’s angle do not reveal the bumper’s misalignment. A road test can reveal subtle issues that static checks miss: a gentle push on the bumper at various speeds can confirm that the mountings hold and there is no tendency to shift or rattle under dynamic load. In the end, the bumper remains a single uninterrupted profile of the Lancer’s front end when the car sits still and the wheels turn. That is the mark of a job done with care, whether undertaken in a dealership service bay or by an adept do-it-yourself enthusiast who has followed the manual’s guidance and respected the vehicle’s engineering.

Maintenance of the bumper is a matter of ongoing care as much as periodic repair. Regular cleaning helps maintain the finish and prevents the accumulation of road salt, grime, and UV-induced fading that can degrade the paint over time. Mild soap and water with a soft cloth are typically sufficient for routine cleaning, but harsh chemicals or abrasive pads should be avoided to prevent micro-scratches and finish dulling. Polypropylene bumpers, common on mass-produced models, respond well to gentle care, while fiberglass or polyurethane variants may require paint-safe cleaners and, occasionally, refinishing if chips or scratches break through the topcoat. A yearly or semi-annual inspection can catch small cracks, loose clips, or edge deformations that, if left unchecked, might worsen with exposure to heat and cold cycles. If damage is minor, some providers offer repair kits or refinishing guidance tailored to the bumper’s material, enabling the owner to restore the finish and protective properties without a full replacement. More significant damage should be evaluated by a qualified technician who can determine whether the frame or support structure beneath needs attention alongside the cosmetic surface.

Protection and appearance also hinge on how well the bumper receives a color match. The 2014 Lancer’s aggressive styling benefits from a finish that mirrors the car’s body color and sheen, creating a seamless blend from fender to fender. When color matching is necessary, technicians use tested primers, base coats, and clear coats, ensuring the finish resists UV exposure and road chemicals. A factory-like finish is more than a cosmetic luxury; it helps maintain the car’s value and protects the underlying materials from moisture penetration and corrosion. For those who upgrade to aftermarket bumpers with graphic accents or sportier lip designs, paint and clear-coat layers must be applied evenly, with attention paid to color tolerances and texture. A mismatch in paint can become a focal point of the front end, undermining the visual intent of the upgrade and inviting further corrective work.

Sourcing a bumper, whether OEM or aftermarket, invites thoughtful consideration of compatibility. The trim level influences whether the bumper accommodates integrated fog lights, a particular radiator grille design, or a set of sensor housings. It is crucial to ensure that a replacement part aligns with the Lancer’s specific trim—such as SE, GT, or Ralliart—and that any functional features align with the vehicle’s electrical and mechanical layout. The compatibility check extends to the mounting hardware; the screws, clips, and brackets supplied with the new bumper should mirror the factory hardware or provide substitutes that fit precisely in the same locations. Since the front end is a shared interface among many subsystems, even a slight difference in mounting width or clip position can lead to long-term misalignment, squeaks, or misbehavior of connected components.

In terms of sourcing, a broad network of auto parts channels exists online and offline, offering both OEM replacements and performance-oriented aftermarket options. For a thoughtful replacement, buyers evaluate the part’s fitment with the Lancer’s trim and year, the bumper’s material, the possibility of spray painting or finishing, and the availability of compatible mounting hardware. The process often involves verifying the part number or cross-reference to ensure a precise match to the 2014 Lancer front-end. While this might seem straightforward, it benefits from a careful review of the vehicle’s service information and parts lookup tools that many manufacturers provide. These tools can be accessed through a vehicle-specific parts lookup platform or the manufacturer’s own portal, enabling the user to confirm that the chosen bumper will satisfy both fitment and warranty considerations.

To widen the context beyond a single source, the broader parts ecosystem features a range of options for those seeking a front-end upgrade. Some owners may explore universal-fit bumper modules that promise compatibility with multiple Lancer variants, emphasizing aerodynamic design and performance. When considering such options, credibility and compliance standards become important: it is essential to verify material quality, the craftsmanship of the mounting points, and certifications that reassure long-term durability. A careful buyer weighs these considerations against the goal—whether it is restoring the original look, improving impact resistance, or adopting a more aggressive or refined styling cue. Ultimately, the best choice respects the Lancer’s architecture, preserves the essential safety functions of the front end, and delivers a finish that remains faithful to the car’s persona on the road.

For readers who want a concrete touchstone about part compatibility and mounting geometry across the Lancer family, a dedicated parts catalog offers context on how front bumpers relate to the surrounding panels. See the broader catalog entry that covers the 2016 Lancer front and rear bumpers to gain a comparative sense of fitment geometry and mounting strategy, which often informs decisions about 2014 models as well. 2016-mitsubishi-lancer-front-and-rear-bumpers. This page helps explain how even small shifts in bumper edges, mounting tabs, or corner radii can influence alignment and overall appearance, reinforcing why a careful, measured approach is always best when working on the Lancer’s front end.

As owners plan their project, they also navigate the practicalities of procurement. Replacement bumpers may be sourced through general auto parts retailers or specialized online marketplaces. The guidance from service manuals and parts lookup tools remains consistent: confirm trim-level compatibility, account for any integrated lighting or sensors, and verify the presence of the correct mounting hardware. When possible, obtaining a kit that includes all clips, fasteners, and brackets helps ensure a smoother installation and reduces the risk of missing components that would otherwise complicate future maintenance. For many, the path toward a well-executed bumper replacement is a blend of careful part selection, precise installation, and diligent maintenance. The results—clean lines, secure fitment, and a front end that behaves as intended in everyday driving—are a testament to attention to detail and an understanding of how every piece in the front assembly contributes to the Lancer’s overall character.

External resource for broader context on front-end parts and supplier information can be found here: https://www.alibaba.com/product-detail/Madly-GAF-Front-Bumper-for-Mitsubishi-Lancer_1600879533733.html. While this link points to a marketplace that aggregates multiple suppliers, it illustrates how a single listing can reference compatibility with several Lancer variants, including 2014 models. The page provides technical specifications, compatibility notes, and supplier details that help illuminate what to expect from universal-fit or broad-application bumper offerings. The important takeaway is not the specific listing but the broader reality that bumper replacements can come from a wide network of sources, and reliability hinges on the seller’s credibility, material quality, and adherence to safety standards.

In closing, the 2014 Mitsubishi Lancer front bumper represents a balance of form and function, demanding respect for fitment, finish, and the front-end ecosystem that it protects. A thoughtful installation respects the vehicle’s engineering, keeps sensors properly aligned, and preserves the sharp, confident stance that defines the Lancer’s look. Maintenance then becomes a regular partner in that effort: clean, inspect, and protect the finish; keep fasteners tight but not over-torqued; and replace damaged pieces with parts that meet the car’s specifications. When these principles shape the approach to the bumper, the result is a car that not only wears a striking front line but also carries forward the integrity of its engineering, year after year on the road.

Final thoughts

The 2014 Mitsubishi Lancer front bumper plays a crucial role in protecting your vehicle, enhancing its aesthetics, and maintaining its value. For business owners, understanding the importance of this component, along with the available options for replacement and proper maintenance techniques, can lead to informed decisions that extend the life and performance of your vehicle. Keep your Lancer in prime condition and ensure your investment serves you well for years to come.