The Evo 9 steering wheel, a pivotal component for the 2006–2007 Mitsubishi Lancer Evolution IX, is engineered not just for aesthetics but for optimal performance that resonates with driving enthusiasts. This article delves into the intricate design and engineering that make this steering wheel a crucial asset for vehicle handling and feedback. Additionally, we will explore the market dynamics surrounding its manufacturing, shedding light on the Chinese production hubs that dominate the landscape. We will also address the rigorous quality control measures that ensure each wheel meets high standards before reaching the consumer. Finally, customization options will be presented, emphasizing how business owners can enhance their offerings in the aftermarket space. Together, these insights uncover a comprehensive view of the Evo 9 steering wheel’s significance in both performance and marketability.

Steering the Evolution: The Engineering Heartbeat of the Evo 9 Wheel

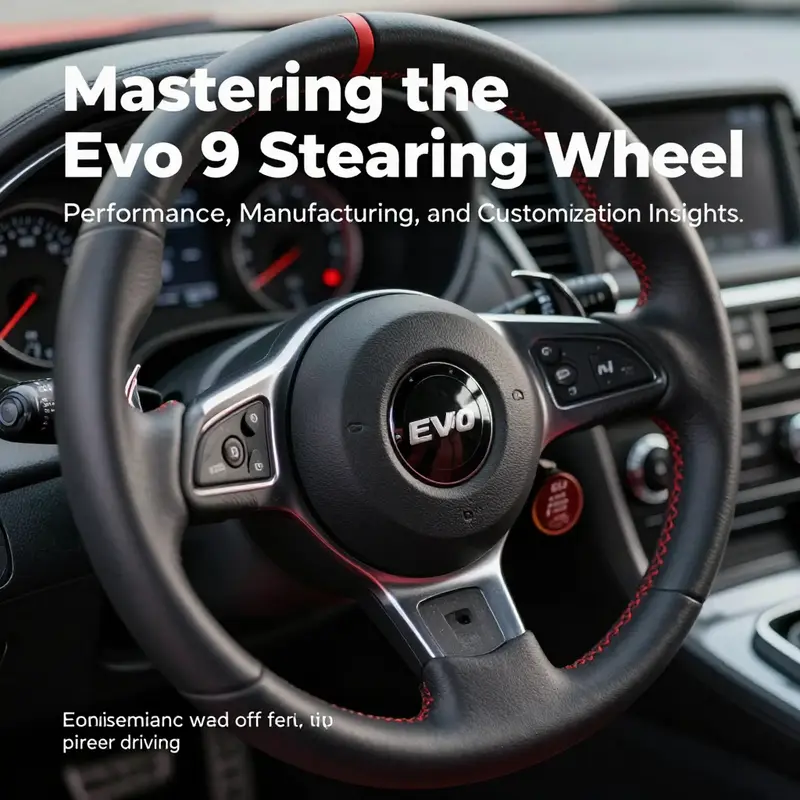

The steering wheel in the Evo 9 is more than a control interface; it is the direct line of communication between the driver and the chassis. Designed for the 2006–2007 Mitsubishi Lancer Evolution IX, it embodies a philosophy that ties cockpit feel to track-ready performance. From the first grip, the wheel signals that every input matters, that weight on the road translates to feedback in the palms, and that the car’s sport-tuned character is not just a set of numbers but a living, responsive experience. In this sense, the Evo 9 steering wheel shares its DNA with the broader Evolution lineage—a lineage built on precision, durability, and a relentless push toward a more immersive driving sensation. The wheel does not merely steer; it interprets the road, channels the chassis’s dynamic intent, and returns that intent to the driver in a form that is almost tactile in its clarity.Construction and materials are a careful balancing act between rigidity, weight, and touch. The core is typically a lightweight, high-strength structure—often aluminum or carbon fiber—that resists flex under aggressive cornering while keeping overall mass low. This is crucial because even a few grams’ difference can alter the feel of steering response at the limit. The wrap complements this core, with options that range from supple leather to the grippy, suede-like texture of Alcantara. The choice of wrap matters as much for comfort as for control: leather provides a confident, traditional feel in all weather, while Alcantara can offer enhanced grip and a slightly cooler, more race-oriented tactility. The result is a wheel that can endure the abuse of track sessions while still feeling refined on a spirited road drive. This combination of core and wrap is not accidental; it is the product of a deliberate engineering choice to maximize driver feedback while preserving the wheel’s structural integrity through repeated high-load cycles.Beyond materials, the wheel’s geometry is a study in ergonomics. The diameter is tuned to align natural hand placement with the car’s seating position, ensuring that even during rapid transitions, the driver’s hands can find a secure, repeatable grip. The shape—round enough for easy, confident handover but with a slightly flattened top or bottom in some iterations—favors visibility of gauges and instruments while keeping the driver’s wrists in an optimal position for quick, precise steering. In a performance car, the smallest discrepancy in diameter or rim profile can influence muscle memory and steering proprioception. The Evo 9 wheel’s geometry is therefore a product of real-world testing, where feel, leverage, and leverage recovery are validated under the stress of spirited driving. In this sense, the wheel’s silhouette is a direct expression of its purpose: to facilitate minute, deliberate inputs that translate into decisive vehicle behavior at the limit, not merely to furnish a stylish cockpit accent.What makes the Evo 9 wheel a compelling reference point is how its design philosophy anchors the driving experience in motorsport heritage without surrendering daily usability. The steering system is conceived as part of a cohesive, performance-focused cockpit. The tactile response—the way the rim communicates road texture, camber-induced load, and tire grip—embodies a philosophy of “uncompromising engagement.” This is not about raw torque or brute force; it is about a symbiotic relationship where the driver’s intent and the car’s reaction are in near-perfect synchrony. In practice, that translates to a steering feel that is direct, linear, and predictable, with just enough weight to convey the car’s weight transfer and traction limits without becoming numb or over-assuring. The wheel’s design thus embodies the Evolution ethos: every element is tuned to keep the driver undeniably connected to the vehicle, a lasting reminder that performance is a marriage of engineering and driver skill.For enthusiasts seeking to extend this cockpit connection, aftermarket and OEM replacement options exist that preserve the Evo 9’s character while offering opportunities for refinement. A common avenue is upgrading to a carbon fiber construction, where a lighter core reduces inertia and a stiffer shell reduces flex. This approach can sharpen steering response and improve precision during quick directional changes, which matter as much on a windy back road as they do on a tight race course. At the same time, professionals and hobbyists alike may pursue a more aggressive grip texture or a different wrap material to tailor tactile feedback to their hands and climate. A heated grip option, for example, can maintain comfort and control in chilly sessions, ensuring that nerves don’t erase the fine line between tire grip and steering input. And while performance upgrades often dominate conversations, there remains a strong case for maintaining a sense of authenticity—the wheel should still feel like it belongs in a car with a motorsport backbone, not like a disposable, one-size-fits-all component. In this balance between weight, rigidity, and tactile experience lies the wheel’s enduring appeal: it anchors the car’s dynamic capabilities in a cockpit that remains accessible to both weekend track enthusiasts and daily drivers who value precision over pomp.The Evo 9’s steering wheel also sits within a broader ecosystem of parts and components designed to complement its performance posture. For those who are exploring the upgrade path, the cockpit becomes a canvas upon which a broader performance narrative can be written. Custom carbon fiber construction, for instance, can pair with an OEM button transfer to retain factory-era functionality while showcasing modern materials. Paddle shifters, where applicable, allow rapid gear changes that keep the driver’s focus within the steering rather than the transmission tunnel, preserving the sense of direct vehicle control. Heated grips, as noted, add a layer of comfort that preserves grip and accuracy during fatigue or colder conditions. Each of these enhancements is not merely a cosmetic upgrade; it is a functional one, designed to sustain the wheel’s intent: to deliver immediate feedback, stable handling, and a cockpit that supports aggressive driving with a clear, unambiguous signal back to the driver.The design and engineering context of this wheel is inseparable from the global manufacturing and procurement backdrop that underpins its availability. In recent years, China has emerged as a dominant hub for high-quality steering wheel production, driven by concentrated clusters in Guangdong, Jiangsu, Zhejiang, and Shanghai. These industrial ecosystems offer end-to-end capabilities, with factories that handle CNC machining, leather or synthetic wrapping, and polymer molding within a tight quality-control environment. Guangdong, in particular, stands out because of its integrated supply chain and the logistical advantages of cities like Guangzhou, Shenzhen, and Dongguan. The result is not only a potential for precision parts but also shorter lead times and more predictable delivery schedules, which matters when enthusiasts need a wheel to match a tight project timeline or a race-prep build. A supplier with such geographic advantages can deliver consistent performance across batches, helping preserve the wheel’s dimensional fidelity and tactile consistency—qualities that are essential when you are integrating a performance component into a tightly tuned chassis. In evaluating suppliers for this critical component, procurement managers must balance quality, cost, reliability, and technical know-how. Some shops may offer lower prices or faster shipping, while others may showcase stronger quality-control processes or deeper engineering collaboration. The best outcomes arise from deliberate, real-world comparisons that consider not only the sticker price but the long-term value of parts that consistently meet performance expectations under high-stress driving. Long-term partnerships with such suppliers can unlock additional customization options—like carbon-fiber textures, button transfer accuracy, paddle-shifter integration, and heated-grip compatibility—without compromising the wheel’s fundamental integrity. This is particularly relevant for enthusiasts who want to preserve the Evo 9’s heritage while ensuring modern reliability and performance in all weather and driving conditions.Within this context, the Evo 9 steering wheel becomes a focal point for a broader cockpit narrative. Its design is a synthesis of sporting purpose, ergonomic science, and practical manufacturing realities. As a result, the wheel is not merely a component but a statement: a reminder that in the Evolution lineage, performance is not a single attribute but a holistic experience. The wheel’s geometry, the feel of the wrap, the rigidity of the core, and the potential for customization all converge to create a cockpit environment where every input carries confidence, where every turn of the wheel communicates a clear front-rear dynamic to the driver, and where the chassis responds with a cadence that feels almost musical in its precision. For readers who want to explore related interior upgrades, a helpful resource is the dashboard Evo-9 page, which aggregates components that align with the Evo 9’s interior ethos and performance horizon. You can learn more about complementary cockpit upgrades there: dashboard evo-9.As the Evolution series continues to evolve, the steering wheel remains a touchstone—an instrument through which the car’s heritage meets contemporary engineering. It is the part of the cockpit that translates vision into motion, intent into traction, and ambition into controlled, exhilarating progress. That the Evo 9 wheel could do all this and still feel approachable in everyday driving is a testament to the careful layering of design choices. It is a reminder that the best performance components do not simply push a car harder; they deepen the driver’s engagement with the machine, inviting better feedback, more precise control, and a richer sense of what it means to push a vehicle toward its limits. For enthusiasts who want to push the limits further still, the path forward is not a single upgrade but a thoughtful, integrated approach—one that respects the wheel’s origin in a motorsport heritage while embracing the possibilities that modern materials and manufacturing can offer. External references can provide context on available carbon fiber options in the broader aftermarket space. For reference, see: https://www.alibaba.com/product-detail/Ever-Carbon-Racing-ECR-New-Design_1600543781497.html

The Global Web Behind a Sport-Tuned Steering Wheel: Market Dynamics, Manufacturing Clusters, and Procurement Strategy

The steering wheel in a sport-tuned chassis is more than a control device; it’s a compact, highly engineered interface where safety, ergonomics, and driver feedback converge. Its role in the broader class of performance parts makes it a textbook case for how market dynamics, material science, and regional manufacturing clusters shape supply chains.

Global market context: steering wheel market is typically in the tens of billions USD, with a recent size around USD 19.5 billion and a low-to-mid single-digit CAGR ahead. Key demand drivers include safer, more connected driving experiences; OEM programs seeking integrated interfaces for advanced driver-assistance systems; and enthusiasts who value material quality and tactile feel. The wheel thus serves mainstream and high-performance segments, with both OEM and aftermarket channels continually refining designs.

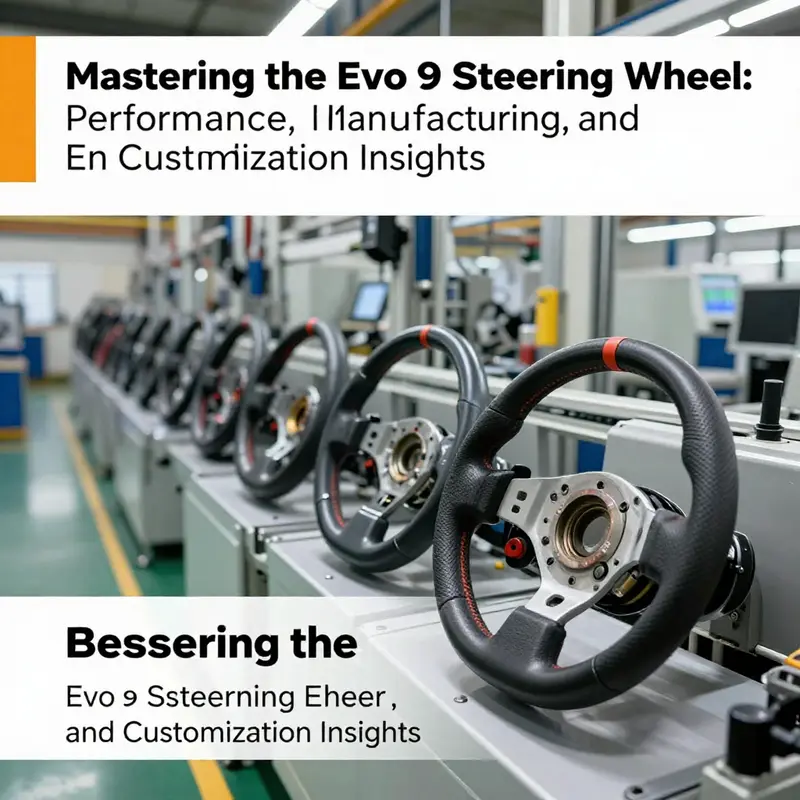

Geography and clusters: manufacturing is concentrated in China and a few supporting hubs. In China, Guangdong, Jiangsu, Zhejiang, and Shanghai host clusters that cover CNC machining, leather finishing, and electronics integration. Guangdong is strong in aftermarket performance parts due to dense supplier networks and rapid prototyping. Jiangsu emphasizes precision machining and automation for components and subassemblies. Zhejiang and Shanghai balance aesthetics, leather work, and sensor integration with scalable production. This geography enables multi-material platforms—carbon fiber, advanced polymers, smart textiles—without sacrificing lead times or quality.

Procurement decisions: buyers prioritize quality, cost, and technical capability. Quality encompasses fit with airbags, torque sensors, and the reliability of bonding and finishes. Cost must be balanced against total cost of ownership, including durability and after-sales support. Technical capability includes material science, rapid prototyping, and blending multi-material assemblies with embedded electronics. The procurement playbook also stresses supply-chain resilience, with strategic partnerships, predictable delivery, and the ability to scale from pilot runs to mass production.

The design and production ecosystem is increasingly driven by automation and digital tooling. Suppliers invest in CNC workflows, bonding and curing processes for carbon fiber parts, and rigorous quality gates. Ergonomics—rim diameter, grip, seam placement—shapes perceived quality and driving confidence, so buyers evaluate suppliers on how well a partner can deliver consistent feel across grip positions and temperatures. In practice, the strongest relationships hinge on joint development programs, transparent traceability, and robust post-sale support.

For readers seeking a broader, data-driven perspective, industry sources provide market analyses that cover size, regional dynamics, and growth trajectories. These references help frame the long-run evolution of aftermarket and OEM supply chains in this space. https://www.kenresearch.com/global-automotive-steering-wheel-market-2019-2030/

Forging Precision: The Quiet Craft of Quality Control in Evo 9 Steering Wheel Production

The Evo 9 steering wheel is more than a grip on a steering column; it is the primary interface through which a driver translates intention into motion. In a high-performance platform like the Mitsubishi Lancer Evolution IX, where chassis tuning emphasizes agile response and fearless feedback, the steering wheel must endure the rigors of track-ready use while delivering reliable, repeatable performance day after day. In the vast ecosystem of Chinese manufacturing that supplies aftermarket and OEM replacement parts, quality control is the invisible yet decisive factor that transforms raw materials into a trusted control surface. The industrial clusters in Guangdong, Jiangsu, and Zhejiang are not just assembly points; they are tightly choreographed networks where CNC machining, leather wrapping, and precision molding converge under unified quality standards. Within this ecosystem, a single component can set the tone for a vehicle’s dynamics, and so manufacturers invest heavily in a multi-layered quality assurance program that spans supplier selection, in-process checks, and final validation. In this narrative, the focus is not only on the wheel itself but on the disciplined process that preserves OEM-level fit, durability, and driver confidence across an increasingly diverse aftersales landscape.

Quality control begins with material integrity. Carbon fiber, polyurethane, and premium leather—the triad that defines the Evo 9 steering wheel’s performance envelope—must meet strict, traceable specifications before they ever meet a tooling line. In the Guangdong corridor, suppliers frequently operate under ISO-certified quality management systems that require documented material certificates, batch traceability, and random sampling to verify tensile strength, heat resistance, and impact durability. Carved from carbon fiber layers or reinforced polymers, each structural element must conform to dimensional tolerances tight enough to maintain a precise fit with the EVO 9’s original steering column interfaces. Leather indications—grain pattern, colorfastness, and finish uniformity—are evaluated against a controlled standard to ensure that the perceived quality aligns with the wheel’s tactile expectations. These assessments are not superficial checks; they are part of a chain of evidence that supports a warranty-backed product and minimizes variability across thousands of units.

The manufacturing floor that turns concept into a steering wheel is a blend of high-precision processes. CNC machining is central to producing the wheel’s core geometry, including the hub interface, horn contact area, mounting points, and any integrated paddle-shifter assemblies. The goal is to reproduce OEM geometry with a tolerance that ensures a seamless connection to the vehicle’s airbag system and a reliable horn function. Quality gates at this stage assess straightness, concentricity, and surface finish. In many facilities, end-to-end production occurs under one roof: CNC machines feed into molding for complex core shapes, which then move to leather-wrapping stations and finally to wrapping-and-assembly modules that complete the wheel with stitched finishes. The controlled environment for final assembly helps prevent contamination and ensures color consistency between the leather wrap and any carbon fiber inlays. The environment itself becomes a silent quality instrument, with temperature and humidity controls that stabilize adhesive performance and prevent warping or delamination of the leather layer.

To maintain OEM compatibility and reproducible performance, the industry has made dimensional verification a non-negotiable practice. Modern suppliers deploy 3D scanning and coordinate measurement that map every valve, horn contact, airbag deployment interface, and mounting hole to the original equipment specification. This level of scrutiny is essential for a vehicle that demands precise steering feel and reliable safety system integration. A wheel that deviates even slightly in mounting bolt patterns or airbag contact geometry can compromise safety or alter steering ratio feel. Traceability is the other half of the equation. Part numbers, batch identifiers, and performance-test records travel with each wheel as part of a complete product dossier. This documentation gives buyers confidence that, even in a multi-supplier supply chain, every wheel can be linked back to its raw materials, inspection results, and assembly lineage.

Beyond raw material and geometric precision, quality control is also a test of performance under simulated real-world conditions. Tensile strength tests confirm that the wheel’s rim structure will resist gradual fatigue and sudden bending moments under aggressive driving. Heat resistance tests simulate long hours in sunlit environments while exposed to abrasion from the driver’s hands and gloves. Impact tests emulate road hazards or a hurried correction during spirited driving. In all cases, the objective is to ensure the wheel maintains its grip and shape under the stress profile typical of a track day or competitive autocross. Randomized testing and sampling guard against systematic errors that could escape a single-line inspection. These tests also feed into a feedback loop that drives continuous improvement—informing suppliers about any drift in material performance or process stability and prompting adjustments before broader production consequences emerge.

The relationship between supplier and buyer is shaped by what the market considers reliable, not merely by the lowest price. A strategic qualification process helps procurement teams navigate the balance of quality, cost, and delivery reliability. In a dense manufacturing milieu where some vendors offer aggressive upfront pricing yet inconsistent long-term quality, an evidence-based approach becomes essential. This approach includes pilot runs, in-depth capability assessments, and real-world comparisons that reveal which suppliers consistently meet specifications across a range of batches and operating conditions. Stories of on-time performance are not mere anecdotes; they become part of risk assessment and contingency planning. A noteworthy example from the ecosystem notes an on-time delivery rate approaching near-perfect reliability when a supplier harnesses integrated production lines, cross-functional training, and responsive logistics planning. In the Evo 9 context, where a wheel is not simply a part but a performance interface, timely delivery translates into minimized downtime for teams that rely on precise upgrades and wheel replacements for race-prepped machines.

Customization adds another layer of complexity to quality control. Enthusiasts often seek carbon-fiber wraps with different weaves, OEM button transfers, paddle shifters, or even heated grips. Each customization path introduces new variables in material behavior, interface fitment, and safety system integration. The QC program must therefore be adaptable enough to validate not just the base wheel but its variants. A carbon fiber wrap, for instance, must maintain its structural integrity when exposed to repeated torque and grip stress, and the wrap must not interfere with airbag deployment geometry or horn connectivity. Paddle shifters and heated grips entail additional electrical interfaces and heat dissipation considerations that must be validated through electrical safety tests and thermal cycling. Even as customization elevates the wheel’s aesthetic appeal and functional versatility, the QC framework ensures that no stylistic choice undermines safety or performance. The discipline here is to separate the variables used for form from those guaranteeing function, while preserving traceability and performance benchmarks across all configurations.

In this quality-controlled world, documentation is as critical as the wheel’s physical properties. Batch-specific quality reports, test certificates, and calibration data anchor the product in a transparent supply chain that B2B buyers can trust. Having a well-documented lineage reduces ambiguity about compatibility with different EVO 9 steering column variants and airbag modules, and it also supports warranty claims with objective proof of compliance. The practical effect is a reduction in post-sale issues, fewer returns, and stronger customer confidence for aftermarket upgrades that must stand up to the expectations of track-day enthusiasts and daily drivers alike. When a supplier demonstrates traceable parts, consistent performance data, and a warranty-backed guarantee, buyers gain a reliable partner rather than a transient vendor. It is this reliability that ultimately underpins the Evo 9 steering wheel’s reputation as a high-performance, safe, and aesthetically compelling control interface.

The ecosystem’s credibility is reinforced through dedicated sourcing and logistics strategies. Guangdong’s cluster advantage—not just in machining but in integrated tooling and quick-turn capabilities—can compress lead times and sustain consistent quality even as volumes scale. The result is a supply chain that remains resilient under demand fluctuations and market shifts, keeping production lines filled with wheels that meet exacting standards. In practice, this translates to a predictable delivery cadence and a robust support network for aftermarket teams that calibrate suspensions, align tracking systems, and plan competitive builds. The entire process—from raw material intake to the final torqueing of a mounted wheel—takes place under a disciplined regime that prioritizes reproducibility, traceability, and continuous improvement. For procurement teams, this is not a distant promise but a living capability that translates into practical, measurable outcomes on the shop floor and in the hands of end users.

To illustrate how these principles connect to the broader ecosystem, consider the interior landscape of Evo 9 projects. The same meticulous approach that governs wheel quality extends to other interior components, where fitment and finish must harmonize with the steering wheel’s tactile feel and control response. For a concrete example of related interior components and to explore the broader dashboard ecosystem, readers can explore the dashboard Evo-9 section, which reflects how interior precision supports overall driving experience. This internal reference helps connect the wheel’s quality program to an integrated interior strategy, reinforcing the idea that high-performance outcomes depend on cohesive, end-to-end execution across all cabin interfaces. See the dashboard Evo-9 for a representative look at how interior parts are aligned with the same standards that govern wheel production. dashboard Evo-9

Finally, the ongoing conversation about Evo 9 steering wheel quality is incomplete without acknowledging the broader industry framework that shapes best practices. External resources offer a panoramic view of supplier landscapes, QC methodologies, and certification trends across automotive components in China and beyond. For readers seeking a global perspective on how leading manufacturers ensure quality while maintaining competitive lead times, an authoritative guide to Evo 9 steering wheel suppliers in China provides valuable context and benchmarks. It is a reminder that quality control is not a single checkpoint but a living system that evolves with materials science, process engineering, and user expectations. External reference: https://www.autopartsb2b.com/evo-9-steering-wheel-supplier-guide-china

Forging the Driver’s Connection: Customization as the Core of the Evo 9 Steering Wheel

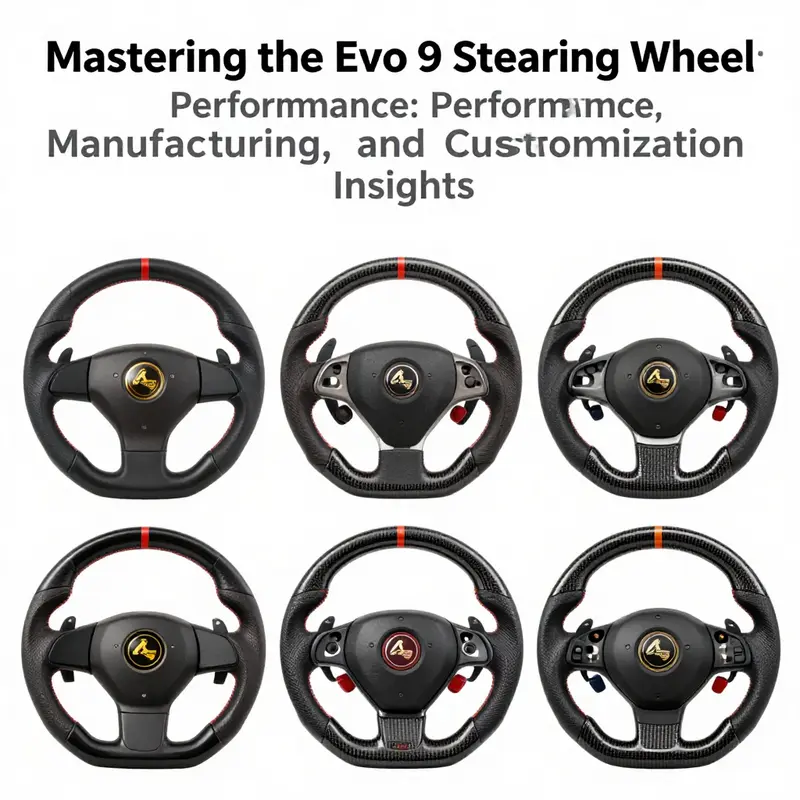

The steering wheel is more than a control surface; it is the tactile heartbeat of a performance machine. For the Evo 9, the steering wheel becomes the decisive link between chassis intent and driver response. In the tuning world, customization is not merely about aesthetics. It is a deliberate calibration of weight, grip, and feedback that translates every shift, turn, and throttle modulation into confident, precise action. When you choose to customize the Evo 9’s wheel, you are choosing a bespoke conduit for the car’s sport-tuned character. You are selecting how the road speaks to you and how you, in turn, respond with your hands, your wrists, and your whole posture. This is why the spectrum of options—materials, colors, textures, and clever integrations—matters as much as the wheel’s diameter or its spoke pattern. It is about forging a personal connection that respects the car’s lineage while pushing its capabilities toward a more intimate, race-informed experience.

Material decisions sit at the core of that connection. Carbon fiber remains the most talked-about option for enthusiasts who crave a lean, racing-minded presence without overburdening the wheel with excess weight. The characteristic weave catches light in a way that visually communicates speed, while the real-world impact is a lighter, stiffer grip surface that reduces fatigue on extended, high-demand drives. Yet carbon fiber is not a one-size-fits-all choice. For daily spirited driving, a premium leather wrap can deliver a warmer, more tactile feel, with a supple yet durable surface that remains comfortable in long sessions and through a wide range of temperatures. The choice between exposed carbon, leather-wrapped rims, or a hybrid approach—carbon on the center spokes with leather on the outer rim—creates a balance between aesthetic drama and everyday practicality. In all cases, the stitching becomes a delicate but meaningful signature; color-matched or high-contrast thread can reinforce the interior’s design language while contributing a subtle tactile cue that signals quality and attention to detail. The driver feels not just a tool, but a crafted instrument aligned with their own visual and physical expectations.

Color schemes extend beyond mere cosmetics. The Evo 9’s interior likely speaks with monochrome, metallic, or bolder contrasts, and the steering wheel is a prime canvas for continuing that dialogue. By selecting a color palette that harmonizes with the dash, seats, and door panels, a driver can create a cohesive, immersive cockpit. Stitch patterns—round stitches for a classic, honeycomb or cross-stitch variants for a sportier texture—accentuate handcraft and precision. The goal is to weave the wheel into the broader interior narrative rather than letting it stand apart as a standalone piece. This is where customization becomes a storytelling device: the wheel tells the story of who you are behind the wheel, while still respecting the car’s engineering heritage and the car’s original design intent.

Beyond materials and color, functional customization moves the Evo 9 wheel from a passive piece to an active partner in performance. One critical feature is OEM button transfer, a process that keeps original controls operational even when the wheel is swapped for a more modern or performance-forward alternative. This is not curiosity for its own sake. Retaining the horn, cruise control, or audio commands in their familiar locations reduces the cognitive load during fast driving and preserves the interface drivers depend on for safety and comfort. A thoughtfully transferred control scheme eliminates the need to relearn essential functions while still delivering a tactile upgrade. The transfer is done with careful attention to fit and electrical continuity, ensuring that the new wheel can meet or exceed the original’s functional reliability.

Another pillar of customization lies in performance-oriented enhancements that are commonly requested by track-day enthusiasts and spirited daily drivers alike. Paddle shifters are one such upgrade that can transform the driving experience by enabling quicker, more precise gear changes without taking hands from the wheel. Properly integrated paddle shifters respond with crisp engagement, cleanly synchronized with the transmission logic, so engagement feels immediate and predictive. The peddle placement, the lever’s travel, and the overall weight of the mechanism all contribute to a sense of directness that mirrors the car’s chassis tuning. For those who prefer manual controls, paddle shifters can be designed to emulate the quick, tactile feedback of a race car, offering a bridge between a traditional manual and a modern automated system.

In colder climates, the comfort of warmth is an unexpected but highly valued dimension of customization. Heated steering wheels are not merely a luxury; they preserve grip consistency and comfort as temperatures plummet. A heated surface reduces the stiff, cold grip that can dull feedback through the palms, helping the driver maintain confidence during chilly morning commutes or late-evening sessions on a track. The best implementations balance warmth with careful control of heat distribution so that the center of the wheel and the fingertips receive even coverage, avoiding hotspots that reduce grip or cause fatigue. The result is a more engaging and forgiving interface that remains responsive as the weather shifts.

Craftsmanship underpins every choice. The Evo 9 wheel is often hand-assembled through multiple precise steps, from machining the core geometry to applying wraps, to final finish works that smooth transitions between materials. This attention to process matters because it protects the wheel’s fit to the hub, centers the rim accurately with the steering column, and ensures a seamless interface with the airbag system, should one be included in the assembly. In high-performance contexts, precision is not an ornament; it is a prerequisite for predictable steering behavior and reliable control during dynamic maneuvers. The end result is a wheel that feels like it was grown specifically for the driver and the chassis, not slapped together as a generic accessory.

A broader ecosystem supports customized steering wheels through regional manufacturing clusters that enable end-to-end production philosophies. In major manufacturing regions, there are clusters that bring CNC machining, leather wrapping, and molding under one roof. This kind of integrated capability reduces lead times, tightens quality control, and can adapt quickly to bespoke requests. When a buyer weighs options, they are weighing not just materials and features, but the reliability of the supply chain and the ability to sustain ongoing customization needs. A strategic approach to sourcing considers how a supplier handles real-world variables: pricing dynamics, delivery reliability, and the capacity to deliver consistent quality across multiple runs and iterations. It is not enough to secure a single wheel; the value lies in building a long-term partnership that can scale with evolving customization desires and the car’s evolving performance trajectory.

For those seeking a truly bespoke experience, the marketplace landscape offers a canvas for creative customization. Beyond standard options, drivers can request fully personalized geometry, unique surface textures, or exclusive color and stitch combinations that reflect a driver’s personal aesthetic and track ambitions. The aim is not to imitate a catalog but to produce something that amplifies one’s sense of control and identity behind the wheel. In this space, the driver is a collaborator, working with craftsmen to translate a personal vision into a tangible, tactile instrument. While some buyers pursue high-end unique finishes, others prioritize subtlety and function, ensuring the wheel remains a precise extension of the Evo IX’s dynamic chassis without shouting its presence beyond the interior’s intended character. The result, when done well, is a wheel that communicates intention to the driver before any word is spoken, a constant reminder of purpose every time the hands settle on the rim.

In the practical realm of decision-making, buyers balance quality, cost, reliability, and technical know-how. As customization demands grow, so does the need for a thoughtful, iterative process. Prototyping, fitment checks, and functional tests can be woven into the path from concept to finished product, ensuring that every new feature harmonizes with the car’s electronics and safety systems. A disciplined approach to evaluation helps prevent overengineering or misalignment with the Evo IX’s chassis characteristics. The objective is to preserve the car’s nimble steering feel, the linearity of feedback through the wheel, and the predictable return-to-center behavior that enthusiasts rely on when pushing toward the limits.

To weave all these threads into a coherent whole, it helps to view customization as a continuum rather than a single decision. The wheel evolves alongside the vehicle and the driver’s skills. It can start with a refined leather-wrapped option for daily driving and grow into a carbon-fiber center with race-inspired paddles for weekend track sessions. Or it can be a fully bespoke creation that aligns with a specific color story and tactile preference while preserving the essential controls through a careful OEM transfer approach. In every path, the wheel remains a reflection of intent—an instrument that translates the car’s performance DNA into an intimate, human-scale experience. The result is not merely a more attractive or modern steering wheel; it is a more expressive, more capable, and more immersive way to engage with the Evo IX itself.

For readers seeking a quick exploration of related interior components in the Evo 9 ecosystem, a related resource on an automotive parts hub provides additional context on how interior pieces fit into a broader upgrade strategy. You can explore a dashboard-focused page that complements the steering wheel by offering a holistic view of the cabin’s integration and interface design. See the dashboard Evo 9 page for a concise look at how interior upgrades align with steering wheel customization and overall ergonomic coherence. dashboard Evo 9

As the ecosystem of customization continues to mature, the planned development path for the Evo 9 steering wheel remains clear: the wheel will keep delivering a deeper, more intuitive connection between driver and machine. It will continue to fuse lightweight materials with tactile interfaces, maintain functional integrity through careful transfer of original controls, and expand into more sophisticated comfort features that still honor the car’s performance DNA. In this way, customization becomes the engine of a living, evolving relationship with the Evo IX—one that keeps pace with driving aspirations, technical innovations, and the evolving tastes of a community that turns every drive into a meaningful dialogue with its car.

External resource: https://www.alibaba.com/product-detail/Evo-9-Steering-Wheel-Upgrade-326_1600587476718.html?spm=a2700.1.women.1&albcat=Automotive+Parts+%26+Accessories&productId=1600587476718&src=shop

Final thoughts

Understanding the intricacies surrounding the Evo 9 steering wheel—from its design and engineering to manufacturing dynamics and customization—is vital for business owners looking to capitalize on this market. Each aspect contributes to a product that not only enhances driving performance but also provides an attractive opportunity in the aftermarket space. With quality and customization at the forefront, the Evo 9 steering wheel stands as a testament to the evolving needs and tastes of automotive enthusiasts, making it a key player in modern vehicle enhancement.