The Mitsubishi Lancer Evolution X has carved out a prestigious presence in the automotive world, particularly among performance enthusiasts. A key component enhancing its appeal is the front bumper, which not only contributes to the car’s aesthetics but also determines its aerodynamics and safety features. As the demand for high-quality aftermarket parts rises, particularly in the context of aging or damaged components, understanding innovations, material technologies, and economic impacts within this niche becomes crucial. The upcoming chapters will delve into innovative designs that define today’s aftermarket offerings, the pivotal role of material technology in bumper production, and the economic ramifications stemming from increasing supply and demand for these essential automotive components.

Racing Lines, Road-Ready: The Evo X Front Bumper’s Aftermarket Evolution

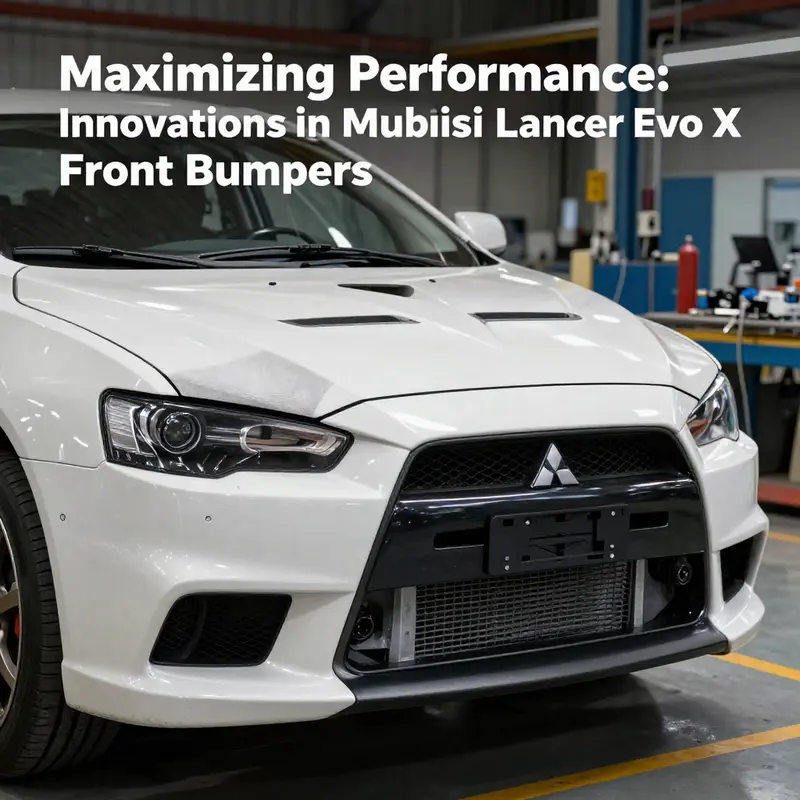

The Mitsubishi Lancer Evolution X emerged as a benchmark for synthetic speed and streetable aggression when it landed in showrooms and on the paddocks of enthusiast communities around the world. As these cars aged, the front bumper—the visible shield that governs both aerodynamics and frontal impact integrity—became a focal point for the aftermarket. Enthusiasts, racers, and restorers faced a simple truth: original parts wear out, acquire damage, or lose the precise fit and gloss that define a modern performance look. The front bumper, more than any other panel, captures the dual demand of function and form. It must manage airflow to reduce drag and lift, accommodate intercoolers, fogs, and lamps, and still present a halo of visual aggression that signals performance even when the car sits in a showroom or a garage. That dual demand—performance and appearance—set the stage for a robust, evolving ecosystem that has persisted across generations of Evo X ownership, a generation produced from 2008 to 2015 and loved long after the factory line stopped turning out new bodies.

What happened in the aftermarket is not merely a shopping list of parts but a networked, cross-border revival of design, engineering, and manufacturing capability. The Evo X’s original front end, with its sculpted air dams and bold, angular lines, invites both faithful replication and aggressive reinterpretation. As the model aged, a global demand for high-fidelity replacements grew, and the sourcing map shifted toward regions with dense automotive accessories industries. Among these, the Guangdong province in southern China—especially Guangzhou—emerged as a central node. In these industrial clusters, the supply chain forms a tightly integrated ecosystem: injection molding for durable plastic shells, fiberglass fabrication for lightweight, impact-tolerant skins, paint shops to deliver OEM-like finishes, and tooling specialists who can reproduce complex curves and attachment points with remarkable accuracy. The proximity of these capabilities reduces bottlenecks from design to delivery, which matters when a shop needs to prototype a new bumper or when a distributor needs a quick replenishment for a popular model. The effect is a faster cycle from concept to customer, speeding up the feedback loop that keeps aftermarket bumpers aligned with real-world durability tests and the evolving aesthetics of Evo X customization.

In terms of materials, the traditional trio—ABS plastic, fiberglass, and carbon fiber—continues to structure most buyers’ expectations, but the balance among them has shifted. ABS provides a durable, impact-resistant basis that lends itself to OEM-style replication and cost-effective production. Fiberglass remains a favorite for its light weight and relative ease of repair in garage settings, making it an attractive choice for budget-conscious buyers or restoration projects. Carbon fiber, once a niche option, has surged into the mainstream of performance-conscious builds. Its weight savings translate into measurable gains in acceleration and handling, while its heat resistance and stiffness give a compelling race-inspired aesthetic that remains practical on the street. The choice among these materials is rarely about a single criterion; it’s about a confluence of fit, finish, weight, and repairability, all weighed against the intended use of the vehicle.

The move toward carbon fiber has been particularly consequential for Evo X bumpers. Builders emphasize not only the raw weight reductions but also the way carbon fiber can support more aggressive aerodynamics without overloading the suspension. For track-oriented cars, a bumper designed with carbon fiber can accommodate larger air intakes, more efficient brake-cooling pathways, and canards that stabilize high-speed cornering. For daily-driven cars, carbon fiber must be paired with intelligent heat management, clear finish protection, and repair processes that minimize downtime after a small abrasion or impact. The complexity of carbon fiber repair—rerunning resin layers, addressing cosmetic waviness, and preserving color and gloss—requires specialized capability, which, in turn, incentivizes partnerships with experienced shops and verified suppliers. This dynamic has led to a broader ecosystem where premium, lightweight front-end options sit alongside more economical, repair-friendly shells, creating an inclusive spectrum for Evo X owners.

All of this material and manufacturing reality feeds directly into design innovations. The modern Evo X front bumper is no longer a single, monolithic chunk of plastic. It has evolved into a modular canvas that can be tailored for airflow, weight, and aesthetic expression. Some versions feature integrated air intakes that channel air precisely where it’s needed—toward intercoolers, radiators, or brake ducts—without compromising the surrounding sculptural lines. Other designs incorporate fog light housings that preserve light distribution while opening up the lower fascia for improved downforce at speed. Aggressive styling cues have also gained prominence: lower grilles sharpen the visual language of speed, while canards and small dent-resistant lips reduce lift at high velocity and provide a more planted feel through rapid directional changes. Each of these innovations can be implemented with a variety of materials, enabling buyers to choose a configuration that matches their mission—from weekend track days to daily commutes that demand a standout look.

Beyond the look and aerodynamics, the Evo X bumper aftermarket story is a case study in production pragmatism. The same Guangzhou clusters that master injection molding and fiberglass fabrication also excel at rapid prototyping and small-to-midsize production runs. For B2B buyers, this translates into shorter lead times and more flexible production models. A shop can order a handful of prototypes for fitment testing, receive feedback from technicians and drivers, and then scale to hundreds of units per month with the same supplier ecosystem. The ability to move from concept to consistent product in a matter of weeks rather than months is a defining advantage that shapes the economics of aftermarket parts. It also helps explain why the Evo X’s upgrade cycle has continued to mature, with more offerings aligned to different driving scenarios—street, strip, and circuit alike. The agility of the supply chain reduces risk for retailers and end-customers, encouraging experimentation with new geometries and finishing options without exposing the buyer to the same degree of cost and delay that once characterized aftermarket projects.

The practical implications of these innovations extend into the realm of compatibility and fitment. While many aftermarket bumpers are designed to be universal or broadly compatible with various Lancer generations, Evo X-centric bumpers increasingly target exacting fitment standards across the model range that spans 2008 through 2015 and beyond. This means more robust mounting points, more precise door and fender gaps, and a polished finish that aligns with the factory appearance when installed. The detailed tolerances matter not only to enthusiasts seeking a clean, seamless look but also to workshop installers who value predictable assembly times and repeatable results. The appeal of this approach is reinforced by the availability of both aftermarket and genuine options, enabling owners to decide between replicating factory specifications and pursuing a distinctive, performance-oriented aesthetic.

In this context, the interplay between design and process becomes essential. An Evo X bumper is not merely a sheet of plastic or a carbon shell; it’s a carefully engineered system that integrates with the intercooler, hood, headlamps, and cooling ducts. The integrated air intakes, for example, must not only look aggressive but must also deliver cooling air at the right pressures and temperatures to sustain engine and turbo performance. Similarly, the lighting architecture must remain compliant with safety norms and provide adequate illumination through the fog-light recess and surrounding contours. Designers in the ecosystem often begin with a CAD model that mirrors the factory geometry and then explore venting and ducting options that improve performance without sacrificing structural integrity. The iterative testing process—through wind tunnel data, computational fluid dynamics simulations, and real-world on-car trials—drives a more robust product that can better withstand the rigors of daily driving and the stresses of high-speed track use.

From a business perspective, this level of engineering sophistication translates into a multidimensional supplier evaluation framework for B2B buyers. Price remains important, but it is not the sole determinant of value. Buyers increasingly assess production capacity to meet demand, the depth of technical expertise available for design validation, and the ability of a supplier to conform to safety and quality standards. After-sales support—warranty coverage, spare parts availability, and clear return policies—also plays a critical role in ensuring long-term reliability and satisfaction. The most reputable suppliers offer transparent lead times, precise BOMs (bill of materials), and clear documentation on material composition, finish durability, and impact resistance. In practice this means that a shop working with a Guangzhou-based supplier might receive a part with a well-documented finish thickness, a guaranteed color-mender for the paint work, and a tested mounting kit that aligns with the Evo X’s factory mounting holes and brackets. This level of detail reduces installation surprises and supports consistent outcomes across different vehicles and driving contexts.

Consumer-facing buyers, too, benefit from this ecosystem’s maturity. The Evo X community values not only performance gains but also the ability to repair or revert when needed. Tubing and ram air ducts, if integrated into a bumper without proper protective coatings, can suffer from heat and impact exposure. Replacing a damaged component becomes simpler when the bumper design accommodates straightforward spares and repair procedures. For many owners, a fiberglass option offers an attractive compromise between cost, repairability, and weight. Yet, those aiming for peak performance may opt for carbon fiber, accepting the higher cost and more complex repair workflow as a natural trade-off for a product that contributes to sharper lap times and a more precise steering feel. The ecosystem’s breadth, from affordable ABS-based designs to high-end carbon fiber bodies, gives Evo X enthusiasts a spectrum that mirrors the car’s own versatility—from daily driver to weekend racer.

Among the more compelling developments is the movement toward customized designs that blend aesthetics with practical integration. Suppliers now offer bumpers with integrated air intakes, ready-to-use fog light housings, and aggressive lip spoilers—each designed to slot into the Evo X’s silhouette without forcing a passenger car’s compromises on spacing or aerodynamics. Customization can extend to color, texture, and even the finish grade. For instance, a customer might request a matte carbon look with a protective clear coat that resists UV fading, while another may want a glossy ABS finish in a color matched to the car’s exterior. The ability to tailor a bumper to a vehicle’s exact configuration—whether it wears a factory hood, whether intercooler piping runs behind the bumper, or whether a particular bumper-to-body gap needs smoothing—helps ensure that the final appearance feels like a factory upgrade rather than a mismatched add-on. Such precision is precisely what makes the Evo X’s aftermarket scene more credible and more widely adopted.

As these elements converge, there is also a narrative about accessibility and affordability. The market now offers a range of options, from new, high-performance aftermarket bumpers to pre-owned units in great condition, that fit any Mitsubishi Lancer Evolution or Ralliart from 2008–2015. This breadth ensures that drivers with different budgets and goals can participate in the upgrade conversation. The availability of both replica and genuine options—each with its own set of advantages—helps maintain a healthy market where decisions are driven by intended use rather than purely by price. A well-maintained used bumper can provide a cost-effective solution for restoration projects or for builders testing fitment on a non-critical chassis, while a carbon fiber shell might deliver the definitive performance stance for a track-oriented build.

The conversation about Evo X bumpers thus sits at the intersection of design ambition, manufacturing capability, and the practical realities of ownership. It is a story about how a model that captivated a generation continues to evolve through the people who redesign, refinish, and reimagine its front end. It also reveals how the aftermarket has matured into a sophisticated value chain where speed-to-market, material science, and engineering accuracy converge to deliver parts that perform as well as they look. In this sense, the Evo X bumper is more than a protective shell; it is a statement of intent. It declares a willingness to push air where it is needed, to trim weight where possible, and to preserve the emotional impact of the car’s face—the first thing people notice when the car rolls into a light or into a corner. It is a technology-led accessory that remains deeply aligned with how performance culture actually works: iterative testing, informed choices about materials and geometry, and the patient accumulation of experience that turns a good aftermarket part into a reliable, repeatable performance upgrade.

For readers who want a concrete pointer into how these designs translate into real-world offerings, the Evo X aftermarket catalog includes options such as genuine CZ4A front bumper assemblies, which embody a bridge between factory accuracy and aftermarket flexibility. These choices become part of a broader toolkit that includes more aggressive, race-inspired variants designed to live on track or in a weekend-show environment. The evolving front-end technology reflects the broader ethos of the Evo X community: a willingness to experiment, a respect for engineering discipline, and a shared recognition that performance and appearance can coexist in harmony when the right combination of materials, processes, and design intent come together. In this way, the Evo X bumper story is far from a static catalogue entry. It is a frontier that continues to move as new composites, new finishing techniques, and new production models emerge from the clusters that power the modern automotive aftermarket.

As a closing thread that gently ties the thread back to the broader article, consider how the Evo X bumper fits into a wider ecosystem of performance enhancements. The same principles that drive bumper design—a blend of aerodynamics, weight discipline, and cosmetic identity—apply across other body panels and accessory categories. The result is a coherent philosophy of modification that emphasizes reliability and performance without sacrificing the car’s inherent character. This philosophy helps explain the Evo X’s enduring appeal and clarifies why the aftermarket front bumper remains a central, dynamic piece of its performance narrative. For readers seeking a deeper dive into the broader innovations shaping aftermarket front bumpers, including evolutionary and structural considerations, an external resource offers a detailed panorama of current trends and technical insights: https://www.mitsubishilancer-evo.com/aftermarket-front-bumper-innovations. In tandem with the internal link to a representative catalog entry for genuine front bumper options, this external overview helps anchor the Evo X front bumper story in a wider industry context and points toward the practical realities of sourcing, testing, and installing these parts across a global marketplace.

One practical takeaway for builders and buyers is to approach the Evo X bumper as part of an integrated performance package rather than a standalone upgrade. Aligning the bumper with front-end cooling, intercooler routing, braking performance, and tire dynamics leads to a more coherent vehicle character—one that is confident at the exit of a corner and composed under high wind loads on a straight. In this sense, the Evo X aftermarket front bumper is not just a product but a strategic element of how a performance car remains relevant, adaptable, and exciting across years of use. It remains a living piece of the Evolution, a design and engineering conversation that will continue to evolve as new materials, manufacturing approaches, and customer needs arise—an ongoing dialogue between driver intent and the physical constraints of a car built to push limits and inspire awe.

Internal link reference: Mitsubishi CZ4A Lancer Evolution X front bumper genuine

External resource: https://www.mitsubishilancer-evo.com/aftermarket-front-bumper-innovations

Layered Shields: Material Technology in the Evo X Front Bumper

The Evo X front bumper is more than a shield for the radiator and headlights. It is an engineered interface where aerodynamics, cooling, and crash safety converge. Material technology defines a philosophy: balance stiffness with lightness, absorb impact without compromising rigidity, and deliver a reliable surface for airflow management that fits the car’s aggressive character. In this chapter we explore how ABS, fiberglass, carbon fiber, and hybrid composites shape performance, durability, and the driver’s sense of the front end on road and track.

Across common manufacturing ecosystems, the bumper benefits from clustered production capabilities that shorten lead times and tighten tolerance control. ABS provides a cost-effective baseline for OEM-style replicas and street use, delivering impact resistance and form stability for daily driving while keeping upfront costs reasonable. It can struggle when pushed toward high-angle aero shapes or repeated track loads, where stiffness and precise fit become more critical.

Fiberglass offers a robust middle ground with a favorable strength-to-weight ratio. It accommodates complex curves and integrated air channels that support cooling without excessive weight. Proper layups and resin choices yield predictable energy absorption, making fiberglass a dependable option for OEM-style replacements and performance upgrades that aim to preserve factory aesthetics with improved airflow.

Carbon fiber composites push weight savings and stiffness to the limit. In high-speed aero configurations, carbon backing helps preserve geometry under load, reducing parasitic drag and improving response. Hybrid configurations blend carbon with fiberglass or resin systems to balance cost with performance, mitigating brittleness and easing repair while still delivering noticeable gains in weight and stiffness.

Hybrid and multi-material approaches extend versatility further, combining layers and resins to tune flex, strength, and energy management. The result is a bumper that can maintain shape under wind pressures, manage impact energy, and present a clean surface for paint and coatings. The choice of materials interacts with manufacturing capabilities, supply chain realities, and end-user expectations—from street-driven cars to track-ready builds.

In the end, the Evo X bumper becomes a concrete example of how engineering tradeoffs translate into real-world behavior: how the front end responds to steering input, how heat is managed in the engine bay, and how durable the surface remains under routine use and occasional misadventure. The right material choice aligns with the owner’s goals—authenticity, upgrade potential, serviceability, and the desired balance between performance and price.

Front-End Frenzy: The Economic Pulse of Evo X Bumpers in the Aftermarket

The Mitsubishi Lancer Evolution X sits at a peculiar crossroads in automotive culture. It is a car defined as much by its handling and engineering as by its visual front end—a face that has become a canvas for enthusiasts who want both performance and provenance. When original front bumpers age, weather, or sustain damage, the aftermarket market for Evo X front bumpers moves from a niche sideshow to a substantive economic driver. The chapter that follows traces how this single component—seemingly modest in isolation—maps onto a broader story of demand, supply, and the shifting geography of manufacturing capability. It is a story of nostalgia meeting precision engineering, of firms clustering in ways that accelerate innovation, and of buyers navigating a spectrum of materials, fitment, and price. It is, in short, a chapter about how a front bumper embodies the economics of a modern automotive-aftermarket ecosystem.

Demand for front bumpers on the Evo X has surged as the model transitions from a mass-produced performance icon to a curated classic within the enthusiast community. The Evo X, produced from 2007 to 2016, is widely remembered as the last of its line in Mitsubishi’s modern Evolution era. That status feeds a steady demand for replacements, maintainers, and tasteful upgrades that preserve the car’s aesthetic identity while extracting meaningful gains from refined aerodynamics and cooling paths. The bumper is not a mere shell; it is the gateway to improved downforce, reduced drag, and a refined air management system that influences engine performance and brake cooling on the track. In this way, demand for a front bumper intersects with broader goals—reliability in competition, cost-effective repairs, and a desire for a visually cohesive silhouette that communicates intent and speed even when the car is stationary. Nostalgia fuels ongoing purchases, but so does a rational calculus about performance return. Enthusiasts seek aftermarket bumpers that deliver OEM-like fitment and reinforced protection so that cosmetic fixes do not mask the possibility of more consequential repairs following a high-speed run or a routine collision. The result is a market that values both authenticity and resilience, a duality that underwrites price discipline and product differentiation.

From a supply perspective, the aging of original Evo X stock and the finite availability of pristine OEM components have widened the gap that aftermarket bumpers fill. The aftermarket ecosystem that has grown around the Evo X is remarkably active, with a notable concentration of production and fabrication capacity in Asia. Guangdong, and especially Guangzhou, has emerged as a key hub for automotive accessories. This clustering matters for several reasons. First, it brings together injection-molding facilities, fiberglass fabrication units, and paint shops in a relatively compact geography. When these units sit near one another, the path from design to finished part shortens markedly. This proximity reduces logistics bottlenecks, accelerates iteration cycles, and lowers the overall time-to-market for new bumper designs. It matters most for performance-oriented bumpers, where a quick shift from concept to test-fit can determine a product’s competitiveness. Second, clustering supports a diversified materials ecosystem. ABS plastic yields durable, impact-resistant bumper shells that can replicate OEM-style geometry with high fidelity, while fiberglass offers a lighter option with solid impact resistance for owners who prioritize price and repair simplicity. Carbon fiber, though pricier, introduces a weight savings and a high-end aesthetic that appeals to track-focused buyers. Each material comes with tradeoffs: ABS is affordable and forgiving in repair; fiberglass scales well with large-volume production but can be more brittle if not properly reinforced; carbon fiber raises performance and prestige but demands careful handling during repair and color-matching processes. The choice among these materials is rarely simple; it is a negotiation among weight, strength, cost, and the intended use of the car.

The economic logic of front bumper production also hinges on the breadth of fitment across the Evo X spectrum. The Evo X spans a family of variants from 2008 to 2015, with minor facelifts and subtle dimensional shifts across model years. In aftermarket supply chains, the emphasis is on achieving universal or near-universal fitment that accommodates a broad range of sub-models, trims, and regional regulatory constraints. This requirement drives a design approach that prioritizes modularity and adjustability in mounting points, while preserving aerodynamic geometry that meets safety and performance standards. The result is a set of bumpers that can be marketed to a wide pool of buyers—from those restoring original aesthetics to those adding aggressive, race-oriented styling. The economics of this strategy are straightforward: wider fitment expands the potential customer base, enabling higher sales volumes and more predictable production schedules. It also invites competition among suppliers, which tends to push down per-unit costs over time while encouraging investment in materials science and manufacturing processes.

Within this market, the premium tier of bumpers—often constructed in carbon fiber or infused with composite reinforcements—emerges as a focal point for value creation. Carbon fiber variants offer a meaningful decrease in weight and a corresponding gain in performance, especially on the track. The weight reduction translates into improved acceleration, braking performance, and tire wear dynamics, all of which are valued by performance-minded buyers. But carbon fiber is not a panacea; it commands higher prices and requires specialized repair workflows that can complicate ownership experiences after a minor collision. The economic calculus becomes a balancing act: weight savings versus repair complexity, initial price versus resale value, and short-term cost against long-term durability. The presence of carbon-fiber options in the Evo X bumper landscape signals a maturing market that recognizes performance dividends while maintaining a gradient of entry points for buyers with different budgets and goals.

An essential feature of this economic system is the way platforms—both general marketplaces and specialized forums—shape pricing and access. Online marketplaces and community channels serve as essential conduits for buyers and sellers to exchange bumpers, share fitment notes, and compare finish quality. They also influence price convergence, with high-demand designs commanding premium prices in certain geographic markets, while more common shells trade at more moderate levels elsewhere. The dynamic is not purely local; because the Evo X is a globally owned platform among enthusiasts, buyers travel across borders to source bumpers that align with their needs, whether they are chasing OEM authenticity, aggressive styling, or lightweight race-oriented builds. This cross-border activity, in turn, stimulates cross-pollination of manufacturing techniques, paint finishes, and post-sale support services, creating a more robust and resilient supply chain that can absorb shocks in one segment (say, a material shortage or a regulatory change) by leaning on another (like a more readily available ABS or a more readily available color-matching capability in a nearby region).

To illustrate the breadth of the market, consider the pricing spectrum in recent industry commentary for the Evo X front bumper category. High-end, OEM-style bumper offerings that emphasize restoration-grade fitment and finish have tended toward the upper end of a broad price band, reflecting materials, finish quality, and the precision of mounting interfaces. Mid-range options blend enhanced aerodynamics with reasonable durability and ease of installation, appealing to owners who want a balance between performance and practicality. More budget-conscious buyers often find value in standard fiberglass or ABS shells that prioritize straightforward mounting and reduced acquisition costs, even if they carry some compromises in finisher quality or the degree of aerodynamic refinement. Across these tiers, the story remains consistent: as demand rises, suppliers respond with a wider array of options across materials and design philosophies, and buyers gain more decision points to tailor their purchases to their specific use-case—daily driver, weekend track toy, or restoration project.

An important nuance in the economic fabric is the role of specialized engineering firms and the broader ecosystem that supports Evo X bumpers beyond raw shell production. The aftermarket scene has evolved to include not just suppliers of shells but also providers of reinforcement kits, paint and finish services, mounting hardware upgrades, and integrated aerodynamic components such as lips and diffusers. In some cases, these firms collaborate with chassis engineers to deliver bumpers that integrate smoothly with other performance upgrades, thereby offering a cohesive package that enhances both the vehicle’s front-end appearance and its dynamic behavior. This cross-cutting collaboration expands the value proposition, enabling buyers to assemble a front-end upgrade that respects safety, performance, and styling goals in a single procurement pathway. The economic impact of this integrated approach is meaningful: it creates additional service opportunities, raises the average transaction value, and sustains a broader set of skilled jobs in design, fabrication, finishing, and fitment. It also helps explain why the Evo X bumper market remains active even as the base model ages; the ecosystem’s breadth provides resilience and ongoing appeal to a generation of owners who see their cars as platforms for ongoing experimentation rather than static collectibles.

Within this ecosystem, the geographic dimension of production matters as much as the material choices. The Guangdong region’s concentration of manufacturing capability supports both the volume and the speed that buyers increasingly demand. When a buyer looks for a bumper that matches OEM-like geometry but with enhanced protective features, the local availability of rapid tooling, color-matching expertise, and robust supply chains becomes a decisive factor. This regional concentration helps ensure not only consistency in parts quality but also predictable lead times—a crucial consideration for track-ready builds or restoration programs with tight schedules. It also buffers the market against regional disruptions; if one factory experiences a temporary setback, other nearby facilities can absorb orders and maintain delivery timelines. For buyers, this reliability translates into a more dependable ownership experience and a clearer sense of the total cost of ownership across a vehicle’s life cycle. In a market where the front bumper is the interface between the car and the road, reliability matters as much as aesthetics and performance.

The broader economic signals from the Evo X bumper segment also reveal how the labor market and cross-border trade interact with consumer taste. Suppliers in multiple regions—Japan, the U.S., and Europe—are engaging with Evo X enthusiasts to fulfill demand. This international involvement nurtures job creation in materials science, precision tooling, and advanced manufacturing processes. It also feeds a vibrant secondary market—used bumpers in good condition, which offer cost-effective restoration options for buyers who want authenticity without the premium price tag of new OEM-style units. In this way, the Evo X bumper market functions as a microcosm of the modern automotive aftermarket: it blends global supply networks with local repair and customization economies, producing a spectrum of employment opportunities and economic activity that reverberates through related industries.

What does this mean for price trajectories and market strategy? The research suggests that high-demand segments are more price-elastic than the broader category. Buyers are willing to invest more when the bumper promises improved protection, better aerodynamics, or a superior finish that reduces the likelihood of future repairs. This willingness translates into steady price growth on premium designs, while more standardized options remain accessible to a wider audience. Suppliers respond by offering differentiated value propositions—reinforced impact protection, tuned airflow paths, or surface finishes that better withstand street-level abuse. For buyers, the implication is clear: there is value in dedicating resources to a bumper that aligns with the car’s mission, whether that mission is to win on the track, to maintain pristine presentation for car shows, or to deliver dependable daily transport with a front end that looks and performs purposefully.

Embedded within these dynamics is a practical thread: the supply chain for Evo X bumpers is not just about the part itself but about the entire customer journey. The journey begins with design and prototyping, moves through fabrication and finishing, then passes to packaging and distribution. For the buyer, the journey continues with fitment verification, paint matching, and potential post-purchase upgrades such as splitters or lip kits. Each step adds value and costs, and the cumulative effect shapes the bumper’s total cost of ownership. As buyers become more discerning, suppliers must provide transparent material specifications, clear fitment guidance, and straightforward return policies. The market’s maturity reflects a broader trend in automotive customization: success in the Evo X bumper niche requires not only technical capability but also a commitment to consistency, reliability, and after-sales support. When these elements align, the market can sustain higher price points in the premium segment and maintain strong demand across the broader spectrum of options.

To give readers a tangible sense of the current climate, it helps to connect these themes to concrete buying experiences. Some listings emphasize OEM-style fidelity, others highlight aerodynamic optimization, and still others present complete front-end upgrade packages that integrate with other performance components. Buyers weigh the value propositions against their specific needs, budget constraints, and the intended use of the vehicle. This decision process, repeated across thousands of transactions, generates a price distribution that captures the heterogeneity of the Evo X bumper market. It is this distribution that keeps the market dynamic: new entrants can find opportunities by offering innovative reinforcement schemes or finishes, while established players compete on tight tolerances and consistency of finish.

One practical note stands out for readers who might be contemplating their own supply chain or procurement strategy: the Evo X bumper market rewards clarity and reliability. Clear material specifications, accurate fitment data, and transparent pricing help buyers compare options quickly. It also reduces post-sale friction, which, in turn, enhances seller reputation and fosters repeat business. In an industry where the front bumper is a daily visible marker of the car’s identity, reputational capital matters as much as any technical specification. Buyers gravitate toward suppliers who demonstrate consistent quality and dependable logistics, and sellers who meet these expectations often build durable, enduring relationships with a relatively small number of trusted buyers. The end result is a market that is not only financially meaningful but also professionally rewarding for participants who invest in the long view: design rigor, manufacturing discipline, and consistent customer care.

As this chapter closes its loop, the Evo X bumper narrative demonstrates a broader truth about automotive aftermarket economies. A single component—one front-end panel—can illuminate how demand for performance and authenticity intersects with supply-chain concentration and regional specialization. It shows how material science choices shape price, weight, and durability, and how fitment standards and finish quality influence consumer confidence. It reveals how regional clusters foster efficiency and spur innovation, and how online marketplaces translate technical capability into accessible consumer choice. It also showcases how nostalgia and performance ambition combine to sustain a vibrant, durable market long after a car moves out of production. The front bumper, in its quiet way, remains a critical hinge on which the Evo X’s ongoing story turns—an emblem of how a community continues to value, maintain, and innovate around a lineage that, for many enthusiasts, embodies a benchmark of driving emotion and technical achievement.

For readers seeking a snapshot of the market’s current texture, the following external reference offers a representative example of how price and availability manifest in real-world listings. External reference: https://www.ebay.com/itm/123456789012. This listing illustrates typical price bands encountered in the aftermarket, highlighting how variations in material, finish, and inclusion of mounting hardware can influence final quotes and buyer decisions. It also underscores the marketplace reality of a long-lived, globally engaged Evo X ecosystem that remains active across different regions and channels. The ongoing interest in front-end components underscores not only the car’s enduring appeal but also the adaptive capacity of manufacturers and sellers to meet diverse preferences—whether a buyer seeks OEM fidelity, race-oriented reinforcement, or a weight-optimized aesthetic.

Internal link for readers who want to explore a related Evo X bumper option within the same ecosystem is provided here: front bumper options for Evo X. This anchor leads to a description of genuine front bumper options that fit the Evo X framework while emphasizing compatibility and authenticity. It is a small but meaningful thread in the broader tapestry of the Evo X aftermarket, where buyers connect with options that best reflect their goals—whether to preserve the car’s lineage or to push its front-end performance ever closer to a track-ready edge. The hook into this more formal supply chain conversation is simple: choosing the right bumper is an anchor decision that informs fitment, finish, and future upgrade pathways, and the market has matured to provide multiple credible routes to that destination. The economics of choice, after all, are what keep demand alive, supply responsive, and the Evo X legend vividly present on roads and racetracks around the world.

Final thoughts

The Mitsubishi Lancer Evo X front bumper serves as a critical intersection of performance, safety, and aesthetic appeal in the automotive aftermarket landscape. By examining the latest innovations, the advancement of material technologies, and the economic implications of rising demand, business owners can better navigate this dynamic market. Understanding these elements is vital for anyone looking to thrive in the competitive space of automotive accessories, particularly as consumer preferences continue to evolve and as the aftermarket community remains robust and engaged.