The Mitsubishi Lancer Evolution X (Evo X) stands as a symbol of automotive excellence, particularly for enthusiasts and businesses alike. With its legacy being a benchmark in performance, the demand for both OEM and aftermarket parts continues to thrive. This guide delves deep into the essentials of Evo X parts, focusing on sourcing, upgrading, and maintaining these vehicles. In the chapters ahead, we will explore the significance of using OEM parts for reliability, the potential of high-performance aftermarket upgrades, and the best manufacturing hubs in China for sourcing these components, equipping business owners with the necessary knowledge to maximize their investment in the Evo X market.

Blueprints of Reliability: OEM Parts Preserve the Lancer Evolution X’s Performance Identity

Blueprints of Reliability: In the evolving world of high-performance sedans, the Lancer Evolution X stands as a measured promise of engineering discipline. This chapter traces how genuine OEM parts—the factory-engineered building blocks—anchor the car’s legacy long after production ceased. The Evo X is celebrated for its precise balance of power, handling, and daily livability. That balance stems from parts designed and manufactured to Mitsubishi’s exacting tolerances, from the engine internals to the finely tuned suspension and the high-temperature stamina of braking assemblies. When owners choose OEM components, they invest in consistent fit, predictable behavior, and a restoration or rebuild path whose outcomes align with the car’s original intent. The objective is not merely replacement; it is the deliberate preservation of the Evo X’s engineered DNA, ensuring safety, reliability, and performance across daily driving, occasional track sessions, and long-term ownership alike.

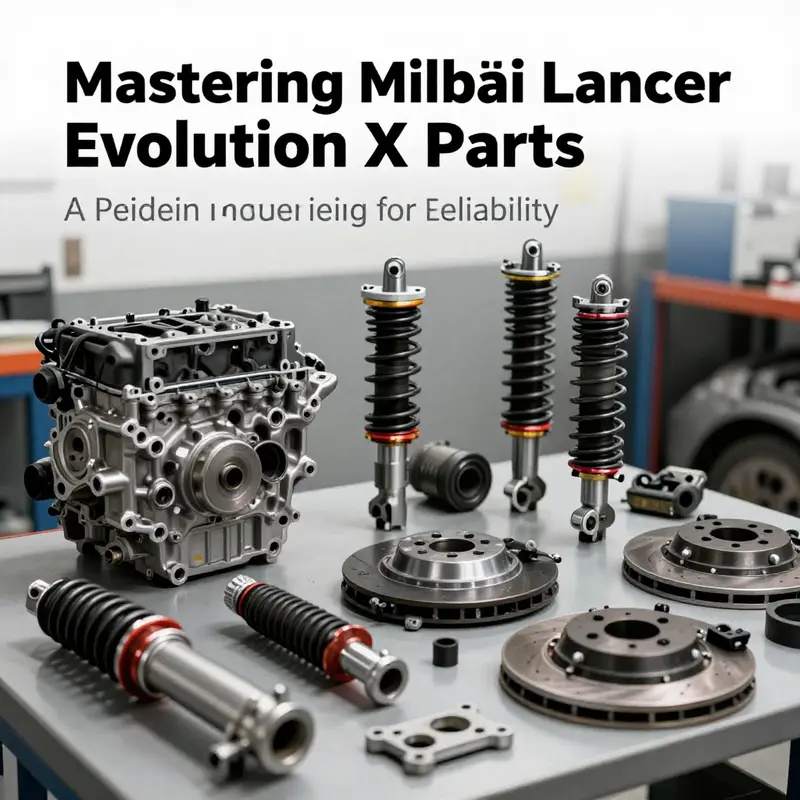

The essence of OEM parts lies in precision. These components are engineered to exact factory tolerances, meaning a piston, a gasket, or a timing element is machined to the same dimensions that left the assembly line. In a turbocharged, all-wheel-drive platform like the Evo X, even minor deviations can ripple through ignition timing, boost response, and rotational balance. OEM engine components—pistons, connecting rods, head gaskets, timing chains, and cylinder head pieces—are crafted to withstand the turbocharged environment while maintaining the intended compression and seating geometry. The payoff is simple and fundamental: reliability. When a factory cap, seal, or valve train element aligns with the original design intent, the risk of misalignment or unintended wear decreases markedly. The result is a drivetrain that behaves as Mitsubishi engineers envisioned and a powerband that remains linear, predictable, and approachable for both daily commutes and spirited back-road sessions.

Equally crucial is the Evo X’s suspension anatomy, which blends rally-bred character with street-friendly ride quality. OEM dampers, springs, control arms, sway bars, and bushings are calibrated to preserve not only ride height but also the geometric relationships that manage tire contact and weight transfer. In a car that uses a sophisticated all-wheel drive system to modulate grip across a spectrum of road surfaces, maintaining proper suspension geometry is essential. OEM components keep the alignment, roll stiffness, and dynamic toe curves aligned with factory intent, thereby protecting the chassis’ handling balance and the system’s ability to coordinate front-to-rear grip. This is not about rigidity for its own sake; it is about preserving the intended interaction between steering effort, chassis compliance, and the Neo-RWD-inspired feel of the Evo X under load. The payoff is a steering economy that remains communicative, a cornering attitude that respects the vehicle’s weight distribution, and a ride that tolerates long sessions without fatigue.

Braking systems illustrate a similar devotion to engineered accuracy. The Evo X’s factory braking hardware is designed to handle heat buildup, fade resistance, and friction stability under high-speed, aggressive driving. OEM rotors, calipers, and pads are matched to the car’s mass, weight distribution, and cooling characteristics. In the context of track days or spirited weekend sessions, the reliability of these components translates into consistent stopping power and predictable thresholds, which are essential for confidence and safety. Choosing OEM braking parts helps preserve the car’s braking torque curve, pedal feel, and thermal resilience, ensuring that braking performance remains within the established envelope that the original development team validated. The resulting driving experience feels cohesive: a chassis that stops with the same intent it exhibits when accelerating, turning in, and exiting a corner.

Beyond the immediate mechanical benefits, OEM parts offer a coherence that matters for long-term ownership. Authentic components are designed with emissions compliance and regulatory considerations in mind, ensuring that the Evo X remains within the bounds of its intended use across regional markets. This alignment is especially pertinent for enthusiasts who plan periodic inspections, homologation checks, or dedicated track events in jurisdictions with strict standards. When genuine parts are installed, the vehicle’s systems—fuel delivery, ignition controls, turbocharging, and exhaust interactions—operate within the calibrated corridors laid out by Mitsubishi. The predictable integration of these parts reduces the likelihood of unintended performance deviations, such as shifts in fuel trim or unintended boost spikes, which can arise when non-OEM pieces fit loosely or interact unfavorably with control algorithms. In short, OEM components safeguard a broader ecosystem: the engine management, the transmission behavior, the all-wheel-drive dynamics, and the chassis’ stability controls, all working in concert as they did from the factory.

The sourcing side of OEM reliability cannot be overlooked. When owners pursue genuine parts, they enter a supply chain built on traceability, quality control, and long-term support. In the context of the Evo X, sourcing decisions extend beyond a single replacement item to a holistic maintenance philosophy. OEM components are backed by manufacturing processes that emphasize consistent material composition, controlled heat treatment, and stringent dimensional checks. The assembly lines that produced these parts adhered to standards designed to ensure interchangeability across production runs, which means that a replacement piece will align with the same assembly points, mounting locations, and service intervals expected by the vehicle’s engineering documents. This consistency is key when a vehicle spans decades of ownership, as it reduces the cognitive load on technicians and the owner alike. It also reduces the risk of compatibility issues that can crop up when aftermarket parts, even if well-intentioned, diverge from the original engineering language. For examples of this principle in practice, OEM hood panels are designed to match the weight, pose, and crash-safety characteristics of the original structure, ensuring proper fit and crash performance alignment while preserving the car’s visual integrity and aerodynamic profile.

In the modern supply landscape,OEM parts are increasingly distributed through global networks that emphasize regional manufacturing hubs and transparent quality standards. The Evo X’s story fits squarely into that framework: components manufactured to precise specifications travel through vetted channels, with credentials that can be traced back to the production floor. This traceability has real-world value. It means a buyer can verify material provenance, review certification documentation, and confirm that the part aligns with the exact spec of the original component. The result is a maintenance or restoration path that respects the car’s original engineering and avoids the uncertainties that can accompany re-engineered equivalents. The Evo X becomes not just a car but a blueprint, a reference instrument for engineers and hobbyists who want to maintain, restore, or modestly upgrade without compromising the fundamental design language that defined Mitsubishi’s performance ethos.

A practical lens on sourcing highlights the realities of procuring OEM parts in a globalized market. While the appeal of factory fidelity remains, the path from factory to garage is mediated by a complex web of suppliers, distributors, and quality checks. In regions with well-developed automotive manufacturing ecosystems, OEM components emerge from manufacturing clusters where CNC machining, forging, and precision casting are routine. The result is a reliable pipeline that supports both fresh builds and preservation projects. For procurement teams, the criteria extend beyond price. ISO certifications verify process discipline; traceability records ensure material origins; and a proven track record in automotive exports demonstrates reliability in large-scale distribution. These are the markers that separate durable, factory-aligned parts from items that merely resemble the original. The Evo X’s maintenance narrative then becomes a story of stewardship—protecting a legacy by upholding the standards that made the car a benchmark in its era.

In the broader context of the Evo X ecosystem, evidence of OEM reliability can be found in the way restoration and preservation specialists articulate their approach. They emphasize the importance of preserving the driving experience—how the steering, throttle response, and brake modulation feel when the car is rolled onto a winding road or a track chalked with cones. The goal is not to replicate a showroom experience, but to achieve the same measured, repeatable performance that Mitsubishi designed. This requires parts that behave as an integrated system rather than as isolated pieces. An engine rebuild that uses OEM cylinders and gaskets, for instance, preserves the intended compression and sealing characteristics, while a suspension refresh that retains the original geometry keeps steering response predictable and consistent with the car’s mass distribution. The end result is a vehicle whose performance metrics—torque delivery, cornering grip, braking confidence—remain faithful to the original engineering values, even as the car ages into a new era of ownership and use.

As we navigate the balance between factory fidelity and the desire for occasional upgrades, it is important to note how this tension shapes decisions about parts and process. Some Evo X owners opt for OEM replacements during routine maintenance to safeguard long-term reliability. Others pursue selective upgrades—still within the OEM framework—such as upgrades to components that wear most under use, provided those choices preserve the integrity of tolerances and fitment. Even when upgrades are considered, the guiding principle remains intact: retain the vehicle’s engineered harmony. This means paying attention to how a modification interacts with control systems, weight distribution, and the vehicle’s stability management suite. The objective is to maintain—or even enhance—predictable behavior, without undermining the very attributes that defined the Evo X as a performance icon. Maintaining that harmony keeps the Evo X not merely fast, but reliable and authentic to its original design intent.

For those who think beyond the immediate mechanicals, OEM parts also support a practical maintenance life cycle. They simplify diagnostic work because technicians can rely on consistent interfaces, mounting points, and electrical connections. This consistency translates into fewer misalignments, fewer compatibility surprises, and shorter repair intervals. In a world where time is money and reliability is a condition of safety, OEM parts offer a clear advantage. They provide a platform for informed budgeting, predictable upkeep, and a maintenance rhythm that respects the car’s advanced systems while allowing owners to enjoy the kind of driving experience that drew them to the Evo X in the first place. This is the deeper value of factory engineering: not only does it support peak performance, it also folds longevity into the ownership story.

In closing this thread of the Evo X’s OEM-centric narrative, the car’s enduring appeal rests on a simple premise: when genuine factory components fit the car as intended, the vehicle performs with integrity, balance, and confidence. The final chapter in Mitsubishi’s performance sedan saga remains alive in the workshop as much as on the road, because the parts that built it continue to define how it moves, stops, and communicates with the driver. The Evo X invites ownership that respects engineering discipline, honors the car’s original intent, and embraces a maintenance culture where every replacement part serves as a trusted link in a meticulously engineered chain. This is the essence of reliability for a legend that still demands respect on every mile.

Internal link note: For a practical reference on OEM compatibility related to body panels and hoods, see the Evo X hood listing with authentic factory-fitment details here: OEM Evo X Hood (U02).

External resource: For an overview of OEM part guidelines and broader context beyond the Evo X, consult the official OEM parts landscape from Mitsubishi Evo resources at https://www.mitsubishievo.com/oem-parts/.

Upgrades that Transform the Evo X: Power, Handling, and Race-Ready Presence

Upgrades that Transform the Evo X: Power, Handling, and Race-Ready Presence

The Lancer Evolution X was conceived as a purposeful performance sedan. Its platform rewards precise upgrades that amplify speed, grip, and driver feedback while preserving daily usability. High-performance aftermarket modifications for the Evo X fall into a few overlapping objectives: increase usable power, improve thermal management and reliability, sharpen handling and stability, reduce unsprung and rotational mass, and refine the car’s visual and lighting presence. Each mod should be considered in the context of the whole car. A bigger turbo must be matched with fueling, cooling, and drivetrain upgrades. Wider tires demand suspension geometry and fender clearance changes. Lighting and cosmetic upgrades need proper fitment to maintain aerodynamics and serviceability.

Begin with clear goals. Are you building a weekend track car, a fast street rally tribute, or a show-quality machine? Goals determine choices and budgets. For track-focused builds, prioritize robust cooling, a strengthened transmission, and progressive brakes. For street machines, aim for incremental power gains, adaptive suspension, and subtle aero. For show builds, weight-saving exterior components and dramatic lighting will achieve the desired look while retaining reliability if properly integrated.

Power upgrades should start with airflow and fueling. A high-flow intake coupled with improved intercooling lowers charge temperatures and reduces detonation risk when increasing boost. Upgraded fuel injectors and an upgraded fuel pump support higher horsepower by ensuring consistent fuel delivery. Moving beyond bolt-ons, a larger, more efficient turbo engages a new level of torque and top-end power, but it increases thermal load and stress on the engine. That requires stronger internal components and a comprehensive tune calibrated on a dyno. Equally important is a robust exhaust system with optimized flow and backpressure characteristics that complement the turbo and tune. Each of these elements must be chosen with the engine’s safe operating limits in mind.

Thermal management and engine durability are non-negotiable. Upgraded intercoolers, oil coolers, and improved radiator cores reduce the risk of heat soak during sustained hard driving. Heat extraction vents and functional scoops help channel airflow through the engine bay to aid cooling. If increased boost is planned, consider reinforced engine internals and a proper cooling strategy before chasing power figures. A conservative, well-executed approach yields a car that performs reliably on track and in spirited street use.

The driveline must follow the power. The Evo X’s all-wheel drivetrain delivers traction, but clutches, differentials, and axles have limits. Upgraded clutch assemblies provide higher clamp force and better heat dissipation for repeated aggressive launches. Limited-slip and torque-vectoring-friendly differential upgrades can control power distribution more predictably during cornering and under heavy throttle. Strengthened half-shafts and attention to transmission cooling help prevent failures when power increases substantially.

Handling upgrades are where the Evo X truly rewards investment. A high-quality coilover or adjustable dampers system lets you dial compression, rebound, and ride height to suit driving conditions. Sway bars and reinforced control arms reduce body roll and improve turn-in precision. Attention to bushings—especially replacing worn rubber with performance-grade alternatives—sharpens the car’s responsiveness. While lowering improves center of gravity, correct alignment settings and camber kits are vital to maintain tire contact patch and prevent premature tire wear.

Wheels and tires form the final link to the road. Lightweight forged wheels reduce unsprung mass and rotational inertia, enhancing acceleration and steering response. Wider wheels accommodate high-performance tires that increase mechanical grip and lateral stability. Tire selection should balance compound, tread pattern, and intended use. Track tires deliver grip at the cost of reduced longevity and cold-weather performance, while high-performance street tires provide a useful compromise. Proper wheel offset and backspacing ensure clearance with suspensions and wider fenders.

Aero and chassis stiffening upgrades work together to keep the Evo X composed at speed. Front splitters, rear diffusers, and wing elements can add downforce and reduce lift. These parts should be selected for function rather than purely for looks. A composite hood with heat extraction vents reduces front-end weight and aids engine cooling. For owners wanting a production-quality fitment, OEM-fit composite hoods are available and deliver a factory-like finish with performance benefits. When fitting widebody kits, consider not just the look but the structural changes required for wheel fitment and suspension travel.

Lighting and interior upgrades improve usability and the overall driving experience. Modern LED headlights enhance nighttime visibility and offer a distinct identity. Interior upgrades focused on driver support—such as bolstered seats and harness-ready mounting—improve stability during spirited driving. Adding instrumentation for boost, air/fuel ratio, and oil temperature gives the driver data to protect the engine. Entertainment and comfort upgrades should not interfere with essential controls or add excessive weight.

Braking upgrades are critical when power and speed increase. Larger rotors, high-friction pads, and multi-piston calipers improve fade resistance and stopping power. Braided stainless lines reduce pedal squish, delivering a firmer, more consistent feel. Cooling ducts that direct air to the brakes help during repeated high-speed stops. Brake upgrades must be matched to wheel size and vehicle balance to avoid unsettling the car under heavy braking.

Integration matters. Many performance parts alter vehicle behavior in subtle ways. For example, lowering the car reduces suspension travel and changes bump steer. Wider tires can alter steering weight and understeer characteristics. A measured, staged approach is the safest path: change one major system at a time, then test and tune. Professional alignment, corner balancing, and controlled testing yield a balanced end product. ECU recalibration is often the final and most important step. A proper tune accounts for all mechanical changes and preserves engine safety across operating conditions.

Sourcing parts demands a pragmatic procurement strategy. High-quality aftermarket materials now come from global supply chains. Manufacturing clusters offer a range of options in composite bodywork, forged internals, and precision-machined components. When buying at scale, prioritize suppliers with automotive certifications and transparent quality control processes. Request materials data sheets, dimensional drawings, and production samples before committing to larger orders. Inspection and third-party testing help verify claims about strength, fatigue life, and material composition.

For individual owners, buying from reputable vendors with documented fitment, return policies, and customer support reduces risk. For projects requiring exact OEM fit or a direct replacement, OEM-style composite components maintain factory tolerances and simplify installation. For highly modified builds that require bespoke geometry or reinforcement, custom fabrication and reinforced mounts will pay dividends in longevity.

Installation and alignment should be left to experienced technicians for major systems. Components that interact with safety systems, such as suspension and brakes, need calibrated installation and torque sequencing. ECU-supported modifications require dyno tuning and data logging to achieve safe and repeatable results. For owners who enjoy DIY projects, handle bolt-on changes first and work within your comfort level. Complex systems like engine internals, turbocharger swaps, and differential work are best handled by specialized shops.

Cost considerations span purchase price, installation, and ongoing maintenance. Some lightweight composite parts offer dramatic performance benefits at moderate cost, while precision forged internals and big turbo kits represent significant investments. Always balance the projected power gains against the expected lifespan of upgraded components. Warranties, serviceability, and local support matter when choosing parts that will be used regularly on the road or track.

Finally, respect regulations and insurance. Certain exterior and lighting modifications may affect compliance in some jurisdictions. Performance upgrades that materially change vehicle capabilities can impact insurance premiums and coverage. Keep documentation of parts, professional installation, and dyno reports to support insurance conversations and maintain resale value.

If you plan to source parts from international suppliers, use verified channels that list supplier certifications and performance records. For direct sourcing and supplier research, a major global B2B marketplace provides access to vetted manufacturers, factory profiles, and trade assurances. These resources simplify the process of finding quality composite hoods, wide-body kits, lighting assemblies, and precision machined internals while offering tools for supplier vetting and logistics planning.

For a readily available example of a performance hood option, consider reviewing the carbon fiber bonnet hood for Evo X listed by an established parts retailer: https://mitsubishiautopartsshop.com/brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x/ .

For broader supplier discovery and verification, explore a global B2B sourcing platform that connects buyers with vetted manufacturers and export-ready suppliers: https://www.alibaba.com

When upgrades are chosen thoughtfully and integrated carefully, the Evo X evolves from capable factory form to a bespoke performance machine. The best builds are not the loudest or the most extreme. They are the most coherent: every part harmonizes with the others, delivering speed, control, and a visceral connection between driver and machine.

China’s Manufacturing Clusters: Strategic Sourcing for Lancer Evolution X Parts

China’s Manufacturing Clusters: Strategic Sourcing for Lancer Evolution X Parts

Sourcing high-quality parts for the Lancer Evolution X requires a clear strategy that aligns component type with regional strengths. China’s industrial map is regionalized, and each cluster offers specialized capabilities, tooling, and ecosystems that make some provinces better suited to particular components. Matching your part needs to the right hub reduces risk, shortens lead times, and often lowers total cost of ownership. This chapter lays out a practical, integrated approach to sourcing Evo X parts from China, with a focus on technical fit, quality control, logistics, and long-term supplier relationships.

Begin by mapping the parts you need to the production strengths of specific regions. For engine internals and highly stressed mechanical components, look to provinces with deep CNC and forging expertise. For structural sheet metal, exhaust systems, and large assemblies, prioritize regions with strong die-casting, stamping, and welding clusters. For high-precision lighting, electronic modules, and decorative pieces, target areas known for consumer electronics and optics manufacturing. Understanding this alignment prevents costly mismatches between capability and expectation.

Guangdong province, with Guangzhou at its core, is the place to source high-performance aftermarket components that require vertical integration and R&D depth. Suppliers here commonly combine prototyping, small-series tooling, and assembly under one roof. That proximity shortens iteration cycles for fitment testing and allows faster ramp-up when variants are needed. If you plan to develop or re-engineer parts that must interface closely with the Evo X’s chassis or cooling architecture, Guangdong’s suppliers can often deliver functional prototypes and short-run production quickly. Their logistics advantage through nearby ports also simplifies export documentation and reduces lead-time variability.

Zhejiang province specializes in precision machining and forged components. Manufacturers in key cities run multi-axis CNC centers and closed-die forging lines. They are ideal for crankshafts, connecting rods, and other high-stress internals that must meet narrow tolerances and fatigue-life requirements. Zhejiang suppliers also lend themselves to collaborative engineering engagements. Expect them to provide material traceability, heat-treatment certifications, and fatigue testing data on request. When sourcing components that will be pushed beyond factory power levels, this region provides the metallurgical and machining competence necessary to avoid catastrophic failures.

Jiangsu excels at sheet metal forming, die-casting, and injection molding. Use suppliers here for exhaust manifolds, intercooler end tanks, body panels, and bracketry. Their tooling houses can produce consistent parts at scale, and they typically maintain robust press and weld capacity. If you need a body kit, diffuser, or structural mounting bracket that must retain precise geometry for alignment, Jiangsu often offers the best balance of production quality and predictable lead times.

Chongqing has grown rapidly as an industrial base for complete assemblies and drivetrain components. If your project involves larger subassemblies—turbocharger cores, assembled engine units, or drivetrain housings—Chongqing’s modern industrial parks and government-backed manufacturing capacity can deliver competitive pricing for volume runs. This region also supports integrated testing facilities, which can accelerate sign-off for complex assemblies that need thermal and vibration validation.

Shandong is a cost-effective option with strong machining resources and a track record of reliable deliveries. Suppliers in Shandong are often willing to support incremental innovation and can partner with local universities for material science inputs. For modular parts that require both machining and small-scale assembly, Shandong strikes a useful compromise between price and quality control.

From a procurement workflow standpoint, take a staged approach. Start with supplier qualification, using certifications and audits as filters. Require ISO or equivalent quality management evidence. For critical items, request process certifications and test reports, not just product photos. Minimum order quantities should be negotiated transparently. Many factories set MOQs to cover tooling amortization. Where MOQs are problematic, consider consolidated buys across multiple SKUs or pooled orders with other buyers to meet thresholds.

Sample validation is essential. Insist on functional samples before tooling begins. For engineered parts, prototypes should undergo fitment on a donor Evo X or a representative jig. Validate clearances, thread engagement, and sealing surfaces. For components that interact with the drivetrain or braking system, include endurance and thermal cycling tests. A one-time approval sample without documented testing is insufficient for safety-critical parts.

Tooling and molds represent a significant up-front cost. Negotiate tooling ownership and maintenance terms up front. If you expect design updates, build flexibility into the contract so progressive tooling changes are straightforward. Use short-run pilot tooling when validating new designs. This reduces the risk of expensive rework once full production begins.

Quality control protocols must be laid out in the purchase contract. Define incoming inspection criteria, acceptable defect levels, and nonconformance handling. For parts that will be subjected to stress, require material certificates and hardness testing. For cosmetic components, include color-matching standards and inspection photographs. Arrange third-party inspections at pre-shipment stages. Independent inspection firms can verify tolerances, perform sampling, and run checks that mirror your own quality expectations.

Intellectual property and design protection are sensitive concerns. Use non-disclosure agreements and, where possible, register designs or utility models in China to protect unique innovations. Keep core engineering work in-house or with trusted partners. When sharing CAD files, use limited-access platforms and watermark drawings. If tooling is created, clarify whether it remains your property or the manufacturer’s. Tool ownership disputes can lead to long-term supply chain friction.

Shipping strategy depends on lead time and component size. Air freight suits small, time-sensitive parts but increases cost. Sea freight economizes for large volumes or bulky items like body kits and intercoolers. Use consolidated shipping for mixed pallets. For heavy or high-value components, consider freight insurance and bonded warehouse options to smooth customs clearance near final markets. Leverage port clusters near the supplier to shorten drayage times and reduce handling.

Customs and compliance require attention. Ensure parts meet destination market standards, including emissions and safety regulations where applicable. Provide accurate HS codes and documentation to avoid delays. For lighting and electronic modules, confirm local homologation requirements. For structural components, ensure materials and markings meet import certificates demanded by your customs broker.

Supplier communication is critical. Frequent updates reduce surprises. Use milestone-driven schedules with clear acceptance criteria. Weekly status calls during ramp-up maintain alignment. When issues appear, seek root cause, corrective actions, and preventive steps. Document everything. A rigorous communication cadence helps transform transactional relationships into reliable partnerships.

Pricing negotiation should account for hidden costs. Ask for itemized quotations that separate material, labor, tooling, testing, and packaging. Include revision fees and rework rates. Negotiate payment terms that match your risk tolerance. Escrow or staged payments tied to milestones can protect both buyer and manufacturer.

Packaging matters more than it seems. Electrostatic-sensitive parts, precision machined pieces, and painted components need tailored packaging to avoid transit damage. Specify shock-rated crates, rust-preventive materials, and clear labeling to expedite inspection and warehousing on arrival.

After-sales support and warranties are part of long-term sourcing. Define warranty length and scope. For performance components, clarify exclusions and allowable operating conditions. Agree on return logistics and repair or replacement windows. A supplier willing to stand behind parts is more valuable than a marginal price saving.

Factory visits and audits remain among the most effective risk-mitigation tools. If feasible, schedule visits during production to observe quality systems, traceability, and worker skill. Factory tours also reveal hidden strengths, like in-house testing rigs or secondary processes that reduce the need for outside work. If travel is not possible, hire a local representative or audit firm for virtual or in-person inspections.

Finally, maintain a continuous improvement mindset. Track failure modes, warranty claims, and field feedback. Feed this data back to suppliers and use it to improve designs, coatings, or material selection. Over time, your supply base can evolve from order-takers to engineering partners, improving margins and product reliability.

If your program includes lightweight carbon fiber body panels, work with suppliers experienced in composite layup and autoclave curing. These workshops differ from metal shops and are often found in regions with strong motorsport and aftermarket aftermarket clusters. For a practical example of a locally manufactured composite item and its sourcing presentation, review this listing for a carbon fiber bonnet for Evo X. The page shows typical finishes and packaging used by reputable suppliers: carbon fiber bonnet for Evo X.

For buyers planning strategic, long-term sourcing, pair regional strengths with disciplined procurement. Use Guangdong for integrated prototypes and aerodynamic pieces. Use Zhejiang for forged internals. Use Jiangsu for sheet metal and molded parts. Use Chongqing for assembled drivetrains. Use Shandong for reliable, cost-effective machining. This alignment shortens development cycles and reduces technical surprises.

For a comprehensive look at China’s automotive aftermarket and supply chain dynamics, consult the strategic sourcing guide provided by global industry analysts. It offers maps, checklists, and procurement frameworks that complement the practices described here: https://www.globalsourcinginsights.com/china-automotive-aftermarket-2026

Adopt these sourcing practices to create a resilient parts program for the Lancer Evolution X. The right regional match, combined with rigorous quality controls and clear contractual terms, will produce parts that perform reliably on the road and at the track.

Final thoughts

The Mitsubishi Lancer Evolution X represents a unique opportunity for business owners involved in automotive parts. Understanding the balance between OEM reliability and aftermarket enhancements can lead to significant performance gains and customer satisfaction. By capitalizing on sourcing strategies from established hubs in China, businesses can ensure a steady supply of quality parts. As you navigate this landscape, consider the high-value investments in both original and aftermarket components to meet the ever-evolving demands of the performance vehicle market.