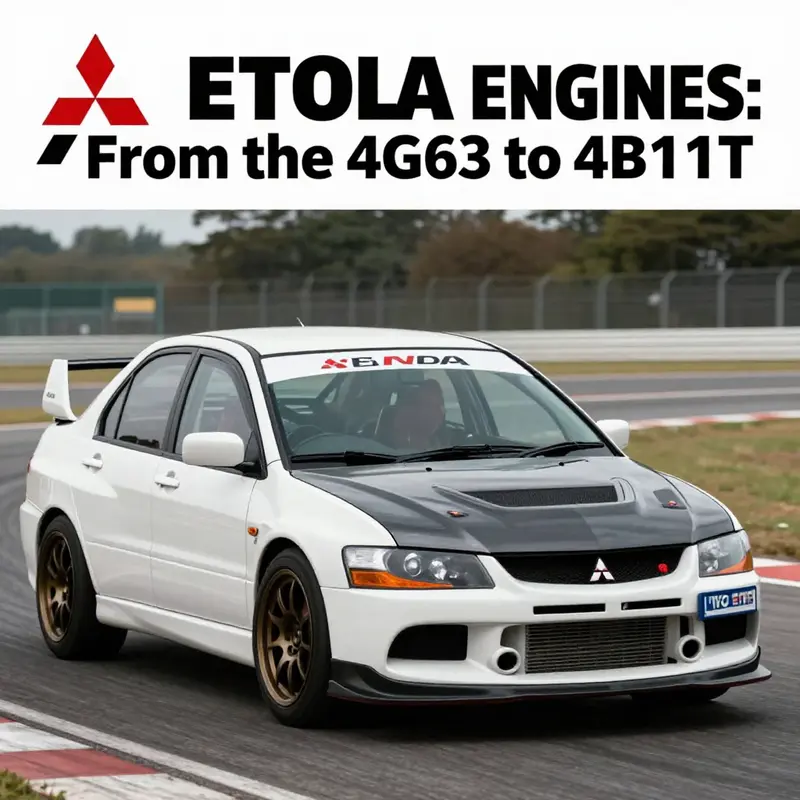

The Mitsubishi EVO series has carved out a legendary place in automotive history, particularly due to its innovative engine designs. Centred around two iconic powertrains—the 4G63 and the 4B11T—these engines demonstrate Mitsubishi’s relentless pursuit of performance and technology advancement. As we delve into their history, technical specifications, and the implications on aftermarket modifications, business owners in the automotive industry can gain valuable insights into both the solid foundation and the soaring heights of performance engineering. Each chapter will detail significant evolutions and innovations, ultimately highlighting how understanding these engines can impact business decisions and market strategies.

From Iron Heart to Modern Turbo: The 4G63’s Rise and the Evo Engine Legacy

The 4G63 did not arrive as a legend; it was forged into one. Born as a robust, naturally aspirated four-cylinder in the mid-1980s, the engine’s basic architecture set the stage for a two-decade-long dominance in rally and street performance. Its naming followed Mitsubishi’s logical code: four cylinders, gasoline platform, Sirius family, and model index. Those dry digits belie an engine with a rare combination of durability, tunability, and racing DNA. The cast-iron block, long-stroke geometry, and stout forged internals created a platform that could be pushed far beyond factory intent without sacrificing reliability. This structural integrity became the foundation of the Lancer Evolution’s character — torque-rich, tractable, and relentless under boost.

When Mitsubishi grafted a turbocharged, dual overhead cam head onto the 4G63 for the first Lancer Evolution, the result was transformative. Engineers did more than bolt on forced induction. They reworked valvetrain dynamics, upgraded fuel delivery and ignition, and improved cooling. The red-head 4G63 introduced into the Evo I was a new beast. Its long-stroke design favored midrange torque, a crucial trait for rallying where traction and tractable power often beat peak horsepower. This configuration allowed drivers to exploit a wide torque band without constant gear shifts. That practicality on loose surfaces and twisty roads translated directly into competitive advantage. The engine’s conversion from a sturdy commuter powerplant into a rally-proven turbo unit is a textbook case of engineering repurposing to meet motorsport demands.

Across successive Evolutions, the 4G63 evolved in measured, meaningful steps rather than radical overhauls. Each generation targeted specific weaknesses and optimized real-world performance. Early changes focused on airflow and spool: larger turbine housings, revised compressor wheels, and more efficient exhaust paths. Valve lift and timing adjustments improved volumetric efficiency. As boost was safely raised, fuel systems and engine management were upgraded to provide precise fueling and spark control. Cooling systems were enlarged and refined to sustain higher thermal loads during extended competition runs. These iterative improvements steadily moved the 4G63 from roughly 195 horsepower in its earliest Evo form to the 280-300 horsepower range in later iterations, while torque figures climbed into the mid-to-high 300 N·m territory in tuned trims.

The Evo II and III models exemplify the philosophy of incremental, targeted upgrades. Increased cam lift and stronger fuel pumps supported higher revs and richer fueling under boost. Engineers raised compression ratios and enlarged turbine inlets to extend the engine’s effective powerband. These were not flashy headlines but careful, performance-driven revisions based on track data and rally feedback. By the time the Evo IV appeared with a power figure flirting with the informal 280 horsepower limit of the era, the 4G63 had become a thoroughly modern turbo engine. The balance between internal strength and improved breathing allowed the factory to push outputs that matched — and often outperformed — competitors with larger displacement engines.

Beyond factory trims, the 4G63’s greatest contribution is its aftermarket life. Tuners quickly discovered that the engine’s iron block and robust internals tolerated significant increases in boost and power. The aftermarket responded with forged pistons, uprated rods, and billet crank upgrades. With appropriate fueling, cooling, and engine control, many stock 4G63s reached 400 horsepower without catastrophic failure. With deeper modification, these engines sometimes surpassed 700 horsepower. This capacity to scale made the 4G63 a darling of both dragstrip builders and rally teams. It also inspired a culture around the Lancer Evolution where upgrade potential was as much a selling point as factory specs.

The 4G63’s influence was not limited to Japan. Partnership projects and global production spread the engine across continents. In North America it powered sporty front-engine, all-wheel-drive coupes and sedans built through collaborations, winning affection in a market dominated by larger displacement units. The engine’s favorable power-to-weight ratio and tuning potential made it a favorite among enthusiasts who sought high performance without large V6 or V8 displacement. In Asia, the engine saw licensed production and adaptation, becoming a powerplant for a wide variety of locally produced vehicles. This global footprint entrenched the 4G63 as a cross-market workhorse, introducing its performance ethos to many automotive cultures.

Motorsport validated the engine’s pedigree. In the hands of skilled drivers and well-prepared teams, the 4G63 propelled the Evolution to multiple world rally victories. The synergy between the engine’s torque characteristics and the car’s drivetrain allowed drivers to exploit traction and maintain momentum through gravel, mud, and tarmac. The result was a period of dominance that cemented both the car and the engine in motorsport history. The engine’s success on stage elevated it from mere component to cultural symbol — the mechanical heart of a car that challenged rival manufacturers and redefined expectations for compact performance sedans.

This legacy led to broad recognition beyond racing circles. Publications and historians alike celebrated the engine as representative of a design philosophy that favored robustness and upgradeability. That assessment rings true: engineers prioritized a strong base configuration, enabling future development. The 4G63 therefore became a teaching tool for engine designers, a practical example of how material selection and geometry influence longevity and tunability. The lessons learned in developing and optimizing the 4G63 informed subsequent designs and influenced aftermarket engineering practices.

By the time the tenth-generation Evolution arrived, Mitsubishi turned a new page. The 4B11T replaced the iron-block 4G63. This new 2.0-liter, turbocharged inline-four featured an aluminum block and dual injection — direct and port — to balance power and emissions. Designed for modern regulatory and efficiency demands, the 4B11T still aimed to deliver competitive power and a lively driving experience. It introduced technologies that the older architecture could not easily adopt, including refined combustion strategies and weight savings for improved vehicle balance. The switch marked an industry-wide shift: high-performance engines increasingly needed to meet stricter fuel economy and emissions standards without sacrificing responsiveness.

The transition from 4G63 to 4B11T was not a repudiation of the past. Instead, it was a refinement for a new era. The legacy of the 4G63 informed the design priorities of the 4B11T; engineers sought to preserve the Evo’s hallmark traits — instant throttle response, usable torque, and robust character — while gaining the benefits of modern materials and injection technologies. The new engine delivered impressive factory numbers and maintained the Evo’s reputation for rapid acceleration and composure under load. Yet for many enthusiasts, the 4G63 remained an emotional benchmark. Its mechanical sound, its resistance to catastrophic failure, and its limitless tuning potential had created a generation of fans who equated that iron block with authenticity.

The story of the 4G63 is therefore twofold. It is both an engineering success and a cultural artifact. Its long-stroke design, cast-iron strength, and capacity for modification made it ideal for a car built around rally-derived dynamics. Its global spread brought its character to diverse automotive markets. Its motorsport achievements offered empirical proof of its capability. And when the era closed, it left a blueprint for balancing durability with performance. For anyone studying the evolution of high-performance four-cylinder engines, the 4G63 offers lessons in material choice, combustion strategy, and the importance of designing for upgrade paths.

For enthusiasts seeking original components today, there remains a strong market for complete 4G63T engines and rebuild parts. Those looking for donor engines or period-correct replacements often find dedicated listings and salvaged units marketed specifically for Evolution builds. One such source lists genuine low-mileage JDM 4G63T engines, complete with transmission and ECU, useful for restorations and swaps: genuine JDM low-mileage 4G63T engine listing. That aftermarket life, and the community that supports it, ensures the 4G63 will remain relevant for years to come.

Industry voices have echoed this sentiment. A modern retrospective described the 4G63 not just as a power unit, but as a distilled expression of a company’s engineering values. That view captures the engine’s double legacy: it is both a technological achievement and a symbol of an era. The follow-on engines carried the torch into a new regulatory and technological landscape. Yet the iron heart of the 4G63 still beats in the memories of tuners, racers, and drivers who learned to trust its dependability and relish its potential. For the Lancer Evolution and its followers, that engine remains the benchmark by which generations of performance four-cylinders are measured. (Further reading: Motor Trend’s feature “The Legacy of the 4G63: Japan’s Most Legendary Four-Cylinder” at https://www.motortrend.com/features/the-legacy-of-the-4g63-japans-most-legendary-four-cylinder/.)

From Tradition to Technology: How the 4B11T Rewrote the Mitsubishi Evo Engine Playbook

4B11T as Evolution, Not Replacement

When the series pivoted from the long-serving 4G63 to the 4B11T, it was not a simple engine swap. It was a deliberate redefinition of what an Evo powerplant could be. The 4B11T preserved the DNA of a rally-bred, turbocharged, high-performance four-cylinder while embracing modern combustion technology, tighter packaging and electronic control. The result was an engine that felt like a new chapter rather than a footnote — one that delivered sharper throttle response, broader torque bands and a platform better suited to contemporary emissions and fuel requirements.

The 4B11T is a 2.0-liter, inline-four, turbocharged engine designed with a modern combustion strategy. It combined direct injection with port injection to control knock, manage deposits and offer flexible fueling under high boost. That dual-injection approach reduced the trade-offs between peak power and real-world drivability. It also made high-boost tuning more predictable: injectors and fueling strategies could be tailored to both low-end response and high-rpm power without sacrificing throttle feel.

A defining mechanical choice was the turbo architecture. Instead of reverting to a single, large-entry turbine that favors top-end power at the cost of increased lag, the 4B11T employed a twin-scroll / dual-entry turbine design. This layout isolates exhaust pulses from paired cylinders, preserving energy and reducing turbine lag. The result is a more linear torque curve. Drivers experienced quicker spool and a crisper midrange without the addictive, abrupt surge that characterizes some older, big-turbo builds. This design choice was central to the Evo X’s reputation for tractable, usable power on road and track alike.

Thermal management and charge cooling were upgraded across the package. The 4B11T’s intercooler and coolant passages were engineered to handle higher sustained loads. A large front-mounted intercooler and an efficient water-cooling arrangement kept intake temperatures down during repeated hard runs. In practice, this meant less power drop-off under track conditions and more consistent ignition timing as intake charge temperature remained controllable. For a car whose heritage demanded repeatable performance under stress, those thermal gains mattered as much as raw horsepower.

Electronics unlocked much of the 4B11T’s potential. An advanced ECU with finely mapped boost control and an electronic throttle allowed precise modulation of torque delivery. For tuners, that translated to a flexible platform: the ECU could be reprogrammed to support a wide range of turbos, fueling strategies and safety limits. That capacity fostered a lively aftermarket, which quickly produced upgrades that widened the engine’s usable envelope. The factory calibration emphasized safety and drivability, but the chassis and ECU could reward measured intervention with substantial gains.

Internally, the 4B11T balanced lightness and strength. The use of aluminum-alloy connecting rods paired with a robust crankshaft and reinforced block geometry provided a compromise between rotating mass reduction and durability. While the factory internals support healthy power increases, enthusiasts aiming for very high outputs often upgrade to forged components and, in some cases, aftermarket billet blocks to address the loads of sustained high-boost operation. For builders approaching quadruple-digit horsepower targets, block and bottom-end reinforcement are common steps. For those curious about block upgrades, a dedicated billet-block resource provides useful context and parts: 4B11T billet block.

How the 4B11T compared to the 4G63 clarified the direction Mitsubishi had chosen. The 4G63 was a simple, brutally effective engine: iron block, forged internals in many trims, and a personality that rewarded straightforward turbocharging and bolt-on tuning. It was easy to understand and cheap to push. The 4B11T, by contrast, is more complex. Direct injection, tighter tolerances and a more modern head layout mean that some traditional tuning shortcuts no longer apply. But the benefits are clear: better packaging for modern emissions hardware, improved mid-range torque, and an engine that scales cleanly with sophisticated electronic and thermal upgrades.

Real-world performance figures underline the shift. Factory ratings vary by market and application, but the 4B11T left the assembly line capable of high two- to low three-hundred horsepower numbers in stock or lightly tuned trims. Special editions and dealer-backed conversions illustrated the platform’s headroom: properly calibrated and fortified, the engine delivered power that outpaced many larger-displacement V-configurations, demonstrating how forced induction and modern engine design can trump displacement alone.

The Evo X’s integration of the 4B11T into its all-wheel-drive system was more than packaging convenience. The engine’s flatter torque delivery and reduced lag allowed the drivetrain to manage wheel torque more predictably. That meant better traction under throttle transitions and more intuitive behavior when a driver modulated power mid-corner. The synergy between driveline electronics, multi-mode center differentials and the 4B11T’s delivery characteristics made the Evo X feel responsive rather than twitchy.

Tuning culture around the 4B11T developed rapidly. Early upgrades targeted intercooling and fueling: larger fuel pumps and injectors paired with front-mounted intercooler upgrades addressed the most common limits to power. Turbocharger upgrades followed, often replacing the stock twin-scroll unit with hybrid variants or larger housings while retaining twin-scroll principles to preserve spool. On the engine management side, standalone or reprogrammed ECUs became popular to harmonize new fueling, timing and boost targets. As the platform matured, turbo manifold design, intake tract smoothing and cam timing optimization became areas where measurable gains could be found.

Yet the 4B11T has its engineering caveats. Direct injection reduces intake valve wash, which improves efficiency, but it also increases the risk of carbon deposits on intake ports over long use. That requires attention in maintenance and sometimes port-cleaning interventions for high-mileage engines. Oil control and cooling upgrades are smart preventative measures for heavily modified applications. In addition, some builders prefer to strengthen the bottom end proactively when targeting very high power figures, because repeated high-boost cycles place sustained stress on connecting rods and bearings. These are engineering realities rather than fatal flaws; they simply shape sensible upgrade paths and maintenance schedules.

The 4B11T’s strengths reshape the way tuners and engineers approach power goals. Rather than simply bolting on a bigger turbo and increasing boost, builders often adopt a systems approach: upgrade fueling, enhance charge cooling, refine the exhaust and tune the ECU holistically. That method yields consistent, driveable power that respects the cooling and mechanical limits of the engine. When properly executed, the results can be dramatic: cars that accelerate like larger-displacement rivals while offering superior fuel economy and emissions control when driven lightly.

Driving impressions reflect these technical choices. Throttle response is quick and predictable. The midrange is broad and usable, allowing strong acceleration without the immediate need to spin to redline. On the track, the engine resists heat soak better than many of its predecessors, and the driveline electronics can apply that torque in a controlled fashion. For everyday use, the 4B11T is civilized; for racing, it can be sharpened into a weapon.

The 4B11T also changed the conversation about small-displacement turbo engines. It demonstrated that with careful thermal engineering, advanced fueling and a turbocharger designed to harness exhaust energy efficiently, a 2.0-liter engine can reliably challenge larger powerplants. The platform encouraged manufacturers and tuners alike to think about performance as a system-level problem: integrate the turbo, intercooler, fuel system and ECU tuning from the start, rather than treating them as afterthoughts.

In the wider narrative of the series, the 4B11T stands as an evolutionary inflection point. It preserved the commitment to all-wheel-drive control and turbocharged urgency while embracing modern engine management and combustion strategies. That balance made the Evo X a capable and adaptable performance sedan, worthy of both street enthusiasm and track duty. The 4B11T is not merely a successor to a legendary engine; it is an updated manifesto on how to extract usable, repeatable power from a compact displacement, in a world that now demands cleaner combustion and smarter electronics.

For those building or maintaining a 4B11T-powered Evo, the strategic priorities are clear: ensure charge cooling and fueling keep pace with any increase in boost, mind the maintenance implications of direct injection, and consider bottom-end reinforcement for high-power objectives. The platform rewards thoughtful, system-level upgrades more than brute-force escalation. When treated with that respect, the 4B11T returns performance that honors the Evo lineage while pointing forward.

For technical reference and deeper specification details, see the Mitsubishi Lancer Evolution X entry on Wikipedia: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution_X

三菱Evo发动机的两代巨力对撞:4G63与4B11T的功率、扭矩与技术演进

当人们谈起三菱翼豪陆神的发动机时,往往想到那台在涡轮增压世界中书写传奇的核心动力。4G63作为系列早期的心脏,贯穿了从第一代到第九代的全部血统,成为一代人心中的“硬核”象征。它代表了一个时代:紧凑的排量、耐用的结构、以及通过可调的涡轮与高压燃烧来追求极致性能的精神。进入EVO X,三菱却在传统基因之上注入全新血液,引入4B11T这台全新的2.0升直列四缸涡轮增压发动机。这一次,改革并非仅仅为了提高数值,而是要在原有的驾控体验上实现更深层次的线性响应、更高的热效率和更先进的喷射技术。两代发动机之间的对话,正是翼豪陆神在技术演进中的清晰对答:一个以坚固的铁质基座和高压涡轮著称的时代,另一个以铝合金缔造、双CVVT以及半封闭缸体技术为标志的新时代。对比并非单纯的数字堆砌,而是对工程学在不同阶段所追求目标的直接体现。4G63的核心在于耐用、可调和可改装的潜力。它依靠一具牢固的铸铁缸体、红头高增压涡轮的推动力,以及可变气门正时(MIVEC)的灵活性,使得在不同环境与改装需求下都能维持强悍的底线。官方数据与大量测试显示,EVO IX阶段,4G63的峰值功率在接近280 PS的区间,扭矩在3500rpm前后保持稳定,形成了在街道与赛道均可被快速响应的综合性能。与此同时,4G63的魅力不仅在于峰值,而在于它的“改装潜力”。无数车迷与改装达人在全球各地把这台发动机改出从常规到极端的多种形态,曾经的无穷想象在大量颗粒状的改装案例中逐步落地。你会发现,4G63的成功并非偶然,而是工程师对耐久性、可维护性和可调性的综合追求所凝聚的结果。与此同时,4G63也承载着行业对涡轮增压技术成熟度的认识。它让人们相信,在一个相对紧凑的排量里,通过涡轮增压、燃油喷射与进排气系统的协同工作,仍能实现极高的动力密度,且在赛道与日常使用之间维持可接受的可靠性。正因如此,4G63成为了Evo系列的精神图腾,而后来的4B11T则被视为向现代高效、高响应与更严格排放标准迈进的技术桥梁。进入EVO X,4B11T以全新的工程哲学进入舞台。它采用全铝缸体结构,相较4G63的铸铁块体,重量减少了显著的约12公斤,这在实际驾驶中转化为更好的加速响应与更敏捷的操控性。更关键的是,4B11T引入了双CVVT(连续可变气门正时)与半封闭式缸体设计,使得气门时序在低中高转速区间的调整更为精准,涡轮迟滞的感觉被显著压制。这样的设计并非单纯为了峰值功率,而是为了打造更线性的动力输出,使驾驶者能够在更广的转速区间内感受到稳定而强劲的推力。就动力水平而言,4B11T在厂标数据上通常被标注为217千瓦左右的最大功率,约合295 PS,峰值转速在6500rpm附近。扭矩方面,官方数据常见的数值是约366牛·米,在3500rpm时就能提供源源不断的扭矩支持。这意味着在日常驾驶中,起步与起动阶段的动力响应会更迅速,快速加速时的能量传递也会更加顺滑。至于0-100km/h的时刻,公开的基准数据通常落在4.9秒这一区间内,这个指标已经足以将EVO X的性能与同级别对手拉开距离。除了峰值与曲线上的提升,4B11T在热管理与排放控制方面也有所改进。铝缸体和更高效的冷却设计协同工作,使得发动机在高负载长时间运转时的热疲劳成本显著降低,这对于赛道连贯性和长期耐用性至关重要。更重要的是,4B11T在燃油经济性与排放表现方面的提升,使其在现代汽车法规和市场环境中具备更强的适应性。这些改进并非单点突破,而是多项工程选择的综合结果:从喷射系统的组合、到气门正时的精细调控,再到缸体材料与散热路径的优化。关于喷射,4B11T在直接喷射和进气道喷射的双喷射系统协同工作下,能够在不同工况下提供更精准的燃油控制与更高效的燃烧,从而提升热效率与动力输出的同时,尽可能降低排放负担。对比之下,4G63的“硬核”风格更像一位久经沙场的战士——它依赖坚固的结构、可观的涡轮响应和广泛的改装社区来维持其高人气。它的优点明显:改装潜力极高,零部件可得性广,改装路线上限宽广,许多团队通过提升涡轮、进排气和燃油管理,将马力推向惊人的水平。4B11T则以更现代的工程理念对标当下的性能标准:更轻的结构、更精准的控制、更好的燃烧效率,以及对日常使用和排放法规的妥善兼容。两者在同一个家族中的并立,像是一部连续的技术史诗:一个以“硬核”为核心的时代,一个以“智能管理与效率”为新纪元的象征。你会发现,这并非简单的两种选择,而是同一支旗帜在不同历史阶段的不同表达。4G63的美学在于它的可变性与低成本改装的魅力。它的铁质底盘让人们敢于在低成本的前提下把动力推至极致,见证了无数极端改装的案例。这份历史积淀塑造了“改装文化”的一座里程碑,也让Evo成为全球热爱改装和工程极客的共同记忆。另一方面,4B11T的美学在于其工程的“平衡艺术”:重量减轻带来的操控改善、双CVVT带来的线性动力输出,以及半封闭式缸体在高负载下的耐久性。这些设计并非为了追求极端的峰值,而是为了在激烈的赛道环境中维持稳定、可重复、易于管理的性能。其实,在日常驾驶中,这种平衡感也极具意义。涡轮迟滞的感知被压制,发动机在中低转速即可提供充足扭矩,换挡时的挂入也更干脆。更先进的冷却与燃烧控制系统意味着巡航与长时间驾驶时的温控压力更小,燃油经济性上也更具竞争力。从工程层面看,4G63与4B11T并非单点对比的结果,而是两代技术在同一驱动哲学下的自然演化。4G63以其耐久性、改装友好性和改装史上的丰富案例,成为了一种文化符号。4B11T则以现代工程的全方位考量,强调材料的革新、气门控制的精细、热管理的优化和排放合规性的协同提升。这两者共同组成了翼豪陆神发动机序列的完整图谱。对于追求极致动力的车手而言,选择并非只有“更高峰值”与“更强扭矩”的简单冲动,而是一种对驾驶体验、可持续性和可重复性的综合考量。4G63提供的强烈线性输出与广泛的改装基础,仍然是许多人心中的首选理由,尤其在需要极高输出的改装场景中,它的潜力如同未完的史诗,等待着新的诠释。4B11T则以更现代的参数与效率表现,吸引着希望在更高效的生产车间与赛道时间之间取得平衡的车主。它证明了“新一代涡轮增压”并非只是把功率挤上去,而是在同一排量框架内,用更先进的材料、控制逻辑与热管理创造出更具持续性的性能。两者的对话,也正映照着整个行业从“硬核发动机”向“智能高效动力系统”的转变轨迹。若你愿意把发动机放在可持续性与性能的光谱中观察,4G63与4B11T就像是两种截然不同的工程美学在同一座赛道上并肩跑动:一个以历史的积淀和改装的自由度为核心,另一个以现代材料科学、电子控制与热管理的综合优化为驱动。它们共同讲述了翼豪陆神在性能与工程之间寻找平衡的故事。本章对比的核心结论也因此而清晰:在原厂状态下,4B11T在功率和扭矩方面通常超越4G63。尽管4G63在改装潜力、可调性与市场参与度方面的声誉无人能及,但从原厂工程数据与科技进步的角度看,4B11T标志着现代高性能涡轮增压发动机的巅峰水平。换言之,4G63的传奇在于它的“后天可塑性”和无数改装的可能性,而4B11T的传奇则在于它将现代工程的多项前沿整合为一个更高效、响应更快、排放更友好的整车动力系统。正因如此,这两代发动机在同一个血统中的并列,不仅没有互相排斥,反而成就了翼豪陆神发动机谱系的完整性与连续性。对于爱好者和研究者而言,理解它们的差异,等于理解技术在不同历史阶段如何回应驾驶者的需求。若要把这一段历史继续向前讲述,便会看到未来的发动机不再单纯追逐峰值,而是在综合效率、热管理与操控性之间寻求更加微妙而深刻的平衡。通过对4G63与4B11T的对照,我们不仅看到了功率与扭矩的数字变化,更看到了发动机工程思想从“力量优先”向“综合性能优先”的转变。正是这种转变,使翼豪陆神不仅成为一台车的名字,更成为一个时代对极限驱动理解的永恒注解。外部参考资料为对这段演进做出更广泛历史背景补充的资源提供了一个更全面的视角。External reference: https://en.wikipedia.org/wiki/Mitsubishi_Evolution

Internal link for deeper technical context: 4B11T billet block

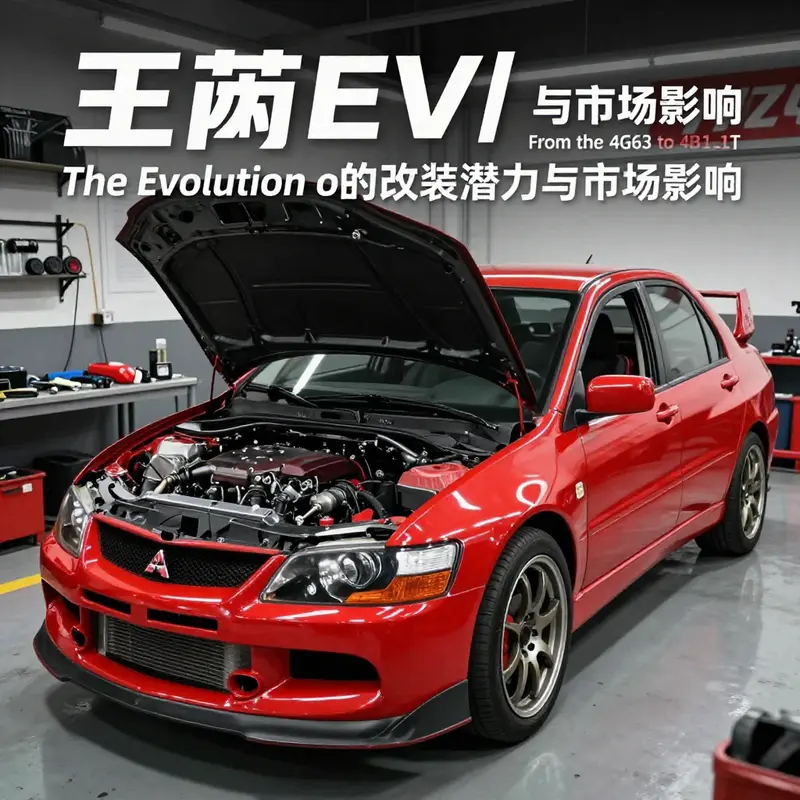

在极限之上驱动传承:三菱Evo发动机改装潜力与全球市场回响

当谈到“Evo”这个名字时,人们看到的不仅是一台紧凑的四门轿车,更是一整套理念的集合:高刚性的底盘、全时四驱的机械艺术,以及源自不同代际的心脏——发动机。本章希望把焦点放在这一对核心力量之上,揭示三菱在发动机层面的改装潜力如何推动一个全球性的改装生态,以及这一生态如何反哺着整车文化与市场格局。核心的起点仍然是4G63涡轮增压发动机,它以铸铁缸体的粗旷耐久著称,成为改装者心中的“动力之王”。尽管厂商在后期逐步过渡到更高技术含量的4B11T,4G63在改装史上的地位从未被重新定义为过时的符号。它的可塑性、可承载的极端工作条件,以及全球持续不断的改装需求,共同铸就了Evo系列在全球赛车与街道改装领域的广泛影响。

这种影响并非源于某一个群体的激情,而是由庞大而持续的市场与文化机制共同驱动。改装空间的宽阔来自铸铁缸体的耐久性、来自成熟的部件生态、来自强大且持续的改装社区,以及来自对动力、操控与整车平衡的综合追求。4G63的耐久性并非简单的“硬派”的代名词,它还意味着在同一发动机平台上进行深度强化成为可能。改装者会通过更换锻造活塞、连杆与曲轴来提升强度,同时保持较长的使用寿命;高流量燃油系统、低背压排气、以及更高效的涡轮增压器组合成为提升动力输出的常用路径。所有这些改动的共同目标,是在不牺牲日常使用可靠性的前提下,挖掘出更多的潜力。

在这条潜力线中,涡轮增压系统的升级始终处于核心位置。早期EVO的4G63通过涡轮和中冷器的组合实现了跨代的性能跃升,从最初的39附近的峰值扭矩到后来的高转速段的强力输出,这种变化是通过对涡轮几何、涡轮端径、排气效率以及气门正时等多个环节的优化来实现的。随着技术的推进,改装者在4G63的基础上探索出更高的压力曲线和更稳定的高转速工作区间。这种探索并非凭空发生,而是植根于全球的改装文化中。来自日本、欧洲、北美等地的改装店和个人爱好者长期积累的经验,已经形成一套可复制性极强的改装逻辑:在保证气密性与冷却效率的前提下,通过优化进排气、提升燃油系统的供给、以及通过ECU调校实现点火时机与喷油时序的精准控制,最大化地萃取发动机潜力。对4G63的改装并不仅仅是“硬件堆叠”,更是一种对发动机电子控制、燃油管理以及热管理系统的综合工程。为了让追求极致动力的路上更具安全边界,改装者们也不断对冷却系统、油路系统和机油供给路径进行强化,以确保在高功率、长时间输出下仍保持系统温控在可控范围内。

正是这种系统性思考,让“改装潜力”成为Evo系列的一张全球通行证。理论上的强度需要通过大量的实际应用来验证,这也正是全球改装市场发展最直观的驱动力。改装社区通过口碑、赛事、以及跨地区的技术交流,逐步建立起一个成熟的供应链:从简单的提升件,如进气系统和排气系统,到更高阶的核心部件,如高强度曲轴、锻造活塞与专用连杆,以及可与之匹配的高性能燃油泵与喷油嘴。每一次部件升级都可能带来新的性能边界的突破。此时,涡轮、冷却、燃油与电控系统像是一个有机的协同体,彼此作用,决定了一个改装方案的成败。与此同时,改装文化的全球化又使得各地的优化方案彼此借鉴、彼此竞争,逐步演化出更安全、更高效的极端动力实现路径。

对Evo而言,这一过程不仅仅属于车主或改装店的私人实验。它已经成为一种跨国界的文化现象,深刻影响着市场结构与消费者预期。全球改装市场的成熟带来多元化的产品线:从轻度提升的日常驱动,到适合赛道的极端改装,再到能够让车身与动力系统协同工作、实现高水平赛道性能的综合方案。厂商与改装品牌在这个过程中并非对手,而是共同维持着一个生态的健康循环。设计更轻的组件、提升散热效率、改进气流管理、以及通过材料科学提升耐久性,所有这些创新常常在Evo的改装故事中被追溯到同一个起点:4G63在铸铁缸体中的坚韧、在涡轮增压控制中的精准。通过持续的迭代,原厂经验与改装专业知识之间的界线被逐步模糊,更多的车主愿意尝试高水平的改装,因为他们相信安全性与性能之间并非不可调和的矛盾。

在讨论市场影响时,不能忽视改装文化对收藏与传承的推动力。改装后的车辆往往在展览、评选、以及历史的回顾中获得新的意义。它们不仅是速度的展示,也是对工艺、工程与审美的综合表达。此种文化资产的增长,也使得某些限量版本与历史车型在全球市场的价值不断攀升。这种收藏价值并非只有稀有性所驱动,它更多来自于改装历史所叙述的技术演进与驾驶者对极致体验的持续追求。更重要的是,改装文化让 Evo 车系在二十多年的传承中保持了鲜活的生命力——一个能够被新一代改装者重新诠释的传奇。

在这一长链条中,关于“潜力”的讨论并不只是在纸面数据或单一部件的提升。它强调的是对整车工程方法的理解,以及在全球化市场中寻找最佳性能与可靠性之间平衡的能力。正因如此,Evo的改装潜力成为市场行为的一种驱动力,让人们在保持对原厂历史的敬意的同时,也愿意以更大胆的方式去探索新的性能极限。为进一步理解这一路径的具体实现,可以参照像 4G63t-billet-block 这样的升级选项,它象征着边界扩展时所涉及的材料强度与结构刚性如何直接影响到高功率输出的稳定性。与此同时,全球范围内关于极端改装的案例也不断被记录与分享,为后续改装者提供可操作的参考框架。

外部证据与行业观察共同支持着这样的结论:即便在极端改装的边缘,Evo 的改装路径仍然以可控、可重复的方式展开。这种可重复性,是市场信心的关键所在,也是全球改装生态长期健康发展的基础。正如一项权威报道所展示的那样,通过严谨的工程实践和极高水平的赛道测试,Evo 的动力系统能够在极端条件下实现令人难以置信的性能提升,甚至在某些极端案例中达成了跨越性突破。此类记录不仅仅是“极端数据”的展现,更是对改装潜力稳定性与可持续性的证明。 External source: https://www.autocar.co.uk/car-news/motorsport/202001/evolution-2000-horsepower-record。

总之,三菱Evo发动机的改装潜力并非孤立的技术现象,而是一个全球性市场与文化共同塑造的结果。铸铁4G63带来的耐久性与可修复性,为深度改装提供了可靠基础;成熟的部件生态和跨区域的知识传播,让改装成为一种全球性语言;而持续的赛事与收藏活动,则把这一语言转译成市场价值与文化资本的双重收益。随着技术的演进,改装方案会更加精细、更加安全、也更加多元。Evo的发动机因此成为一种“传承中的创新”范式——在对极致动力的追求中,人们不断寻找、验证与分享更高效的能源利用方法。只有把握住这一点,才可能在未来的改装旅程中,继续看到那些在全球范围内被热切讨论、广为模仿并且不断被超越的改装故事。

Final thoughts

The story of the Mitsubishi EVO engines, culminating in the advancements from the 4G63 to the 4B11T, illustrates a commitment to performance that resonates deeply within the automotive industry. Business owners should recognize that these engines not only serve as benchmarks for high performance but also as a rich source of opportunities for aftermarket enhancements and market expansion. As enthusiasts continue to seek upgrades and modifications, understanding the intricacies of these engines will enable businesses to offer tailored solutions while capitalizing on the demand for high-performance automotive parts and services.