The 2008 Mitsubishi Lancer, particularly in its Evolution X variant, stands out in the automotive industry for its performance-driven engineering and innovative technology. Central to this is the monumental 2.0-liter inline-four turbocharged engine that delivers an impressive blend of power and efficiency. Understanding the intricacies of this engine extends beyond mere mechanics; it’s crucial for business owners who may consider the Lancer for corporate or commercial applications. In the chapters that follow, we will delve into the engine’s performance specifications, explore its technical innovations, review maintenance practices, engage in a comparative analysis with competitors, and assess its broader market impact. This comprehensive overview aims to provide actionable insights into how the 2008 Mitsubishi Lancer’s engine can align with your business objectives.

Turbocharged Precision at the Core: The Engine Story of a 2008 Performance Sedan

The engine is more than a collection of cylinders and pistons within a compact steel shell. In a performance-focused 2008 model, it is the living heartbeat that translates air, fuel, and timing into the immediacy of acceleration, the steadiness of a wide torque curve, and the confidence of all-wheel control. The core engine family for this platform centers on a 2.0-liter inline-four that could be tuned to deliver a broad spectrum of driving experiences. When paired with a dual-clutch transmission and an advanced all-wheel-drive system, that same powertrain becomes a versatile platform—capable of quiet efficiency in daily use and explosive response when the road opens up. The offspring of this design lineage is a turbocharged engine that could push the limits of everyday practicality while still satisfying the demands of high-performance driving. This is the engine story of a 2008 performance sedan, a narrative built on a family of four-cylinders that shared architecture, improved flow, and the same quest for balance between power and efficiency.

At the practical end of the spectrum, there was a smaller, 1.8-liter four-cylinder variant. This engine delivered about 110 horsepower and roughly 125 pound-feet of torque, transforming into a capable daily driver when mated with either a five-speed manual or a four-speed automatic. The focus here was not peak muscle but a livable blend of responsiveness and fuel economy, a sensible compromise for drivers who needed a sedan that could cover long commutes without sacrificing real-world usability. The engineering philosophy behind this unit emphasized a light, efficient frame, lower inertia, and straightforward intake and exhaust paths that kept turbocharging off-boost complexity to a minimum. It established a baseline that allowed the car to perform reliably in a wide range of conditions while still providing adequate propulsion for everyday traffic scenarios.

The next step up in displacement carried with it a more sophisticated set of technologies, reflecting the global intent of the model as a versatile performer. The 2.0-liter DOHC engine found its way into higher trims and specific markets, bringing about a meaningful bump in power and torque. In the 2.0-liter DOHC variant, output rose to about 147 horsepower with approximately 143 pound-feet of torque. This engine featured DOHC architecture paired with variable valve timing, a technique that refined the timing of air and exhaust gas exchange. The result was a more flexible torque band and smoother throttle response, particularly useful when negotiating winding roads or merging onto busy highways. The improved breathing helped with both performance and efficiency, as the engine could adjust valve timing to optimize volumetric efficiency across a broader range of engine speeds.

For markets that prioritized a more immediately engaging drive at a mid-range price point, a second 2.0-liter option offered around 150 horsepower and again about 143 pound-feet of torque. This variant shared a similar DOHC layout and valve-timing technology, but it was tuned to extract a touch more output from the same architecture. The differences between the two 2.0-liter lines were subtle, yet meaningful in everyday driving: one variant leaned toward a steadier, more linear delivery, while the other offered a slightly livelier response in midrange revs. In both cases, the engineers preserved the essential character of the engine family—compact size, robust midrange, and the possibility of satisfying performance enthusiasts in the right configurations. The engine’s reliability in this family became a hallmark of the model line, with many owners praising the power delivery as crisp and predictable, and the mechanicals showing resilience with regular maintenance.

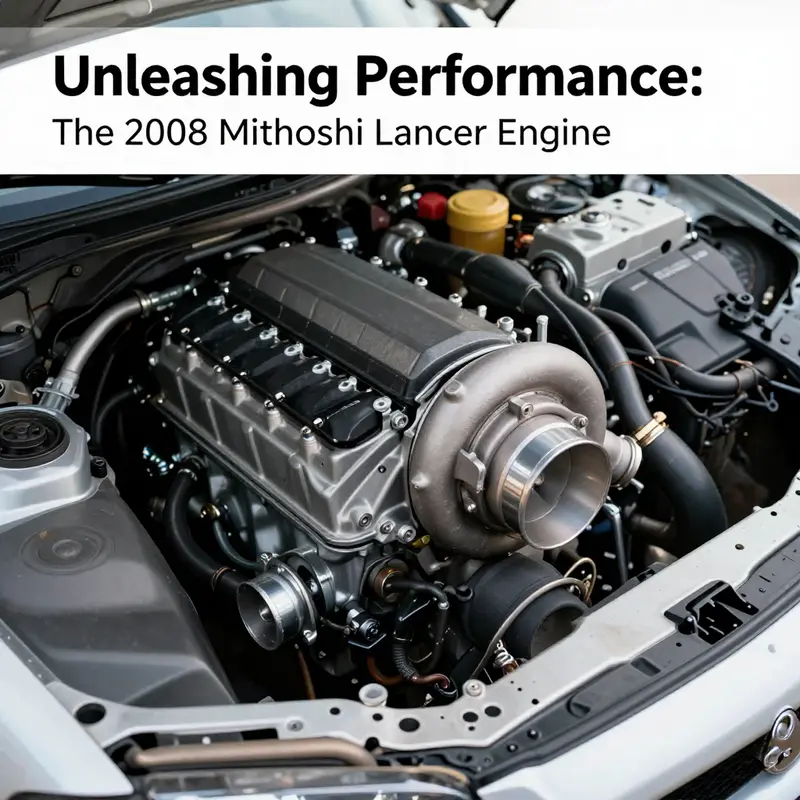

Amid these naturally aspirated variants, the performance-focused Evolution X variant represented the pinnacle of turbocharged sophistication within the lineup. The turbocharged 2.0-liter inline-four delivered power in a league of its own: approximately 217 kilowatts (about 293 horsepower) and a torque peak near 366 newton-meters. The upgrade was not merely about more horsepower; it was a refocusing of the entire intake and exhaust flow, compression, and turbo response. The turbocharger, with its efficient compressor and tuned turbine geometry, enabled a faster spool and stronger midrange torque, while the intercooling path helped maintain density of air under higher boost. The integration with a dual-clutch transmission and an advanced all-wheel-drive system created a propulsion architecture capable of precise and immediate throttle behavior. The official performance metrics—the 0 to 100 kilometers per hour sprint in 5.9 seconds and a top speed around 242 kilometers per hour—illustrate how the engine’s characteristics could translate into both track-credible times and confident, stable highway behavior. The engineering team did not treat the engine as a standalone unit; it was designed as the core of a high-intensity driving system, where turbocharged power, quick-shifting gears, and AWD traction work together to optimize grip, cornering, and overall control.

Behind the numbers lies a broader engineering logic that favors a robust breathing path and careful calibration. The engine’s turbocharger, intake and exhaust paths, and fuel delivery were developed with a clear focus on a balance between performance and emissions. In official manuals and contemporary reviews, the turbocharging system is described as a key enabler of the high-output configuration while still retaining a reasonable level of everyday usability. The DOHC arrangement, combined with variable valve timing, allowed the engine to adapt its valve events to boost efficiency during cruising and to unleash peak torque at higher revs when the driver commanded a more aggressive drive. The result is not merely power on a dyno chart; it is a dynamic system that responds predictably across a wide range of speeds, enabling confident overtaking, swift acceleration from low speeds, and stable high-speed cruising.

Another dimension of the engine story concerns the way these variants were packaged for different markets. The 1.8-liter base engine was commonly paired with either manual or automatic transmissions, emphasizing easing operation and long-term reliability. The 2.0-liter variants, with their DOHC and MIVEC-like timing control, offered a more advanced package that could be tuned for different regulatory environments and customer expectations. In some markets, the 2.0-liter units were linked to higher-tier trim lines, where a more refined driving experience and improved midrange performance were valued. In others, these engines served as the basis for a performance-calibrated experience, where enthusiasts would look for more aggressive throttle response and sharper cornering dynamics. Across all markets, the engines shared a common lineage: a compact, robust architecture designed to deliver both the flexibility to excel in daily driving and the capability to deliver thrilling performance when conditions allowed.

The practical reality of maintaining a car with this engine family comes down to understanding its core needs. The modern version of this engine, especially in its turbocharged form, benefits from disciplined maintenance: timely oil changes with a quality lubricant, attention to boost control and intercooling integrity, and a steady supply of clean air and fuel. The reliability record for the 2.0-liter variants has generally been favorable, with many owners reporting responsive throttle, steady torque delivery, and minimal drama in daily operation. It is a testament to a design philosophy that sought to maximize efficiency and durability in equal measure. Even as tuning culture and performance expectations shifted over the years, the learning from the engine’s DOHC architecture and its valve-timing strategy remained a reference point for engineers in similar performance-oriented compact sedans.

In this chapter, the interplay between turbocharging, valve timing, and all-wheel traction is framed not just as a list of specs but as a narrative about how a family of four-cylinders could adapt to different performance goals without losing its identity. The base 1.8-liter engine served practical daily needs while preserving driveability and efficiency. The 2.0-liter variants offered progressively more dynamic capabilities, with the higher-tuned version becoming a benchmark for the era’s turbocharged performance platforms. The Evolution X, in particular, demonstrated how a carefully calibrated turbocharged engine can deliver blistering acceleration with a controllable, communicative throttle—the kind of power that informs the chassis, the tires, and the driving experience as a whole. This is the engine’s story: a story of breathing capacity, rapid response, and the stubborn, steady drumbeat that makes a performance sedan feel alive at every RPM.

For readers who want a tangible point of reference on era-specific hardware, a widely referenced component set for the period remains a useful benchmark: evo-x-halfcut. This reference to a familiar platform component helps illustrate how enthusiasts thought about compatibility and performance tuning during that era. It is a reminder that the engine could be at the heart of a broader ecosystem of parts designed to sustain a high-performance identity while accommodating everyday use. In the broader literature, this engine family is often examined alongside official technical manuals and respected automotive reviews that analyze how the turbocharged path, the valve timing strategy, and the drivetrain integration collectively shaped both performance and practicality. The balance achieved by these engines—robust midrange, efficient cruising capability, and the ability to deliver dramatic acceleration when summoned—speaks to a design approach that valued predictability, repeatability, and a long, confident driving experience.

As the chapter closes, it is clear that the 2008 engine family offers more than a set of specifications. It embodies a design philosophy that understood the difference between peak numbers and real-world behavior. It delivered convincing performance without sacrificing reliability or daily usability. The route from a modest 1.8-liter four to a high-torque turbocharged 2.0-liter, through to the pinnacle of a dual-clutch, all-wheel-drive performance machine, reflects a coherent strategy: build an engine that can rev, respond, and deliver power with precision across a broad spectrum of driving situations. The tale continues beyond the page, inviting readers to consider how the principles behind this engine family informed later developments in performance sedans and how the balance between turbocharged power and drivetrain control remains a defining challenge for engineers aiming to merge excitement with everyday practicality.

External resource: https://www.mitsubishi-motors.com/

Engineering Velocity: The 2.0-Liter Twin-Scroll Engine and the Engineered Pulse of a 2008 Lancer Performance Chapter

The 2008 Lancer line brought a shift in how a compact sport sedan could balance everyday usability with track-ready performance. At the heart of the most capable variant lay a 2.0-liter inline-four that was not simply tuned for more power, but engineered for a very particular response: a broad, usable torque band that could be coaxed into action with minimal throttle input, followed by a surge of linear power as revs climbed. This was not a mere refinement of an existing engine; it represented a deliberate rethinking of how air, fuel, and exhaust interact within a compact, mid-size chassis. The engine’s output—approximately 293 horsepower and 366 Nm of peak torque—was impressive on paper, yet the more telling story lay in how those numbers translated into driveability, predictability, and confidence on a twisty road or a racetrack. In a landscape where turbocharged four-cylinders often sacrificed low-end torque for high-end bragging rights, this design chose a different balance. The architecture and calibration aimed to flatten the power curve, yielding a power delivery that felt both accessible and relentlessly capable as the RPM needle moved upward.

A primary driver of that capability was the engine’s twin-scroll turbocharger. The concept behind twin-scroll design is elegantly simple yet technically demanding. Exhaust pulses are divided into two separated scrolls that feed a single turbine. This separation reduces interference between exhaust pulses, allowing the turbine to spool more quickly and respond more crisply to throttle inputs. The result is a noticeable reduction in turbo lag and a more immediate throttle response, especially in midrange where everyday driving and most competitive laps occur. The engine’s engineers coupled this with careful turbine housing sizing and intake routing to produce a linear ramp of torque, rather than a sudden spike. The overall effect is a power delivery that feels controllable, almost intuitive—precisely the kind of responsiveness that a driver can rely on when negotiating a corner and a straight in quick succession.

Complementing the turbocharger’s speed was a broad, well-managed flow of air and fuel. Here, the variable valve timing system played a crucial role. The technology, a form of electronic control on both the intake and exhaust camshafts, is a modern interpretation of the classic variable-valve principle. In practice, this meant the engine constantly optimized the time and duration that each valve opened, depending on engine speed, load, and temperature. The benefit showed up as stronger torque at lower to mid RPM and better power availability as revs rose. The result was more than a larger peak horsepower figure; it was a more usable, more forgiving engine that rewarded smooth inputs with a satisfying and predictable response. In practical terms, drivers could accelerate with confidence in a wide window of speeds, not just when the tachometer needle hovered near the redline.

The choice of materials and construction further distinguished the engine from its contemporaries. To reduce weight without sacrificing strength or durability, the block and head were crafted from aluminum alloy. This choice lowered the engine’s overall mass, which in turn reduced the load on the rotating assembly and improved throttle response and efficiency. At the same time, aluminum’s heat-dissipation properties aided in managing the stresses of forced induction and high-rev operation. Lower weight and better cooling work in concert to improve responsiveness and reliability under demanding use. Combined with the turbocharger and variable-valve timing, the lightweight architecture allowed the engine to coax more performance from less mass, a fundamental aspect of dynamic handling in a performance-oriented compact.

Another critical component of the package was the transmission, which brought a dual-clutch design into a platform that demanded both racing-derived quickness and practical, real-world usability. The dual-clutch transmission provided rapid gear changes with minimal interruption to power delivery. In performance mode, shifts could be extremely fast, almost seamless, allowing the engine’s torque to remain in its broadest possible band. The result was a drivetrain that could exploit the engine’s torque curve with minimal lag between gears, contributing to the rapid acceleration times reported by performance figures. Yet the same transmission also offered smooth, predictable behavior under normal daily use, a testament to the engineering intent: a car that could thrive on a track yet remain a capable daily driver.

The numbers themselves—0–100 km/h in 5.9 seconds and a top speed around 242 km/h—summarized the package well, but the chassis dynamics and the on-road feel were deeper indicators of what this engine achieved. The drive presented a sense of balance: power arrive with a controlled push rather than an abrupt shove, allowing the driver to place the car with a degree of precision and confidence in diverse conditions. This balance was the product of the engineering team’s careful integration of turbocharging, variable valve timing, and lightweight construction within a chassis that offered all-wheel drive and a responsive, high-precision suspension geometry. The result was not simply speed in a straight line, but the kind of performance that translates into confidence around a bend, a character that endears a car to both enthusiasts and casual drivers who value consistent, predictable behavior.

Beyond the immediate sensations of speed and grip, the deeper engineering choices spoke to a broader philosophy. The design team aimed for a powertrain that could deliver torque across a broad RPM range, rather than a peak that disappeared as soon as the tachometer moved away from the center. In everyday terms, this meant you did not need to wring the engine to extract performance; rather, the car would respond with ample momentum from as low as mid-range RPM, then sustain momentum as the turbo spooled and the intake charge was optimized by MIVEC, Mitsubishi’s valve-timing technology. The purpose of MIVEC—and of the dual cam phasing on both intake and exhaust—was to reconcile two often competing objectives: high performance and fuel efficiency. The engine management system used precise camshaft timing to extract more air and fuel into the combustion chamber during the opening and closing cycles that maximize the pressure forces and energy release. In practice, this produced a more complete burn, better pumping efficiency, and less waste heat for the same power output, a feature that became a familiar comfort for drivers who appreciated the combination of mid-range torque with occasional bursts of high-end power.

Detailing the mechanical lineage of the engine also reveals an incremental evolution anchored in practical reliability. In this architecture, aluminum construction did not merely reduce weight; it improved heat management and contributed to smoother, more uniform piston movement under heavy load. The engine block’s geometry and the head’s cooling passages were designed to handle sustained boost pressures without distortion or excessive temperature rise. This is where the billet-block concept, often associated with higher-rigidity builds in performance programs, becomes an important reference. A billet-block approach can further increase stiffness and reduce the risk of block flex under extreme boost and aggressive tuning. For those curious about this facet of engine engineering, the reference block design and its potential advantages are described in industry resources under the label 4b11t-billet-block, a point of interest for enthusiasts who study the evolution of high-performance four-cylinders. 4b11t billet block serves as a useful waypoint in understanding how modern engines push toward greater rigidity while preserving the compact packaging that makes this class so compelling.

From a practical standpoint, the engine’s architecture was designed to harmonize with a refined all-wheel-drive system. The AWD layout worked in concert with the turbocharged powertrain and the dual-clutch transmission to deliver traction where it mattered most—during aggressive corner entry and mid-c corner exits. The AWD system’s role was to allow the driver to use the engine’s broad torque distribution without sacrificing stability when the car was pushed toward its limits. In this sense, the engine’s performance could be harnessed in a controlled manner, rather than presenting the driver with a raw power surge that overwhelmed the chassis. The combination of drivetrain, turbo dynamics, and valve timing created a cohesive driving experience where the engine’s character is not merely about peak numbers but about a consistent cadence that the chassis could manage without surprises.

The chapter of this engine’s history also reflects a broader shift in how manufacturers approached performance compact cars at the time. Rather than relying solely on brute force, the engineering team pursued a blend of advanced control strategies, precise calibration, and materials science to optimize efficiency, responsiveness, and reliability under varied driving conditions. The objective was to produce a powertrain that felt both purposeful and forgiving, rewarding skill without punishing the driver for an imperfect input. The end result—a combination of vigorous acceleration, brisk throttle response, and confident cornering—made the 2008 release a standout in its class. It offered a template of what a well-integrated turbocharged four can achieve when complemented by modern valve timing, a light yet strong block, and a transmission that preserves momentum through shifts rather than interrupting it.

For readers who want to situate these engineering choices within the broader landscape of performance technology, it is helpful to view them as a coherent system rather than as disjointed components. The engine’s innovations worked in tandem with the vehicle’s steering, suspension, and braking systems to deliver a compelling driving experience. The synergy between combustion dynamics, exhaust efficiency, and drivetrain control created a driving character that many enthusiasts remember as both tractable in daily use and exciting at the limit. This is the essence of engineering velocity in a modern compact sport sedan: the ability to transition smoothly from a calm, confidence-building daily ride to a spine-tingling, track-ready performance machine when the moment calls for it.

External reference: https://www.mitsubishi-motors.com/en/vehicles/lancer-evolution-x/

Engine Stewardship for the 2008 Mitsubishi Lancer: Practical Maintenance that Preserves Performance

Engine stewardship for the 2008 Lancer blends routine attention with a few focused tasks that preserve power, economy, and longevity. Whether your Lancer carries the MIVEC-equipped naturally aspirated motor or the high-strung turbocharged 2.0 found in sporting variants, the principles are the same: clean oil, correct fluids, fresh consumables, and regular inspections keep the engine breathing and timing as designed.

Start with oil, because it is the engine’s first line of defense. The variable valve timing system central to MIVEC depends on stable oil pressure and clean oil passages. Use the manufacturer-recommended viscosity and oil quality for your climate and driving style. Typical recommendations for many 2008 Lancer engines are 5W-30 or 10W-30. Synthetic oil offers better stability and thermal protection, especially for turbocharged engines, and it helps protect the valve timing actuation under heat. Change oil and filter at conservative intervals if the car sees hard driving, short trips, or dusty roads. For normal use, follow the interval in the owner’s manual. Clean oil preserves hydraulic lifters, solenoids, and turbo bearings, and it reduces carbon buildup that harms efficiency.

Air and fuel systems are the next priority. A clogged air filter increases intake restriction and forces the engine to work harder. Replace the air filter according to mileage and environment, and inspect the intake tract for loose clamps or leaks. Fuel injectors benefit from periodic cleaning. Using quality fuel and a professional injector service at longer intervals restores spray patterns and combustion quality. Spark plugs should be inspected and replaced between approximately 30,000 and 60,000 miles depending on the plug type and engine. Worn plugs increase misfires and stress ignition coils, reducing fuel economy and throttle response.

Timing components and valve control deserve special attention. Some 2008 Lancers use a timing belt, others use chains depending on the engine variant. If your engine is belt-driven, replace the timing belt and associated tensioners and idlers within the manufacturer’s recommended window, commonly around 60,000 to 100,000 miles. A failing belt risks catastrophic internal damage. If your engine uses a timing chain, inspectors should still evaluate chain condition, tensioner performance, and guides at service intervals. Valve timing systems like MIVEC rely on oil pressure and a responsive solenoid. Dirty oil, clogged screens, or electrical issues at the solenoid can cause irregular valve timing, rough idle, and loss of power, so include the timing solenoid and its harness in routine checks.

Turbocharged engines add a few additional care items. Let the engine idle briefly after spirited runs before switching off. This cool-down period reduces oil coking inside the turbo and extends bearing life. Use high-quality oil and adhere to shorter oil-change intervals if the vehicle is driven hard. Inspect the turbo oil feed and return lines for leaks and blockages. Check intercooler hoses and clamps for secure fitment and watch for oil in the intercooler, which indicates leakage or seal wear. Monitor boost-related components — wastegate actuators, vacuum lines, and boost control solenoids — for proper operation, because malfunction can cause lean or rich running and damage internal parts.

Cooling and belts matter more than owners often realize. Maintain proper coolant concentration and level, and flush the system at the intervals recommended in the service manual. Overheating accelerates component wear and risks head gasket failure. Replace accessory belts and inspect for cracks, glazing, or glazing-induced slipping. Belt-driven water pumps and tensioners should be inspected when belts are serviced. A failing pump reduces flow and can produce localized hot spots that stress piston rings and valve seats.

Vacuum and PCV systems deserve a simple but consistent check. A faulty PCV valve inflates crankcase pressure, pushes oil into the intake, and fouls sensors and valves. Clean or replace the PCV components and check vacuum hoses for cracks. A small vacuum leak can upset idle and fuel trims, leading to rough running and increased fuel use.

Electrical items also influence engine life. Keep ignition coils and wiring in good shape. Heat and moisture shorten coil life, so inspect boots and connectors. A single failing coil can cause misfires and allow raw fuel into the exhaust, which damages catalytic converters and reduces performance.

Fluid quality beyond oil matters as well. Use the correct coolant, transmission fluid, and differential lubricant specified for your drivetrain. A sudden change in fluid type can alter operating temperatures and friction characteristics. For vehicles with dual-clutch or automated manuals, follow the specific service intervals for transmission fluid and software updates; many drivetrains rely on fresh fluid for clutch cooling and hydraulic control.

Routine inspections often catch small problems before they become large failures. Check for oil leaks at valve covers, oil pan gaskets, and turbo oil lines. Inspect the exhaust system for leaks or loose hangers; exhaust leaks near the manifold affect oxygen sensor readings and engine management. Periodically scan for stored trouble codes. Early detection of sensors or actuator failures keeps the engine running clean and prevents collateral damage.

Driving habits shape how often maintenance is needed. Frequent short trips mean the engine never reaches optimal temperature, promoting condensation and accelerated oil contamination. Heat-cycling from heavy driving stresses components. If the car is used in cold climates or dusty conditions, shorten service intervals. Moderate driving and consistent maintenance are the simplest path to long engine life.

When parts do wear, choose replacements that meet OEM specifications. High-quality aftermarket components that match factory tolerances are acceptable and often cost-effective. Avoid cheap substitutes that cut corners on heat treatment or sealing surfaces. For performance-oriented engines, some owners upgrade components like oil coolers, high-capacity air filters, or reinforced engine blocks. Those upgrades require matching supporting maintenance and, at times, re-tuning to keep air-fuel ratios and ignition timing within safe limits. If you consider block or internals upgrades, review resources specific to the 4B11T engine architecture, such as information on a 4B11T billet block, before committing to extensive modifications: https://mitsubishiautopartsshop.com/4b11t-billet-block/

Finally, keep records. A simple log of oil changes, filter swaps, and replaced parts preserves resale value and helps a mechanic diagnose issues. Follow the service schedule in the owner’s manual for service intervals unique to your engine variant. If you own a turbocharged model, err on the side of more frequent checks and fluid changes. The difference between an engine that lasts 150,000 miles and one that reaches 300,000 often comes down to routine care and timely replacement of minor components.

If a problem arises, be systematic. Start with basic checks: oil level and condition, coolant level, visible leaks, and stored error codes. Address ignition and fuel delivery items before assuming major mechanical failure. Many drivability complaints trace back to plugs, coils, filters, or vacuum leaks. When in doubt, follow the diagnostic flow in the service manual and prioritize repairs that protect the engine core — oiling, cooling, and timing systems.

Adopting a consistent maintenance routine ensures the 2008 Lancer’s engine remains responsive and durable. Clean oil, fresh consumables, vigilant inspections, and correct fluids reduce wear and preserve the precise timing systems that make these engines perform. The investment in regular upkeep pays back in smoother operation, better economy, and fewer unexpected repairs. For the official schedules and fluid specifications tailored to the 2008 Lancer, consult the manufacturer’s technical guidance: https://www.mitsubishi-motors.com/owners/manuals/2008-lancer.html

Engine Face-Off: How the 2008 Mitsubishi Lancer Stacks Up Against Its Class

A focused comparison of engines reveals the Lancer’s strengths and compromises. The 2008 model line offered a spectrum of powerplants, from efficient four-cylinders to the rally-bred turbocharged unit in the high-performance variants. At the core of the Lancer’s appeal was a clear engineering intent: deliver usable torque, straightforward drivability, and strong performance in the mid-range. That intent shaped how the car compared to common rivals and how it behaved in real-world driving.

The naturally aspirated 2.0-liter four-cylinder in the Lancer prioritized mid-range torque and everyday responsiveness. Mitsubishi’s valve-timing system operates to broaden the usable powerband. The result is a car that feels willing to pull from lower RPMs, easing city driving and highway merging. Competing sedans often used different strategies. Some smaller engines emphasized peak efficiency and high-rev horsepower. Others emphasized high-rpm power at the expense of low-end torque. Against those choices, the Lancer’s larger 2.0 delivered a more relaxed and accessible personality. Drivers felt power earlier, less often needing to downshift to make progress.

Comparing this naturally aspirated 2.0 to the Civic’s engine lineup highlights these differences. The Civic prioritized efficiency and refinement, with smaller displacement choices that returned excellent fuel numbers. However, the Civic’s smaller engines sometimes required higher revs to access strong power. The Lancer’s 2.0 offered a satisfying alternative: more shove in everyday gears, with only a modest economy penalty when driven reasonably. Similarly, a direct competitor well known for its high-revving small engine traded torque for peak rpm thrills. That design rewarded drivers on winding roads but felt less practical for routine traffic. The Lancer’s tuning choices favored broad usability over chasing peak horsepower numbers.

The Lancer’s variable valve timing also improved throttle response across mid-range speeds. This characteristic made the car feel more engaging during overtakes and merges than some rivals with simpler timing systems. In real driving, that translates to fewer downshifts, quicker passes on two-lane roads, and a more composed, less breathless acceleration profile. Owners who value usable torque over outright revs often prefer engines tuned this way.

Beyond the naturally aspirated engines, the turbocharged 2.0-liter found in the Lancer’s performance variants fundamentally changed the comparison. The turbocharged unit produced substantially more power and torque. Coupled with an advanced all-wheel-drive system and a dual-clutch transmission in certain trims, the package delivered quick launches, impressive mid-range thrust, and confident traction under hard acceleration. Compared to sport trims of rivals, the turbo Lancer was in a different league. Rivals offered spirited options, but few matched the combination of turbo output and drivetrain sophistication found in the Lancer’s high-performance models.

That turbocharged setup was not only about peak numbers. It delivered a linear, usable delivery that felt engineered for both daily and aggressive driving. Turbo systems can suffer from lag and abrupt power spikes. Here, the calibration emphasized tractable boost and a friendly torque curve. The transmission and all-wheel-drive hardware also transformed chassis behavior. Where front-wheel-drive competitors tended to understeer when pushed, the Lancer’s drivetrain allowed faster corner exits and more confidence when accelerating mid-corner.

On fuel economy, naturally aspirated Lancer variants held their own. They rarely matched the smallest engines in absolute consumption, but they balanced consumption with performance in a way that many drivers found practical. The turbo models predictably consumed more when driven hard. Yet because the turbo allowed lower average engine speed for a given pace, careful drivers could see respectable economy on steady highways. Real-world tests reflected these trade-offs, showing the Lancer as a sensible compromise between performance and efficiency.

Durability and maintenance shaped buyer decisions as well. The Lancer’s engines used conventional service intervals and parts that were broadly available. The turbo model included additional components, such as the turbocharger, intercooler, and heightened cooling needs. Those elements required attention if the car was driven aggressively. For enthusiasts planning modifications, the engine’s architecture rewarded sensible upgrades. Billet and performance blocks and reinforced components were available from the aftermarket. For owners pursuing higher boost or sustained track use, these parts provided a path to reliable power increases. For a relevant performance component, see this discussion of a 4B11T billet block, which many builders reference when strengthening the 2.0 turbo platform.

The package-level differences also matter. Many rivals leaned on lighter curb weights and simpler drivetrains to achieve agility. The Lancer could not ignore the mass added by its all-wheel-drive and performance hardware in top trims, but engineers compensated via suspension tuning and chassis reinforcement. The net result was a car that felt planted and immediate when driven fast. Against lighter front-wheel-drive rivals, the Lancer often inspired more confidence when roads turned twisty or traction was limited.

Noise, vibration, and harshness levels reveal another layer of distinction. The naturally aspirated engines were refined for daily use, with pleasant, unobtrusive noise profiles. The turbo versions offered throaty character without excessive harshness. Some competitors emphasized ultra-quiet refinement in their cabins, pushing NVH beyond the Lancer’s level. Others prioritized sound and feel and allowed more engine intrusion. The Lancer struck a middle ground: alive enough to be engaging, yet calm enough for long drives.

Finally, the Lancer’s engines shaped the car’s market positioning. The base and mid-level engines positioned the car squarely as a practical compact sedan. The turbo models elevated the Lancer into a performance niche few competitors dared to occupy. That breadth gave buyers options. Those wanting efficient daily transport could choose a modest engine. Those seeking a performance machine could opt for the turbocharged variants. Few competitors offered such a clear spectrum from sensible commuter to rally-capable sports sedan within the same family.

Taken together, the 2008 Lancer’s engines were thoughtful compromises: practical, tunable, and often more driver-friendly than the smallest, peak-oriented rivals. The turbo variants stood apart, offering performance that eclipsed many mainstream sport trims. Where the Lancer did not lead was absolute lightness or absolute cabin silence. Instead, it offered usable torque, well-calibrated systems, and a drivetrain architecture that rewarded both calm commuting and spirited driving.

Further technical specifications and independent test numbers can be found in the detailed review and spec sheet: Car and Driver – 2008 Mitsubishi Lancer Specifications.

Powertrain as Bridge: The 2008 Lancer Engine and Its Quiet Market Transformation

The 2008 Mitsubishi Lancer, and especially the Evolution X variant, is synonymous in performance circles with a remarkably capable 2.0-liter inline-four turbo engine. That powerplant, delivering close to 293 horsepower and peak torque around 366 Nm, paired with an intelligent all-wheel-drive system and a dual-clutch transmission, created a verifiable benchmark for how turbocharged efficiency could coexist with tangible track-ready capability. Yet the most consequential ripple of that engineering achievement did not unfold on showroom floors or in the occasional road-test headline. Instead, it unfolded across a broader, less visible stage: China’s rapidly expanding auto industry, where the 4G63 family’s turbocharged lineage became a central, adaptable powertrain solution for a generation of domestic brands chasing scale, credibility, and speed to market. The Lancer’s 2.0-liter core, iconic in its own right, thus became a bridge—between a single model’s performance story and a wider industrial narrative about how mature, external powertrains can accelerate the ascent of an entire national industry.

In China, sales dynamics for the Lancer sedan reflected a familiar pattern: a once-promising design faced competitive pressures, changing consumer tastes, and a crowded field of rivals. By 2006, the market’s glare had shifted away from this particular sedan, even as the broader Mitsubishi portfolio carried a volume of engineering expertise that could be repurposed beyond badge loyalty. What mattered more was not the Lancer’s trunk space or its styling but the engine’s enduring reliability and the way its technology could be reused as a ready-made solution. The 4G63 turbocharged engine, part of the broader Mitsubishi powertrain family, gained a reputation that extended far beyond any single vehicle’s life cycle. It became a common reference point for dozens of Chinese automakers as they sought to compress development timelines and reduce research intensity without sacrificing performance targets.

The transformation was not a sudden shift but a gradual rethinking of what constitutes a competitive vehicle. The Chinese automotive sector, characterized by its rapid scale-up and a penchant for leveraging external strengths, began treating certain powertrains as strategic inputs rather than mere components. The 4G63 turbo, with its robust turbocharging architecture and proven durability, emerged as a “ready-made” solution that could be dropped into varied body configurations and tuned to suit different market segments. This practice—borrowing a mature, well-understood powertrain from abroad to jump-start product development—proved particularly valuable for smaller, newer brands with constrained R&D budgets and limited engineering resources. The effect was twofold. First, it lowered barriers to entry, transforming ambitious vehicle concepts into viable, roadworthy products with credible performance credentials. Second, it allowed these brands to cultivate a narrative of reliability and performance around their offerings, a strategy that often translated into faster sales or quicker access to financing and customer trust.

Across segments and brands, the engine’s reach became illustrative. Models like Lu Feng X7, Great Wall H5, and Chery Tiggo, among others, found their powertrains in Mitsubishi-sourced engineering, with the 4G63S4T variant often cited as a practical benchmark for turbocharged capability. Even brands such as Geely and Zotye—early in their own journeys toward broader international recognition—relied on these tried-and-true components to illustrate that they could deliver a modern, competitive propulsion package without attempting to reinvent the wheel from scratch. The narrative of the Chinese auto industry in that era thus shifted from a simple comparison of features to a more nuanced appreciation of how mature, externally sourced powertrains could accelerate not just product development but the entire supply ecosystem that supported it. This was a form of industrial acceleration that stayed largely quiet in the consumer sphere yet proved transformative for the domestic market.

The broader strategic pattern bore a distinctive cultural stamp often described in industry analyses as the Chinese characteristic: a willingness to integrate mature, third-party components into a growing product lineup to reduce risk and speed up time to market. In practice, this meant more than simply borrowing an engine. It meant a tacit agreement among suppliers and automakers to align on a shared, credible propulsion base that could be scaled and adapted. For newer brands, that alignment was a powerful signal—proof that they could deliver vehicles that met contemporary performance expectations without the prohibitive costs of independent, end-to-end engine development. The success of these partnerships rested on more than just the raw horsepower. It depended on the engine’s modularity, its compatibility with local manufacturing practices, and the reliability of the supply chain that underpinned ongoing production. Over time, the Mitsubishi powertrain family became a de facto standard in several Chinese assembly lines, a quiet but pivotal driver of the nation’s ascent into the global automotive arena.

These dynamics carried important long-term caveats. The reliance on external powertrains created a risk vector centered on supply continuity and strategic access. In the 2020s, as corporate ownership and organizational restructurings altered the global automotive landscape, observers warned that changes in ownership or strategic priorities could affect the availability of well-established engines to emerging markets. The analysis published in 2025, which framed Mitsubishi’s role in China as an enabler of the country’s automotive rise despite brand challenges, underscored this point. If access to proven powertrains were to become constrained, smaller manufacturers could find themselves back at square one, scrambling for bespoke engineering work while contending with higher costs and longer development timelines. The tension between leveraging a mature powertrain and maintaining long-term independence remains a central theme in discussions about China’s auto industry evolution. Yet the historical record also shows a different truth: the engine’s legacy endures not primarily through the Lancer itself but through a cascade of vehicles that carried its core technology into millions of road miles around the world.

A telling facet of this legacy lies in how the engine’s influence extended beyond the technical specifics of turbocharging, fuel delivery, or exhaust tuning. It became a case study in the practicalities of industrial globalization: how a single, well-proven powertrain can act as a catalyst for local experimentation, supplier development, and brand-building under tight budgetary constraints. In that sense, the 2008 Lancer engine did not merely power a car; it powered a process. It demonstrated that a mature powertrain could be effectively decoupled from its original chassis and integrated into an array of platforms, each with its own design language and market positioning. This decoupling, in turn, seeded a more flexible problem-solving culture among engineers and managers in the Chinese market—one that valued reliability, modularity, and the ability to iterate quickly on tuning and calibration across various product families.

Of course, the direct market impact of the 2008 Lancer itself in China remained modest. Its sedan form did not catalyze a sales surge, and the brand’s share in that arena fell under the weight of competition and shifting consumer preferences. Yet in a larger analytic frame, the engine’s contribution was more meaningful as a strategic input. It offered a credible, scalable propulsion option that could be deployed across a spectrum of models, from compact crossovers to more utilitarian pickups. That cross-application versatility helped Chinese automakers demonstrate a broader capability to deliver diverse product lines without compromising certain performance benchmarks. The broader narrative, then, is less about a single launch victory and more about a powertrain’s ability to unlock systemic improvements—development speed, supply chain maturity, and a growing reputation for reliability in a market that demanded both affordability and merit across multiple vehicle categories.

In reflecting on the 2008 Lancer’s engine as a transformative tool, it is helpful to anchor the story in a concrete but understated image: a mature turbocharged four-cylinder that could be calibrated for different outcomes, from everyday practicality to spirited driving dynamics. Its influence extended beyond peak horsepower figures and torque curves. It provided a practical template for how to balance performance with manufacturability in a rapidly growing market. It taught that a powerful engine could be more than a badge of performance; it could be a strategic asset that enabled a broader industrial ascent. The legacy endures in the hundreds of thousands of vehicles produced with its propulsion DNA, vehicles that helped establish credibility for Chinese automakers on the world stage even as the original badge faced its own headwinds. In this sense, the engine’s impact on the automotive industry is not measured by a single model’s success, but by a generation’s ability to translate proven technology into scalable production and market confidence.

For readers tracing the arc from performance engineering to global industry dynamics, the tale of the 2008 Lancer engine offers a compact case study in how a single powertrain can seed growth opportunities far beyond its immediate context. It is a reminder that automotive innovation is not simply about what twitches on a dashboard or speeds down a track; it is also about how design choices travel across borders, how supply chains adapt to new partners, and how the strategic use of existing technology can accelerate an entire industry’s learning curve. The engine’s story thus becomes a quiet but essential chapter in the larger history of global carmaking—one that illuminates the often unseen ways in which mature technology can incubate a new generation of manufacturers, boost regional competitiveness, and widen the safety margin between aspirational design and practical production reality.

For those curious to explore a concrete node in this web of influence, a closely related documentation of Evolution X technology offers a detailed look at how a high-performance, turbocharged powertrain can be linked to a sophisticated all-wheel-drive architecture and a modern dual-clutch transmission. This resource delves into the construction and calibration nuances of the engine system in a way that complements the broader market narrative presented here. 2008-2015 Mitsubishi Lancer Evolution X GSR turbocharged 2.0-liter inline-four linked to a five-speed manual transmission and a Super All-Wheel Drive system 25000 miles

External resource: https://www.globalautomotive.news/2025/09/mitsubishi-engines-china-autos/

Final thoughts

As we’ve explored, the 2008 Mitsubishi Lancer’s engine is not just a mechanical component but a strategic asset for businesses considering performance, reliability, and maintenance. With its rich specifications and innovative design, the Lancer stands out in its class, representing a balance of power and efficiency that can elevate any fleet. By understanding the engine’s capabilities and advantages, business owners can make informed decisions that not only enhance operational efficiency but also provide significant value over time. The insights gathered in this exploration affirm the 2008 Mitsubishi Lancer as a viable choice in today’s competitive automotive landscape.