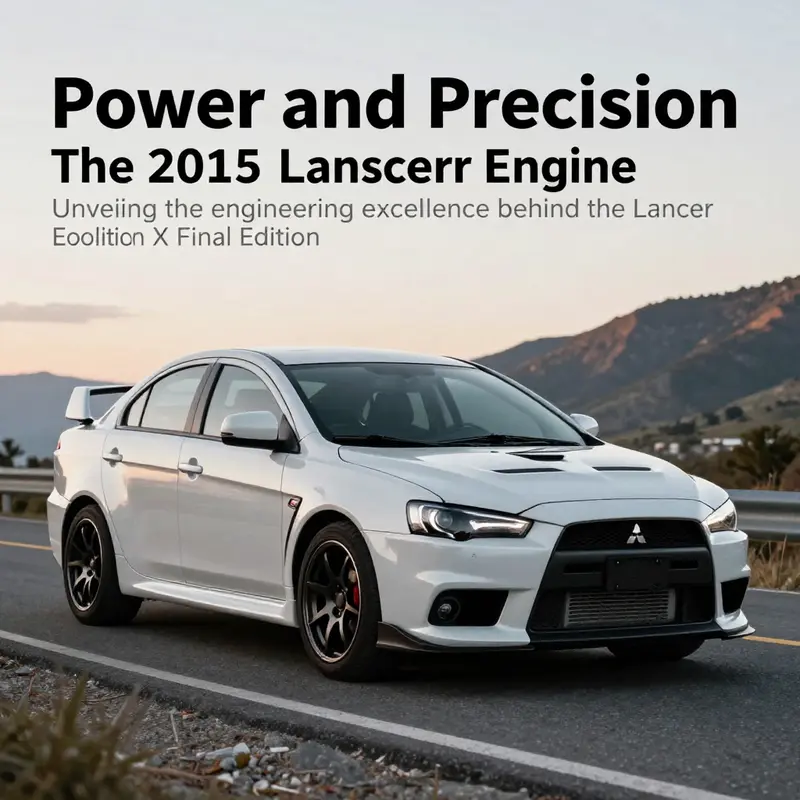

The 2015 Mitsubishi Lancer Evolution X Final Edition represents the pinnacle of engineering in performance vehicles, boasting an impressive engine that embodies power, responsiveness, and technological innovation. Targeting business owners and automotive enthusiasts alike, this article delves into the engine’s specifications, potential performance modifications, and the thoughtful design principles that make it a standout choice in the sport compact segment. By understanding the Lancer Evo’s engine, business owners can appreciate its relevance in both performance and marketability, providing insights that may bolster dealership strategies, enhance customer offerings, and strengthen brand allegiance. Join us in exploring the intricacies of this remarkable automotive masterpiece through three focused chapters.

Final Edition Pulse: Inside the 2015 Lancer Evolution X Final Edition’s 2.0-Liter Turbo Engine

On the eve of the Evolution X Final Edition’s closing chapter, Mitsubishi tuned a familiar, tightly wound engine into a form fit for a finale. The 2015 Lancer Evolution X Final Edition carried a reinforced 2.0-liter turbocharged inline-four that served as the chassis’s beating heart and the driving experience’s guiding hand. This wasn’t a new engine in the sense of a clean-sheet redesign; it was a deliberate evolution of a well-honed architecture. The Final Edition’s 2.0-liter four-cylinder was configured to deliver torque through a broad operating window, with the aim of keeping response crisp and the power delivery linear enough to complement the car’s all-wheel-drive choreography. The factory spec calibrated to deliver a robust level of performance that would stand up to enthusiasts who seek more than straight-line speed; the goal was balanced, track-capable feel while preserving reliability for everyday use. The result was a powertrain that could be felt as much as measured on a dyno, a testament to a platform that had spent years refining its power, response, and ability to translate torque into controlled, usable acceleration. If one surveys the engine’s role within the Final Edition, it becomes clear that the 2.0-liter turbocharged inline-four was designed to reward a driver who values mid-range torque and linear throttle response in the upper revs. The Final Edition’s official figures, issued by the factory, reflect a deliberate tuning choice: horsepower figures in the low 300s and torque in the mid-to-upper range, the range where a performance sedan relies on to push through corners and onto straights with authority. This approach aligns with the Evo’s broader philosophy—traction, balance, and predictable behavior at the limit rather than peak numbers. The engine’s character is underscored by its delivery: a surge of torque that arrives with confidence and sustains through a broad rpm band, allowing the AWD system to do its work without the driver chasing horsepower peaks. In practice, the Final Edition’s engine feels like a well-tuned instrument rather than a one-note accelerator; it invites the driver to explore the car’s handling envelope, confident the engine will stay with them. To understand what the Final Edition represents, it helps to place it in the lineage of the Evolution X’s powertrain. The 2015 era carried a core 2.0-liter turbocharged four that had proven its mettle across iterations, refinements aimed at improving low-end responsiveness, mid-range torque delivery, and top-end breathing. In the context of the year, official numbers varied by market, but the essence remained constant: a robust, mid-sized turbo four with a torque peak well into the mid-range that encouraged eager throttle application. The Final Edition, however, carried a slightly elevated sense of purpose as the last hurrah for a platform that became a benchmark in its class, framed to satisfy purists and enthusiasts who believed in AWD performance and rally-inspired handling. In other words, the Final Edition’s engine wasn’t about raw numbers alone; it was about how those numbers translated into real-world, track-ready capability and predictable street behavior. From a design perspective, this 2.0-liter turbo is a compact, highly engineered power plant featuring modern overhead-cam architecture with a multi-valve head and a balance between efficiency and high-rpm breathing. The turbocharger, intercooling, and fuel delivery system were integrated to deliver cohesive response, with engine management tuned to optimize spool, boost pressure, and fuel atomization in a way that complemented the AWD layout. The chassis’ dynamic character—grip, front-rear stiffness balance, and the way it rotated under power—was intimately tied to how this engine produced torque and how that torque was distributed to the wheels. This is where the evo—both as a machine and a story—found its voice: not just in horsepower peaks but in the way torque arrived and sustained itself, the throttle character translated to tire slip, and the drivetrain translated engine rotation into confident acceleration out of corners. Beyond the factory numbers, the evo community has long understood that the Final Edition’s engine serves as a platform for modification, a tradition that began early in the Evolution lineage. While stock figures present a strong baseline, many owners pursue enhancements that emphasize response time, efficiency at high load, and power reserves for track or controlled street testing. Upgrades that alter airflow, fuel delivery, and calibration can push power levels upward, and such changes are typically accompanied by careful attention to fuel system capacity and intercooling efficiency. In practical terms, the pursuit of more power often involves raising injector flow to meet demands of a larger amount of air, refining the intercooler to reduce intake air temperature under sustained boost, and tuning engine management to balance timing, fueling, and boost across the rpm range. The reality is that the Final Edition’s engine, while already well-engineered, provides a platform whose performance ceiling can be extended with judicious, controlled modifications. That possibility is part of the Evo’s enduring appeal: a powertrain that remains tractable and reliable while delivering more aggressive performance when called for. When discussing numbers in the context of the Evo X’s engine, it is important to appreciate both stock output and practical upgrades. The factory specification for the Final Edition sits in the upper echelons of its segment, reflecting a calibration tuned for mid-range torque and stable high-rpm behavior. The broader Evolution X family has a documented history of outputs that illustrate the relationship between architecture, turbocharging, and drivetrain dynamics. The mid-range torque is a hallmark of the design, keeping the car lively not only at useful speeds but during brisk acceleration out of corners or through straights. In the final edition, those qualities are heightened by reinforcement and refinement that reflect a late-model, high-torque, all-wheel-drive philosophy the Evo lineage spent years perfecting. From a mechanical perspective, the Final Edition engine is part of a broader conversation about durability and performance under load. Enthusiasts who push the upper limits of the powerband often consider strengthening the engine’s lower-end components to withstand extended high-boost operation. A billet-block upgrade represents a logical path for those pursuing higher power and reliability; it speaks to strengthening the bottom end, contributing to more consistent behavior during hot-lapping or sustained acceleration. The engine becomes not only a source of speed but a more stable platform for pushing the vehicle to the edge of its dynamic envelope. In this sense, the Final Edition engine stands as a bridge between a storied lineage and a modern, high-performance expectation. It connects the rally heritage of Mitsubishi’s AWD system to a contemporary road-and-track reality where power is delivered with precision. The engine’s character—torque delivery, throttle response, and compatibility with a demanding drivetrain—reflects a philosophy that values balance as much as brute force. The AWD architecture contributes by offering a way to harness the engine’s power through careful torque management, enabling the car to press forward through turns and over uneven surfaces. The Final Edition thus represents a culmination: a last act that respects the Evo’s core strengths while acknowledging the modern appetite for tunability and real-world performance accessible to enthusiasts who value both speed and control. As the chapter closes on the engine that powered Mitsubishi’s final Evolution, it becomes clear that the 2.0-liter turbocharged inline-four did more than move a car quickly. It embodied a philosophy of performance that balanced tight packaging, broad torque, and the AWD capability that the Evo championed. This was not merely about horsepower numbers but about how those numbers were realized on the street and on the track: a torque-rich stride, an engine that assisted the chassis rather than overpowering it, and a platform that encouraged a driver to explore its limits with control. For readers who wish to connect the engine’s broader technical lineage to practical, hands-on interest, a broader historical context can be found in external resources that trace the Evolution’s development and significance in performance sedans. See for example the Evolution entry on a general reference source: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution.

Unlocking the 4B11T: Practical Performance Mods for the 2015 Lancer Evolution Final Edition

The 2015 Lancer Evolution Final Edition arrives with a stout 2.0-liter turbocharged inline-four, the 4B11T, rated at 303 horsepower and 305 lb-ft of torque from the factory. That rating is a solid baseline. It reflects careful balance between power, reliability, and the complex all-wheel-drive system. Yet the Final Edition was built on the idea of a proper send-off. Owners and builders often push the 4B11T well beyond factory limits. This chapter traces common upgrade paths, explains why each mod matters, and ties upgrades into a cohesive plan that preserves drivability and protects the drivetrain. The aim is a practical narrative that helps you plan sensible, staged modifications rather than a scattershot list of parts.

Begin with purpose: what do you want from the car? Increased midrange torque for spirited canyon runs calls for different choices than a high-boost drag or a grippy track car. Define targets in terms of horsepower and use. From there, every change becomes a deliberate move toward that goal. The stock 4B11T breathes well but is constrained by factory-rated turbo sizing, fueling capacity, cooling, and electronic controls. Removing those limits requires balanced upgrades. The most impactful single change is usually forced-induction hardware. A larger, more efficient turbocharger can add significant power, but it also increases stress on the engine and drivetrain. That trade-off is central. Upgrading turbo hardware without addressing fueling, intercooling, exhaust flow, and engine management leaves the tune precarious and unreliable.

A larger turbo builds more airflow. More airflow, when matched to fuel, translates to more power. But a turbo upgrade should be paired with a high-capacity fuel system. That means larger injectors and a fuel pump capable of delivering higher volume at the required pressure. Upgrading injectors is straightforward, but they must be matched to the engine’s fueling map. Tuning the engine control unit is mandatory after injector or turbo changes. Tuning refines ignition timing, boost delivery, and fuel maps to maintain safe air-fuel ratios and avoid detonation. Without proper tuning, the engine may run lean under boost and risk severe damage. Many builders prefer a staged approach: begin with an intake and exhaust, then upgrade fueling and intercooling, and finally a turbo and an ECU calibration. This order preserves drivability and keeps costs manageable.

Air delivery is more than just the turbo. A cold air intake and a well-planned intake tract reduce intake air temperature and pressure drop. Colder air is denser. Denser air improves combustion and helps resist detonation at higher boost. On the other end, a high-flow exhaust system reduces backpressure and improves spool and throttle response. Together, intake and exhaust free the engine to breathe, and they form the low-cost foundation for further gains. However, on their own they yield modest horsepower increases compared with forced-induction or fueling upgrades. Their real value is in optimizing the efficiency of larger upgrades.

Intercooling is a critical performance foundation. A larger, more efficient front-mounted intercooler reduces charge-air temperatures and limits heat soak during repeated high-boost runs. Cooler charge air reduces the risk of detonation and allows timing to be advanced more aggressively for power. When increasing boost, intercooler capacity must often scale accordingly. Without upgraded intercooling, even modestly increased boost pressures can lead to diminishing returns due to heat buildup.

Engine management sits at the center of any serious power upgrade. Reprogramming the factory ECU unlocks control over boost targets, fuel injection timing, ignition timing, and safety limits. For many builds, a calibrated ECU tune provides the best balance of power and safety while retaining factory conveniences. Advanced builds may move to a standalone management solution for absolute control over fueling, boost control, and knock mitigation strategies. A good tune accounts for fuel octane, trim maps, and the specific combination of hardware in the car. It is also the tool that turns potential into reproducible performance on a dyno or track.

Fuel quality and octane are often overlooked. Higher boost needs higher octane fuel to resist knock. In parallel, some builders adopt methanol or water-alcohol injection systems to reduce intake temperatures and suppress detonation. These systems can allow more aggressive timing and boost without changing the engine’s static compression. They are an effective, lower-cost method to gain power safely, especially when pump fuel is limiting. But they add complexity and require reliable delivery to avoid catastrophic lean conditions under boost.

The internal strength of the 4B11T is respectable, but the limits of a stock bottom end become apparent as power climbs. Rods, pistons, and the crank should be reviewed when pursuing very high power targets. Forged pistons and uprated connecting rods reduce the risk of failure under high cylinder pressures. For builds pushing the envelope, a stronger block or a billet main cap solution adds peace of mind. The idea is to match internal hardware to the expected peak torque. If you plan to exceed the factory torque figure by a large margin, internal reinforcement becomes a necessary investment rather than a nice-to-have.

Beyond the engine itself, the transmission and drivetrain must be addressed. The Final Edition uses a robust all-wheel-drive system, but its clutches and differentials have limits. A much higher peak torque figure increases the chance of clutch slip or drivetrain breakage. Upgrading the clutch and considering strengthened axles or reinforced differential components reduces the risk of failure. Similarly, transmission cooling and gearbox service intervals should be revisited. Power is only useful if you can reliably put it to the road or track.

Thermal management covers more than the intercooler. An upgraded radiator and an oil cooler help manage under-hood heat during extended hard driving. Oil temperatures influence both lubrication and detonation thresholds, so keeping oil cool improves consistent performance. Transmission and differential oil coolers also preserve gear life when the car is pushed beyond stock power and load profiles. Thermal stability keeps the engine producing clean, repeatable power lap after lap.

Tuning for drivability matters. A powerful car that is unpleasant to drive undermines the purpose of many builds. Boost delivery curves, throttle mapping, and torque management all influence day-to-day use. A larger turbo may yield higher peak figures but can introduce lag. Advanced tune strategies such as variable boost control and anti-lag systems can reshape power delivery but at a cost to longevity and noise. Many owners prefer a moderate turbo that improves midrange torque while keeping spool and throttle response friendly. That choice typically yields a more usable car on mixed street and track duties.

Expectations should be calibrated into realistic upgrade tiers. Small bolt-on upgrades—intake, exhaust, intercooler, and ECU remap—can lift the 4B11T’s output by a healthy margin while keeping the stock block and drivetrain intact. Mid-level builds, including a larger turbo, upgraded injectors and pump, and supporting cooling, commonly double the real-world torque in the midrange. High-power builds that exceed the block’s comfort zone require forged internals, block strengthening, and heavy-duty drivetrain upgrades. Each step multiplies complexity and cost, so plan the end goal early to avoid wasted parts and rework.

Dyno tuning and iterative testing are non-negotiable. Real-world results vary based on altitude, intake temperature, and fuel quality. A dyno provides a controlled environment to measure gains and to tune safely. Multiple dyno pulls are typical during a tune to refine fueling and timing across the rev range. Data logging during street and track use closes the loop, revealing how the engine behaves under real conditions. Successful builds rely on a cycle of upgrade, tune, test, and refine. Skipping any part of that loop amplifies risk.

Traction and chassis upgrades play an equal role as engine mods. With increased power, suspension, tires, and brakes need attention. Modern all-wheel-drive systems can mask poor chassis setup, but the car still needs effective suspension geometry and tires to put down the power predictably. Braking upgrades and high-temperature brake fluid become necessary as lap speeds rise. Stiffening bushings and reinforcing mounting points improves responsiveness and feedback. Power without control becomes a liability rather than an asset.

Street legality and emissions compliance are practical considerations. Some performance modifications affect emissions outputs and may violate local regulations. Before installing hardware that alters exhaust or the engine control system, check local laws. Depending on the jurisdiction, certain upgrades may require inspection, certification, or a return to stock for road use. Planning around these constraints keeps the car usable without surprises.

Budgeting and phased builds reduce regret. Start with a well-defined target and plan upgrades in stages. Prioritize foundational changes that protect the engine and drivetrain: fueling, cooling, and proper engine management. Buy components that fit the next stage to avoid swapping out parts twice. A staged build also spreads costs and gives time to assess real-world needs. Join builders’ communities to learn from others’ experiences and to avoid pitfalls unique to the 4B11T platform.

Finally, consider professional installation and tuning for major upgrades. Many performance failures trace back to poor installation or inexperienced tuning. A reputable tuner familiar with the engine and the car’s drivetrain can save money by preventing damage. Document every change and maintain logs. That information proves invaluable when diagnosing issues or when returning to stock for inspections.

For those looking to explore specific engine-block upgrades and machining options that increase bottom-end reliability, there is a resource that details block reinforcement approaches for the 4B11T. Refer to the technical overview of a strengthened 4B11T block to understand the benefits of billet main caps and other reinforcement methods: 4B11T billet block.

When considering turbo theory, airflow, and efficiency around compressor maps, a clear external primer helps make tuning decisions more informed. A concise explanation of how turbochargers function and how they influence power delivery is useful as a companion to hardware choices: https://en.wikipedia.org/wiki/Turbocharger

Every modification decision for the Final Edition should reflect a balance among power, reliability, and intended use. The 4B11T responds well to thoughtful, staged upgrades. It rewards owners who match airflow, fuel, cooling, and control in a coordinated plan. Above all, treat power as part of a system. When each component supports the rest, the result is an Evo that feels cohesive, powerful, and dependable on road or track.

Final Edition Powerplant: Engineering the 4B11T for the 2015 Lancer Evolution

Final Edition Powerplant: Engineering the 4B11T for the 2015 Lancer Evolution

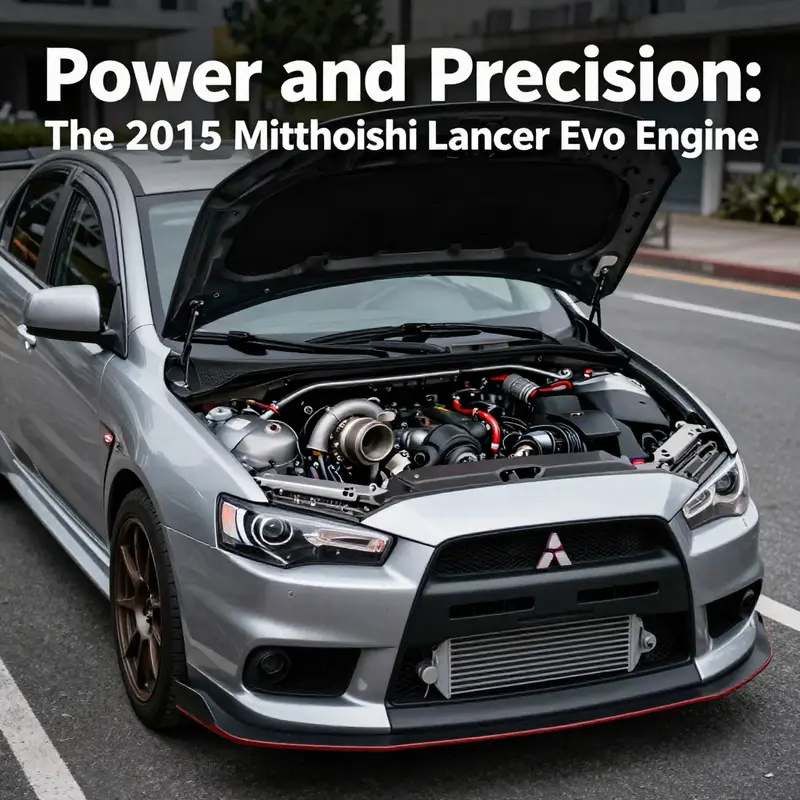

The 2015 Lancer Evolution Final Edition’s engine is the clarion call of a performance lineage. Its 2.0-liter turbocharged inline-four, internally designated 4B11T, was refined to deliver a decisive blend of race-capable output and everyday usability. That combination shaped every engineering choice, from the crank’s metallurgy to the turbocharger’s flow characteristics. The factory figures—303 horsepower at 6,500 rpm and 305 lb-ft (414 N·m) of torque between 3,000 and 4,500 rpm—tell only part of the story. The underlying architecture and design priorities reveal how Mitsubishi extracted peak potential while preserving the durability and drivability the Evo badge requires.

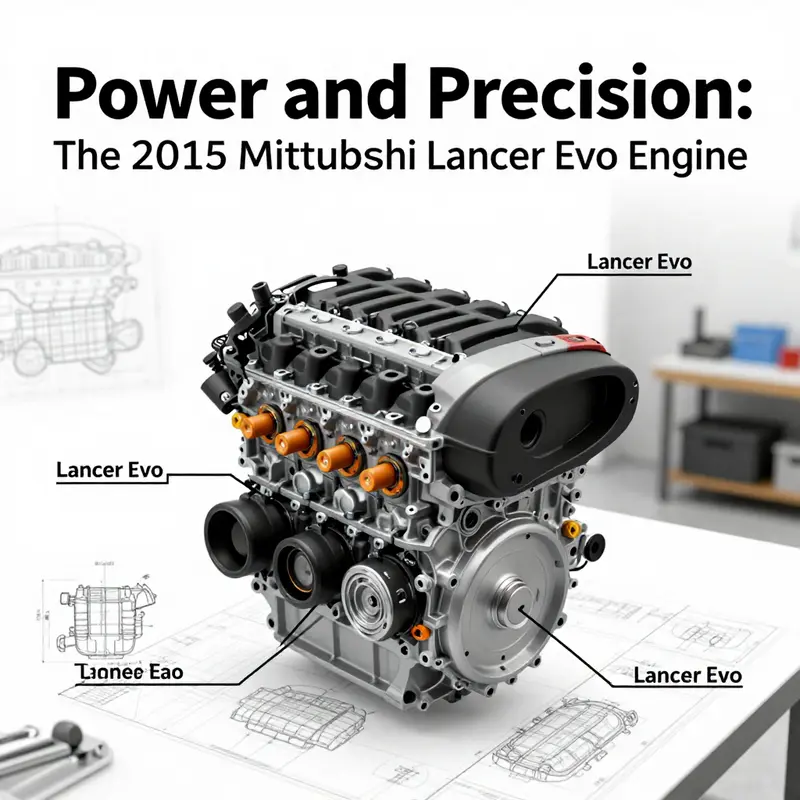

At the heart of the Final Edition is an engine block and rotating assembly built to tolerate heat, pressure, and frequent high-load use. The designers specified a forged steel crankshaft to withstand repeated high-rpm torque pulses. Forged steels resist fatigue far better than cast alternatives, so the crank can survive extended track sessions. Complementing the crank are connecting rods made from a titanium-alloy. Titanium offers a high strength-to-weight ratio and reduces reciprocating mass. Lower reciprocating mass helps the engine rev more freely and reduces stress on bearings and the crank at high rpm. Pistons and rings, while tailored for the combustion characteristics of a turbocharged direct-injection engine, sit in reinforced cylinders designed to handle elevated cylinder pressures and occasional knock mitigation strategies.

The decision to use direct injection was central to the engine’s performance and efficiency balance. Direct injection permits higher compression ratios without detonation, because fuel is introduced directly into the combustion chamber. That approach improves atomization and cooling of the intake charge. Cooler, denser charge improves knock resistance and produces a more complete burn. For a turbocharged engine that must deliver broad torque across a useful band, direct injection brings sharper throttle response and cleaner midrange power. It also allows calibrations that favor fuel economy in normal driving, while remaining capable of aggressive fueling under boost.

Turbocharging on the Final Edition is accomplished with a twin-scroll design. Twin-scroll turbochargers separate exhaust pulses from paired cylinders into two scrolls. This separation reduces pulse interference and preserves exhaust energy, enabling quicker spool and stronger low-end torque. For a street car that must feel responsive immediately off the line, that quicker spool is crucial. Engineers tuned the turbine housing and compressor matching to provide a controlled powerband. The goal was to maintain usable low-end torque while allowing for the strong top-end power that peaks at 6,500 rpm. That compromise defines the Evo’s signature personality: immediate response with a linear climb in power.

Beyond forced induction, the Final Edition’s internals are reinforced to accept higher stress and potential aftermarket tuning. Reinforcements include improved fasteners and areas of the block that bear load from the main caps. Some owners pursue further strengthening for extreme builds, often adding billet or sleeved components. For those interested in block reinforcement options, a useful reference discusses a billet version of the 4B11T block and its applications.

Cooling and charge-air management received a careful rethink as well. Turbocharged engines create localized hotspots. To protect valves, pistons, and turbo bearings, the Final Edition uses a higher-capacity intercooling path and optimized coolant flow. The intercooler reduces intake temperatures, thereby increasing air density and helping prevent knock during high-load runs. Oil cooling also plays a crucial role. An upgraded oiling circuit and an efficient oil cooler maintain viscosity and lubrication under sustained stress. Thermal management is not glamorous, but it is essential. The ability to hold consistent combustion timing and oil pressure separates a capable street car from a weekend track car.

Fuel delivery for the Final Edition balances factory reliability with headroom for tuning. The stock injector sizing supports the factory power and allows some margin for bolt-on upgrades and mild tuning. The engine management system features mapping that takes turbo spool, intake temperature, and knock-sensor feedback into account. It modulates boost and ignition timing to maintain safe operation across a wide envelope. This strategy gives drivers predictable throttle behavior under normal use, while enabling precise tuning for higher-performance setups.

One of the Evo’s defining traits is its mechanical sympathy with the driver. That extends to the transmission choice. The Final Edition retained a five-speed manual gearbox, chosen for its direct mechanical feel and robust gearing for high-torque application. The gearbox’s gear ratios and the clutch assembly were selected to match the 4B11T’s torque curve and rev range. The manual provides a tactile connection between engine and road, helping drivers manage boost and put power down precisely. It also simplifies the drivetrain architecture over more complex dual-clutch systems, reducing potential losses and improving reliability under extreme use.

Drivetrain integration was another engineering focus. The AWD system, a performance-oriented all-wheel drive, was tuned to the engine’s torque characteristics. Power distribution strategies were calibrated to maximize traction out of tight corners and to translate midrange torque into forward acceleration. Torque vectoring and center differential behavior were configured so the car would feel balanced during both aggressive maneuvers and spirited street driving. Mounting points, driveshafts, and differentials were reinforced to handle the engine’s torque and the higher loads that come from enthusiastic drivers.

Noise, vibration, and harshness (NVH) received careful attention. A performance engine must still be tolerable in daily use. The engineers isolated certain frequencies through mounting design and harmonic balancing. The titanium-alloy rods and forged crank contribute to a tighter, more refined mechanical behavior. Intake and exhaust acoustics were tuned to deliver an evocative soundtrack without producing intrusive cabin droning during highway cruising. The result keeps the engine engaging and communicative, while remaining comfortable for longer trips.

Combustion control and emissions were balanced against peak performance. Modern engines must meet regulatory standards even when tuned for high output. The Final Edition uses advanced ignition mapping, adaptive knock control, and precise fuel metering to meet emissions targets without sacrificing raw power. The factory tune represents a careful calibration: strong power, robust midrange torque, and acceptable emissions across differing driving cycles. For those who pursue higher outputs, aftermarket tuning often focuses on boost control, fueling, and timing adjustments. These modifications can dramatically raise peak power, but they require matching supporting hardware and careful calibration to maintain engine longevity.

Reliability under stress drove choice of materials for wear-prone areas. Cylinder walls, bearing surfaces, and valve train components are treated with coatings or made from materials that reduce friction and wear. Valve springs and retainers are selected to resist float at high rpm. Head gasket design and fastener torque sequences account for increased cylinder pressures in a boosted engine. These seemingly small choices compound into significant durability gains when the engine is driven hard or tuned for greater output.

The Final Edition’s engine layout also supports maintenance and modification accessibility. Inline-four packaging keeps the engine compact. That compactness benefits weight distribution and under-hood space, which in turn helps cooling system routing. Service points like filters, belts, and spark plugs are placed for practical access, making routine maintenance easier. For tuners, the engine bay leaves room for intercooler piping, upgraded intake systems, and larger turbo installations. This practical arrangement contributed to the model’s popularity among enthusiasts seeking performance upgrades while preserving reliability.

While the factory output establishes a strong baseline, the 4B11T platform has clear headroom for aftermarket development. Common upgrade paths include higher-flow injectors, increased fuel delivery, improved intercooling, and larger or differently characterized turbochargers. Each modification changes how the engine breathes and responds. For example, upgrading injectors without matching fuel pumps can create lean conditions under high boost. Adding a larger turbo without revising fueling and tuning can increase lag. Thoughtful, staged upgrades yield the best long-term results. Professionals typically recommend upgrading the fuel system and heat management first, then tuning boost and timing once the engine reliably handles higher loads.

Engine management plays a central role in realizing upgrades. A calibrated ECU provides precise control over timing, fueling, and boost. Many experienced tuners prefer a conservative approach to ignition timing when power increases significantly. This helps avoid detonation and reduces stress on pistons and rods. Knock-detection systems remain vital. When modifying, matching the safety nets of the factory system—either by retaining them or implementing equivalent protections—is essential for protecting investment and preserving engine life.

Track use and repeated high-load driving demand particular attention to consumables and support systems. Cooling upgrades, higher-capacity oil coolers, stronger clutch packs, and reinforced drivetrain components are typical on vehicles used regularly in competition or on track days. Brake systems and tires must also be upgraded to cope with increased performance. The engine is only one part of a performance ecosystem, and the Final Edition was engineered to integrate well into that system when upgraded responsibly.

Owners and builders have recorded substantially higher power outputs from the 4B11T with systematic upgrades and dyno-proven tuning. The baseline 303 horsepower can be significantly exceeded with matched hardware and careful calibration. But raising peak numbers comes with trade-offs: increased heat, higher mechanical stress, and more frequent maintenance intervals. Proper cooling, oiling, and driveline upgrades mitigate these issues and extend vehicle longevity.

From a design philosophy standpoint, the Final Edition’s engine is the product of deliberate compromises. The engineers chose materials and components that favor a blend of track resilience and street manners. They prioritized a responsive, usable torque band rather than a narrow, peak-focused curve. They ensured that the engine would be satisfying for the enthusiast driver, yet dependable for daily use. That balance resonated with the evolution community and with drivers who wanted a capable, predictable performance car.

In practical terms, buyers of the Final Edition receive an engine that is ready for aggressive driving out of the box. The factory specification provides a strong foundation for further upgrades. For builders who choose to pursue more power, the platform’s architecture and aftermarket ecosystem offer many options. A prudent upgrade strategy, focused on fuel, cooling, and ECU control, will unlock significant gains while protecting the engine’s integrity. The community around the Evo series has developed substantial knowledge, and numerous upgrade paths have matured over time.

This engine’s legacy is not only in its numbers. It represents the culmination of iterative improvements across previous models. Each refinement—stronger internals, improved turbocharger technology, better thermal management, and more precise fuel delivery—was aimed at delivering a distinct driving experience. The Final Edition is the engineered answer to the question: how do you extract maximum usable performance from a compact turbocharged four-cylinder while keeping it reliable and enjoyable? The 4B11T’s design choices provide that answer.

For official technical reference and a deeper look at the Evolution program, the manufacturer’s evolution overview offers further detail. (See: https://www.mitsubishimotors.com/evolution/)

For additional information on block reinforcement options for this engine, consider this resource on the 4B11T billet block: 4B11T billet block

Final thoughts

The 2015 Mitsubishi Lancer Evolution X Final Edition encapsulates a blend of advanced technology, engineering prowess, and market-ready enhancements that appeal to performance-driven consumers. Understanding its engine specifications not only highlights the vehicle’s inherent capabilities but also lays the groundwork for discussions on performance modifications, which can significantly enhance its appeal. Furthermore, recognizing the engineering principles involved in its design provides valuable insights for business owners looking to resonate with customers who prioritize performance and innovation. The Lancer Evo stands as a testament to vehicle engineering excellence, merging power with purpose.