The Mitsubishi Lancer Evolution X has captivated car enthusiasts with its performance and style. Among the key upgrades transforming this vehicle is the carbon fiber hood, a modification that not only reduces weight significantly but brings a host of performance benefits. Understanding how this upgrade works requires a closer look at its implications on vehicle weight, performance enhancements, effective design features, and the intricate manufacturing processes involved. This article delves into the evolution of the carbon fiber hood for the Evo X, articulating how its lightweight composition impacts performance and efficiency, exploring the functional designs that cater specifically to the Evo X’s turbocharged engine, and discussing the manufacturing and sourcing concerns that underscore this significant aftermarket upgrade.

Less Weight, More Edge: How a Carbon Fiber Hood Sharply Enhances the Evo X

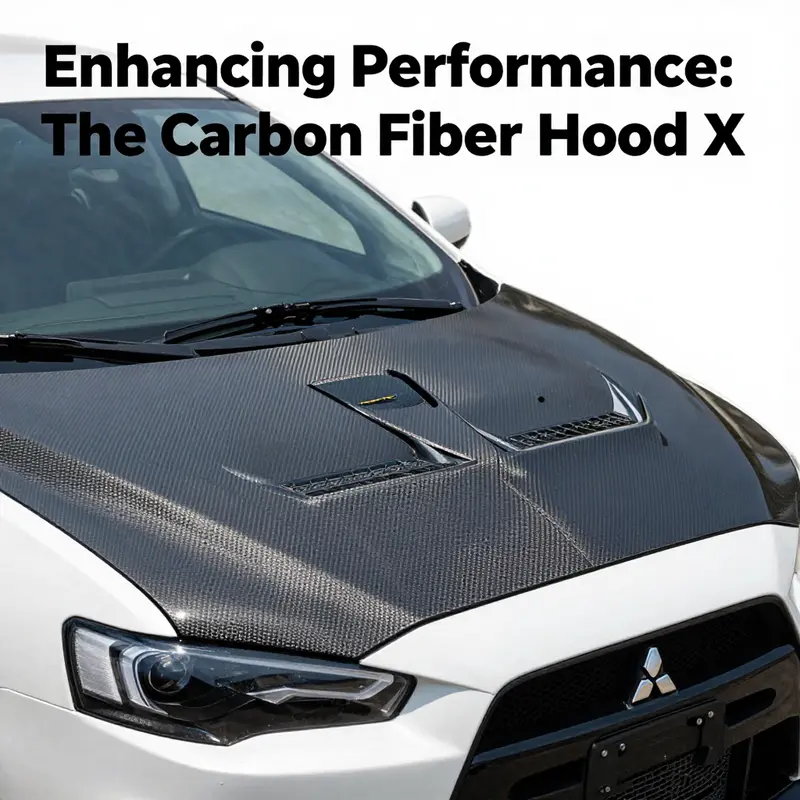

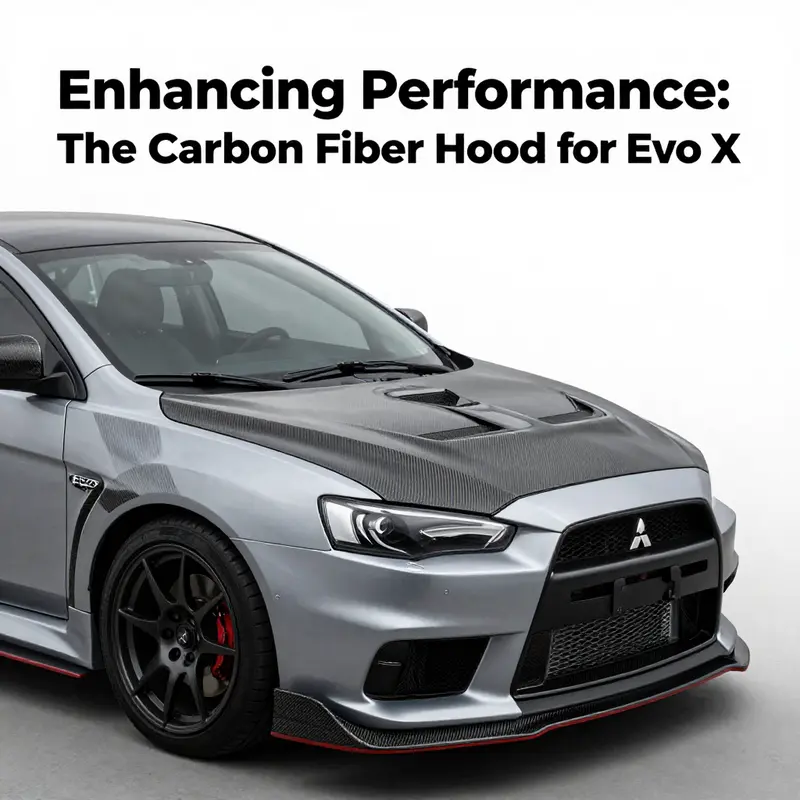

The Mitsubishi Lancer Evolution X is built on a foundation of rally-bred performance and precision. Swapping its factory hood for a carbon fiber replacement is one of the most immediate ways to sharpen that character. The change is often thought of as cosmetic, but the real impact is measurable and multi-faceted. A carbon fiber hood reduces mass at the front of the car, refines weight distribution, and enables better cooling and aerodynamics when designed with functional vents and scoops. These improvements translate to quicker, more confident responses on the street and the track.

Carbon fiber’s appeal starts with the numbers. A full replacement hood typically saves between 20 and 35 pounds, roughly 9 to 16 kilograms. Those figures vary by vendor and design, but they are consistent enough to be meaningful. The material itself is far lighter than steel and significantly lighter than aluminum. Crucially, it maintains a high strength-to-weight ratio. A well-made panel resists flexing while shedding mass where it matters most. Reducing weight at the front end of the Evo X does more than help lap times; it changes how the car communicates with its driver.

Lowering the hood’s mass reduces the inertia that the front suspension and steering feel. With less weight over the front wheels, the suspension reacts faster. Tire contact patches settle more quickly after bumps. That means sharper turn-in and a calmer chassis during transitions. Drivers notice improved steering precision and feedback. The car feels more willing and responsive at medium and high speeds. In tight sequences, such as chicanes or mountain roads, the reduced front mass helps the Evo X change direction with less delay.

Acceleration also benefits from shedding weight up front. A lighter hood lowers total vehicle mass, which reduces the power required to accelerate. On a turbocharged platform like the Evo X, that often means quicker sprints from a dig or out of corners. The improvement in 0–60 times may be measured in tenths of a second, but on the track those tenths add up. The same mass reduction helps braking: lower kinetic energy needs to be dissipated, and brake feel can become more progressive. With reduced front-end load, the brake system can stabilize more predictably under heavy deceleration.

Beyond raw mass savings, the placement of that weight matters. Moving less mass forward reduces polar moment and yaw inertia. The car rotates more willingly around its center. In practical terms, drivers experience this as easier rotation into corners and improved mid-corner control. The Evo X, already tuned for agility, becomes even more nimble. For enthusiasts who tune suspension geometry or run stiffer springs and dampers, the hood’s weight drop lets those changes show their benefits without being masked by excess frontal mass.

A carbon fiber hood can also influence aerodynamics and lift characteristics. At speed, front-end lift reduces tire load and compromises high-speed stability. While aerodynamic devices ultimately set downforce levels, reducing the frontal mass that interacts with aerodynamic pressures helps. A lighter hood means less mass being accelerated by lift or buffeting, so the chassis holds steadier. Moreover, many carbon fiber hoods come with vents and scoops that actively manage airflow across and through the engine bay. Done correctly, these features reduce under-hood pressure and help extract hot air, which stabilizes intake temperatures and decreases heat soak on critical components.

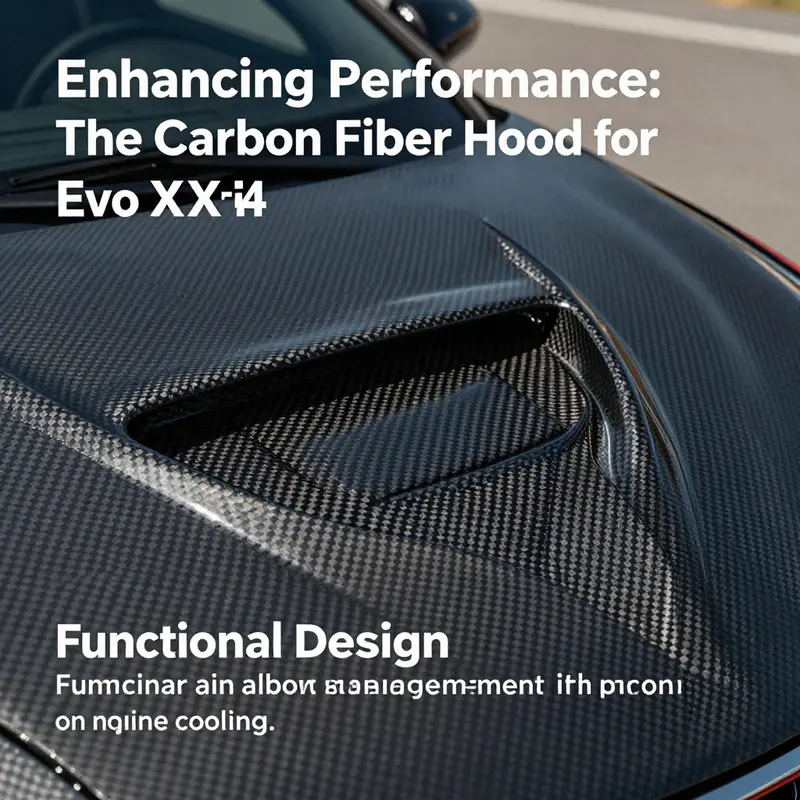

Functional scoops are especially valued on the Evo X. The turbocharged 4B11T engine benefits from directed airflow. A raised center scoop can channel cool ambient air toward the intake or the intercooler area. Cooler, denser intake air improves combustion efficiency and helps the turbocharger make consistent boost. During sustained high-load driving, such as track stints or spirited canyon runs, this can translate to steadier power delivery and reduced likelihood of heat-related detuning. That said, functionality requires careful design. A poorly executed scoop may admit water in heavy rain or create turbulent airflow that increases intake noise. Proper sealing and routing are necessary to prevent unwanted water ingress and to maintain intake system reliability.

Engine cooling is further aided by venting that allows heated air to escape the engine bay. When hot air is trapped, temperatures rise and components can reach thermal limits faster. Strategic vents relieve pressure and create a more efficient thermal path for heat to leave the bay. This helps inlet temperatures, oil and coolant stability, and even prolonged brake performance. On circuits where multiple hard laps are common, improved cooling can preserve lap times by reducing the rate at which performance drops off during a session.

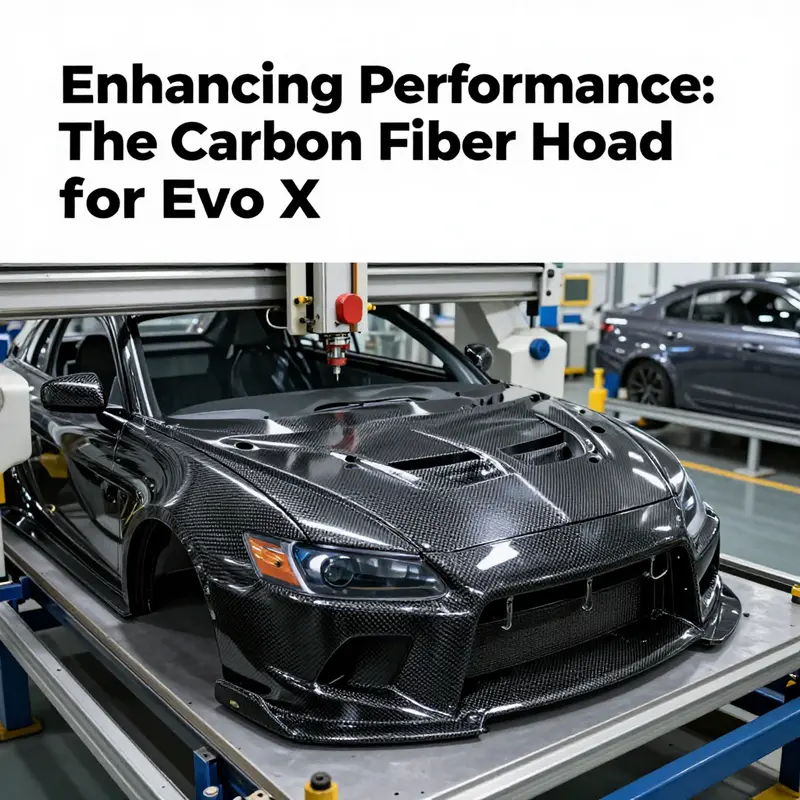

The materials and manufacturing processes behind a carbon fiber hood determine how well these benefits are realized. High-grade pre-preg carbon fiber, cured under controlled heat and pressure in an autoclave, yields consistent lamination and resin distribution. CNC-machined molds provide tight tolerances for fitment and consistent panel thickness. Quality layup techniques and specified resin content ensure the hood retains its shape and strength under load. Buyers should look for documentation that describes fiber grade, resin type, and curing method. Specific fiber grades such as T300 or T800 indicate different tensile strengths and stiffness. Certifications or test reports that confirm proper layup and resin ratios are valuable indicators of engineering rigor.

Manufacturing quality goes beyond materials. Fitment precision affects how the hood interfaces with the rest of the car. Poorly fitting panels can introduce gaps that increase aerodynamic drag and reduce the intended cooling efficiency. They may also require additional trimming or shimming, which can compromise the part’s integrity. A hood that sits flush with the fenders and aligns neatly with the windshield does more than look right; it preserves planned airflow paths and reduces wind noise. Many reputable suppliers use prototype and R&D cycles to refine clamp points and hinge geometry. This attention to detail reduces installation time and preserves factory latch and safety functionality.

Authenticity matters, and there are telltale signs of a well-made hood. Pre-preg material with even fiber orientation, smooth resin surfaces, and consistent weave patterns indicate careful layup. Clean interior finishes and proper reinforcements around hinge areas and mounting points show attention to structural loads. Reinforced bumpers near latch and hinge attachments prevent stress concentrations that can lead to cracking. Transparent specifications that list dimensions, resin content, and fiber grade help buyers compare like-for-like. Typical dimensions for an Evo X hood cluster around 172 x 165 x 35 cm, though variations exist with scoops and vents.

Aesthetics remain an important factor. The exposed weave of carbon fiber provides a modern, purposeful look that complements the Evo X’s aggressive stance. Clearcoat finishes preserve the weave and offer UV protection. Some owners prefer a painted or wrapped finish to match body color while keeping the core benefits intact. Either way, the visual upgrade signals performance intent while actually improving dynamics.

Installation and use come with practical considerations. A lighter hood changes how the car needs to be handled when the bonnet is open. Hinges and struts notice the weight difference, and some fitments require new hood props or gas struts rated for the changed mass. Latches and secondary catches must remain compatible to ensure occupant and pedestrian safety. When vents and scoops are functional, routing for cold air intakes and heat shields can require slight adjustments. Waterproofing measures around the intake path are recommended to prevent water ingestion in severe weather.

Owners who track their Evo X will appreciate that the hood’s thermal and weight benefits compound with other upgrades. Reduced front mass pairs well with brake upgrades and suspension tuning, allowing those components to work more effectively. Similarly, improved airflow improves intercooler and intake performance, helping to sustain power under duress. On the street, the reduced fuel burn during acceleration and the lessened load on brakes deliver tangible day-to-day benefits.

Durability is a key concern. High-quality carbon fiber panels resist dents and corrosion unlike steel. They can, however, be damaged by impact or improper mounting. Repairs are possible and typically involve patching with compatible fiber and resin systems. Owners should store and handle the panel with care to avoid chipping the clearcoat or cracking thin sections near vents. Regular inspection of mounting hardware and clearcoat integrity helps prevent small issues from becoming structural problems.

For buyers weighing options, consider how the hood will be used. A visually focused, non-functional panel reduces weight and offers the look of performance with minimal integration work. A functional design with vents and scoops amplifies cooling and intake benefits but may require additional sealing and integration with intake plumbing. Look for suppliers who publish clear specifications and provide fitment support. If you want the best return on investment, prioritize authentic pre-preg layup, autoclave curing, and defined fiber grades.

Real-world examples show that the hood’s impact is not merely theoretical. Drivers report sharper cornering, improved throttle response, and steadier power during hard sessions. Track times often tick down as handling becomes crisper and temperatures stabilize. On the street, the combination of lighter front weight and improved cooling results in a car that feels more lively and composed. These outcomes depend on proper installation and selecting a panel that matches the car’s intended use.

If you are exploring options, consider a product listing that matches your goals. One source that offers a direct, Evo X–specific carbon fiber hood can be reviewed at this internal listing for a brand new original carbon fiber bonnet for Evo X: https://mitsubishiautopartsshop.com/brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x/. That page includes dimensions, finish options, and compatibility notes useful for comparing fitment and finish.

When performance is the objective, a carbon fiber hood is more than style. It reduces rotational inertia, sharpens steering, shortens braking distances, and helps maintain intake and coolant temperatures. Those benefits are magnified when the hood is produced using pre-preg materials, autoclave curing, and precise tooling. Buyers should prioritize verified material grades and clear technical specs. Practical considerations such as hood latch compatibility, water ingress protection for functional scoops, and finish care are important for long-term satisfaction.

A carbon fiber hood is a focused upgrade. It affects the dynamic core of the Evo X by moving mass, shaping airflow, and changing how the car reacts to driver inputs. Whether the goal is faster lap times or a more engaging daily drive, the hood delivers a concise set of benefits that align with the Evo’s performance DNA. For additional technical details and product information, visit the manufacturer’s site: https://evolveextreme.com

Sculpted Performance: How the Carbon Fiber Hood Transforms an Evo X’s Cooling, Weight and Aero

Functional Design and Real-World Tradeoffs\n\nA carbon fiber hood for the Evo X is far more than a cosmetic swap. It alters how the car breathes, moves, and reacts to sustained load. The design decisions that go into a high-quality hood influence cooling efficiency, weight distribution, aerodynamic balance, and even cabin noise. In practice, those decisions are a blend of engineering priorities and stylistic cues, with each tradeoff affecting everyday driving and track performance. This chapter traces the core functional elements of that design, explains why they matter to Evo X owners, and highlights the practical tradeoffs worth considering.\n\nAt the center of the hood’s performance story is ventilation. Vents and scoops are not ornamental. They are channels that control airflow through the engine bay. A raised center scoop, common on Evo X hoods, captures dynamic pressure at the nose and directs cool air into the intake or toward heat sources. Side or center vents provide escape paths for hot air trapped over the turbocharger, intercooler piping, and exhaust manifolds. When the car is cruising, cool air flows into the bay and pushes hot air out through those vents. Under sustained hard acceleration, this exchange becomes critical. Without effective venting, heat soak raises intake temperatures and reduces power consistency. With the right vent geometry, intake charge temperatures fall, detonation margins improve, and lap times become more repeatable.\n\nVent placement matters. A vent near the cowl helps evacuate heat rising from the top of the engine. Vents placed ahead of the intake better cool the air feeding the turbo. Designers also tune vent size and angle to avoid turbulence that undermines airflow. For the turbocharged 4B11T in the Evo X, a hood that channels air toward the cold air intake or front-mounted intercooler reduces intake air temperature during high-load runs. That benefit is measurable; racers and tuners report more consistent torque delivery and fewer temperature-related power drops. But seals and fitment are equally important. A functional scoop that funnels air into the bay must be sealed at the intake or fitted with splash guards. Without these precautions, heavy rain can find a path into the intake, risking hydrolock or damage to sensitive components. Practical owners often balance vent aggression with weather protection and routine maintenance needs.\n\nWeight reduction is the second pillar of functional design. Replacing the factory steel hood with a carbon fiber unit typically reduces front mass by thirty to fifty percent. This drop in weight shifts the car’s dynamic balance. Reduced mass over the front axle lowers the polar moment of inertia. The result is quicker turn-in, improved responsiveness, and reduced understeer under mid-corner load. Braking distances shorten slightly because there is less mass to decelerate at the front. The cumulative effect is a sharper, more agile chassis that reacts faster to steering inputs. For drivers who use their Evo X on track or in spirited street driving, the tactile gain is unmistakable.\n\nHowever, identical weight numbers can mask structural differences. A properly built carbon fiber hood must offer enough rigidity to resist flexing at high speeds. Pre-preg carbon fiber cured in an autoclave is the benchmark for this. Proper layup schedules, fiber orientation, and resin content determine stiffness. Cheap hoods may shave weight at the expense of rigidity, producing flutter at speed or poor panel fitment. Structural integrity also influences crash performance. A high-quality carbon hood will resist dents and maintain dimensional accuracy over time, even under heat and UV exposure. Poor materials, by contrast, can delaminate or warp. For Evo X owners seeking both performance and longevity, verifying manufacturing processes and material grades matters. Look for documentation indicating pre-preg use, autoclave curing, and specified fiber grades such as T300 or T800. These details indicate a build that balances lightness with durability.\n\nAerodynamics are the third major consideration. A hood is the first surface that encounters airflow rising from the front bumper and wheel wells. A sculpted profile can smooth that airflow, reducing drag and managing local pressure over the front end. Strategic venting can also create useful downforce by accelerating air through exit ducts and lowering pressure above the engine bay. That negative pressure helps keep the front end planted at speed. For high-speed stability, a hood that integrates with the front bumper, splitter, and fender geometry produces better results than an aggressive hood installed in isolation. In other words, the aerodynamic benefits of a carbon hood are amplified when considered as part of the car’s entire aero package.\n\nYet, aggressive venting can produce noise. Increasing airflow through the engine bay changes the acoustic environment. Owners often notice more mechanical roar and wind-induced noise due to pressure differentials at high speeds. Some drivers embrace the raw, race-inspired sound. Others prefer a quieter cabin. Designers mitigate this by tuning vent aperture and using internal baffles that decouple airflow from cabin resonance. A small layer of thermal and acoustic insulation behind the hood can mute noise while preserving cooling. Keep in mind that adding insulation reduces some of the weight savings and can alter thermal transfer. It’s a tradeoff every owner must weigh: sound and rawness versus comfort and insulation.\n\nFitment and mounting detail rarely headline conversations, yet they define the difference between a crisp upgrade and constant adjustment. A carbon hood must align with OEM latch points, hinge locations, and fender gaps. Quality manufacturers machine their molds precisely and test fitment across multiple production cars. When fitment is spot-on, the hood uses factory hardware and the OEM latch. When fit is poor, owners resort to hood pins, shims, or custom brackets. Hood pins are a common solution for track cars; they add redundancy and a motorsport look. But they also change how the hood behaves in an impact. Proper reinforcement around latch holes is essential. Look for hoods with built-in reinforcements or backing plates where hardware attaches. This extension of design foresight prevents cracking and elongation under stress.\n\nThermal management extends beyond airflow. The hood’s inner surface absorbs and radiates heat. Some hoods use a carbon weave on both sides; others add a resin-rich finish or clear coat. How the hood handles heat influences under-hood temperatures during idling and slow-speed traffic. A hood that conducts heat poorly might trap heat near the headlight and cowl area. Conversely, a hood that helps radiate heat can lower bay temperatures when parked or during pit stops. High-temperature resistant resins and proper curing reduce the risk of discoloration or structural change from repeated thermal cycles. UV-resistant clear coats protect the visible carbon finish, preserving appearance and preventing surface degradation.\n\nVisual aggression is more than vanity; it signals the hood’s intent. The distinctive carbon pattern and sharp lines broadcast a performance focus. That psychological cue matters for enthusiasts building a coherent package. A hood with vents and a scoop not only moves air better. It telegraphs a purpose-built approach. For many owners, that look is part of the satisfaction. Good hoods incorporate a finished look under the bonnet as well. Smooth inner surfaces and neat edge treatments reduce the likelihood of chafing wires and hoses. Attention to detail in finish and fit indicates broader quality in manufacturing.\n\nManufacturing origins influence those details. Over recent years, regions with vertically integrated composite supply chains have dominated production. Proximity to pre-preg suppliers, mold makers, and R&D centers enables shorter iteration cycles and tighter quality control. This industrial clustering leads to better priced, higher-quality hoods available at scale. For buyers, sourcing from a reputable supply chain reduces the chance of surprises. When shopping, verify manufacturing claims and ask for layup specifications, curing methods, and fiber grades. A transparent supplier will share these details.\n\nSelecting the right hood requires assessing use case. For a daily-driven Evo X, moderate venting with weather sealing and acoustic treatment strikes a good balance. For a track-focused car, larger scoops, more aggressive vents, and lightweight layups favor thermal performance and weight savings. Consider also compatibility with existing upgrades. Cold air intakes, front-mount intercoolers, and turbo plumbing interact with hood airflow. A hood that channels air toward the intake amplifies cold-air system efficiency. Conversely, a mismatch can create recirculation zones that hurt performance. If the car already has widebody fenders or a deep splitter, the hood’s aerodynamics must harmonize with those elements. When in doubt, consult tuners who test combinations on track or dyno. Small changes in vent orientation or hood angle can materially affect under-hood pressure and intake temperatures.\n\nMaintenance and repairs deserve attention. Carbon fiber resists rust, but it can suffer from impact delamination. Small stone chips in the clear coat are cosmetic but, if left untreated, can propagate. Repairs are possible, but they require skill and correct materials. A factory-style finish makes repairs easier. Keep spare hardware and alignment shims on hand when installing. Routine checks of mount points, seals, and fasteners prevent fatigue failures. If the hood uses a functional scoop feeding the intake, inspect the scoop seals and any installed splash guards regularly. Heavy rain and high-pressure car washes are natural antagonists to open intake paths.\n\nCertifications and documented testing provide peace of mind. Certifications indicating proper resin content and fiber orientation, or evidence of dimensional testing against OEM parts, reduce risk. Some manufacturers publish vacuum bagging and autoclave pressure cycles, showing their process control. Those numbers are not marketing fluff; they indicate repeatability in production. In aftermarket purchases, documentation is a reliable proxy for quality. It also helps when fitting other components. Accurate dimensional specs, commonly around standard hood size ranges, simplify integration. When shopping online, prioritize listings that include measured dimensions, stated material grades, and clear photographs of the inner and outer surfaces.\n\nFinally, consider the overall vehicle package. A carbon hood is a strong statement, but it performs best as part of a considered build. Pairing a well-designed hood with intake upgrades, intercooler efficiency improvements, front aero components, and tuned suspension magnifies the net performance gains. The hood reduces mass, improves cooling, and can refine aero balance, but these benefits compound when other systems are aligned. Whether the goal is lap time, daily enjoyment, or a show-grade build, the hood’s functional design features should complement the rest of the car.\n\nIf you want a reference hood that exemplifies these traits, review detailed product listings for original carbon fiber bonnets designed specifically for this model, which include fitment specs and manufacturing details. For sourcing and fitment options, consider this listing for an original carbon fiber bonnet for the Evo X: original carbon fiber bonnet for Evo X.\n\nFor a deeper look at materials and manufacturing techniques used in high-quality hoods, consult a reputable overview of carbon fiber composites and curing processes. Carbon fiber reinforced polymer

Forging Gravity: The Manufacturing Craft and Global Sourcing of the Evo X Carbon Fiber Hood

The carbon fiber hood conversation for the Evo X is a story that blends performance engineering with global logistics, a narrative where materials science and supply chains come together to reshape the way a sports sedan behaves on road and track. It begins with a simple premise: replace heavy steel with a lightweight, high-strength composite that can endure the heat, humidity, and pressure of spirited driving while preserving or enhancing the car’s bold silhouette. But the truth lies deeper. The hood is not just a sheet of material; it is a meticulously engineered system. Its form must respond to the Evo X’s aerodynamic goals, engine cooling needs, and the realities of weather and road debris. The manufacturing path chosen—whether wet layup or the more performance-driven dry layup using pre-preg carbon fiber—directly affects weight, stiffness, and even how the hood interacts with the car’s intake system. This is not a simple swap. It’s a carefully choreographed sequence of design, tooling, curing, and finishing that must align with high standards of quality and repeatable performance on the street and on the track. In practice, the dry layup approach, cured in an autoclave, has become the preferred route for high-performance applications. The dry process minimizes resin uptake, which translates into a lighter, stiffer panel and tighter tolerances. It is a method that rewards precision. The result is often a hood that shaves 40 to 50 percent of the stock mass, depending on the exact layup schedule, fiber plain weave, and resin system chosen. The Evo X’s front-end mass, once a mix of steel and components arranged for crash protection and heat management, now rests on a panel whose stiffness helps the front end track more predictably, especially when the car is loaded with aero elements or when the engine is pushed hard. The hood’s center section, raised and sculpted, isn’t mere ornamentation. It is an air-management feature that funnels cooler air toward the engine bay or into the intake tract, depending on how the hood is engineered. This functional scoop, when correctly integrated, can help mitigate heat soak and maintain throttle response during demanding driving. For turbocharged variants of the Evo X, where the 4B11T engine thrives on temperature control, the hood’s airflow design matters. It can alter intake temperatures, which in turn influences power delivery and the consistency of performance under heat and load. Yet these benefits require careful sealing and fitment. Water ingress is a recurring caveat for functional scoops, and some designs may call for sealing modifications or gaskets that manage rain and wash while preserving the hood’s aerodynamics. The engineering story also includes the reality that noise levels can rise as more air is drawn through vents and around the hood’s contours. The soundscape of a high-performance street car changes with the hood’s geometry, a reminder that every performance gain carries a potential side effect. This balance between benefit and trade-off is at the heart of how builders and enthusiasts evaluate carbon fiber hoods for the Evo X. When we step back from specifics and look at materials, the hood embodies the choice between options that deliver real-world results. Genuine carbon fiber hoods are typically built from high-grade prepregs, reinforced with epoxy resin, and cured under autoclave pressure. The autoclave step—often governed by precise temperature and vacuum profiles—ensures uniform resin distribution, minimized voids, and consistent thickness across complex curves. The result is a panel whose strength-to-weight ratio is exceptional, a critical factor given the hood’s location at the car’s leading edge, where it bears wind load and potential impact from road debris. This is where the geometry of the mold becomes as important as the carbon fiber itself. Molds must capture the Evo X’s distinctive lines, including the raised center section and any integrated vents, while accommodating the hood’s sealing interfaces with the fenders and hood hinges. For manufacturing teams, this means bespoke tooling. The molds are often CNC-machined to tight tolerances and then finished to ensure the surface quality required by high-end CFRP products. In many cases, the molds are sourced from OEM specifications or created through reverse engineering using high-resolution 3D scans. The accuracy of these molds translates into fitment compatibility, which is a non-trivial factor for both aftermarket fitment and the car’s aerodynamics. The result should be a hood that sits flush with the fenders, closes with consistent gaps, and integrates with the car’s front end geometry without requiring extensive adjustments. On the sourcing side, the Evo X carbon fiber hood ecosystem is deeply global. China remains the dominant source for carbon fiber automotive components, with concentrated manufacturing clusters in Guangdong and Jiangsu. Guangzhou, particularly Baiyun District, hosts a large share of specialized carbon fiber hood production. Proximity to ports and a mature auto accessory supply chain provides advantages for rapid prototyping, small-batch runs, and scalable manufacturing. Suppliers in these regions offer a spectrum of options: universal-fit hoods tailored to a broad audience and custom-fit solutions engineered specifically for the Evo X. This flexibility makes the region attractive for both small shops that want to validate concepts quickly and larger outfits that require consistent, repeatable output for a broader customer base. A robust supplier evaluation framework emerges in this context. Reputable producers typically carry recognized certifications such as ISO 9001 and, in some cases, IATF 16949, signaling disciplined quality management systems. They also document production processes, including autoclave curing protocols, resin content, and ply layup sequences, which are essential for assessing mechanical behavior under real-world conditions. Buyers increasingly demand tangible performance data: proof that the hood maintains its shape under load, that the vents achieve the intended airflow, and that there is a clear, measurable weight reduction. This is where independent test reports and third-party validation become valuable, offering a counterpoint to marketing claims and helping buyers compare options across different suppliers and layup strategies. Pricing follows a spectrum. For standard, universal models, prices can begin around the mid-range and move upward with the complexity of the layup and the degree of customization. In the more specialized segments—dry carbon options, OEM-style fits, or specific hood geometries designed for optimal sealing and vent placement—costs rise accordingly. The economics of carbon fiber hoods are not merely about raw material cost. They encompass tooling amortization, the number of required molds, the controls for resin content, and the time invested in curing cycles. It is no accident that dry carbon solutions, while more expensive upfront, may offer value through superior rigidity and longer-term durability on a demanding track schedule. Beyond cost, durability and fit contribute to resale value. Enthusiasts prize authenticity and consistency; OEM-style or OEM-fit patterns tend to retain value because they preserve the perception of a genuine engineering approach, even for aftermarket parts. The Evo X ecosystem rewards choices that preserve, or even enhance, the car’s structural and visual dialogue. In addition to functional performance, the aesthetic dimension remains vital. The carbon fiber hood’s 3k twill weave—visible through the clear coat—offers a race-inspired texture that complements the Evo X’s aggressive stance. For many owners, that weave is not just a look; it is a testament to the hood’s construction quality, a visible marker of the manufacturing discipline that lies beneath. The dimensions associated with a typical carbon fiber Evo X hood—often around 172 by 165 by 35 centimeters in the packaging and clearance envelope—provide a practical frame for planning fitment and alignment with the car’s inner structures, including the radiator, intercooler plumbing, and front bumper architecture. While universal options are accessible and economical, custom-fit hoods engineered specifically for the Evo X provide tangible benefits in sealing and aerodynamic optimization, making them attractive for track-focused builds or show cars. In these applications, the hood becomes an integral part of the vehicle’s performance envelope, influencing wake flow, front-end lift, and how the engine breathes under load. Suppliers recognize this, offering both wet-lay and dry-lay capabilities to balance budget with performance goals. The wet layup route, while simpler in some respects and often more forgiving in terms of equipment requirements, can result in higher resin content, adding weight and potentially affecting long-term stiffness. For some applications, this may be an acceptable trade-off when a lower upfront cost is essential or when a project calls for quick, flexible iteration. Yet for serious performance work, dry layup and autoclave curing typically deliver the cleanest, most repeatable results. The industry’s knowledge base continues to evolve, with studies that validate the structural behavior and testing of CFRP front hoods under realistic loading and temperature conditions. A detailed study on the design, manufacturing and testing of CFRP front hoods offers technical validation and deeper insight into material behavior, reinforcing best practices for engineering a hood that performs as intended. For those exploring the broader landscape of manufacturing science behind these panels, the cited study provides a rigorous reference point and a bridge to the practical lessons discussed here. In practical terms, a successful Evo X carbon fiber hood procurement hinges on more than the raw materials. It requires a disciplined approach to design integration, a clear understanding of the car’s cooling and intake paths, and a supplier network capable of delivering consistent quality at scale. A thoughtful buyer will seek suppliers who provide transparent specifications, including dimensions, weave structure, resin systems, and a clear description of the curing method. They will value corroborating data from performance tests and, when possible, independent testing that confirms the hood’s behavior under high-load conditions. The decision to invest in a carbon fiber hood for the Evo X is a decision about risk, return, and the alignment of engineering intent with driving passion. It is the choice to pursue weight reduction without compromising fit, to pursue airflow and cooling gains without introducing unacceptable pressure on seals, and to pursue a distinctive aesthetic that communicates the car’s performance philosophy. As such, the narrative of manufacturing and sourcing is inseparable from the car’s performance story. The ecosystem’s maturity—comprising mold design, layup decisions, curing processes, and the reliability of supplier networks—mirrors the Evo X’s own blend of precision engineering and driver-centric experience. For enthusiasts and procurement managers alike, the path forward is clear: prioritize robust engineering data, invest in molds and tooling that mirror OEM geometry, and work with suppliers who can demonstrate consistent, traceable quality across batches. When the hood is properly integrated, the Evo X responds with more immediate throttle reaction, refined front-end handling, and a presence that is unmistakably modern and purposeful. The hood becomes a statement of intent: a commitment to performance that respects the car’s heritage while embracing a dynamically evolving technology. To readers who want to explore practical references and product positioning in this space, a representative resource on carbon fiber options for Evo X components can offer a concrete starting point and help frame expectations for fit, finish, and long-term durability. carbon fiber hood resource. External technical validation, meanwhile, can be found in detailed research on the material behavior of CFRP front hoods, which provides rigorous context for the performance attributes discussed here. For those who want a deeper dive into the science and the testing that underpins these design choices, the following external resource is recommended: https://www.mdpi.com/2076-3417/15/18/13576

Final thoughts

The carbon fiber hood for the Mitsubishi Lancer Evolution X represents a compelling intersection of performance, design, and innovation. Lightweight yet robust, this upgrade significantly enhances vehicle capabilities without compromising aesthetics. With its functional features aimed at improving engine performance and cooling, car enthusiasts can reap substantial benefits, particularly in high-demand driving conditions. Furthermore, understanding the manufacturing processes and sourcing of these hoods reveals the quality and care integral to aftermarket upgrades. For business owners, offering such premium products can position you ahead in the competitive automotive aftermarket market, attracting enthusiasts eager for performance enhancements that deliver tangible improvements.