In the competitive landscape of high-performance automotive engineering, the Mitsubishi Lancer Evolution 10 (EVO 10) stands out as a remarkable achievement. This vehicle’s transmission technology, particularly the innovative 6-speed SST dual-clutch transmission and its manual counterparts, has captured the attention of enthusiasts and industry professionals alike. Understanding these systems not only sheds light on their performance dynamics but also reveals their potential for aftermarket modifications and future developments. Each chapter in this guide dives deep into the OEM technology, the advantages of its dual-clutch system, market demands for manual options, tuning potentials, and what the future holds for EVO 10 transmission technologies.

EVO 10的原厂传动核心:6速SST双离合的设计与表现

第十代传动哲学与双离合的技术骨干

第十代EVO以一套6速SST双离合变速箱为原厂标配。它并非简单的自动箱,而是将机械感与电子控制深度融合的产物。核心理念是实现最快的档位切换,同时尽量减少动力中断。为此变速箱采用两套离合器,分别控制奇数档与偶数档。当前档工作时,下一个档已被预选,换挡时只需切换离合即可完成换档。这种架构带来了接近无缝的动力传输体验,尤其在加速和激烈驾驶时表现明显。

变速箱的电子控制单元并不只是执行机构。通过对发动机扭矩、节气门开度和车速等多个变量的实时处理,变速箱能在毫秒级改变换挡节奏。配合驾驶模式选择系统,变速箱会自动调整换挡转速、换挡延迟和换挡时的发动机配合策略。普通模式偏向平顺与燃油经济;运动及更激进模式则优先响应速度与转速维持,从而提升在弯道与加速段的连贯性。

SST变速箱在材料与执行器上也追求轻量与精密。为减轻手感与提高响应,换挡拨片与控制杆件多采用轻合金材料。电控执行器的响应时间被优化,确保拨片命令能迅速被机械系统实现。与此同时,与全时四驱的耦合设计使得变速箱不仅是动力传递装置,更是整车动态管理的一部分。通过与中央差速器及扭矩分配逻辑交互,变速箱换挡动作会影响前后扭矩配比,从而在出弯与抓地力分配时提供直接帮助。

然而,工程设计总有取舍。双离合的高效率与快速换挡以复杂的结构与热管理需求为代价。离合器片在频繁换挡或高扭矩条件下会产生大量热量,若冷却不足,则会加速磨损或触发防护策略,导致打滑或降档保护。再者,双离合的承载极限通常低于某些强化机械式手动变速箱。在大幅度提升动力输出后,原厂双离合极限容易成为瓶颈。

日常使用与维护要点

在日常驾驶中,SST兼具舒适与性能。普通道路与高速巡航时,变速箱的平顺性与燃油效率优于传统液力变矩器自动变速器。使用方向盘拨片进行手动换挡,可以保留驾驶参与感。对于车主而言,定期维护比传统变速箱更重要。变速箱油的温度与更换周期直接影响离合器寿命。冷却系统、机油散热器,以及变速箱机电单元的固件更新,都是维持长寿命的关键。

对高负荷使用者,诸如山道攻弯或赛道驾驶,额外的冷却与更频繁的保养非常必要。改变驾驶模式,并在长时间激烈驾驶后给予变速箱冷却时间,这些都是延缓热衰与保护离合的有效手段。

作为改装平台的优与艰

第十代EVO的变速箱策略给改装社群带来了两类思考。一方面,原厂SST在街道与一般赛道日活动中表现优秀,且保留了自动模式下的便利。另一方面,其承载极限限制了高功率改进的上限。改装者通常面对两种路径:在原厂SST基础上强化与降温,或彻底更换为更耐用的机械方案。

在保持SST的前提下,常见强化包括升级离合器片、改善散热器、加强软件映射以及更换更耐磨的能源传输部件。但即便如此,扭矩上限仍受限于齿轮、轴承以及离合器尺寸。若目标是稳定输出超过原厂承受范围的动力,车主往往会选择更换变速箱架构。

替换方案中,强化手动变速箱是多数人的首选。手动箱的优点在于结构简单、承载能力更高,并能给驾驶员更直接的操控反馈。许多改装项目会装配加固齿轮、短行程换挡机构以及加强离合器组件,以应对显著提高的马力与扭矩。对于那些希望保留“人车一体”体验的车手,这是合乎情理的选择。

对寻求极限赛道表现的人,序列式变速箱是更直接的解决方案。序列箱以快速、可承受高扭矩和重复强烈换挡著称。它能将换挡时间压缩到毫秒级,同时提高可靠性,适配数倍于原厂输出的动力需求。选择序列箱意味着放弃日常驾驶的便利,但能在赛场上提供决定性优势。

系统匹配与整车动态

任何对变速机构的改动,都需要重新审视整车动力学。换装手动或序列箱时,离合器踏板、换挡行程、发动机控制单元与四驱扭矩管理策略,都需重新校准。缺乏整体匹配会导致抓地力分配失衡、驱动轴应力不均或电子防护频繁介入。因此,改装并非只换一个零件那么简单,它牵涉到传动、冷却和控制系统的整体协同。

此外,变速箱更替往往伴随传动轴与差速器的改造。高扭矩情况下,目标是使每一环节的强度超过发动机输出的峰值。否则,新的薄弱环节会迅速暴露,从而导致更严重的故障。

从车主视角的决策要点

选择保留原厂SST还是更换变速箱,取决于目标与预算。若目标是街道日常使用并保留激烈驾驶的可能,原厂SST经过适当强化与冷却提升后,能提供良好的平衡。若目标是持续高功率输出并在赛道上频繁使用,手动或序列式方案更具长期性价比。最终决策应基于对驾驶习惯、动力目标与可承受维护成本的综合考量。

对于那些考虑翻新或更换SST核心组件的车主,可参考已存在的再制造与升级方案,例如有关EVO X SST DCT470的再制造信息,这类资源能提供可替换零件与改良策略的参考。(EVO X SST DCT470 再制造6速变速箱)

参考资料:

https://mitsubishiautopartsshop.com/full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x/

Edge in Motion: The Precision and Potential of the EVO X’s 6-Speed DCT

The tenth generation Mitsubishi performance sedan earns its driving magic through a transmission that acts as a precision instrument and throttle driven accelerator. The six speed dual clutch automatic, often described as a DCT, sits at the heart of the EVO X dynamic character. It is more than a box that shifts gears; it is a tightly tuned system that preselects the next gear while the current one remains engaged, enabling shifts that feel nearly instantaneous and that preserve the momentum built into the car. In practice, the difference between a traditional automatic and this DCT is the difference between a stutter and a leap forward. Power travels through a direct path, and when the driver presses the throttle, the drivetrain responds with a surge that keeps the foot in touch with the accelerator and the eyes on the road ahead. It is a synergy of hardware and software, of hydraulic precision and electronic choreography, shaping the EVO X into a compact of speed and control rather than a simple horsepower figure wearing a chassis. The architecture of the six gears merges the nimble behavior of a manual with the ease of an automatic, offering a driving experience that is both engaging and practical. The DCT uses two clutches, each preloading a different set of gears, so that when one gear disengages the other is already engaged and ready to drive. The result is shock free, near instantaneous gear changes that preserve the engine s torque curve as if the car had been wired to anticipate every accelerator input. This seamlessness matters on the street and on the track, where milliseconds matter and where the human can feel the difference between a clean, linear pull and a lugging, interrupted surge. In normal terrain, the transmission behaves like a courteous companion, gliding through gears to minimize fuel consumption without depriving the driver of that familiar EVO immediacy. When the road unfurls into tighter bends or a freeway on ramp demands a hard shove, the system can switch into sportier logics, sharpening the response and pulling the engine into its most ready range for high speed acceleration. The three built in driving modes Normal Sport and a more aggressive Super Sport beyond Sport in some configurations aren t cosmetic toggles. They are differently calibrated minds that tune the shift strategy, throttle response, and throttle blip behavior to match the driver s intent and the road s mood. In Normal, the transmission strives to keep revs low, raise efficiency, and shift early to minimize fuel use and cabin noise. In Sport, the mapping tightens up. It not only raises the engine s redline where applicable but also speeds up the shift logic, so the next gear is preselected earlier, preserving momentum through curves and overtake maneuvers. Super Sport raises the stakes further, increasing gear holding, sharpening throttle sensitivity, and making downshifts more aggressive, which keeps the engine in a lively state even when the car is loaded with lateral forces. The electronic brain, guided by the SI DRIVE system, reads inputs from the accelerator, brake, and steering wheel, and translates them into a shifting cadence that feels intuitive rather than mechanical. The result is a transmission that respects the driver s intent while delivering a consistent, race bred temperament. Even with the automated convenience, the EVO X does not abandon driver involvement. The steering wheel carries paddle shifters that allow manual override of the automatic sequence. A quick flick of a paddle can command an early upshift or a drum tight downshift, and the engine s response remains instantaneous. The benefit is a hybrid of control and simplicity: you can hand tune the moment of engagement without dropping into a manual gearbox, preserving the steadiness of automatic torque delivery while reclaiming a racer s immediacy when called for. It s this balance between automated precision and human directed timing that helps the car feel both approachable for daily driving and exhilarating at the limit. The chassis responds to the transmission cadence, so weight transfer, tire grip, and steering input flow in concert with the shifts. The entire system becomes a feedback loop, where the driver s intent and the car s reaction unfold in a nearly telepathic sequence. Yet no discussion of performance is complete without acknowledging the practical limits of any transmission that aims to sustain high power. In stock form, the six speed dual clutch layout handles a broad spectrum of driving scenarios, delivering a compelling blend of speed and reliability. But as horsepower climbs beyond the mid range, the transmission s internal stress rises. The clutches, gear sets, and control software can approach the boundaries of their thermal and mechanical endurance if the engine is pushed into higher torque regions for sustained periods. Here the EVO Xs appeal becomes twofold. First, it remains highly capable as a street performer, delivering quick shifts and confident response without sacrificing daily usability. Second, it becomes a platform for serious modification, where owners often explore iterations that align the transmission with enhanced powertrains or track focused ambitions. In the spectrum of common upgrades, two paths recur with striking clarity. One is the conversion to a fortified manual gearbox. The other is a more radical leap toward race adapted sequential gearboxes that drop directly into the drivetrain with minimal adaptation and maximum clutchless or clutch assisted speed. In most practical terms, the factory DCT is admired for its balance, and the typical upgrade route favors preserving the core DCT behavior while reducing the risk of power induced bottlenecks. For many enthusiasts, maintaining the DCT with a modest power increase preserves the EVO Xs identity a car that can be both a reliable daily driver and a capable performance machine. But the landscape of modification is nuanced. When horsepower climbs toward four hundred and beyond, some owners seek a clearer, more direct handshake between the engine and the axle. A well documented approach in the community has been to replace the stock DCT with a strengthened manual transmission. This swap strips away the potential slipperiness of clutches under extreme torque and returns to the familiar, tactile sense of gear engagement an acknowledgment that raw mechanical feedback can be more dependable when you are nudging a high horsepower setup to the edge on a track. The appeal is not merely the rhythm of the gears; it is a deeper connection to the car s momentum, a deliberate, left footed mastery of how torque moves the chassis through the corners. For the purist and the racer alike, there are even more radical avenues that bypass the conventional route altogether. Some builders gravitate toward sequential transmissions designed for racing, where the shift cadence is not limited by the same thermal constraints as a conventional dual clutch drive train. A sequential gearbox can offer even faster, more precise upshifts and downshifts, tailored specifically for high heat, high load competition environments. These systems can match or exceed the engine s torque delivery at the limits, creating a state where horsepower and chassis dynamics align with a single, unbroken focus on speed and control. While these options push the envelope of daily usability and routine maintenance, they illustrate how the EVO X platform serves as a living workshop. It invites engineers and drivers to explore the edges of what is possible when a chassis is designed to live at the intersection of precision engineering and raw performance. The practical takeaway from all this is less about choosing a single path and more about recognizing how the transmission shapes every facet of the car s character. The stock six speed DCT, with its rapid gear changes and multi mode logic, offers a best of both worlds recipe: effortless everyday drivability and the ability to surge into performance as soon as the driver demands it. When the engine breathes through the rev range with minimal interruption during shifts, the car feels immediate, alive, and precisely controlled. The paddles invite a tactile dialogue with the drivetrain, and the SI DRIVE modes translate the driver s intent into a shifting strategy that keeps the engine in its most effective zone. In this way, the EVO Xs transmission becomes more than a mechanism; it is an enabler of a driving philosophy one that values smooth power delivery, swift response, and a balanced sense of involvement. As a concrete reference point and a tangible illustration of the upgrade ethos, consider the EVO X SST DCT 470 reconditioned 6 speed automatic transmission, a widely cited implementation in discussions of performance oriented DCT maintenance and replacement. This example embodies the mindset of preserving core drivability while ensuring the system can sustain the demands of enhanced performance. For readers who want a real world anchor to the discussion, this option typifies the practical choices enthusiasts weigh when planning a build that keeps the car s identity intact while expanding its capabilities. It is also a reminder that the EVO X platform, in its stock and modified forms, remains a versatile canvas for exploring how shifting technology can harmonize with torque, grip, and tempo on both street and circuit. External resources can illuminate the broader engineering context behind these shifting strategies. For a technical overview of how dual clutch transmissions optimize torque delivery and shift timing, see the external reference: https://en.wikipedia.org/wiki/Automatic_transmission. This backdrop helps readers appreciate why a car like the EVO X can feel so responsive and alive when the gears change in a heartbeat, and why the choice between maintaining a DCT versus adopting a manual or sequential alternative matters for the overall driving experience. And for those who want a concrete, shop based path to a known DCT upgrade, an illustrative internal option provides a practical reference: EVO X SST DCT 470 reconditioned 6 speed automatic transmission. This link anchors the discussion in a real world repair and upgrade scenario, offering a sense of the options and the realities of maintaining a high performance DCT in the face of increasing power demands. The chapter thus threads a narrative that moves from the fundamentals of the transmission s architecture to the practical decisions owners face when keeping the EVO X s shift rhythm in step with their ambitions.

EVO X 手动变速箱的市场与需求:稀缺性、情感驱动与改装热潮并行

在三菱EVO X的传动系统话题里,手动变速箱的市场与需求早已演变成一个跨越技术、情感与收藏价值的综合现象。官方路线在第十代时放弃了传统的六速手动配置,转而以双离合变速箱为主。这一转变并未消解驾驶者对手动换挡的渴望,反而在二手市场和改装圈中放大出另一种“驱动情感”。手动挡版本在市场上的稀缺性,逐渐塑造出一种超越日常使用的资产属性。对于热衷于驾驶本真的玩家而言,手动换挡不仅是便捷的操作,更是一种对机械性的直接、直观的体验。正因如此,市场上的手动挡EVO X被视作纯粹驾驶乐趣的象征,其价格和收藏价值往往显得尤为坚挺。\n\n在2026年初的市场环境中,原厂手动挡EVO X的供给几乎是稀薄的。早期版本、边缘限量版或具备良好车况、低里程且保留原厂状态的案例,成为收藏家和真•驾驶爱好者竞相追逐的对象。统计显示,完整的原厂手动挡车型在二手市场上的价格往往显著高于同代其他配置的车型,且价格区间普遍落在一个较高的水平。这个趋势并非偶然,而是由多重因素共同推动的结果:一方面,手动挡的稀缺带来直接的供需不对称;另一方面,市场对“驾驶乐趣的原始表达”越来越看重,手动挡被包装成一种情感资产,成为跨越时间的收藏品。若以价格区间来理解,极佳车况、低里程、无事故记录且保持完整原厂状态的原厂手动挡EVO X,价格常常在高位盘整,甚至在特定时点呈现上涨态势。这种现象在 enthusiast 社群里被广泛讨论,成为评估一辆EVO X价值时的重要参照。\n\n然而,现实并非只有买卖的静态价格。市场的热度也来自于改装文化的持续繁盛与技术探索的不断深入。原厂的双离合变速箱虽然在换挡速度与平顺性上表现出色,但在动力极限和持续高负荷场景下,耐久性与改装空间常常成为讨论的核心。正因为此,许多车主把注意力投向改装路径,希望在保持整车真实性与可用性的前提下,提升传动系统的承载能力与响应速度。最常见的改装方向,是在尽量保留现有平台的前提下,替换为更能承载高功率输出的传动方案。这一思路在圈内有广泛讨论,而且也带来了一系列新的技术挑战——从传动比和热管理到离合器的耐用性、变速箱的热衰减以及整体底盘的协同表现。对于那些追求“近似手动驾驶体验”的用户来说,这条路既是现实的解决方案,也是情感的延伸。\n\n在这一背景下,市场对手动变速箱的需求不仅仅来自于想要体验“左脚发力”的乐趣,更来自于对驾驶控制感的追求和对极致操控的持续探索。一些车迷甚至愿意将现有的自动/双离合版本进行深度改装,以模拟或接近手动换挡的体验,抬升整车的赛道化潜力。这类改装并非简单的替换,它往往伴随着对离合器系统、变速箱支撑、传动轴、底盘刚度以及电子控制系统的重新调校。改装的目标,是让动力传递更加直接、响应更加敏捷、换挡时的纵向感受更接近“手动”的清晰反馈。虽然从法规和耐用性角度需要谨慎评估,但这种趋势真实存在,成为推动相关组件市场活跃的重要因素。同时,改装市场的热度也不可避免地推高了整车平台的关注度,使得手动变速箱在二手市场之外的周边部件、维护服务与改装文化的生态圈不断扩展。\n\n值得注意的是,市场对于“手动变速箱的精神象征”赋予了它独特的位置。对于许多收藏家和资深驾驶者而言,手动挡不仅是操作方式,更像是一种对品牌传承的情感缠绕。它承载着一代又一代驾驶者对纯粹操控的记忆,以及对经典驾驶体验的怀念。即使官方通道已经转向自动化的传动技术,手动变速箱的精神象征在社区中仍被广泛讨论与纪念。这种情感驱动不仅影响个人购买决策,也在一定程度上推动厂商与改装厂之间的市场互动,形成一种特殊的市场韵律。\n\n从长期来看,这一现象也揭示了一个更广的行业动态:高性能汽车平台如何在新技术与传统机械美学之间找到平衡点。双离合或其他先进传动技术在提升效率与一致性方面扮演关键角色,但它们也可能在情感和可玩性的维度上略显单薄。手动变速箱的市场需求恰恰折射出驱动者对“可控性、参与感、直接反馈”的持续追求。这些因素共同作用,使得手动变速箱成为不仅仅是传动系统的一个选项,而是一种对驾驶者与机器之间关系的深刻认识。\n\n若把改装热潮视作市场对极致性能的一种探索,则需要理性理解其边界。高功率输出与极端载荷对传动系统的要求极高,因此选择何种改装路径,应以对整车安全、可靠性和长期维护成本的综合评估为前提。某些时候,车主会把目标定位在提升传动系统的耐用性与热管理能力上,而不是单纯追求更快的换挡速度。在这个意义上,改装不仅是一种技术挑战,也是一种对成本与收益之间平衡的考量。对那些希望了解更深入的改装路径的读者,可以参考以下页面,该页面以具体的技术条目展示了在高性能应用中传动系统再制造与升级的方向与可选项: Evo X SST/DCT470 六速自动变速箱(再制造)。\n\n综合来看,EVO X 的手动变速箱市场并非单纯的价格博弈,它是一个错综复杂的生态系统,涵盖稀缺性、情感驱动、收藏价值、以及持续的改装探索。原厂手动挡车型的极端稀缺性,造就了高价值的收藏潜力,同时也促使改装路径成为一种新的市场维度,引导人们重新评估传动系统在整车性能中的地位。未来,随着市场对驾驶情感的持续追求与改装技术的进一步成熟,手动变速箱的精神象征可能在某种程度上获得新的诠释。它不再只是一个简单的驾驶工具,而成为一种跨越时代的驾驶文化符号。

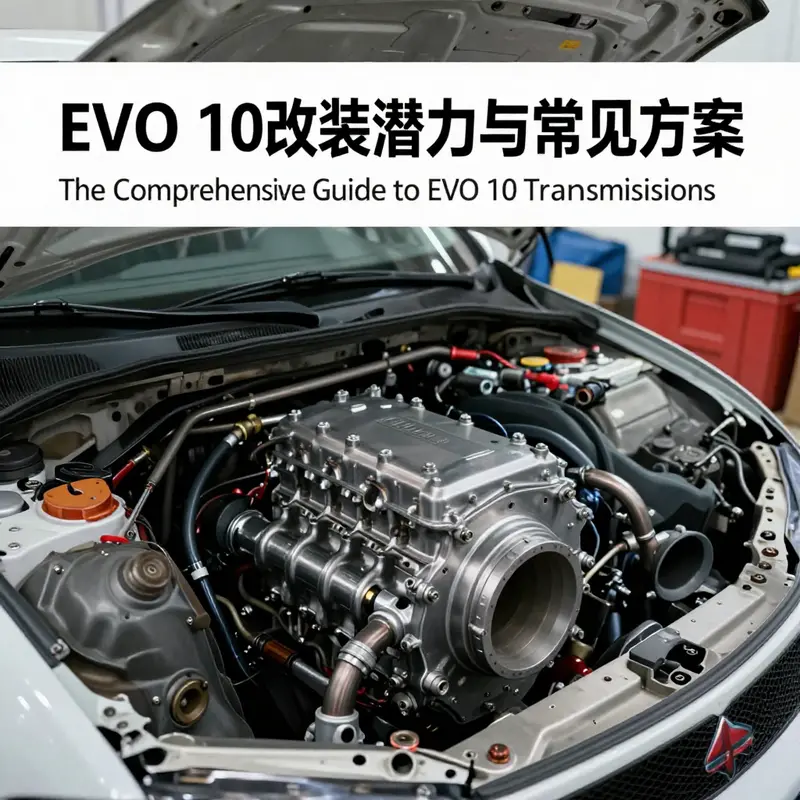

EVO 10传动改装:从原厂双离合到赛道级变速箱的可行路径

EVO 10传动改装:从原厂双离合到赛道级变速箱的可行路径

三菱EVO 10的传动系统是其性能改装路线图的核心枢纽。原厂的六速双离合自动变速箱在日常与竞技之间找到了平衡,但当动力被大幅提升时,它很快成为限制整车性能的瓶颈。因此,了解这台车从出厂传动到完全赛化的升级链条,是每位改装爱好者必须掌握的知识。本文将以连贯的叙述,梳理常见的改装思路、权衡要点和实战建议,帮助你在选择传动方案时更有把握。

EVO 10出厂装配的双离合变速箱以快速换挡和平顺传动著称。它结合自动模式的便利与手动换挡的参与感,适合多数车主的日常与激烈驾驶需求。变速箱的控制逻辑还能随驾驶模式调整响应,使得车辆在日常与激烈驾驶间切换更自然。然而,任何双离合系统都有其承载极限,特别是在持续高扭矩输出时。大量改装案例都显示,一旦发动机输出超出原厂设计范围,传动组件——尤其是离合单元、齿轮和驱动轴连接——会成为最先受迫害的部分。面对这种现实,车主常走的两条主路是:强化原有双离合,或彻底转换为机械式传动解决方案。

强化原厂双离合的做法包括重制或更换关键部件,以提高其承受扭矩的能力。通过升级摩擦片、增强换挡执行器和改善散热路径,可以在一定范围内提升耐久性。不少改装厂提供针对这代变速箱的重建服务,能将系统扭矩承受值提升许多。选择这条路线的好处是保留原车的驾驶逻辑和车内便利性。短处是成本可能高昂,且在极高马力的环境下,仍存在耐久性风险。如果你的目标是控制成本,同时保持日常可用性,这是一条值得考虑的折中路线。你可以参考具体的重制实例,了解常见的增强细节,例如离合材料、电子控制器的耐热处理和散热设计。EVO X SST (DCT470) 6速重制变速箱信息

但对于追求纯粹驾驶体验或是准备挑战高马力的车主,转向机械式变速箱往往更具吸引力。最常见的替换方案是改装为强化的六速机械变速箱。机械变速箱的结构简单,承载能力经过强化后通常优于同等价位的双离合系统。它能承受更高的扭矩峰值,也更容易在赛道上进行快速维护和调整。手动变速箱的另一个优点是带来更直接的驾驶反馈,这对许多车迷而言是重要的情感价值。但需要注意,手动系统对离合器操作和使用习惯要求更高。若用于赛道,离合片和同步器等部件的更换频率会比原厂系统高。

在机械化改装之外,还有一条极端但高效的路径:采用序列式变速箱。这类变速箱以最快的换挡速度和极高的可靠性见长。它们为赛车设计,换挡时间极短,能承受远超街用系统的扭矩负荷。序列式变速箱的主要劣势在于成本和适用性。其价格通常高昂,安装过程复杂,并且常常需要重新配置换挡机构、传动匹配和电子控制系统。对于只在赛道短时使用的车辆,或者作为项目车的车主,这依然是实现800马力及以上稳定输出的最直接方式。

不论是强化原厂系统,还是更换为手动或序列式变速箱,驱动系统的其它部分也必须同步加强。举例来说,驱动轴、中心差速器和半轴必须具有匹配的强度与疲劳寿命。四驱系统内部的差速器逻辑在高功率输出下也需要对应改装,以防车轮打滑或零件损坏。刹车系统必须跟上提升的速度,悬挂需要更精确的阻尼控制和更低的簧下质量。整车匹配是一道复杂命题,任何单点升级都可能引发新的瓶颈。因此,制定改装计划时要从系统性角度出发,考虑动力、传动、底盘和制动的联动升级。

改装决策要建立在明确目标之上。若目标是街道与周末赛道兼顾,优先考虑耐用性高、日常便捷的方案。若目标是极限赛道成绩或高马力直线加速,则序列式或按赛车规格强化的机械变速箱更合适。在预算有限的情况下,可以先进行分阶段升级:先通过软件优化和轻度硬件加强提升发动机输出,然后观察传动系统反应,再决定是否更换整个变速结构。这样可以避免在早期投入过多资金,使得最终变速系统与实际需求相匹配。

此外,改装过程中的法律和安全问题不容忽视。任何涉及传动、排放或噪音的改动,都需要遵守当地法规。改装应在专业车间进行,并保留必要的检测文档与合格证书。赛道用车辆与道路行驶车辆的改装标准不同,必须清楚区分用途,以免带来法律风险。

在执行层面,有几条实用建议值得遵循。首先,选择经验丰富的改装技师。他们能提供针对性方案,避免常见误区。其次,所有新增或更换部件都需与车辆的电子控制单元配合,必要时进行专业级ECU调校。第三,做好散热管理和润滑升级,尤其是在强化传动与高马力输出下。最后,建立维护档案,按计划检查关键部件,如离合、齿轮、轴承和驱动轴,做到预防性更换。

总之,EVO 10的传动改装是一条从保留原厂便利到彻底赛化的完整路径。每一步都有明确的利弊与风险。理解这些路径,并据此设定清晰目标,能让改装工作既高效又可控。无论你偏好灵活好用的双离合强化,还是追求机械操控的手动化,抑或走向极致的序列式变速箱,关键在于把握整车匹配与持续维护的节奏。

更多关于序列式变速箱的参考可以查看此内容,以了解它们在EVO平台上的应用案例。 https://mitsubishiautopartsshop.com/full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x/

EVO 10变速箱的下一步:双离合的传承与向混动时代的演进

Evolution of a Transmission Concept

The sixth-speed dual-clutch transmission that came with the EVO 10 left a clear imprint on what performance-oriented automatic gearboxes could be. Its design sought a balance between the mechanical intimacy of a manual and the convenience of an automatic. That balance is now the starting point for any discussion about how this transmission concept will develop. The path forward is not a single upgrade. It is a convergence of software finesse, mechanical strengthening, hybrid integration, and platform thinking. Each element reshapes what owners and tuners will expect from a transmission once associated with a compact rally-bred sedan.

At its core, the factory dual-clutch unit proved that a transmission can be fast, precise, and engaging. Future iterations will refine those strengths. Software will tighten the link between driver intent and gear selection. Smarter control logic will anticipate throttle inputs and adapt clutch engagement curves in milliseconds. The result will be shift quality that feels both quicker and smoother. Improved calibration will reduce torque interruption during gear changes, enhancing acceleration and traction. These software advances will follow the trend of moving mechanical performance gains into code, where updates arrive without physical rebuilds.

On the mechanical side, durability is the chief concern. The original unit served well within its design envelope. When power rises dramatically, however, internal limits reveal themselves. Reinforced clutch packs, hardened gear sets, and upgraded bearings will be standard responses. Cooling also grows in importance. High-power applications demand larger oil coolers and thermostatically regulated flow. Heat management prevents clutch glazing and keeps hydraulic actuation crisp. For the EVO 10 platform, these are the tangible upgrades that will extend usable life under heavy load.

A strong aftermarket will remain central to the transmission’s future. Many owners choose to replace the factory unit when power goals exceed safe limits. Upgraded manual gearboxes, heavy-duty clutch systems, and fully sequential race gearboxes are all proven routes for high-horsepower builds. For those who prefer to keep the automated feel, strengthened reconditioned units and bespoke torque management systems offer compromise. Practical retrofit paths already exist, including professionally rebuilt units designed for higher torque. One useful resource for standard replacement and reconditioned units appears as an available listing for the EVO X SST DCT470 reconditioned 6-speed unit, which illustrates how rebuilt transmissions can serve the community.

The rise of electrification frames a different direction altogether. Transmission designers are already blending dual-clutch concepts with electric-assist layouts. Hybrid drivetrains change mission requirements. Instead of only carrying engine torque, future gearboxes will act as an interface between combustion engines and electric motors. They will need to accept torque from multiple sources, manage regenerative braking, and shift while electric drive fills torque gaps. This complexity demands modular gearing arrangements and robust control architectures. A transmission that once only had to manage clutch engagement must now coordinate motor torque fills, clutch blending, and seamless transition between propulsion modes.

Lightweight materials will be more than a trend. They are a necessity for keeping vehicle mass in check while adding hybrid hardware. Magnesium shift paddles and carbon fiber trim hint at what enthusiasts already pursue. For transmissions, this translates to high-strength aluminum alloys, advanced heat-treated steel, and composite housings in non-critical areas. Reducing rotational mass lowers inertia and improves responsiveness. Component-level optimization yields both performance and economy gains—a critical selling point as stricter efficiency targets spread through the industry.

Platform and modular design will underpin production realities. Rather than crafting bespoke gearboxes for single models, manufacturers and suppliers will develop families of transmissions. These families will handle a range of power outputs with modular clutch packs and interchangeable internals. For an EVO-like vehicle, a scalable gearbox means a single basic architecture can be tuned down for daily driving or beefed up for track duty. This approach controls costs and speeds development. It also broadens the potential for parts crossover and easier aftermarket support.

Control integration is another essential thread. Modern transmissions are as much about software as mechanics. Future units will integrate more deeply with stability control, torque vectoring systems, and adaptive differentials. That integration will enable more sophisticated launch control, sharper downshifts, and predictive gear selection based on cornering inputs. It will also allow powertrain-wide optimization where the gearbox, engine, and electric assist work as a single system. For the driver, the payoff is a more cohesive and transparent driving experience.

For owners, the practical consequences of these trends are clear. If you aim to keep a factory-feel shifting experience while substantially increasing power, plan for software and cooling upgrades first. Many tuning shops calibrate shift logic and add thermal management to raise the safe horsepower limit. If your goal exceeds what strengthened automatic architectures can handle, a gearbox swap remains a prudent path. High-quality manual conversions deliver robustness and driver engagement. For ultimate performance, some turn to race-spec sequential gearboxes. These options trade daily comfort for durability and ultra-fast shift times.

Parts availability and rebuildability will shape the transmission’s longevity in aftermarket circles. A transmission whose internals are serviceable will always attract more attention. Builders and shops prefer to tune and repair rather than replace entire units. That’s why modular designs and standardization of key components matter. The easier it is to source clutch packs, dog rings, and gear sets, the more likely the community will extend a platform’s life.

Safety and drivability concerns must not be forgotten. Any modification that alters torque delivery must be matched with appropriate cooling, tuning, and drivetrain reinforcement. Poorly matched control maps can create harsh engagement or unexpected torque spikes. These outcomes stress center differentials, driveshafts, and axles. Planning must be holistic. Think beyond the gearbox itself. Consider differential upgrades, strengthened half-shafts, and chassis tuning to ensure the car handles the extra forces reliably.

Finally, the cultural aspect influences technical choices. The EVO 10 gathered a passionate following because it offered an engaging driving experience with mechanical honesty. Future transmission solutions that honor that spirit will find eager buyers. That means tuning priorities may still favor immediate driver feedback and mechanical feel, even as electronics manage complexity. The ideal future gearbox will not simply be the fastest. It will be precise, predictable, and adaptable to drivers’ varying tastes.

In sum, the evolutionary arc for the EVO 10’s transmission concept follows several converging paths. Software and control logic deliver smoother, faster shifts. Mechanical reinforcement and thermal management enable higher power handling. Hybrid integration recasts the transmission as a multi-source torque manager. Lightweight materials and modular architectures improve efficiency and manufacturability. For owners and builders, the choices range from incremental upgrades to full replacements. Each choice balances feel, durability, and daily usability. The real future lies in how these elements combine. When they do, the result will be a gearbox that preserves the platform’s dynamic identity, while meeting modern demands for efficiency and adaptability.

For a clear look at available reconditioned options and core gearbox replacements, see this listing for the EVO X SST DCT470 reconditioned 6-speed unit: EVO X SST DCT470 reconditioned 6-speed.

For industry context on how transmission design is shifting to handle electrified drivetrains, refer to this market analysis: https://www.fortunebusinessinsights.com/automotive-transmission-market-size-share-growth-2032

Final thoughts

The Mitsubishi EVO 10 transmission systems represent a fusion of engineering excellence and market responsiveness. From the original 6-speed SST dual-clutch technology to the sought-after manual options and the vast potential for modifications, these transmissions cater to a diverse range of automotive enthusiasts. As the automotive landscape evolves, the EVO 10’s transmission will continue to adapt, paving the way for innovative enhancements and performance breakthroughs. Understanding these characteristics not only informs prospective buyers but also highlights the substantial value in further developing this high-performance platform.