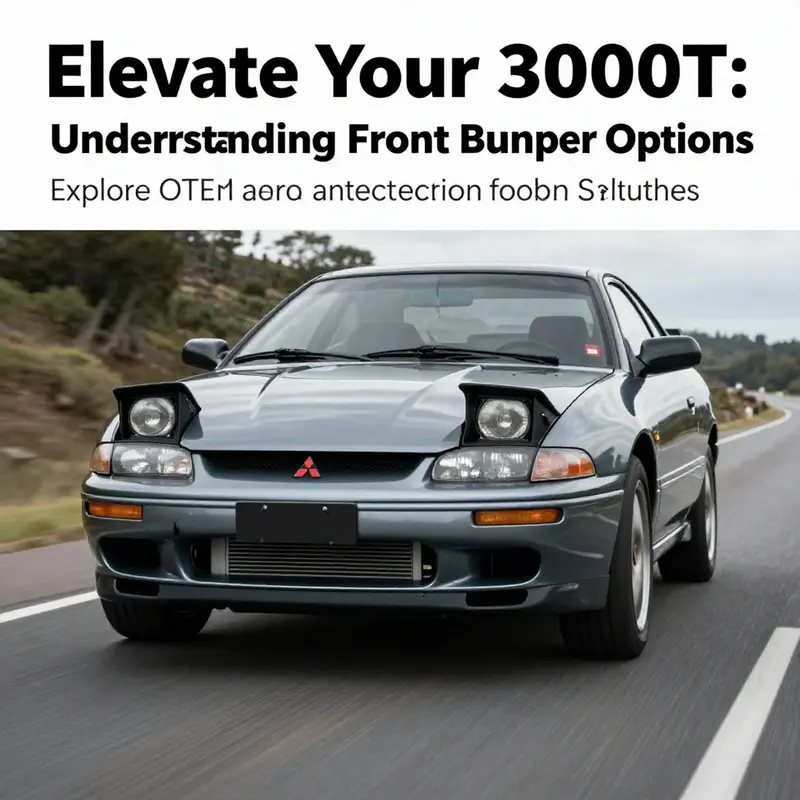

The front bumper of a 1998 Mitsubishi 3000GT is not just an aesthetic element; it plays a vital role in vehicle safety and performance. Recognizing the various options available is essential for business owners and car enthusiasts alike. This article will explore OEM choices for those seeking authenticity, delve into aftermarket enhancements that provide unique styling and performance benefits, consider materials used in design, discuss market dynamics affecting purchasing decisions, and highlight the aesthetic and functional impacts of the front bumper’s design. Each chapter will contribute to a comprehensive understanding of how these components can enhance the Mitsubishi 3000GT experience and cater to various customer needs.

Choosing an OEM Front Bumper for the 1998 Mitsubishi 3000GT: Sources, Fitment, and Practical Choices

Where to find a true OEM front bumper and what to expect

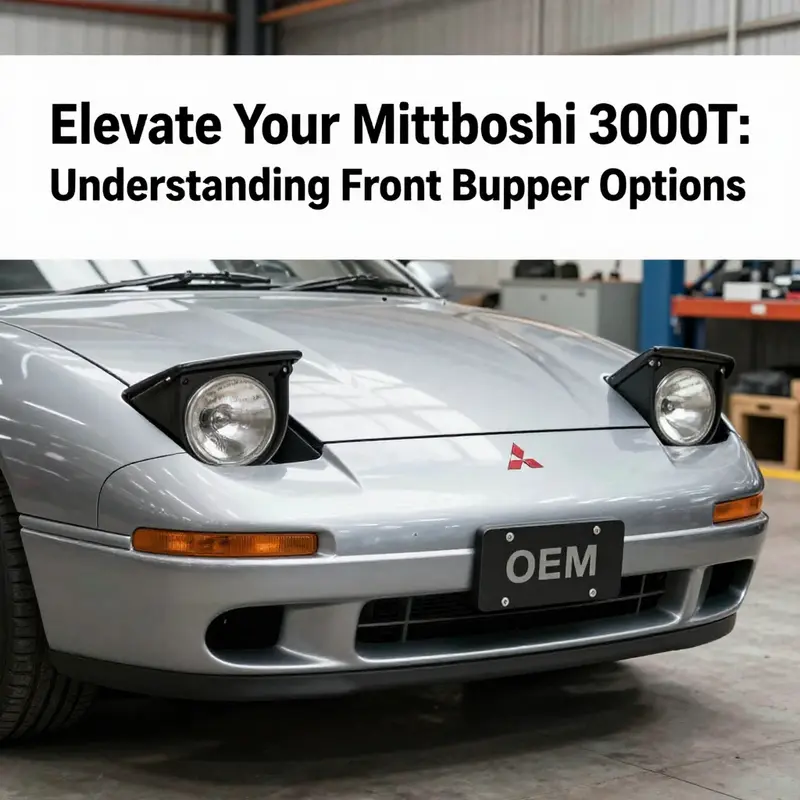

When you prioritize authenticity and fit for a 1998 Mitsubishi 3000GT, original equipment parts are the natural choice. An OEM front bumper preserves original lines, mounting points, and factory attachment hardware. That matters for fitment, crash performance, and the seamless look owners want. Genuine bumpers are still available, but sourcing them requires patience and some know-how.

Authorized dealerships remain the most straightforward route to obtain a genuine factory bumper. They can cross-reference your vehicle by VIN, verify the correct part number, and order direct from the manufacturer when stocks are available. This guarantees compatibility with trim-specific differences, such as fog light cutouts, sensor mounts, and grill profiles. Dealership pricing is typically higher than other sources, but it reduces the guesswork and risk of receiving a mismatched or incomplete assembly.

If dealership pricing or availability is a constraint, online OEM parts catalogs provide a middle path. The official parts catalog for North America lets you search by model year and VIN and often shows exploded diagrams and part numbers. Using that catalog helps you confirm the exact panel needed. It also reduces returns and compatibility headaches because you can match part numbers to your vehicle. For older models, the catalog can show superseded part numbers when direct production has ceased.

The secondary market supplies many OEM bumpers in varied condition. Salvage yards, specialist parts shops, and online marketplaces frequently list used original bumpers. Listings vary from cosmetically pristine bumpers to units described as “rough but usable.” A cheaper, used OEM bumper can be a smart choice when the goal is a correct fit while minimizing cost. Expect potential scuffs, prior repairs, and the need for repainting. Confirm whether attachment clips, reinforcement brackets, and fog light bezels are included. Missing hardware can multiply installation time and costs.

Online auction and classifieds platforms are a common hunting ground. Listings often specify model range, like the 1997–1998 SOHC Base fitment, which helps when searching. However, photographs and seller descriptions may omit critical details. Ask targeted questions: were the mounting points checked? Is the backing reinforcement intact? Are there cracks around the fog light openings? Does it include mounting clips? Request additional images of the inner side and mounting edges before committing. If shipping is required, ensure the seller uses rigid crating and adequate cushioning to prevent damage.

Used OEM parts also come with hidden costs. Paint-matching to factory colors may require expert blending. Surface repair for cracks often demands plastic welding and reinforcement for a durable fix. Shop labor for installation and refinishing can outstrip the part cost. Still, many owners prefer to invest in a used OEM bumper rather than an aftermarket alternative when originality is the priority.

Consider the subtle fitment differences between trim levels. Some bumpers were produced specifically for models with fog lights, narrower or wider grille openings, or distinct trim strips. Confirm compatibility with your 3000GT’s equipment list. If you own a performance trim, check for reinforcement beams and tow hook access. Small mismatches can lead to alignment gaps and require adjustments to headlight or fender mounts.

When an OEM new part isn’t available or is cost-prohibitive, a carefully chosen used unit often makes the best sense. Inspect closely for signs of previous crash repairs. Look for textured surface inconsistencies, overspray, or uneven seam lines. Check inside for reinforcement damage, since unseen structural issues can compromise crash protection and mounting strength. When in doubt, consult a body shop for an inspection before purchase.

Installation considerations are straightforward but important. The OEM bumper should align with factory mounting points. Use original-style clips and bolts where possible. Replace brittle plastic clips, hidden retainers, and weather seals instead of reusing them. Reusing worn fasteners leads to misalignment and rattles. Ensure fog lights and sensors are reconnected and calibrated after installation. A final check of panel gaps under varied lighting will reveal alignment issues early.

If your goal is restoration, sourcing an OEM bumper painted to match the car can save time. That option is usually more expensive, but it removes the need for a separate paint shop visit. Conversely, buying an unpainted OEM bumper keeps costs down and allows you to match the finish precisely at a later date.

For those weighing OEM versus aftermarket, it helps to know what each path offers. Genuine bumpers prioritize original fitment and factory safety characteristics. Aftermarket bumpers often favor aesthetics, modifications, or reduced weight. If you consider alternatives for style or performance, review compatibility carefully and confirm that mounting points match the original. You can also review aftermarket options for inspiration, including one-piece lightweight designs favored by performance enthusiasts. A popular resource on aftermarket choices shows several styling options for the 3000GT and related models which can help frame that comparison: Duraflex version front and rear bumper options for 1994–1998 3000GT/Stealth.

Budget planning should include the cost of the part, shipping, painting, any necessary reinforcement work, and installation. For older vehicles, allocate additional funds for replacing brittle clips and aging hardware. Properly restoring an OEM bumper is rarely just the purchase price. It is an investment that pays off in fit, finish, and long-term durability.

Finally, when you find a promising OEM bumper, verify the part number against the manufacturer’s catalog. Confirm the seller’s return policy and shipping protections. If you are uncertain about the fit or condition, arrange local pickup or use a third-party inspector. Accurate research and careful inspection will increase the odds of landing an OEM front bumper that restores the 1998 Mitsubishi 3000GT to its original presence and performance.

For direct VIN-based searches and official parts verification, consult the manufacturer’s parts catalog: https://www.mitsubishiparts.com/

Front Bumpers for the 1998 Mitsubishi 3000GT: OEM versus Aftermarket Choices and Fitment Realities

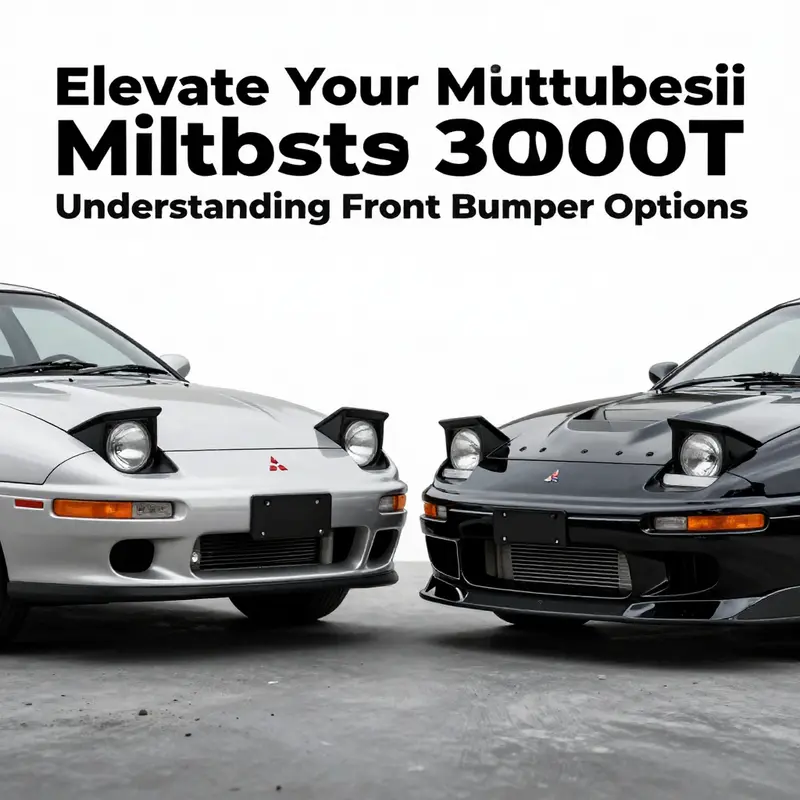

The front bumper of a 1998 Mitsubishi 3000GT is more than a cosmetic face; it shapes aerodynamics, cooling, and crash energy management while signaling whether the build aims for restoration, street performance, or a bold, modern stance. In the 1990s sports coupe landscape, bumper design threaded the needle between authentic lineage and evolving aftermarket ideas, and 3000GT owners frequently encounter two broad paths: restoring authentic contours with OEM-style parts or embracing one-piece aftermarket designs that promise a cleaner look and targeted performance gains.

OEM-aligned options can still exist, especially late-model base bumpers that mimic stock lines while allowing for refinish and minor modification. Purists often start here to preserve fit points and mounting geometry, knowing that condition and availability vary. The practical reality is that these pieces may arrive rough but usable, requiring careful prep, repainting, and sometimes reinforcement behind the fascia to withstand daily driving or show-routine use. An OEM route prioritizes authenticity, a factor many builders weigh against the time and cost of refinishing.

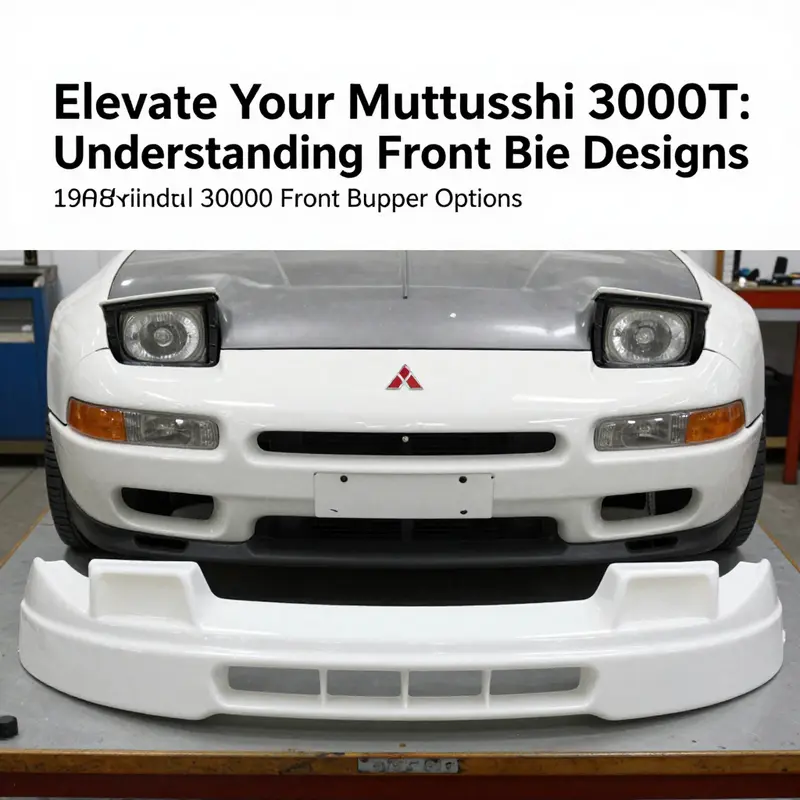

The aftermarket scene expands the spectrum with one-piece bumpers in fiberglass reinforced plastic and other composites. These designs emphasize a streamlined silhouette, reduced seam lines, and potential weight savings, often pairing a bold lower lip with vents or sculpted cooling paths. While they can improve appearance and airflow, fitment hinges on exact year, trim, and chassis coordinates, and finishing work—sanding, sealing, priming, and painting—remains essential to achieve a durable, roadworthy surface. A representative option typically aims for compatibility with the 1994–1998 software family and the Stealth sibling, while leaving room for integration with fog lights, grills, and reinforcement bars.

When evaluating a specific aftermarket bumper, buyers should confirm core compatibility with the radiator support, impact absorbers, mounting points, and any lighting or sensor hardware. The reported gains in appearance or airflow should be weighed against the need for proper alignment, durability, and long-term upkeep. A practical path is to identify the owner’s objective (restoration, track-ready stance, or daily-driver refresh), verify fitment by year and engine configuration, assess material trade-offs (OEM plastics versus reinforced composites), and ensure compatibility with reinforcement structures and auxiliary components.

In sum, the 1998 3000GT front bumper decision is a balance between authenticity and contemporary styling goals. By clearly outlining the objective, verifying year-specific fit, and anticipating finishing and mounting requirements, owners can select a bumper that harmonizes with the car’s chassis and the intended use—whether that means preserving a showroom look or embracing a streamlined, performance-oriented front end.

Choosing the Right Material for a 1998 Mitsubishi 3000GT Front Bumper: Strength, Fit, and Finish

Material matters more than many owners expect when choosing a front bumper for a 1998 Mitsubishi 3000GT. The bumper defines the car’s face and the first line of defense in minor impacts. It also shapes airflow, supports lighting and trim, and dictates how much work you’ll need to do before getting road-ready paint and fitment. Understanding the trade-offs between common materials helps you match a part to your goals, whether those goals are restoration, daily driving, or aggressive modification.

Fiberglass has long attracted enthusiasts because it allows dramatic styling. It is easy to mold into complex curves and aggressive air dams. That flexibility means aftermarket designers can deliver distinct looks that OEM tooling would never produce. For the 3000GT, that results in bumpers with pronounced splitters, larger intakes, and sculpted edges that appeal to show cars and track builds.

But fiberglass brings compromises. It is relatively brittle compared with thermoplastics. Small impacts can produce chips, cracks, or hairline fractures that demand bodywork. Many fiberglass parts arrive with surface imperfections—waves, air bubbles, or thin sections—because hand lay-up and mass-market finishing vary in quality. To achieve a factory-level finish, expect sanding, filling, and multiple primer coats. Mounting points can be misaligned off the shelf, requiring trimming and bracket fabrication to match the 1998 Mitsubishi 3000GT’s existing supports. For buyers who value low weight and radical styling, fiberglass remains a strong choice. For those who prioritize durability and easy installation, it often proves frustrating.

In contrast, ABS plastic offers a different set of advantages. This thermoplastic combines toughness with some flexibility. Under low-speed impacts, ABS tends to flex and return to shape rather than crack. It resists abrasion and road debris quite well. Because ABS is molded using injection techniques, finished parts often show consistent surface quality and accurate mounting points. For a 3000GT owner who wants a straightforward swap, minimal bodywork, and a reliable finish, ABS is a practical option.

ABS also lends itself to dynamic shapes that still improve aerodynamics. A well-designed ABS bumper can smooth airflow around the car, reduce lift, and integrate functional features such as splitter sections and fog light housings. It accepts paint and primer readily, so most owners can complete the installation without specialized bodywork equipment. That lowers installation cost and shortens turnaround time compared with fiberglass.

Another material sometimes used in high-end or custom builds is carbon fiber. Carbon fiber brings extreme stiffness and a high strength-to-weight ratio. It has become synonymous with premium performance parts. However, it comes with higher cost and a fragile finish that can delaminate if improperly bonded. In addition, carbon exterior pieces are often used as cosmetic overlays rather than primary crash-absorption elements. For a 3000GT restoration that emphasizes originality, carbon panels may clash with period-correct aesthetics. For a race-oriented conversion where every pound matters, carbon fiber can make sense.

Beyond the base material, pay attention to construction details. Fiberglass and ABS bumpers are rarely drop-in replacements without minor adjustments. Check the location and condition of mounting tabs, reinforcement brackets, and inner supports. Some aftermarket bumpers omit the inner energy-absorbing foam or the metal bracketry that bolts to the chassis. Reinstalling those elements or fabricating replacements adds time and cost, but it restores the structural behavior expected in minor collisions.

Finish quality must guide your buying decision. A used OEM bumper might be listed as functional but cosmetically rough. That approach keeps costs down and can suit a budget build. Expect sanding, filler, and alignment work. A new molded ABS piece will often need less prep and may arrive ready for paint. Fiberglass parts typically need the most prep work, especially if you want a seamless paint finish.

Think about the car’s intended use. For daily drivers, durability and repairability should rank high. ABS or OEM replacements often outperform fiberglass in long-term usability. For weekend track cars, a fiberglass bumper may be preferred because it is cheap to replace and offers the aggressive airflow channels racers like. For show cars, finish quality and fitting precision are paramount, pushing the choice toward high-quality ABS or professionally finished carbon pieces.

Installation considerations influence the final cost more than the sticker price. Professional installation by a licensed body shop is a reasonable expectation for fiberglass. The shop will align the bumper, repair imperfections, and ensure paint adhesion. ABS pieces are easier for competent DIYers to fit and finish, though alignment and seam gaps still require patience. If the bumper will support sensors, lights, or aftermarket splitters, verify mounting compatibility. Some modern aftermarket parts were not designed for the 1998 3000GT’s factory sensor layout, requiring custom wiring and brackets.

When evaluating listings, weigh three practical questions: how much cosmetic work is needed, how accurate are the mounting points, and what reinforcement parts are included. A used OEM bumper may be inexpensive but require bodywork and bracket replacement. A low-cost fiberglass option may deliver the desired look but demand hours of prep. A molded ABS bumper often provides the smoothest path to a clean installation.

Finally, consider long-term ownership. Material choice affects insurance claims, repair costs, and resale value. A bumper that cracks easily increases long-term expense. Conversely, a high-quality ABS or OEM bumper that absorbs minor impacts and resists road wear can be a smart investment. If you choose fiberglass for style or weight savings, plan on a reliable body shop relationship and extra budget for touch-ups.

For owners who want to explore aggressive bodywork options for the 3000GT, it’s useful to compare complementary upgrades like aftermarket hoods and lips. For example, a well-executed carbon fiber hood can change weight distribution and visual balance with a new bumper. Learn from other 3000GT projects that pair different materials to achieve a holistic result: a durable ABS bumper for daily resilience, paired with lightweight top-end parts for performance gains. See a representative project on a carbon fiber hood replacement for the 3000GT for context and fitment concerns: 1994-1999 Mitsubishi 3000GT Pit Fighter carbon fiber hood.

For a direct example of a molded aftermarket front bumper compatible with 1994–1998 models, consult the official product listing here: https://www.duraflex.com/products/3000gt-front-bumper-version-1

Between Authenticity and Aggressive Aesthetics: The Market Dynamics of 1998 Mitsubishi 3000GT Front Bumpers

Front bumpers on the 1998 Mitsubishi 3000GT do more than frame the grille and lights. They set the car’s first line of defense against aerodynamic lift and low-speed impacts, and they carry a heavy weight in the eyes of enthusiasts who value period-correct styling as much as performance. As the model aged into the late 1990s, the market for replacement bumpers became a study in scarcity, a dynamic defined not by mass production but by a stubborn subculture of owners, restorers, and gearheads who treat every part as a hinge between memory and possibility. The bumper’s availability today reveals a market structured around a few well-worn paths: rare OEM components preserved or found in salvage yards, and a vibrant, often divergent aftermarket scene that promises lighter weight, distinctive looks, and sometimes questionable fit. In short, the front bumper has become a focal point of decisions about authenticity, cost, and the practical realities of keeping a classic sports car roadworthy and relevant to contemporary tastes.

Online auction platforms have become the centerpiece of this market. The listings tell a story about value, condition, and the expectations of buyers who want to maintain the car’s silhouette without breaking the bank. A 1997-1998 Mitsubishi 3000GT SOHC Base OEM Red Front Bumper, offered at 425 dollars with a prior price of 531 dollars, embodies the tension between the premium attached to genuine parts and the realities of wear. Descriptions like ‘rough but usable’ signal a pragmatic buyer who accepts cosmetic or minor structural flaws if the component can be mounted, aligned, and painted to an acceptable standard. This kind of language is not a flaw; it is a window into an ecosystem where restoration budgets, labor, and time all factor into the decision to source original equipment versus salvage something functional and cost-efficient. The fluctuation in price—driven by condition, supply, and the relative urgency of a repair—underscores a market that is less about instant gratification and more about strategic sourcing for a car with a small but dedicated following.

On the aftermarket side, the market has grown from necessity into a hobby in its own right. Among the options, one-piece front bumpers made from materials like Fiberglass Reinforced Plastic (FRP) have carved out a space for custom aesthetics and weight savings. The Vader-style front bumper, popular among 1994-1998 3000GT and Dodge Stealth builds, demonstrates how design choices can shift the car’s character without touching the core chassis. These parts are not merely appearances; they influence aerodynamics, brake cooling, and weight distribution in ways that matter on both the street and the track. The FRP materials, while not as forgiving as OEM plastics in terms of impact resistance, offer ease of modification and a lower price point for hobbyists experimenting with wide-body looks or aggressive stance. The decision to adopt such a bumper often reflects a balance between performance fantasies and the practicalities of installation, paint matching, and fitment with guards, grills, and headlights. Enthusiasts weigh the advantage of a more aggressive, modernized front end against potential compromises in alignment, mounting hardware, and knock-on effects to bumper-to-body gaps.

Lurking beneath this surface is a more structural truth: parts for the 3000GT in 1998 form a niche market defined by low production volumes and a community that preserves the car’s legacy through dedicated channels like specialty suppliers and salvage operations. OEM bumpers remain scarce and expensive, with pricing sensitive to the pros and cons of condition and originality. Meanwhile, the aftermarket sector thrives on flexibility, offering alternatives that fit a range of budgets and skill levels. For restoration purists, this can be reassuring, a signal that a pristine, factory appearance is still possible, albeit at a premium and with careful sourcing. For builders who prize distinctive silhouettes or performance-first goals, the aftermarket options provide a canvas to shape the car’s identity without surrendering the essential lines of the original design. The combined effect is a market that rewards knowledge—knowing which years, trims, and body panels share compatibility—and patience, as a part found today may require weeks or months of negotiation, ship times, and condition checks before it becomes a usable component on the car.

The choice between OEM and aftermarket bumpers often comes down to fitment realities and the owner’s broader project vision. A rough but real truth is that an authentic piece can carry a premium not just for its brand but for the assurance that it will align with the car’s geometry, mounting points, and impact studies from the factory. However, the time and money required to locate, ship, and refinish such a part can rival the expense of newer aftermarket solutions that promise straightforward installation and a modernized aesthetic. In this sense, the 1998 3000GT bumper market acts like a microcosm of the wider collector-drivetrain landscape: a balancing act between reverence for originality and the practicalities of owning a vintage performance car in an era of rising build quality and diverse customization options. For readers exploring this space, a case in point is the Duraflex version 1 front-rear bumper set for 94-98 3000GT/Stealth. It embodies the pragmatic appeal of an integrated styling package that can transform the front end while keeping costs within reach; see Duraflex version 1 bumper set for 94-98 3000GT/Stealth. This kind of option highlights the market’s dual promise: the ability to redefine the car’s face with relative affordability and the responsibility to address fitment, prep, and paint as part of the ownership journey.

To see a snapshot of current listings in real time, one can review active listings on external marketplaces such as this example: https://www.ebay.com/itm/1997-1998-Mitsubishi-3000GT-SOHC-Base-OEM-Red-Front-Bumper/404769979174.

How the 1998 3000GT Front Bumper Shapes Style, Safety, and Performance

The front bumper of the 1998 Mitsubishi 3000GT does more than cover the car’s nose; it defines the coupe’s character and directs how the car performs on the road. Its broad, low-slung face, integrated fog housings, and sculpted lower air dam gave the 3000GT a forward-leaning, purposeful stance. That stance was not just for looks. The bumper was engineered to manage airflow, protect vital components, and support the car’s advanced features. For owners and restorers, understanding these combined aesthetic and functional roles clarifies why replacements and upgrades remain in demand.

Visually, the 1998 bumper was meant to communicate speed. The wide mouth of the grille appears to pull the car forward. Sharp edges and flowing contours wrap around the headlights and wheel arches, producing a silhouette that feels taut and modern even decades later. Designers balanced smooth surfaces with pronounced cutaways to create contrast. That contrast made the 3000GT stand out beside other performance coupes of the era. On the street, the bumper’s lines work with the hood and fender shapes to make the car read as a single, cohesive object rather than a collection of panels.

Beyond immediate visual impact, the bumper contributed to perceived technological sophistication. Integrated fog light recesses and the pronounced lower air dam suggested engineered utility. Those features hinted at underlying systems—cooling, braking, and sometimes forced induction—that relied on controlled airflow. The aesthetic language therefore also served a messaging purpose. It told prospective buyers that the car was performance-oriented and thoughtfully detailed.

Functionally, the bumper plays a critical role in airflow management. The large central intake and flanking channels funnel cool air to the radiator and, when equipped, to the intercooler. That is essential for maintaining safe engine temperatures during spirited driving. The lower lip and splitter geometry reduce front-end lift by directing airflow downward and smoothing turbulence beneath the car. For high-speed stability, those design choices make a measurable difference in how the 3000GT tracks and responds to steering inputs.

Energy management in a collision is another major function. The bumper assembly integrates crush zones and energy-absorbing materials that help dissipate impact forces before they reach the engine bay and cabin. Those internal structures are invisible but essential. They preserve structural integrity in minor to moderate impacts and reduce repair bills in many cases. The assembly also includes mounting points for lighting, sensors, and fasteners. Proper fit and alignment keep the hood gaps tight and ensure body panels share load paths as intended.

Material choices further reflect the trade-offs between originality, weight, and durability. Original equipment bumpers are molded to meet manufacturer specifications for impact absorption and fit. They use materials that balance flexibility and strength to meet safety regulations. Aftermarket options often prioritize different attributes. Lightweight composites, including fiberglass reinforced plastics, reduce weight and are easier to modify for custom bodywork. They appeal to enthusiasts who want to shave mass or fit aggressive aero components. However, composite bumpers sometimes sacrifice the flex and energy-return characteristics of OEM pieces. For a collector intent on authenticity, that trade-off matters.

The market for replacement and upgraded bumpers for the 3000GT reflects these diverging goals. Buyers seeking to restore a car to original condition often hunt for OEM units. Those parts age, and many listings note signs of wear, dings, or previous repairs. A used OEM bumper may be described as “rough but usable,” which signals a balance between affordability and authenticity. Conversely, drivers focused on visual statement or track-oriented performance can choose one-piece aftermarket bumpers that accept larger openings, different fog lamp mounts, or integrated splitters. These allow a transformation of the car’s front end while enabling functional changes to airflow.

Installation considerations are practical and important. Because the bumper interacts with headlights, mounting brackets, and fender edges, fitment is critical. Aftermarket pieces often require trimming and shims for a precise fit. An exact OEM replacement will align with factory fasteners and typically needs less bodywork. That difference influences labor costs and the timeline for a repair or upgrade. Paint matching is another variable. Original finishes from the late 1990s have aged, and blending a newly painted bumper into an older front clip takes skill to avoid visible seams.

For owners contemplating a purchase, resale availability and the secondary market shape decisions. Salvage yards, specialist sellers, and online marketplaces offer a range of conditions and prices. Some buyers prefer a patinaed OEM bumper that preserves the car’s history. Others prefer aftermarket options that deliver a modern interpretation of the classic silhouette. The choice often comes down to intended use: show and authenticity, daily driving, or performance and track use.

A practical tip for anyone replacing the front bumper: assess the hidden attachments and adjacent components before committing. Radiator supports, crash rails, and headlamp mounts can be damaged when the bumper is. Replacing only the visible piece without checking these elements can lead to repeated failures or fitment issues. A careful inspection reveals whether additional parts are warranted, and it often reduces surprises during installation.

The front bumper’s enduring appeal lies in how it synthesizes style and engineering. It shapes first impressions while performing essential functions every time the car moves. Whether an owner chooses an original piece with character or a contemporary composite upgrade, the bumper remains central to the 3000GT’s identity. For those exploring replacement options, the secondary market contains both OEM and aftermarket choices. Enthusiasts looking for a one-piece aftermarket set that fits 1994–1998 models can review a Duraflex-style front and rear bumper set designed for compatibility with the 3000GT and related models.

For an example of an OEM unit available on the secondary market, see the listing linked here: https://www.ebay.com/itm/1991-1999-Mitsubishi-3000GT-Stealth-Front-Impact-Bumper/402758169957

Final thoughts

Understanding the various front bumper options for the 1998 Mitsubishi 3000GT is crucial for making informed decisions in the automotive aftermarket. Whether opting for OEM parts to maintain authenticity or choosing aftermarket enhancements for performance and aesthetic modifications, business owners should consider the material, market dynamics, and functional impacts of these components. By recognizing the unique features and advantages offered by each bumper style, owners can better cater to customer preferences and enhance the appeal of their vehicles. The front bumper is not merely a decorative piece; it encapsulates the spirit of the 3000GT, reflecting both its heritage and the individuality of its owners.