As the automotive industry continually evolves, the Mitsubishi Lancer Evolution X, a standout performer, represents a pivotal shift in engineering. Its 2.0-liter turbocharged engine, known as the 4B11T, not only enhances driving dynamics but also redefines expectations around performance. This article takes a deep dive into the specifications and performance enhancements of the Evo X motor, examines various engine variants and tuning options available to enthusiasts, highlights technological innovations that set it apart, and discusses its lasting market impact and legacy. Each chapter offers business owners valuable insights into why this engine has become synonymous with automotive excellence.

Under the Hood of Precision: The EVO X 2.0-Liter Turbo Engine and Its Drive-Train Symphony

The Mitsubishi Lancer Evolution X represents a deliberate leap toward refined power and precise control, a convergence of advanced engineering that makes a modern four-door rally legend feel perfectly at home on a winding road or a race-bred track. At the center of that achievement sits a 2.0-liter inline-four turbo engine, a compact powerplant designed to deliver more than raw thrust. This engine, known internally by its code, is built with an all-aluminum block. The material choice cuts weight where it matters most and aids heat management, a combination that translates into quicker throttle response and more predictable power delivery across a broad rev range. In practice, the aluminum architecture reduces inertia in the powertrain and helps the chassis respond with greater immediacy to driver input, a critical feature when the car is pressed through a sequence of quick transitions. The result is not only stronger performance but a more faithless relationship between pedal and progress, a quality that motivates confidence whether one is chasing a personal best on a back road or tuning for a competitive track session.

Power originates from a compact, high-revving four-cylinder layout that punches above its displacement when the turbocharger spools. The engine’s air handling and fuel delivery are closely coordinated to maximize efficiency and reliability at high boost levels. The fuel system uses sequential multi-point injection, a choice that allows precise metering of fuel to each cylinder as manifold pressure and engine speed change. This precision is essential for maintaining clean combustion and stable idle, even as the boost builds and the intake pressure climbs. A timing system delivers the breaths of air and fuel in a carefully orchestrated sequence, with electronic control adjusting the timing to preserve both torque and efficiency across the engine’s operating window. In this respect, the EVO X’s power unit is not just about peak horsepower; it’s about a broad, usable torque curve that makes the car feel eager, even in mid-range revs where street driving and back-road scrambles happen the most.

The heartbeat of this powertrain is its turbocharger arrangement, a twin-scroll design that helps minimize lag and maximize response. By separating exhaust gas pulses and routing them to alternate scrolls, the turbo spools more quickly and contributes to a more linear rise in boost as engine speed climbs. The practical upshot is a car that feels energetic from low revs and continues to pull with authority as the tachometer sweeps toward redline. The turbo’s behavior is carefully matched to the engine’s breath and the intake tract, so the driver experiences a surge of usable torque rather than a sudden spike that can unsettle the chassis. This balance between boost onset and throttle response is a hallmark of the Evolution X, reinforcing the sense that the engine and chassis are tuned as a single system rather than as separate modules.

A modern engine’s personality is as much about how it breathes as about how it breathes fire, and the EVO X integrates a variable valve timing electronic control system that optimizes both intake and exhaust timing across the rev range. When the engine is lugging, the system favors torque that can pull the car forward with composure; as the revs rise, the timing shifts to sustain power and keep the engine breathing cleanly. This electronically controlled variable timing helps manage intake flow, combustion stability, and exhaust velocity, contributing to both enhanced performance and more efficient operation in everyday driving. The design philosophy here is straightforward: give the driver accessible torque in normal driving while preserving the ability to chase higher speeds when the road or the track invites it. In practical terms, this means smoother power application, better throttle modulation, and a more forgiving response when the driver asks for acceleration while cornering. Aesthetically, the tech reads as part of a holistic approach that emphasizes drivability as much as outright peak figures.

For many enthusiasts, the engine’s nominal ratings—roughly a factory-approved range of 291 to 303 horsepower and torque in the neighborhood of 366 to 422 Nm (270 to 311 lb-ft)—signal not just peak numbers but the broad envelope of capability the car offers. Those figures are not static; they shift with model year, trim level, and market calibration, a reminder that the EVO X is a platform that matured through refinement rather than a single snapshot of performance. The result is a motor that welcomes high-speed operation with confidence while remaining approachable in daily use. The engine’s characteristics—strong mid-range torque, a responsive throttle, and a linear love of revs—work in concert with the car’s drivetrain and chassis geometry to create a driving experience that feels both purposeful and predictable.

The engine’s relationship with the transmission is an essential part of its everyday character. The EVO X was offered with two broad pathways: a traditional five-speed manual and a six-speed dual-clutch automatic transmission. The standard setup on many trims is the manual, which supplies a direct, tactile connection to the engine’s torque and a tangible sense of involvement. For higher trims, including performance-oriented specifications, the six-speed dual-clutch transmission (often marketed in the lineage as a rapid, race-inspired automatic) became the preferred choice for those who want swift gear changes without removing their hands from the wheel. The automatic option reduces shift times dramatically and helps keep the engine in its sweet spot under rapid driving, adding a modernity to the car’s performance without sacrificing the engine’s eager nature. The pairing of a turbocharged, high-torque engine with a dual-clutch transmission creates a compelling dynamic: rapid momentum on straights, coupled with the kind of precise, controlled power that’s crucial for confident handling through corners.

The EVO X’s performance story would be incomplete without addressing its all-wheel-drive system, which brings together center differential control, yaw management, and stability logic to deliver composure in corners and traction on slippery surfaces. The AWD architecture is designed to keep tire contact with the road under diverse conditions, transmitting the engine’s torque to all four wheels in a way that preserves the car’s intended balance. In practice, this means the chassis can be driven closer to the limit with more confidence, as the system modulates torque distribution to maintain grip and direction. The result is a car that can be pushed hard through a bend yet remain forgiving enough to prevent abrupt, controllable fade in the event of unforeseen inputs. This holistic integration of drivetrain components underlines a broader philosophy: power, grip, and steering feedback should operate as a cohesive trio, not as isolated elements competing for attention.

The EVO X’s path forward marked a clear shift from its predecessor. The earlier generations relied on a cast-iron block and a more conservative overall approach to weight, heat, and response. The all-aluminum engine block, coupled with refined turbocharging and electronic control, represents a purposeful optimization aimed at delivering sharper responses and better heat management. Weight reductions in the engine assembly translate into lower inertia and quicker transitions into and out of boost, which, in turn, aid handling fidelity and throttle predictability. When paired with the AWD system’s refined distribution and the transmission’s rapid-shift behavior, the result is an operating envelope that favors precision and confidence—an important distinction for a platform intended for both road performance and circuit use.

Enthusiasts often regard the EVO X as a platform that rewards thoughtful preparation and smart upgrades. Among the upgrade paths discussed in enthusiast communities is a billet engine block for the 4B11T, a hardware modification that can offer improved strength and heat management under high power output. The potential benefits include reduced flex under load, improved reliability under sustained boost, and a more robust foundation for further tuning. Importantly, any upgrade of this kind should be undertaken with an awareness of the engine’s overall thermal and mechanical design, ensuring that the cooling system, turbocharging response, and engine management software are harmonized with the stronger block. For those curious about such avenues, an accessible reference is a dedicated billet-block upgrade that highlights how an engineered block can support stronger sleeved or reinforced componentry while maintaining the engine’s compact footprint. See the discussion here for more on this path: 4B11T billet block. While upgrades can enhance capability, they should be approached with care, taking into account how changes propagate through the intake, exhaust, cooling, and control strategies.

The chapter’s broader arc is not merely about peak numbers. It is about an architecture that aims for refined power delivery, accessible drivability, and credible track performance. The EVO X engine achieves this through a careful balance of lightness, breathing efficiency, and controlled boost. The all-aluminum block reduces mass where it matters, the twin-scroll turbo architecture accelerates responsiveness, and the sequential fuel and timing strategies enable stable, repeatable combustion across a spectrum of driving conditions. The electronic control of valve timing—an approach that optimizes how the engine breathes at different loads and speeds—plays a central role in shaping the engine’s character. Together with the drivetrain’s coordinated all-wheel-drive dynamics, these elements contribute to a driving experience that feels precise, predictable, and capable of more aggressive pursuit when the driver wishes to push beyond everyday speed.

In sum, the EVO X motor is a compact, highly integrated system whose design philosophy centers on turning power into usable performance without demanding a bespoke race-car mindset from the operator. The engine’s architecture—an all-aluminum block, a turbocharged breath, precise fuel and timing control—works in concert with a sophisticated all-wheel-drive framework and a choice of transmission that favors either direct engagement or rapid, seamless shifting. The numbers—roughly between 291 and 303 horsepower and torque in the mid three- to four-hundred Newton-meter range—are best understood as signs pointing to a broader capability: an engine that delivers robust, usable performance across a wide operating envelope. In the hands of a skilled driver, the EVO X becomes more than a collection of specifications; it becomes a vehicle whose powertrain and chassis communicate with clarity, inviting the driver to explore, to balance, and to refine the moment of acceleration and the art of cornering. The car’s design prioritizes a cohesive, confident feel at the limit, and the engine’s character—the way it builds boost, the way it breathes with a measured surge, the way it integrates with the transmission and the AWD system—helps realize that aim.

External resource for official specifications and documentation: https://www.mitsubishimotors.com

The 4B11T Saga: EVO X Power, Variants, and the Tuning Odyssey

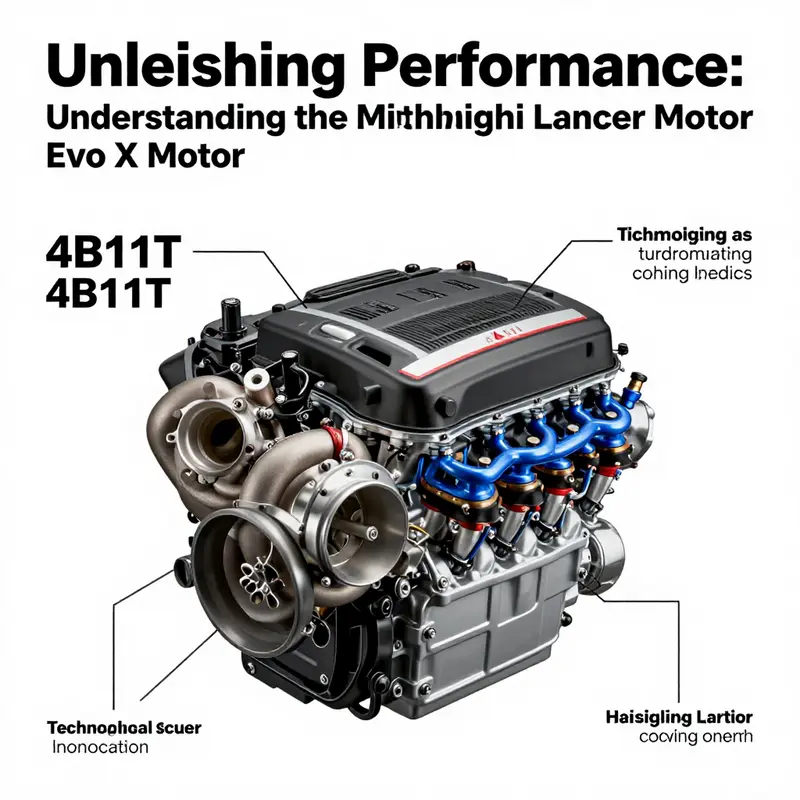

The Mitsubishi Lancer Evolution X rests on a compact, highly engineered core that defines its identity on the road and track alike. At the center of that identity is the 2.0-liter inline-four, aluminum-alloy heart that breathes through a turbocharged path and a careful symphony of intake and exhaust tuning. This engine is the 4B11T, and its design marks a departure from the heavier, iron-block predecessors that many enthusiasts once assumed would power the rally-inspired Lancer for years to come. The switch to an all-aluminum block and head dramatically reduces unsprung weight and rotating mass, which in turn improves heat management, throttle response, and handling finesse. Add in Mitsubishi’s MIVEC variable valve timing system, and the 4B11T becomes not just a specification but a performance philosophy. It invites scrutiny from engineers and thrill-seekers alike, because its fundamentals sit at a sweet intersection of efficiency, strength, and potential that invites modification without surrendering confidence in everyday drivability.

From the moment the EVO X rolled onto the scene, the 4B11T was defined by a trio of factory configurations that reflected different goals—open-road pace, track-ready sharpness, and then a celebratory culmination that honored the lineage. The GSR, MR, and Final Edition variants each locked in distinct power outputs and transmission strategies, yet all shared the same foundational engine architecture. The GSR, the base model, delivered an amiable yet purposeful 291 horsepower and 366 Nm of torque, paired exclusively with a five-speed manual. It offered a purer, more driver-focused experience, with the engine’s character shaped by a tunable throttle response and a chassis that rewarded precise, track-spirited driving but remained accessible for everyday use. By contrast, the MR—often described in the company’s marketing as the higher-performance variant—pushed the 4B11T to 303 horsepower and 422 Nm of torque, driven by a more aggressive ECU calibration and an upgraded turbo setup. The MR’s standard twin-clutch six-speed transmission (TC-SST) emphasized faster, more deliberate shifts that could keep the car in its power band with less flick of the wrist, and its track-ready character was reinforced by refined intake and exhaust paths that promoted a more instantaneous surge of torque. This pairing of power and transmission strategy created a distinctive vibe: a car that could charm with its nimble street manners yet demand respect on the circuit when the throttle opened.

Then came the Final Edition, a 2015 homage that capped the EVO X production run with some of the best factory hardware Mitsubishi offered for this platform. It retained the 303-horsepower output of the MR, but it clothed the engine in a package designed for the enthusiast who wants a comprehensive, turnkey experience: Bilstein dampers paired with Eibach springs, BBS forged wheels, and red Brembo calipers signaling the performance intent from the first glance. The Final Edition wasn’t merely cosmetic; its suspension and braking upgrades improved ride control and fade resistance on demanding roads andte tracks, delivering a cohesive, all-around performance that remains highly prized today.

The engine’s all-aluminum construction was more than a weight-saver; it was part of a broader thermal strategy. Aluminum’s heat dissipation properties help keep the 4B11T cooler under sustained boost, which is pivotal when the car spends time on twisty roads or a race course where temperatures can climb. Yet aluminum also presents a challenge: the engine must be engineered to tolerate repeated cycles of heating and cooling, especially when modifications push bore-to-stroke relationships, rod angles, and piston loads toward the upper limits of tolerance. The EVO X’s architecture handles this well, but it also invites a careful approach to tuning. Enthusiasts who push beyond factory specifications typically pair ECU remapping with turbo upgrades, intercooler improvements, and exhaust refinements to unlock the engine’s potential while maintaining reliability and safe detonation margins.

A central theme of the 4B11T is tunability. Factory tuning established a solid baseline, but the engine’s design invites a broad spectrum of upgrades that can dramatically alter power delivery and drivability. ECU remapping is a common path, where precise recalibration of fuel delivery, boost targets, and ignition timing can yield an extra 30 to 50 horsepower with proper hardware support. The goal isn’t simply more horsepower; it is to shift the engine’s power band to a region where the turbocharger spools more aggressively or where pulse widths align with a cleaner, more consistent charge air. In practice, many builders aim for outputs in the 350+ horsepower range, but doing so requires more than a simple software tune. Supporting modifications become essential to handle higher boost levels, including upgraded intercoolers to fight heat soak, freer-flowing intake paths to minimize pressure drops, and exhaust systems that reduce backpressure while preserving the engine’s breathing characteristics and exhaust note.

Turbocharger upgrades lie at the heart of the most dramatic transformations. A larger unit such as a Garrett GTX2516 or a BorgWarner EFR 6066 provides higher sustained boost and improved transient response. The trade-off, of course, is heat management and lag mitigation. This is where the EVO X’s AWD foundation and chassis rigidity come into play. A well-integrated turbo upgrade will not only push peak horsepower upward but also expand the usable torque across a wider RPM band, allowing the car to accelerate with confidence in corners and on straights alike. This is critical when the goal is to maintain tractable power while preserving street manners, which is a delicate balance many EVO X owners pursue with care.

Intercoolers and intake systems are the next line of defense against reliability issues that often accompany forced induction. A high-efficiency front-mount intercooler reduces charge-air temperatures more effectively than the stock unit, which lowers the risk of heat-induced knock and permits more aggressive timing and boost. Cold-air intake systems, properly designed for the EVO X’s under-hood air dynamics, can also contribute to marginal gains by reducing charge air temperature and improving flow. The result is a faster, more responsive throttle that makes the turbo’s presence felt earlier in the rev range.

Exhaust systems complete the breathing cycle. A full-tuned system—whether built from stainless steel or, for the most ambitious builds, lightweight titanium—can reduce backpressure and improve exhaust scavenging. The combination of a freer exhaust with a robust intercooler and an optimized intake path helps the engine reach its target horsepower more efficiently. Beyond the numbers, these changes alter the engine’s character: a deeper, more aggressive note under load, and a cadence that aligns with a driver’s sense of speed and control.

For those chasing extreme power, forged internals become a practical necessity. As boost and heat rise, pistons, connecting rods, and the bottom end must withstand higher cylinder pressures. In such builds, the engine is not simply tuned; it is rebuilt to support sustained power with reliability. The EVO X, with its strong bottom end by modern standards and the availability of aftermarket performance components, can accommodate these levels of resourcing and engineering. The result is a car that remains livable on the street while delivering exhilarating acceleration on track.

All of this power, especially in a car built around an advanced all-wheel-drive system, hinges on a chassis that can manage grip, weight transfer, and steering response. The EVO X’s chassis geometry, coupled with its AWD system, offers a receptive platform for torque to be applied without instability. The interplay between power delivery, tire grip, and suspension tuning creates a compelling dynamic: the driver can apply a touch of boost and still maintain control, or push aggressively and feel the car settle into a measured, predictable line through a corner. This harmony is part of why the EVO X has endured as a favorite for tuners who want to push the envelope while maintaining an everyday balance that makes the car practical for daily use.

Within this ecosystem of power and control, some builders seek additional reliability and rigidity through targeted upgrades. The community frequently references strengthened engine blocks and reinforced mounting points as the backbone of higher-output builds. Within the catalog of parts one might explore, the option to consider a lightweight, reinforced block stands out as a pivotal decision for serious performance work. For those curious about a specific upgrade path, the 4B11T billet block option offers a compelling blend of weight savings, heat management, and strength that can support extended high-boost operation without compromising durability. 4B11T billet block provides a tangible example of how builders approach the bottom end with modern materials and manufacturing techniques. This kind of component, while not a universal requirement, signals a broader shift toward preparing the EVO X platform for extended high-power running.

As a result, the 4B11T is not simply a single specification but a spectrum of configurations and potential evolutions. Each variant—GSR, MR, Final Edition—represents a snapshot of the engine’s capabilities under different constraints. The tuning landscape that surrounds it is equally varied, offering pathways that range from a refined street tune to a track-focused build that emphasizes durability and repeatable performance. The engine’s architectural decisions—aluminum construction, MIVEC timing, turbocharging, and the practical realities of boost management—provide a flexible foundation that continues to attract both enthusiasts and engineers. The EVO X’s motor is not merely a powerplant; it is a platform for experimentation that requires respect for mechanical limits and a thoughtful approach to cooling, lubrication, and structural integrity.

For readers seeking a deeper dive into factory specifications and real-world performance, archival access at the MMNA resources and contemporary automotive journalism offer a detailed baseline. The interplay between official data and independent testing helps illuminate how these engines perform in varied conditions, from controlled test tracks to spirited road scenarios. In particular, the Final Edition’s review captures the essence of a closing chapter for the Evo X, where performance upgrades were balanced against usability and reliability, creating a well-rounded, exhilarating vehicle that stood as a culmination of a long-running engineering dialogue. External reference: https://www.caranddriver.com/mitsubishi/lancer-evolution-x/review/a27873/mitsubishi-lancer-evolution-x-final-edition-review/

The EVO X demonstrated that a compact, purpose-built four-cylinder could be a versatile platform for both road driving and serious performance work. Its engine, the 4B11T, serves as a bridge between Mitsubishi’s engineering heritage and a modern era of tunable performance. The variants show how a single engine family can be tuned in distinct directions, reflecting different philosophies of speed, handling, and driver engagement. In the hands of trained engineers and skilled enthusiasts, the 4B11T remains a living dialogue about power, efficiency, and the art of delivering that power to a capable chassis. The chapter on variants and tunings does not conclude with mere specifications; it offers a lens into how power systems evolve when subjected to human curiosity, precision, and the relentless pursuit of speed in a controlled, predictable, and enjoyable manner.

How the Evo X Motor Rewrote Performance: Engine, Drive Control, and Component Synergy

The Lancer Evolution X introduced a new definition of compact performance by repositioning the engine as an integrated control center rather than a standalone powerplant. At the heart of that shift sits the 4B11T, a 2.0-liter, all-aluminum inline-four turbocharged engine. Its design choices ripple through the car’s dynamics. The lightweight aluminum block reduces overall mass and improves heat rejection. That change alone altered weight distribution and thermal behavior, letting engineers tune suspension and cooling with greater freedom. Beyond materials, the 4B11T brings variable valve timing, direct valve control, and a turbocharger mapped to a usable torque curve. Together, these elements redefine what drivers feel through the throttle and steering wheel.

The engine’s construction matters because it sets the mechanical baseline. Compared with the older cast-iron architecture, the 4B11T’s aluminum block cuts weight while aiding heat transfer. That helps keep intake and charge temperatures lower during hard operation. Lower thermal inertia means consistent power lap after lap. Internally, the 4B11T balances forged and cast components to manage both everyday reliability and track demands. The turbocharger is sized and tuned to deliver strong midrange torque, reducing lag and keeping boost available through corners. The result is a broad, usable powerband that rewards both aggressive and precise inputs. Peak output numbers quantify that progress: the engine delivers nearly three hundred horsepower and a robust torque plateau centered in the midrange. Those figures translate to rapid acceleration and flexible response across speeds.

Valve timing innovation plays a central role in extracting both efficiency and power. The variable valve timing system adjusts intake timing dynamically to match load and rpm. Under light throttle, timing favors efficiency and smoothness. Under heavy demand, it moves to prioritize airflow and higher cylinder filling. That transition is seamless to the driver, creating more linear throttle response and stronger high-rpm breathing. The combination of variable timing and a modern intake manifold design reduces the need for extreme cam overlap tuning. That makes the engine more tractable in traffic and more aggressive on a track. It also reduces the compromise between low-end tractability and high-end power that often plagues turbocharged engines.

But an engine is only part of the story. The Evo X treats the drivetrain as a dynamic system where torque must be actively managed. Its integrated four-wheel control system coordinates multiple subsystems to sculpt traction and handling. An active center differential decides how to split torque between the front and rear axles. That differential responds to throttle, steering angle, and wheel speeds, shifting torque to the axle with better grip. At the rear, yaw control alters left-right torque biasing to rotate the car into corners. These two elements work together: the center differential determines the front/rear balance while the rear yaw control fine-tunes rotation and turn-in feel. Electronic stability functions monitor wheel slip and adjust braking and engine torque to preserve the intended line. Anti-lock braking aids safe deceleration while the broader suite of systems keeps the car poised at its limits.

The synergy between engine torque and drive control is vital. When the turbo builds pressure, the torque vectoring system can route force to the wheels that will best use it. That means the car keeps its nose from pushing outward and can be more aggressive on throttle mid-corner. On a high-speed sweep, torque distribution smooths steering effort and maintains stability. During short-radius maneuvers, yaw control helps bring the tail into balance. Because these responses are fast, the driver experiences a single, unified behavior rather than a stack of independent corrections. The integrated control strategy turns raw power into usable performance and makes high-speed driving more confidence-inspiring.

Transmission choices reinforce that integration. The standard manual gearbox provides a direct, mechanical link to the engine. Its ratios are chosen for a balance of acceleration and highway cruising. The optional twin-clutch transmission represents a different philosophy. With two clutches and pre-selected gears, shifts occur in milliseconds. That speed keeps torque delivery continuous and minimizes driveline shock. Paddle shifters let the driver command shifts without removing hands from the wheel. In circuit use, the twin-clutch unit allows quicker exits from corners and steady torque through direction changes. On the street, it smooths gear changes and can be tuned to be more forgiving in traffic.

The transmission and drive-control systems also enable electronic launch strategies and mapped driving modes. These modes alter torque distribution, throttle response, and shift logic. A sportier map brings more immediate throttle bite and sharper shifts. A comfort-oriented map soothes responses and shifts earlier for efficiency. The ability to change behavior on the fly makes the car adaptable to different roads and driver intent. It is a modern interpretation of versatility: a single car can be tractable and precise, daily usable and capable on a racetrack.

Chassis control complements the powertrain with suspension and brakes engineered for consistent performance. Tuned dampers and progressive springs control body motion through aggressive inputs. The collaboration between damper valving and spring rates optimizes tire contact patch behavior. That means the car resists excessive roll but still communicates surface changes. Suspension geometry, including careful attention to roll center and camber curves, keeps the tires working in their optimal range through cornering. Those choices deliver a balance between grip and predictability. Engineers dialed compliance into the front and rear assemblies to give both cornering bite and straight-line stability.

Stopping performance was improved to match higher cornering speeds. Large ventilated discs and multi-piston calipers provide strong initial bite and consistent fade resistance. Brake cooling is not an afterthought; ducting and vent placement help evacuate heat during extended hard use. The entire braking system is selected for repeatable pedal feel and a stable midpoint. That lets drivers modulate braking force precisely as speeds and track conditions change. Combined with the anti-lock and stability functions, the brakes become a critical tool for lap time and safety.

Beyond factory specifications, the Evo X’s engine and drivetrain were designed with modification in mind. Strengthened blocks and aftermarket reinforcement options exist for those pushing power beyond stock limits. Upgraded cooling, intercooling, and exhaust routing commonly accompany power increases. For owners exploring heavy modification, specialized engine blocks and machining services can provide the structural base for larger turbos and higher cylinder pressures. A notable resource for those reinforcing the engine block can be found at this page covering a specific billet block option: 4B11T billet block.

What ultimately differentiates the Evo X is not any single component. It is the deliberate marriage of a responsive turbo engine to a predictive drive control system and well-matched chassis hardware. Power delivery is not brutally raw; it is sculpted by valve timing, boost management, and tailored gear ratios. Traction and yaw control feed off that sculpted torque to provide a cohesive driving sensation. Suspension and brakes complete the package, turning potential into repeatable, usable performance. The outcome is an engine and drivetrain package that rewards precision and confidence equally.

This chapter has traced how material choices, valve control, turbo mapping, and drivetrain integration combine to form the Evo X’s motor identity. Each element supports the others, producing a car that feels connected from throttle tip-in to apex exit. For technical details and official specifications, refer to the manufacturer’s resource: https://www.mitsubishimotors.com/

Engineered for Precision: The Evo X Motor, Market Impact, and the Lasting Legacy

From the moment the Evo X arrived, the 4B11T engine defined its character: lightweight, turbocharged, and tuned for balance rather than raw peak numbers. Its all aluminum block and head reduced weight, improved throttle response, and allowed the chassis to feel more eager in quick transitions. The result was a powertrain that rewarded careful driving and offered reliability as a daily companion.

Moving from the 4G63 family to the 4B11T signaled a shift in philosophy: weight savings enabled sharper handling, better heat management, and a more predictable torque curve. With around 291 horsepower in stock form, the engine retained a broad torque band and a linear, usable surge that suited the Evo X’s all wheel drive chassis.

The market reacted to this package by valuing a car that could be enjoyed on a winding road and still be comfortable on a highway. Enthusiasts could tune the engine and turbo system without compromising daily usability, building a culture of measured upgrades. The combination of a torquey yet controllable turbo and a chassis that communicated through steering and feedback made the Evo X a standout in a crowded segment.

Beyond specifications, the Evo X earned a lasting legacy as a driver focused machine. Its open platform for modification, rally heritage, and emphasis on driver input created a blueprint for what performance sedans could be when engineering clarity took precedence over electronic complexity. Even after production ended, the car remains a touchstone for enthusiasts who value engagement, predictability, and tunability.

Final thoughts

The Mitsubishi Lancer Evolution X has left an indelible mark on the automotive landscape, particularly with its advanced 4B11T engine. From exceptional specifications to innovative technologies and a wide range of tuning options, the Evo X has captivated enthusiasts and business owners alike. Its legacy in motorsport and among automotive circles continues to inspire new generations. Understanding the power and engineering behind this model provides valuable insights for those interested in high-performance vehicles and their market significance.