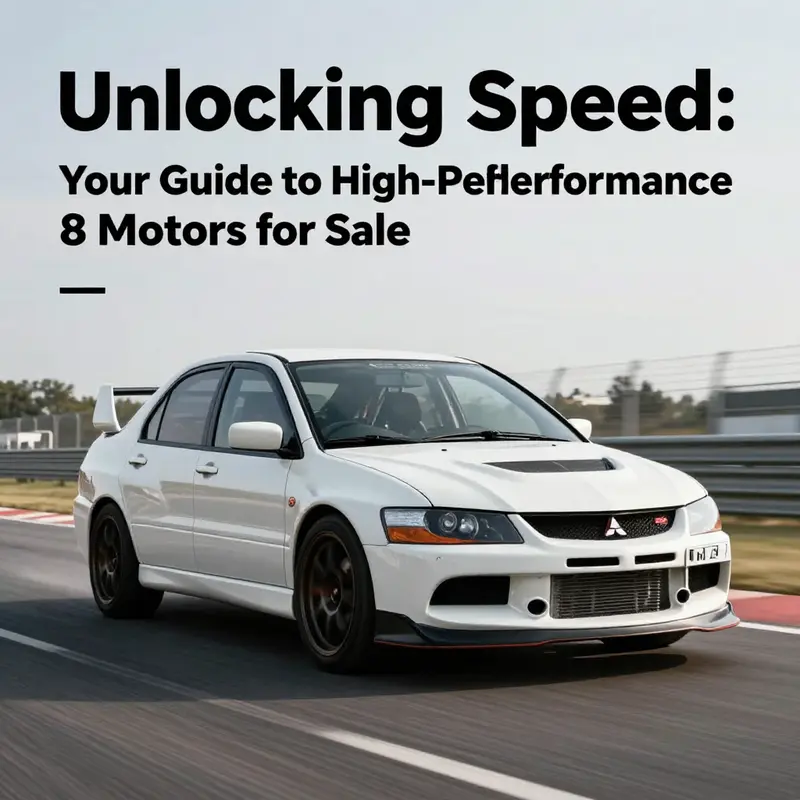

As the automotive industry evolves, high-performance engines like the Mitsubishi Lancer Evolution VIII (Evo 8) are at the forefront of racing modifications and enthusiast projects. These engines offer the power and reliability that business owners need when supplying performance parts to a dedicated clientele. In this guide, we will delve into the world of Evo 8 motors for sale, specifically focusing on high-performance crate engines. We’ll clarify what constitutes a crate engine and why these options are essential for automotive projects. Furthermore, we’ll explore how to evaluate suppliers effectively, examine the technical specifications of these engines to understand their performance metrics, and discuss the current market trends and demand for Evo 8 motors in the automotive industry. Each chapter will present valuable insights aimed at helping business owners make informed decisions.

Crate Engines for the Evo 8: Reading Beyond the Price Tag to Find Precision, Power, and Proven Reliability

The Mitsubishi Lancer Evolution VIII has earned a lasting reputation in both competitive circles and enthusiast garages for one reason: the potential that sits inside its turbocharged four. When builders seek more power or a repeatable platform for a late-model restoration, a high-performance crate engine becomes a focal point of the plan. Yet a crate is not a simple box of parts. It is a carefully assembled, tested, and validated assembly that promises consistency across many miles of road and multiple sessions on the track. For Evo 8 builds, the crate engine is less a commodity than a carefully negotiated agreement between a builder’s ambitions and a supplier’s capability. In practice, that means looking past the headline numbers and the glossy photos to understand what went into the core, how it was tested, and what kind of aftercare accompanies the sale. The 4G63T platform—an engine family that has lived through countless iterations in motorsport and street performance—remains central to this conversation. Its enduring cadence comes from a blend of robust design, engineering flexibility, and the willingness of credible shops to push the limits of machining, balancing, and testing. When you source a crate for the Evo 8, you are placing a bet on engineering discipline as much as on horsepower figures.

The danger of shopping by price alone is real. A crate engine can arrive with enticing specs, but if the underlying processes are opaque, what you gain in peak numbers may be lost in reliability. A legitimate, high-performance crate engine is not merely a collection of rebuilt components; it is a cohesive assembly that reflects a disciplined manufacturing philosophy. The most telling indicators of that philosophy show up in the shop’s in‑house capabilities and the data it can produce. A credible operation will typically demonstrate in-house CNC block machining, which ensures the block carries precise deck heights, bore alignments, and mating surface finishes. Cylinder head porting, when performed under controlled flow conditions, reveals whether the breathing paths have been optimized for the intended cam profiles and turbocharger response. Crankshaft grinding and dynamic balancing are more than steps; they are assurances that rotating parts will spin true at high rpm and under the varied thermal loads of a race or daily driving. These elements—together with meticulous surface finishing, proper filtration, and robust oiling—are the trinity that supports durable power.

Beyond the hardware, the proof of performance rests on engineering validation. A serious crate engine program will offer a data package that speaks to the engine’s endurance and reliability. Thermal cycle testing demonstrates the way materials and clearances respond to repeated heating and cooling, a critical factor for an engine that may see long races followed by street sessions. Leak-down measurements provide a snapshot of sealing integrity under pressure, a quick way to gauge the quality of valve seats, gaskets, and cylinder walls. Cold-flow bench data gives insight into how air and fuel move through the intake and exhaust paths when the engine is not yet warmed up. The combination of these measurements paints a clear picture: a crate engine that has been built with attention to tolerances, materials, and finish, and that can be trusted to repeat itself under the stress of real-world use. In this context, the distinction between a rebuilt engine and a purpose-built, high-performance crate becomes evident. The latter is designed with repeatability in mind, and that repeatability often hinges on a company’s willingness to publish and stand behind data from these precise tests.

The Evo 8 is well suited to a crate approach precisely because it represents a platform with well-understood limits and a robust aftermarket ecosystem. The 4G63T family has powered countless race cars and fast street builds, so the template for a successful crate is not a mystery. The challenge lies in translating that template into a consistent, auditable process across batches of engines. A procedural, transparent approach—documented machining tolerances, clearly defined material specifications, and traceable test results—becomes the backbone of trust between builder and supplier. When a crate engine is delivered, the buyer should be able to point to specific data sheets that accompany the unit. Those sheets are not mere paperwork; they are a map of the engine’s life story, from its internal clearances to its dyno-developed fuel and boost curves. Without that map, the risk of misalignment between the engine and the rest of the build rises, and with it, the potential for misfire, seepage, or inconsistency on the track or in daily use.

In practice, these standards translate into practical steps during sourcing. A builder who values reliability will seek out suppliers who can clearly articulate their capabilities and show evidence of their process. The strongest candidates maintain a closed loop of quality control, with documented checks at critical stages—from raw block preparation and cylinder head work to final assembly and pre-delivery testing. A supplier should be able to describe how they manage tolerances across components, how they verify balance and alignment, and how they validate performance through independent or in-house testing. The goal is not merely a fast-ticking dyno curve but a durable curve that remains steady over hundreds of miles and multiple heat cycles. In other words, the best crate engines deliver both the thrill of power and the quiet confidence that comes with engineering discipline.

It is worth noting a broader reality of the market: a wide array of sources exist, spanning local shops to global platforms, each with different strengths and constraints. For Evo 8 enthusiasts pursuing authentic, race-ready components, the search often intersects with global sourcing channels that provide access to high-performance blocks, heads, and associated hardware. The emphasis, again, should be on depth of capability and transparency of data rather than surface-level promises. A responsible buyer will scrutinize not only what is included in the crate but also what is not included, and what is required to bring the engine to life in a specific application. This includes understanding the fueling strategy, turbocharger choice, intercooling, exhaust architecture, and the engine management approach that will map to the crate’s particular tolerances and breathing characteristics. While some crate engines come in as nearly turnkey solutions, others require targeted tuning, bolt-on upgrades, or even modest reworking to align with the intended boost levels and RPM envelopes. The decision to buy hinges as much on the anticipated synergy with the rest of the build as on the horsepower figure itself.

As part of the decision-making process, many builders also consider the after-sales and service ecosystem. Power on the dyno is compelling, but longevity on the road or track matters most to the project’s success. A supplier with clear post-sale support—whether it is setup advice, help with final assembly, or rapid assistance in case of a warranty event—adds a layer of security that money cannot easily replace. The total cost of ownership, including potential downtime or rework, can be a better predictor of long-term value than the sticker price on the crate itself. In this light, the buyer’s due diligence should extend beyond the crate’s technical sheet to the supplier’s responsiveness, technical communication, and willingness to provide ongoing guidance after the sale. The combination of precise engineering, validated data, and reliable support is what converts a crate engine from a flashy headline into a dependable workhorse for the Evo 8.

For readers who want a tangible starting point in this broad landscape, it can be helpful to explore discussions and resources that emphasize technical validation and process transparency. These insights remind us that the strongest crate programs reveal their strength in the details. In addition to technical documentation, practical considerations such as the compatibility of the crate with your existing components—fuel system, intake and exhaust routing, heat management, and engine management strategy—should be part of the evaluation. A well-matched crate can unlock a build’s potential without forcing compromises in reliability or daily usability. The result is an Evo 8 that delivers not only blistering power but consistent performance across sessions, with predictable behavior that a driver can trust in every lap or street drive.

If your project leans toward integrating broader upgrades while maintaining the crate’s reliability, you might also consider components that complement the engine’s performance envelope without upsetting its fundamental balance. For instance, selecting an OE-inspired front-end component set can help preserve weight distribution, while lightweight upgrades elsewhere can free up energy for the powertrain. In such a context, the crate engine becomes the core platform around which carefully chosen ancillary parts align. The chapter of your build that begins with a crate engine ends with a chassis and electronics conversation that remains deeply informed by the engine’s proven capabilities. The result is a cohesive car that not only accelerates with authority but also handles with the predictability that race-tuning demands. An EVO 8 project that achieves this blend stands as a testament to disciplined sourcing, comprehensive validation, and the patient work of engineers and builders who treat every dollar and every torque reaction as part of a long, trusted process.

For readers seeking a practical example of the broader ecosystem around Evo 8 projects, consider the potential value of related parts and documentation that underscore a coherent upgrade path without relying on glossy marketing. To explore one aspect of ecosystem compatibility, you can reference a resource that discusses OEM-replacement upgrades and their role in maintaining or refreshing the vehicle’s identity while pursuing performance goals. See this internal reference: OEM headlights for Evo 8-9. This link highlights how a builder can align aesthetics, weight distribution, and electrical integration with a performance-focused drivetrain. While the crate engine remains the centerpiece, such considerations illustrate how a well-planned package comes together under a shared philosophy of reliability and purpose. Keeping the broader build in view ensures that the Evo 8 remains a balanced machine where power, confidence, and control work in harmony.

External reference for further context on high-performance 4G63-based builds and testing practices can be found here: https://www.alibaba.com/product-detail/High-Performance-4G63-Parts-Tools-for-Mitsubishi_1600295874695.html

How to Vet Sellers When Shopping for an Evo 8 Motor: A Practical Sourcing Playbook

Evaluating and vetting sellers for an Evo 8 motor requires a practical, evidence-driven approach. Price and a glossy listing are only the start. When you pursue a rebuilt or modified crate engine based on the 4G63T platform, you are buying a system that must fit mechanically, perform reliably, and survive the stresses of boosted operation. That means your procurement process must measure manufacturing competence, test discipline, transparency, and after-sales support in equal measure.

Start by insisting on proof of core manufacturing capability. A credible engine builder will not merely assemble parts; they will control critical machining and metrology processes in-house or through long-standing, audited partners. Ask whether the supplier performs CNC machining of the block and heads, whether they run valve seat and guide work with the proper equipment, and whether crankshafts are ground and dynamically balanced on modern machines. These are not marketing details. They determine internal clearances, oiling behavior, and fatigue resistance under boost.

Equally important is test data. Rebuilt high-performance engines should come with objective test results. Thermal cycling figures show how assemblies behave across operating temperatures. Leak-down or leakage measurements document sealing integrity for rings and valves. Cold-flow bench data, where applicable, demonstrates oil and coolant behavior through galleries and passages. When a supplier provides raw test data or summarized reports, you can verify whether a unit has been stress-validated or merely cosmetically refreshed.

Transparency is the next filter. Good suppliers will offer documentation beyond a single photo. Request material certifications for critical parts, torque specifications used during assembly, and the calibration certificates for balancing and measuring equipment. Ask for photographs or short videos of key processes. If the supplier refuses, hesitates, or offers vague answers, treat that as a red flag. If they supply ambiguous test claims without supporting numbers, push for evidence or move on.

Understand engine composition and compatibility before you commit. The Evo 8 engine family traces to the 4G63T architecture, typically a cast-iron block with an aluminum head. Rebuilt crate assemblies may include upgraded pistons, forged rods, or reinforced blocks, depending on the intended power level. Verify bore and stroke, compression ratio, and whether the head has been ported or modified. Each modification alters compatibility with turbochargers, intake manifolds, and engine management systems. Confirm the physical fit—mounting points, sensors, and oil/coolant line placements—so the motor integrates with your vehicle or project without costly adaptation.

Reliability and performance metrics matter and are often reflected in real-world track records. Look for customer feedback from buyers who ran similar tune and usage profiles. If possible, obtain references who operated the engine for hundreds or thousands of miles under a comparable boost level. Reviews and testimonials are useful, but corroborate them with technical evidence. A buyer who reports trouble-free daily driving under mild tune offers a different signal than a customer who used the engine in sprint racing.

Supplier validation also requires simple but effective due diligence steps. Verify the supplier’s registration, factory address, and any export credentials. If they claim to operate in a known manufacturing hub, confirm that claim with public records or third-party listings. For suppliers overseas, request remote factory tours via video call. During that call, watch for production flow, workstations for machining and assembly, and test benches. Note whether technicians can explain processes clearly and provide the names and qualifications of key engineers.

When you evaluate quotations, look beyond unit price. Total landed cost includes tooling, inspection, shipping, customs duties, and any rework you might face. Ask about breakouts for packaging specifications, whether the engine is drained and preserved for shipping, and how major assemblies are braced to prevent damage during transit. Insist on protective crating and clear labeling.

Define acceptance testing and contract terms up front. Specify a pre-shipment test protocol and require photographic evidence or video of the test run. Include minimum acceptable metrics for oil pressure, coolant temperature stability, and absence of smoke or abnormal noises during the run. Define a window of time for remedial action if issues appear after delivery. Make sure the warranty or sales terms specify what is covered and what is not. Common exclusions include damage from improper installation, owner’s tuning beyond specified limits, or abuse during racing events.

Payment terms are a negotiation point that also speaks to supplier reliability. Avoid paying the full amount up front for higher-risk purchases. Use staged payments tied to milestones such as order confirmation, completion of assembly, and successful pre-shipment testing. If you must pay in advance, insist on documented inspection windows and escrow services where practical. For repeat buyers, volume or standing orders can justify more favorable terms.

Inspect parts compatibility and spare parts availability before purchase. Rebuilt crate engines sometimes use upgraded internals that require special rings, bearings, or gaskets. Confirm that the necessary seals and replaceable items are available from reliable channels. Ask whether the supplier offers a spare parts kit and what the expected service intervals are for wear items under your planned use.

Logistics and customs planning are often overlooked but can create major delays. Confirm harmonized system (HS) codes, export documentation, and any certification required by your jurisdiction. Factor in lead times for shipping and customs clearance. If the supplier offers drop-shipping, verify the origin documentation and whether the engine will move under a commercial invoice that meets import regulations.

Evaluate after-sales support and technical responsiveness. A responsive supplier will provide installation guidance, torque spec lists, and tuning baselines. They should be prepared to field technical questions and supply replacement parts within a clear timeframe. Response time is critical when issues arise; ask for a commitment on maximum response times and the escalation path for engineering-level support. Consider whether the supplier maintains bilingual technical staff, which helps avoid misunderstandings across time zones.

Spot the red flags early. Beware of listings that rely heavily on stock images or generic copy. If a listing promises extreme power figures with no verification, pause and demand dyno charts and build sheets. If the supplier resists sharing serial numbers for previous builds or test documentation, that indicates a possible lack of traceability. Be cautious with unusually low prices. A significantly cheaper crate unit can result from corner-cutting in casting, improper heat treatment, or used parts salvaged without full reconditioning.

When possible, arrange third-party inspection. Independent engine inspectors or mechanical engineers can perform pre-shipment checks and witness test runs. They can verify tolerances, gauge clearances, and document the condition at the time of shipment. This independent evidence is valuable in dispute resolution.

For buyers seeking OEM compatibility, look for sellers who can supply adapter kits, sensors, and wiring harness notes. Rebuilt units intended for performance often require ECU mapping, different intake piping, or upgraded fuel systems. Confirm the scopes of these changes and whether the supplier will provide a baseline map or recommend tuners who are familiar with the platform.

Finally, build relationships rather than transactional one-offs. A supplier who understands your goals and maintains transparent records becomes a partner. That partnership reduces friction on future orders and helps secure preferential access to parts or priority turnaround. For one-off purchases, document everything in writing: acceptance tests, warranty terms, and the escalation path for disputes.

For a practical example of supplier evaluation and a checklist of verification steps, consult a comprehensive sourcing guide available online. It compiles supplier profiles, verification criteria, and sample test reports you can use to benchmark offers. See the guide here: https://www.alibaba.com/product-detail/High-Performance-Evo-8-Crate-Engine-for-Mitsubishi_1600549794297.html

If you want to review example listings and compare donor-engine conditions, an internal resource catalogs low-mileage 4G63T engine listings with photos and condition notes. It helps you understand what to look for in crank, block, and head condition before committing to a rebuild or crate purchase: low-mileage 4G63T listing.

Applying these criteria will sharpen your supplier selection. Seek manufacturing proof, insist on test data, define acceptance terms, and vet logistics and warranty details. The right supplier will help you translate a crate engine listing into a reliable, high-performance powerplant that fits your project and your risk tolerance.

Beyond the Crate: Navigating Evo 8 Motor Options for Sale with a Buyer’s Eye

A horsepower story often begins with a label, but the real merit of an Evo 8 motor for sale isn’t what the listing promises in a headline. It’s what sits beneath the cover—how a crate or rebuilt powerplant was engineered, tested, and prepared for the track or a high-performance build. In markets where high-performance Evo 8 crate engines circulate, the conversation tends to circle back to a practical reality: these assemblies are rarely brand-new, and they are almost always intended for serious automotive projects, race applications, or specialized restorations. The fascination with more power meets a rigorous checklist of engineering competence. Buyers who learn to read the signs—what processes were used, what tests were performed, and how the supplier communicates after the sale—often find themselves with a more reliable, durable, and predictable power source than a merely attractive price tag suggests. The nuanced value in these engines emerges when performance metrics meet disciplined manufacturing standards and accountable after-care.

At the heart of any high-performance Evo 8 crate engine discussion is a simple distinction: you’re often looking at a rebuilt or modified assembly rather than a brand-new unit. The appeal lies in refurbished cores that have been modernized for race readiness and endurance under repeated heat and load. The motorsport mindset values consistency over novelty. It’s not about the latest feature, but about repeatable behavior under thermal cycling, surge, and sustained high-RPM operation. In practice, this means evaluating how a supplier handles core machining, balancing, and assembly tolerances. The most credible players demonstrate a pipeline that begins with precise machining of the block and cylinder heads, continues through meticulous valve-seat work and crankshaft finishing, and ends with dynamic balancing that minimizes vibration at speed. If a listing can point to data from thermal cycle testing, leakage measurements, and cold-flow bench analysis, that is a signal the engine has been through more than a cosmetic rebuild and is ready for road or track duty.

The global supply landscape shapes what buyers encounter when they search for these motors. A substantial portion of high-performance Evo 8 crate engines originates from Asia, where skilled machinists, specialized foundries, and engine builders participate in a highly technical ecosystem. The best vendors emphasize more than the sum of their catalog listings. They provide a transparent narrative about their capabilities: CNC machining of the engine block, valve-seat machining, crankshaft grinding, and dynamic balancing; they present data that demonstrates the quality of their assemblies. They also understand the value of post-build testing—which includes thermal cycling to simulate repeated heat soak, leak-down measurements to indicate gasket and seal integrity under pressure, and cold-flow bench data to map airflow and intake efficiency. In short, the credible supplier turns a crate engine from a concept into a quantified performance package by sharing verifiable engineering data, not rhetoric. This approach aligns with how serious buyers assess risk, plan integration, and forecast long-term reliability.

Within that framework, the Evo 8 crate market often revolves around rebuilds or modifications rather than fresh manufacturing. The practical reality for automotive applications that rely on consistent power delivery is that a rebuilt or modified assembly can offer a disciplined balance of cost, availability, and readiness. It’s common for engines to come with an agreed-upon specification—target power bands, reliability margins, and a defined service window for post-install checks. This means understanding how the engine was decommissioned from its prior use, what components were upgraded or replaced, and how the resulting unit was tested before shipment. Buyers should expect documentation that accompanies the crate—fabrication notes, torque tables, material grades, surface finishes, and test certificates. When these elements are present, a purchaser gains confidence that the motor will respond predictably to throttle input, will maintain oil pressure under load, and will retain performance across a racing-grade operating envelope. The narrative becomes more actionable when a supplier can translate a spec sheet into real-world results, complete with data packs that tell a story of thermal behavior, mechanical integrity, and dynamic balance that can be trusted during a long stint on the limiter.

The decision to pursue a high-performance Evo 8 motor for sale also requires an awareness of the broader mechanical ecosystem around these assemblies. The powerplant does not operate in a vacuum; it breathes through its cooling system, its timing and fueling approach, and its connection to the vehicle’s transmission and engine management. A credible crate engine package will typically include or at least outline the compatibility framework for fuel delivery, ignition timing, and exhaust routing. It should acknowledge the role of supporting hardware—as with any race project, the engine alone does not deliver usable performance without a matching intake system, turbo or compressor architecture, intercooling, and a control strategy calibrated for the specific vehicle and use case. In practice this means buyers should look for honest guidance on bolt-on components, the expected oiling regime under sustained high-RPM operation, and the cooling demand the engine will impose. Good suppliers anticipate these questions and supply engineering notes that clarify how to approach the installation in a way that preserves precision clearances, valve timing integrity, and the crucial balance between power output and drivability.

For those who need a real-world frame of reference, the historic benchmark for a turbocharged four-cylinder of this generation remains a robust mid-to-upper 260s horsepower range under tuned conditions, with responsive throttle behavior and strong mid-range torque. This figure is a touchstone for enthusiasts evaluating crate options because it frames what an engine set out to achieve rather than what a dealer may advertise as peak output. The top speed and acceleration figures are less a property of raw horsepower and more a function of engine response, fuel mapping, drivetrain efficiency, and the vehicle’s gearing. In practice, a high-quality engine that arrives with credible test data and a documented build history often translates to a predictable powerband, stable manifold pressures, and consistent engine vitals across a race distance or a winter test regimen. Those attributes matter not just for peak performance but for the repeatability that racers rely on when tuning a chassis, dialing in traction control strategies, and calibrating engine maps for diverse track temperatures.

The topic of powerplants labeled Evo 8 also invites a contemporary counterpoint: modern electric propulsion variants that carry the same badge into a different light of performance. In some circles, electric configurations marketed with similar nomenclature emphasize metrics like motor power, torque delivery, and range efficiency rather than turbo lag and boost stability. A representative figure for these electric concepts is a mid-range electric motor around 800 watts, with performance data that highlights acceleration and hill-climbing ability alongside battery compatibility. The comparison is instructive because it underscores the difference between combustion-based crate engines and electric powertrains that may carry the same archetypal designation in certain markets. The critical takeaway remains: whatever the propulsion path, success hinges on honest data, controlled testing, and a transparent engineering narrative that aligns with the vehicle’s intended use. While the crate engine buyer may still prefer a traditional, proven powerplant, understanding both sides of the equation helps set realistic expectations for performance, reliability, and long-term maintenance.

As a practical step in the procurement journey, a buyer should treat a listing like a contract in progress rather than a finished catalog item. Ask for the core specifications, the exact machining tolerances achieved, and the post-build test suite that accompanies the unit. Request a lean, evidence-based data package: thermal cycling curves that map temperature rise and fall, leak-down plots that quantify gasket integrity, and cold-flow graphs that illuminate airflow behavior through the intake and exhaust paths. The most credible offers will attach a concise, readable report that ties mechanical measurements to performance predictions, not just a snapshot of horsepower. They will also present a clear after-sales pathway: a warranty framework, a protocol for diagnosing issues after installation, and a point of contact who can respond promptly to questions. In a market where a single listing can be the difference between weeks of project downtime and a successful engine swap, these operational details are the true indicators of value.

To connect the technical with the practical, consider the following example as a conceptual anchor. A reputable crate-engine program might supply the platform as a rebuilt core with upgraded seating surfaces, reconditioned valve train, and a balanced rotating assembly. It would accompany the build with a heat-cycle test schedule that demonstrates stability across several thermal cycles, sealing tests confirming gasket integrity under pressure, and a cold-flow assessment validating that the engine breathes cleanly at startup. The documentation would also map out how the engine integrates with the vehicle’s management system, including timing maps, fuel-pressure targets, and recommended oil specifications to maintain a healthy oil film across the bearing surfaces. For the buyer, this level of detail shifts the conversation from price to performance expectancy and risk mitigation. It transforms the decision from a simple purchase into a quantified investment in reliability and track-ready capability. When both the engineering rigor and the service framework are evident, a crate engine becomes less of a gamble and more of a trusted component in a high-performance build.

For readers seeking a concrete reference point that blends historical engineering with practical procurement, a credible listing of a genuine legacy engine can provide useful insights into how a project should progress. A representative example shows the type of documentation that accompanies a well-vetted engine, and it helps frame expectations about what constitutes a rigorous, test-proven, and installation-ready unit, even if the exact model lineage differs across catalogs. External resources can provide additional perspective on how these engines have historically performed in the broader ecosystem of performance tuning. For a precise benchmarked spec reference that reflects typical outputs and performance envelopes for a generation-era turbocharged four-cylinder, technical databases and manufacturer literature offer a detailed lens. External resource: https://www.zeperfs.com/mitsubishi-lancer-evo-viii-265-hp-specs-performance

Why Demand for Evo 8 Crate Engines Is Rising — Market Forces, Supply Hubs, and What Buyers Should Insist On

Market Dynamics and What Buyers Should Demand for Evo 8 Crate Engines

The market for Evo 8 motors—most commonly encountered today as high-performance crate engine assemblies—is shaped by a concentrated group of buyers and a specialized supply chain. Enthusiasts, race teams, and custom builders drive steady demand because these engines deliver a well-understood blend of torque, response, and upgrade potential. That demand sits against broader industry currents: a projected rise in the global motors market, continued interest in high-output internal combustion solutions for off-road and rally-style applications, and a shift among buyers from low-cost purchases to investments in long-term reliability and documented performance.

Several supply-side trends explain why interested buyers now find more options than ever. Production clusters in industrial regions with mature precision machining ecosystems enable full-cycle engine services. In these hubs, foundries, CNC shops, metallurgy specialists, and dyno facilities sit close together. The result is faster prototyping, better quality control, and the ability to supply engines that have been bench-tested and calibrated rather than simply repackaged. Vertical integration is no longer a luxury; it is central to delivering crate engines that can be trusted to perform under race or street conditions.

Market growth forecasts reinforce the momentum. Analysts estimate that the broader automotive motors sector will grow at a steady compound annual rate over the coming years, increasing demand for durable and efficient powertrains. Within that environment, enthusiasts who want a tactile, tunable driving experience continue to favor high-performance internal combustion packages for specific use-cases—rally cars, drift builds, and adventure or off-road vehicles. This niche demand supports a market where professionally rebuilt or modified crate engines command premium prices when they include verifiable engineering and testing data.

Price remains a factor, but it is no longer the only one. Buyers have become more discerning. They want evidence of engineering discipline: in-house CNC machining of the block, precision valve-seat work, crankshaft grinding, and dynamic balancing. They ask for test results that go beyond a single dyno run—thermal cycle data, leak-down measurements, and cold-flow bench results all demonstrate that a supplier has applied rigorous process controls. Those indicators separate hobby-level rebuilders from suppliers positioned to serve professional shops and race teams.

Demand patterns reflect use-cases. Some buyers seek turnkey replacements to return a vehicle to original performance with improved durability. Others want crate engines with specific performance goals in mind—different compression ratios, reinforced internals, or tailored ECU calibrations for higher boost levels. Racing and time-attack communities value engines that have been validated on the dyno and fitted with appropriate ancillaries so the unit can be dropped in with minimal additional fabrication. Meanwhile, the restoration market for older models looks for low-mileage donor engines or carefully reconditioned assemblies that preserve drivability without sacrificing safety.

The availability of professionally rebuilt crate engines changes procurement behavior. Instead of hunting through salvage yards or piecing together parts from disparate sources, buyers can evaluate complete packages. That simplifies logistics and often reduces the time between purchase and installation. However, it also raises the bar for supplier due diligence. When a seller offers a crate engine at a tempting price, a smart buyer will verify that the advertised components match documented processes. Buyers should request machining certificates, photographs of work stages, and test reports. Transparency is a strong predictor of repeatable quality.

A practical way to benchmark a vendor is to review the types of tests and validations they provide. Thermal cycle testing shows how the assembly handles repeated heating and cooling, which is crucial for engines that will see wide load and temperature swings. Leak-down and compression data reveal the quality of cylinder sealing and valve work. Cold-flow bench results, while less commonly available, demonstrate how fuel and air travel through the intake and cylinder assemblies under flow conditions. Combined with dyno curves and ECU mapping notes, these data points provide a multi-dimensional picture of performance and reliability.

Sourcing logistics also matter. Suppliers located near strong logistics corridors offer faster transit times and clearer customs documentation. That reduces the friction for international buyers and helps shops plan installation timelines. Warranties and after-sales support become increasingly important when engines cross borders. A supplier who will answer tuning questions, send replacement components, or provide additional calibration files reduces long-term risk. In many cases, a slightly higher initial investment in a crate engine with comprehensive support will save time and money compared with a bargain-basement unit that leaves the buyer on their own.

The maturation of the market also affects how enthusiasts approach upgrades and modifications. Rather than chasing peak horsepower numbers at any cost, many buyers prioritize consistent, predictable power delivery and parts longevity. That trend favors suppliers who incorporate modern machining tolerances and improved metallurgy into rebuilds. Reinforced crankshafts, upgraded bearings, and improved coatings for friction surfaces are examples of changes that extend service life while preserving the engine’s character. Buyers who plan further tuning must consider the engine’s headroom for boost and mechanical stress; quality of the core assembly dictates how far a powertrain can be pushed before failure risk climbs.

Not all listings are created equal, and the market includes a wide range of sellers. Some present low-mileage donor engines with minimal refurbishment. Others advertise fully balanced, ported, and mapped crate assemblies intended for immediate performance use. Comparing these options requires clarity on intended use. A road-driven car benefits more from conservative rebuilds with strong sealing and thermal stability, while a dedicated race machine requires hardened components and aggressive calibration. The choice influences the supplier selection process and the acceptable level of warranty and support.

To illustrate how choices vary across the market, consider the difference between a low-mileage donor engine and a professionally rebuilt crate unit. A well-documented donor unit may offer original components with known history, which is valuable for restorations and some performance projects. A crate engine, however, is typically rebuilt with performance-oriented processes: block decked, crankshaft dynamically balanced, head ported and pressure-tested, and ECU tune optimized. The crate approach reduces installation surprises and shortens commissioning time, but it demands higher scrutiny of the builder’s technical capabilities.

When sourcing an Evo 8 crate engine, a practical checklist helps buyers avoid common pitfalls. First, request evidence of core machining capabilities—CNC block work, valve-seat machining, and crankshaft grinding. Second, ask for test reports: thermal cycles, leak-down numbers, and dyno sheets. Third, verify ECU calibration support and whether the supplier will provide base maps or assist with local dyno tuning. Fourth, confirm logistics and warranty terms, especially for cross-border purchases. Fifth, compare turnaround times and whether the supplier can deliver additional ancillaries as part of the package to minimize compatibility issues. Finally, review customer references and examples of previous builds to confirm repeatability.

The market will continue to evolve as more technically capable suppliers enter the space and buyers insist on measurable quality. For those who are building competitive vehicles or who simply want a reliable, tunable powerplant, the emphasis has shifted away from cheapest-available options toward demonstrable engineering and support. Knowing where to look and what to ask converts market abundance into a strategic advantage: carefully sourced crate engines reduce installation risk and extend the usable life of the vehicle.

For buyers who prefer a direct comparison with donor engines listed online, a helpful example is a genuine JDM low-mileage 4G63T engine listing that shows what low-mileage donor units typically include and how they are presented. Reviewing such listings side-by-side with crate engine packages clarifies differences in documentation, testing, and warranty support.

For deeper guidance on sourcing and evaluating high-performance crate engines from manufacturers that operate full-cycle production and testing, refer to the strategic sourcing guide linked below. It highlights supplier capabilities, testing expectations, and regional strengths within important industrial hubs.

External resource: https://www.alibaba.com/product-detail/Strategic-Sourcing-Guide-High-Performance-Evo_1600947552488.html

Internal reference: https://mitsubishiautopartsshop.com/genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached/

Final thoughts

Understanding the landscape of high-performance Evo 8 motors for sale is vital for business owners who wish to meet the rising demand for these engine options. We’ve dissected the core elements that make crate engines attractive components in automotive projects, as well as how to critically assess suppliers to ensure quality and reliability. Familiarity with technical specifications is imperative to optimize engine performance for clients. Lastly, keeping an eye on market trends can guide your business strategy, ensuring you meet customer needs effectively. By embracing these insights, business owners can position themselves advantageously in the competitive performance automotive market.