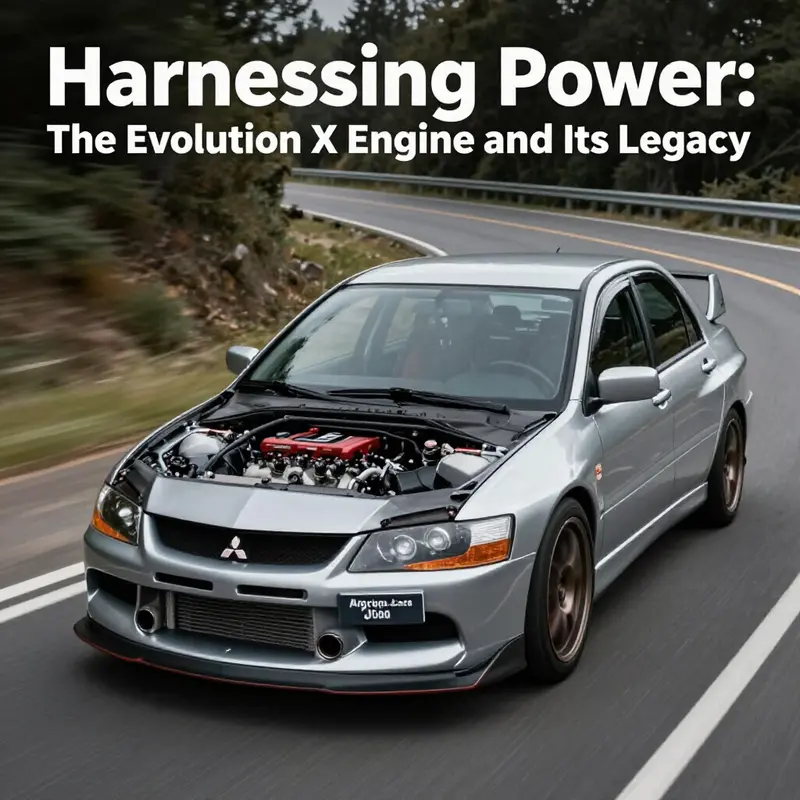

The Mitsubishi Lancer Evolution X, known affectionately as Evo X, has garnered a legendary status within the automotive performance community, particularly because of its remarkable 4B11T engine. From its innovative turbocharging technology to its extraordinary power output, the Evo X engine exemplifies high-performance engineering. Understanding its components, including its durability and modifiability, engine management systems, and the world of aftermarket components, is essential for business owners aiming to capitalize on the growing demand for performance automotive parts. This article unfolds the intricacies of the Evo X engine, offering insights that will be invaluable for strategic sourcing and high-quality automotive solutions.

Breathing Fire: Twin-Turbo Power and Variable Valve Timing in the Evolution X Engine

The Evolution X represents a decisive turn in Mitsubishi’s lineup, adopting a turbocharged, high-revving powerplant as its core. Rather than simply boosting a familiar naturally aspirated block, the design embraces a twin-turbo architecture paired with an advanced valve timing strategy that works in concert to transform responses across the rev range. In this configuration, power delivery is a carefully choreographed flow of air and timing that yields confidence from the moment the throttle opens and persists through the upper tach. The result is a powertrain that feels both responsive in everyday driving and utterly capable on a track. The engine’s essence lies in two interconnected ideas: boosted air charge that arrives swiftly and predictably, and variable valve timing that makes the engine breathe more efficiently at every speed and load condition.\n\nAt the heart of this setup is a twin-scroll turbocharging system. By dividing the exhaust pulses into two distinct scrolls feeding two turbines, the system helps the exhaust gases spin the turbines quickly and with greater efficiency. The outcome is quicker boost onset and better control of thrust as torque builds. This reduces lag and provides a broader window of usable torque. The turbo layout complements the engine’s mechanical strength by delivering a robust air charge without demanding extreme engine speed to achieve meaningful velocity. In practice, the car accelerates with immediacy that remains linear and manageable whether the driver is exiting a corner or merging onto a highway. The twin-scroll approach also helps maintain boost at lower rpm and smooths the transition as pressure climbs, contributing to a more tractable driving experience for daily use and on the race circuit.\n\nThe second pillar is a sophisticated valve timing system that actively varies when the intake and exhaust valves open and close. This electronic control allows the engine to optimize breathing across a wide spectrum of speeds and loads. In practical terms, that translates to stronger low end torque without sacrificing high end performance. The strategic adjustment of valve timing helps keep the air charge efficient and controls volumetric efficiency as boost pressure rises. When paired with turbocharging, variable valve timing acts as a harmonizer: it tunes the intake phase to minimize pumping losses and maximize the effectiveness of forced induction, reducing perceptible lag between pedal input and propulsion. The synergy between boosted airflow and tailored valve timing creates a broad, usable power band and a quick throttle response that sustains as rpm climbs.\n\nThis integrated approach shapes the engine’s character in everyday driving too. The electronic throttle control paired with a tunable engine-management strategy yields a light, responsive feel while cruising, yet it can reconfigure for aggressive response as boost builds. In a performance setup, the ECU can be tuned to exploit both turbo deliverability and valve timing, shaping turbo spool, throttle mapping, and transient response so that pedal inputs translate into predictable acceleration. In short, the architecture provides a foundation for a driver’s sense of control, even as the engine revs toward its upper limits.\n\nDurability and modifiability sit hand in hand within this platform. The engine’s internals are designed to withstand significant power upgrades, given the right supportive components and careful tuning. Forged connecting rods and a forged crankshaft contribute to a robust bottom end that can tolerate higher torque while maintaining structural integrity under spirited driving. The architecture invites modification as a measured progression: the same foundation that yields strong stock performance provides a solid base for increased power with proper cooling, lubrication, and control strategies. For enthusiasts seeking greater capability, billet-block options represent a high-integrity path. They illustrate how the hardware supports not just more power but enduring reliability under demanding conditions. A dedicated reference discusses billet-block upgrades in depth and serves as a practical starting point for understanding how such an upgrade interacts with the rest of the powertrain.\n\nFrom a performance perspective, the standard specification set demonstrates engineering ambition. The engine delivers horsepower and torque figures that place it among the most capable four-cylinder turbocharged powertrains of its era, with factory outputs that push into the high three to low four hundreds of horsepower and a broad torque curve across gears. Those numbers tell part of the story; the torque curve—how torque arrives and stays available—defines the everyday character of the car. With turbocharging and valve timing working in tandem, the engine can deliver substantial torque from relatively low rpm and hold power as speed climbs, providing a linear, controllable push rather than a sudden rush. The targeted engineering of the ECU helps preserve throttle control and driveability as boost builds, yielding a cohesive driving feel rather than a sudden spike in acceleration.\n\nThe practical implications extend to maintenance and reliability. A high power engine demands more robust cooling and lubrication, so architecture and component choices are tuned to keep heat and stress within predictable bounds. The integrated approach—turbocharging that is responsive rather than runaway, plus valve timing that adapts rather than follows a single map—helps maintain reliability at elevated output. The resulting platform supports prudent upgrades, including forged internals and well matched turbo components, while keeping warmth and lubrication within a predictable envelope. The broader aftermarket ecosystem around this platform mirrors a mature market, offering engineered options that fit the engine’s architecture. The sourcing network across major manufacturing regions helps ensure access to parts that meet durability and compatibility standards. In short, a turbocharged, variable valve timing engine is about delivering consistent, controllable performance across conditions, not just peak numbers.\n\nFor readers who want to dive deeper, technical guides discuss how valve timing interacts with turbo charging and how engine management maps translate into real-world performance. A well balanced upgrade program—covering the block, the rotating assembly, the turbo system, and the engine-management software—can unlock meaningful gains without compromising reliability. The integration of boosted air, precise timing, and tunable electronics represents a coherent approach to speed and control rather than simply stacking power. The Evolution X engine embodies this harmony as a platform designed for both track performance and daily practicality.\n\nExternal resources provide technical grounding that complements this narrative. For a deeper understanding of official engine specifications and how Mitsubishi framed the Evolution X powertrain, consult the manufacturer engineering documentation on the engine. External resource: https://www.mitsubishimotors.com/evolutionx/engine-specs.html

Power Under Pressure: Evolution X 4B11T Output and the Performance Mindset

The Evolution X engine, born from Mitsubishi’s lineage of turbocharged four-cylinders, represents a study in how power is delivered, managed, and made usable on the road. The 4B11T is a 2.0-liter inline-four with turbocharged aspiration, combining a twin-scroll turbo, electronic throttle control, and Mitsubishi’s MIVEC variable valve timing to produce a distinctive and driver-friendly power curve. The result is not merely a peak figure on a spec sheet; it is a carefully engineered relationship between air, exhaust, and electronics that translates into the characteristic pull that has defined the model’s reputation for spirited, driver-focused acceleration. In the Evo X, this power is delivered through the engine’s design so that torque arrives early enough to wake the chassis without overwhelming traction or handling. The numbers, when read in context, reveal a powertrain that pursues not just speed, but a coherent, predictable sense of momentum that a driver can rely on in a corner, on a highway merge, or when chasing a track-lap rhythm.\n\nThe published power output for the 4B11T is commonly cited as up to 291 horsepower at 6,500 revolutions per minute, with peak torque around 300 pound-feet at 3,000 rpm. Those figures sit atop a broader torque band and a spool strategy that defines how that power is felt in real-world driving. The torque peak at relatively modest engine speed—three thousand rpm—means that midrange acceleration remains robust, so a driver can execute confident roll-ons and overtakes without needing to hunt for the right gear. The horsepower peak, while arriving at a higher rpm, is supported by the same twin-scroll architecture that reduces lag and fosters a more linear, controllable power delivery as the engine climbs toward its redline. What drivers perceive on the road is not simply a single number but a broad, usable envelope of performance that rewards precise throttle modulation and smooth shifts, especially when paired with the six-speed manual transmission that has become part of the Evo X’s driving identity.\n\nThe engine’s DOHC layout, combined with MIVEC, is more than a badge of modern technology—it is a practical strategy for managing airflow and combustion across the rev range. The dual overhead camshafts enable independent control of valve timing and lift, which, when combined with MIVEC, allows the intake and exhaust events to be tailored to the engine’s current needs. At lower rpm, the system favors quicker spooling and earlier torque delivery, so the car feels more responsive from a stop or when merging. As the revs climb, the same valvetrain continuity assists peak power development without the abrupt transitions that can unsettle chassis balance. The twin-scroll turbo further enhances the responsiveness by separating exhaust pulses to optimize turbine speed, reducing turbo lag and improving charge pressure stability through the midrange. The result is an engine that feels eager in the lower to midrange and progressively fast as the tachometer rises, a characteristic that makes the Evo X feel both tractable in daily use and exhilarating on a back road or circuit layout.\n\nThe six-speed manual transmission that typically accompanies the Evo X is more than a mechanical pairing; it is a deliberate channel for the engine’s output to the road. Short, positive shifts and well-chosen gear ratios allow a driver to keep the turbocharged air pressure in the sweet spot where throttle response remains crisp without chasing revs. In practice, the manual transmission helps preserve the engine’s torque characteristics by enabling rapid, controlled downshifts into cornering sequences and upshifts that align with track or road demands. This pairing—an engine designed for a broad, usable torque curve and a transmission that preserves and channels that curve—helps explain why the Evo X feels balanced rather than top-heavy in performance. The balance of torque, response, and transmission control is at the heart of the car’s driving dynamics, and it is precisely this balance that has drawn enthusiasts to the platform for both everyday driving and more ambitious projects.\n\nFrom a durability and modification perspective, the 4B11T has earned a reputation for robustness and a readiness to accept power upgrades. The engine’s forged internals provide a sturdy foundation for higher power levels when paired with appropriate supporting modifications. Enthusiasts have long regarded the 4B11T as a capable baseline for tuning, with the potential for substantial gains when the bottom end and fuel delivery, cooling, and ignition systems are upgraded in concert. In this context, a strengthened bottom end—such as a billet-block upgrade—offers a clear path to pushing the engine well beyond stock output while preserving reliability under increased torque. For readers curious about strengthening the bottom end, a practical option is explored in upgrade literature that describes billet-block paths designed to resist the extra stress of higher performance without sacrificing engine integrity.\n\nThe engine management system—a modern ECU capable of being recalibrated for performance gains—ties the hardware together. Tuning the ECU can unlock additional headroom by refining boost targets, fuel delivery, ignition timing, and variable valve timing strategies across the RPM band. In the Evo X framework, such tuning is a common step toward aligning the engine’s output with the driver’s preferences and the chassis’ handling characteristics. Yet the reality is nuanced: gains from software alone depend on the supporting hardware and the quality of the fueling and cooling systems. This is where the 4B11T shines as a platform. Its architecture accommodates recalibration with less risk of detonation or premature wear when matched with appropriate hardware upgrades and cooling improvements. The resulting power increases are not purely mythical numbers; they reflect a carefully engineered synergy between turbocharging, valve timing, and management electronics that is the heart of modern performance engines.\n\nWhile the factory numbers carry weight, the Evo X’s potential emerges when drivers and builders respect the engine’s design philosophy. The stock torque peak at 3,000 rpm is not a ceiling but a foundation for predictable, repeatable dynamics. In real-world driving, that means confident launches, smooth midrange acceleration, and the ability to sustain urgency through mid-capacity corner exits. The turbo architecture and MIVEC system create a window in which the engine remains responsive across a broad rev range, so even as the throttle becomes more aggressive, the engine remains controllable. It is this blend—torque availability, throttle modulation, and a well-matched manual transmission—that makes the Evo X enjoyable to drive in everyday traffic and exciting on a winding road or track. The power output characteristics thus reflect more than peak numbers; they reveal a philosophy about how performance should be delivered in a way that invites both precision driving and musical engine feel.\n\nIn the broader context of performance engineering, the Evo X engine demonstrates how a well-integrated powerplant can deliver a coherent experience that balances punch and predictability. The 4B11T’s output is a product of careful choices in turbo technology, valve timing, and electronic control, all calibrated to work with the car’s chassis dynamics and driver expectations. It is not merely a metric to chase on a dyno, but a living set of characteristics that shape how quickly the car can accelerate, how easily it can be driven at the limit, and how forgiving or raw the experience feels when power is pushed to the edge. The Evolution lineage has always differentiated itself by delivering a performance that feels both modern and communicative, and the 4B11T engine remains a core driver of that identity. For future readers and builders, the takeaway is clear: the power figures tell a story, but the story is completed by how that power is made usable through design choices that favor response, balance, and durability, all of which contribute to the Evo X’s enduring status among performance enthusiasts.

Built to Be Tuned: How the Evo X Engine Delivers Durability and Scope for Power

Durability and Modifiability: the Evolution X engine as a tuner’s foundation

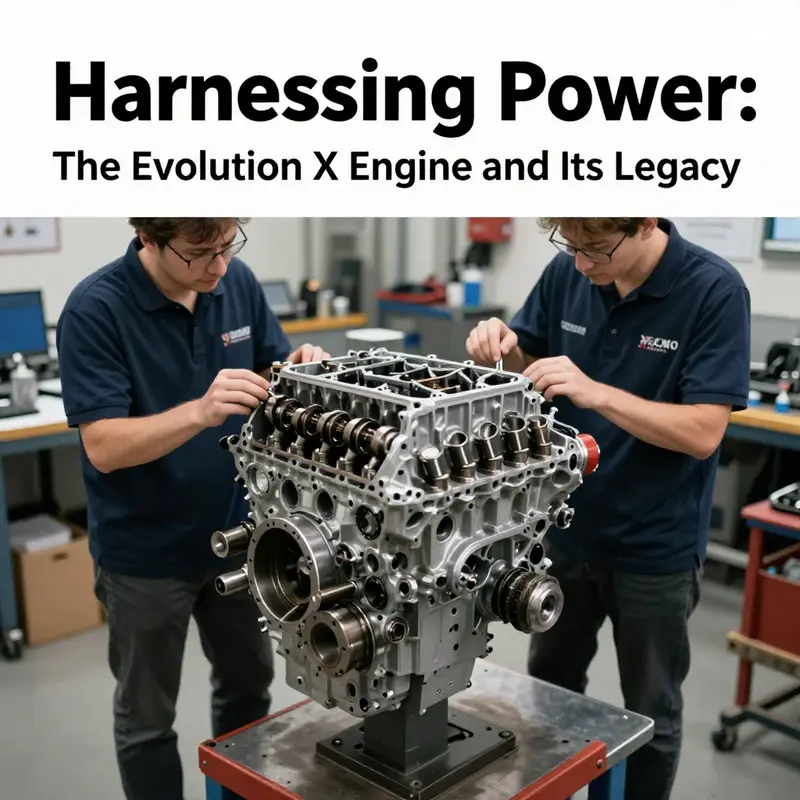

The engine at the center of the Evolution X is purpose-built to resist the stresses that come with high power and spirited driving. Its all-aluminum construction keeps weight down while preserving structural rigidity. The design includes forged rotating components that provide a strong, fatigue-resistant core. This combination creates an engine that can accept significant increases in boost and displacement without immediate structural failure. From this baseline, modifiers can confidently pursue power targets that would cripple lesser designs.

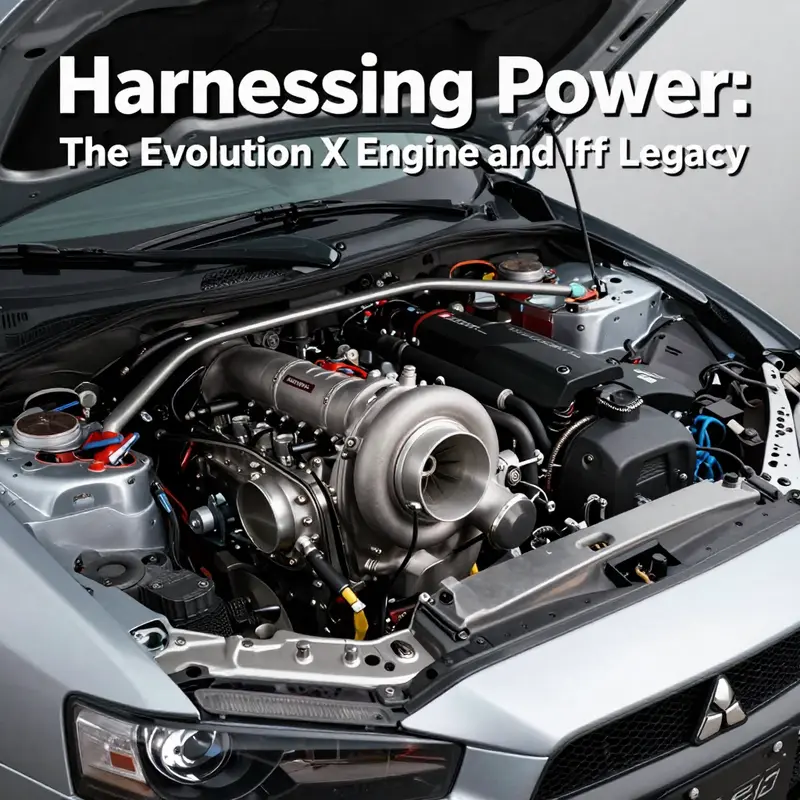

Fundamental hardware choices set the stage for both longevity and upgradeability. A forged crankshaft and forged connecting rods limit flex at high rpm and under elevated cylinder pressures. The block and head architecture allow for efficient coolant and oil passages, which helps control temperatures during hard use. Variable valve timing adds responsiveness across the rev range, enabling both street manners and track performance. A twin-scroll turbocharger reduces lag and improves spool characteristics compared with older single-scroll turbos, allowing higher effective power without sacrificing daily-drive behavior.

Modifiability hinges on not just what the factory built, but how the system responds when stressed. The engine management system uses electronic throttle control and a reprogrammable ECU. That means timing, fuel maps, and boost control can be adapted to match hardware changes. When tuner-friendly strategies align with robust mechanicals, reliable +50% or greater power increases become realistic with correct supporting parts. Critical supporting modifications include upgraded turbochargers or hybrid units, larger intercoolers, higher-flow fuel pumps and injectors, and enhanced engine cooling. Without those, stress becomes concentrated in weak subsystems rather than distributed across the engine.

Ignition is a practical example. The coil-on-plug layout on this engine improves ignition precision and reduces signal loss. It replaces long spark plug wires with coils mounted directly on the plugs. For stock outputs, original coils suffice and are reliable. But as boost and compression rise, coils must produce consistently higher spark energy to ensure complete combustion. When spark energy falls short, misfires and incomplete burns appear. That reduces power and increases thermal and mechanical stress. High-output coils address this by providing stronger, more consistent sparks at elevated cylinder pressures.

Addressing the ignition system early during a build is a sound strategy. Upgraded coils increase resistance to heat soak and voltage collapse under load. They also contribute to stable idle and throttle response under boost. Combined with careful tuning, they reduce detonation risk by promoting a faster and fuller burn. This supports higher ignition advance and allows higher peak cylinder pressures without pre-ignition. For builders targeting substantial horsepower increases, treating the ignition as a performance component is as important as choosing a turbo or fuel system.

Beyond ignition, the engine’s bottom end and block strength matter when chasing very high power. Many tuners move to fortified blocks or sleeved solutions when going beyond factory safe limits. For those wanting an engineered upgrade over the stock block, a purpose-made block option can be a wise investment. The availability of such components opens the door to builds that maintain reliability even when displacement or boost is significantly increased. For more information on engineered block upgrades, see this note on the 4B11T billet block.

Valvetrain and head work are the next logical areas. Upgraded valve springs, retainers, and hardened valve seats allow higher rpm and tougher valve events. Porting and head-flow improvements enable better cylinder filling, which increases power and lowers pumping losses. Cylinder head studs or better head nuts are often fitted to ensure consistent clamping force under high boost. That prevents head gasket issues when boost and cylinder pressures rise above stock levels.

Thermal management is a silent partner in reliability. The more heat an engine produces, the more likely parts will suffer from thermal fatigue. Larger radiators, higher-capacity oil coolers, and upgraded intercoolers reduce thermal spikes and keep operating temperatures in safe bands. Oil selection and management strategies matter as much as hardware. High-quality synthetic oils with appropriate viscosity help maintain oil pressure and protect bearings under prolonged high-load driving. Regular oil and filter changes at conservative intervals protect the investment and extend life.

Fueling also dictates durability. When power increases, more fuel is required to keep mixtures safe under boost. Upgrading pumps, rails, and injectors prevents lean conditions that otherwise lead to detonation. Properly sized fuel components, matched to a tuned ECU strategy, ensure combustion remains stable. For many builds, fitting a higher-flow fuel pump and larger injectors is a prerequisite to safe power gains.

Engine management and tuning tie all upgrades together. A reflash or stand-alone strategy that maps fuel, timing, boost, and transient behavior will extract the best from mechanical changes. Closed-loop strategies that retain some emissions controls can be beneficial for daily drivers. Aggressive track setups often require more direct control. The key is incremental, measured tuning on a load-bearing test environment like a chassis dyno. Conservative safety margins on timing and AFR during initial pulls reduce the risk of damaging detonation.

Transmission and drivetrain considerations cannot be ignored. A powerful, durable engine will quickly reveal weaknesses in the gearbox, clutch, and differential if those parts remain stock. Strengthening the clutch, differential, and even the gearbox itself ensures the power reaches the road reliably. Reinforcements to the driveline help maintain predictable handling and reduce the chance of catastrophic failure under surge or wheelspin.

Practical steps for a build that balances power and longevity begin with a phased plan. First, establish cooling and fueling capacity. Next, address ignition and engine sealing, including head studs. Then, upgrade the turbo or forced induction hardware and match it with tuning. Finally, secure the drivetrain to cope with extra torque. Each phase should include inspection points to catch wear early and prevent small issues from escalating.

A culture of maintenance and conservative tuning makes a big difference. Regular compression checks, leak-down tests, and scheduled inspections of bearings and seals help catch fatigue before it leads to failure. Many successful long-term builds emphasize gentler break-in periods after major changes and avoid continuous high-load operation until all new components have been validated.

In the end, the platform’s success comes from an engineered baseline that accepts modifications without immediate compromise. Thoughtful upgrades, careful tuning, and preventative maintenance create a resilient engine. That is why this platform remains so attractive; it asks for attention, but rewards careful builders with a wide envelope of performance and reliable service life. For focused guidance on the ignition upgrades mentioned earlier, consult this authoritative ignition coil guide: https://www.motor1.com/tech/2026/01/evolution-x-ignition-coil-guide/.

How the Evo X’s Engine Management Orchestrates Power: Inside the 4B11T Brain

Engine Management: The Brain That Shapes the 4B11T

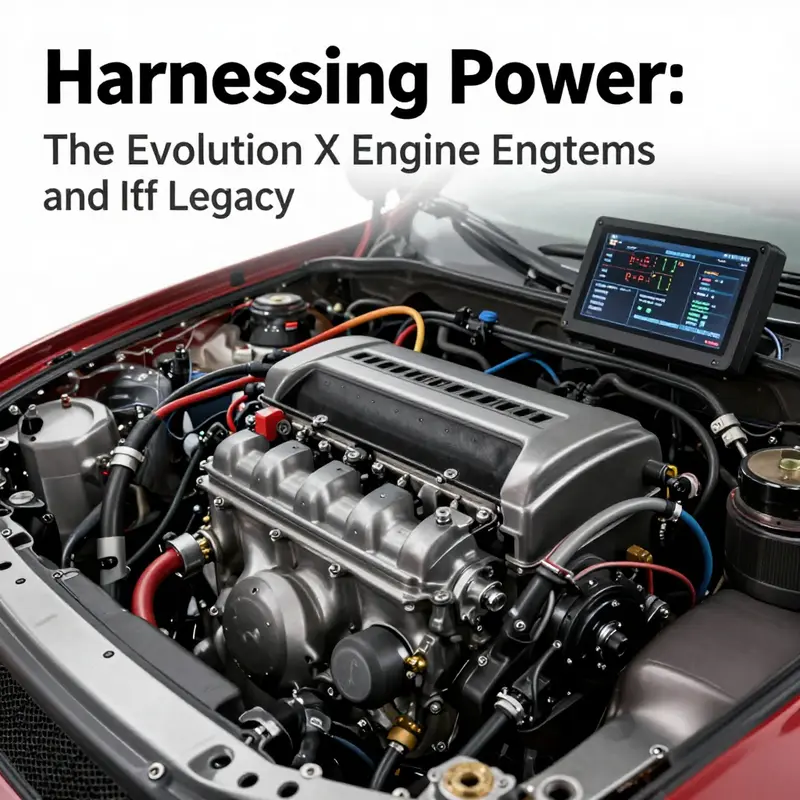

The Evolution X’s 4B11T engine does not rely on mechanical luck to produce its power. The engine management system (EMS) is the instrument that turns parts into performance. It monitors intake conditions, tailors fuel and spark, governs boost, and coordinates variable valve timing. Every decision happens in milliseconds. The result is the familiar balance of high-end power, usable low-end torque, and repeatable reliability that defines the Evo X experience.

At the system level, the ECU functions as a deterministic feedback engine. It reads a matrix of sensors and uses calibrated maps to translate those readings into actuator commands. The core loops are fuel control, ignition timing, and boost regulation. Supporting loops manage idle speed, throttle response, emissions, and driveability features. This layered approach lets the EMS respond to both instantaneous demands and longer-term adaptations, such as trim corrections and temperature compensation.

Fueling is the foundation. The EMS measures air mass or manifold pressure, intake temperature, and engine speed, then computes required injector pulse widths. Closed-loop control uses oxygen sensor feedback to trim short-term deviations. Over longer runs, the system stores learned corrections to maintain stoichiometry across changes in altitude, fuel quality, or component wear. In turbocharged operation, the EMS quickly transitions to open-loop strategies during wide-open-throttle episodes. There, predefined fuel enrichments protect against knock and keep combustion temperatures within safe limits. The art of tuning is adjusting those transitions and targets so the engine neither runs lean under boost nor swims in fuel when cooling is adequate.

Ignition control dovetails with fueling. The ECU uses crank and cam position sensors to place spark precisely. A knock sensor network listens for detonation and prompts instant, conservative timing retards when it detects abnormal combustion. That safety net enables aggressive base timing maps without risking catastrophic failure under variable conditions. The interplay between ignition and boost is particularly critical for the 4B11T. With its twin-scroll turbo, pressure and exhaust energy distribution change across the rev range. The EMS compensates by advancing or retarding timing to keep torque delivery smooth while preserving component longevity.

Boost control is where the EMS turns the turbocharger into a tuner’s canvas. The ECU modulates a solenoid-controlled wastegate valve to shape boost curves. Factory strategies favor linear, predictable boost with a focus on midrange torque. For many tuners, altering the boost target across RPM and gear is the quickest path to power gains. The ECU’s ability to enforce boost limits by gear, temperature, or engine load makes it a powerful tool. It can also implement safety measures like boost cut when knock or overboost is detected.

Variable valve timing is another critical lever. The 4B11T’s VVT (MIVEC) system shifts cam timing to widen the torque curve. The EMS commands phaser positions based on RPM, load, and throttle input. At low RPM it favors overlap that improves torque and efficiency. At high RPM it advances timing to keep valves open for better top-end breathing. Integrating VVT with turbo control demands nuance. Too much overlap under boost can raise cylinder pressures and trigger knock. The ECU balances valve timing, ignition, and fueling to extract power while avoiding unwanted combustion events.

Sensor integration is the nervous system. The EMS samples intake air temperature, manifold absolute pressure, throttle position, engine speed, coolant temperature, and exhaust oxygen levels. It synthesizes those inputs to estimate conditions that are not directly measured, like cylinder fill and air mass. Modern ECUs also read clutch, transmission, and wheel-speed sensors to tailor engine behavior to traction and driveline demands. On production Evo X systems, electronic throttle control and traction management are tied into the same architecture. That integration allows features such as launch control, throttle-tip-in smoothing, and traction-based torque reduction to work in harmony with the engine’s core maps.

Hardware interfaces matter. The ECU drives high-energy ignition coils and injectors, controls a boost solenoid, and communicates over vehicle buses. A robust wiring harness and reliable connector design keep signal quality high. This is one reason why sourcing complete harnesses or half-cut units is common in repairs or swaps. A halfcut item typically includes the engine, wiring loom, and ECU, streamlining integration when replacing a damaged drivetrain. For those seeking such components, a reliable halfcut source can save considerable installation time and avoid the pitfalls of mismatch between ECU firmware and harness pinouts. See an example of an Evo X halfcut for reference: Evo X halfcut.

Tuning and aftermarket intervention rely on the EMS’s flexibility. Reprogramming the ECU can yield significant gains by raising target boost, adjusting fuel maps, and altering timing tables. The ECU’s built-in calibrations for safety sensors, knock thresholds, and cooling limits, however, remain crucial. A competent tune blends aggressive targets with conservative safety margins. Many tuners also pair software changes with hardware upgrades—larger intercoolers, upgraded fuel pumps, or stronger clutches—to ensure the engine can sustain higher outputs without reliability compromise.

Data logging transforms the EMS from a controller into a teacher. Logged parameters like knock counts, long-term fuel trims, and intake temperatures reveal trends that guides tuning decisions. For example, rising intake-air temperatures after repeated pulls indicate heat soak and suggest the need for a larger core or better charge-air plumbing. Persistent positive fuel trims under load suggest fueling limitations. These diagnostics minimize guesswork and pinpoint the necessary upgrades.

Reliability in demanding environments depends on both the EMS and the drive-train it controls. When the engine is pushed on track or in rally stages, the ECU’s calibration choices determine how hard components must work. Conservative fueling or timing can protect pistons and bearings but at the expense of lap time. The Evo X’s success comes from an EMS that strikes an effective compromise: it allows spirited driving while retaining safety margins for component longevity. For enthusiasts, final performance improvements often follow a pattern: strengthen the mechanical base, then recalibrate the EMS to use that strength.

Modern engine management also supports emissions and diagnostics. Onboard self-test routines monitor catalysts, oxygen sensors, and other emissions components. Diagnostic trouble codes help locate malfunctions quickly. While these systems can complicate tuning, they also reinforce reliability by alerting owners to failures before they become catastrophic.

Finally, consider future-proofing and compatibility. The 4B11T’s ECU architecture is adaptable. It supports map switching, additional sensor inputs, and, in many cases, aftermarket engine management upgrades. Whether the goal is a mild software reflash or a full standalone conversion, understanding the factory EMS behavior is essential. The smartest modifications respect the ECU’s role as a safety arbiter. They augment its capability while preserving its core responsibilities: protecting the engine, ensuring drivability, and delivering the character that defines the Evo X.

The Evolution X’s engine management is not an afterthought. It is the system that synthesizes hardware into a coherent driving experience. Understanding its sensors, control loops, and safety strategies is critical for anyone who wants to tune, repair, or extract more from the 4B11T. When the ECU is tuned with respect for mechanical limits, the result is a stronger, more predictable, and more enjoyable Evo X.

From Factory Rhythm to Aftermarket Resilience: Navigating the Evolution X Engine’s Component Sourcing and Build Paths

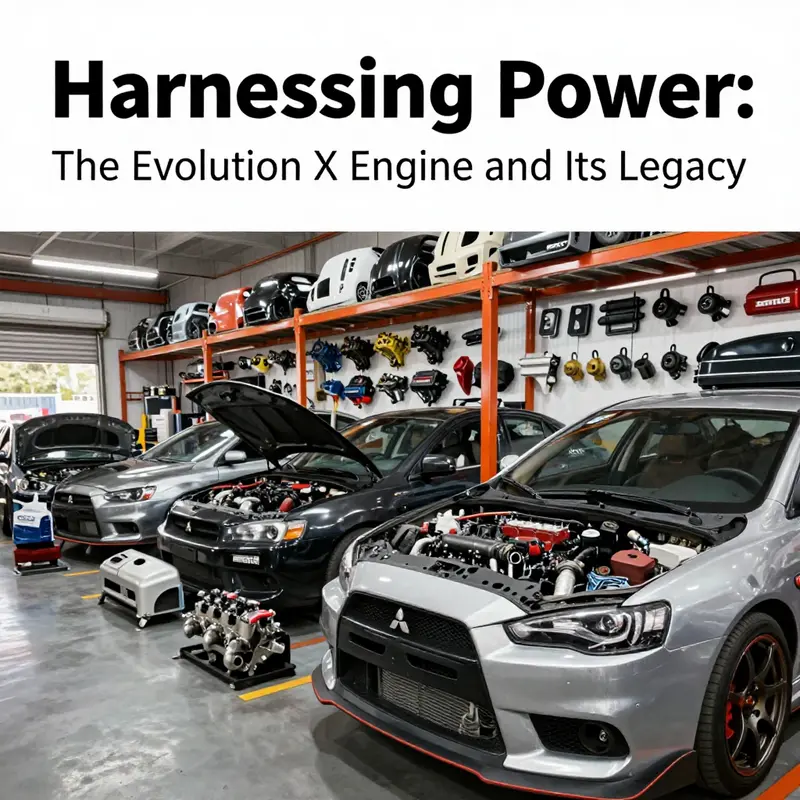

The Evolution X represents a high point in a lineage built on focus and precision. Its powertrain is a compact, turbocharged four-cylinder that rewards discipline in tuning and care in component selection. When builders turn from the showroom spec to the open-ended world of aftermarket parts, they enter a landscape where every choice matters not just for peak numbers, but for driveability, reliability, and long-term durability. The chapter that follows traces the currents that shape sourcing and integration for the Evolution X engine, weaving together the hardware that enables real power with the practical pathways that bring it to life on the street, on the track, and in the shop that sustains it. The story is less about chasing the single best bolt and more about understanding the ecosystem that makes a serious, streetable build possible: a network of parts, suppliers, verification practices, and engineering considerations that together form a coherent pathway from stock to spirited performance.

At the heart of any Evo X upgrade is the recognition that the factory engine, while capable, tends to meet reliability and performance goals through conservative limits. The engines in this family are designed with robust internals and thoughtful management, but enthusiasts quickly learn that performance often hinges on a suite of complementary components: the turbocharging architecture, the intercooling strategy, the intake manifold, the exhaust path, and, critically, the engine management system. Each element has a role in how the engine breathes, how quickly it responds to throttle input, and how consistently it delivers power across rev ranges and temperatures. The narrative of aftermarket parts is not simply one of higher numbers; it is a narrative of more precise control over airflow, more efficient heat management, and more predictable fuel delivery. In this sense, sourcing becomes as much about creating harmony as it is about achieving peak thrust.

A key thread in the sourcing tapestry is the geographic and industrial landscape that now underpins modern performance components. Regions known for precision manufacturing have become hubs for drivetrain and forced-induction parts, with a concentration of capability focused in large industrial provinces. Among these hubs, the Guangdong and Jiangsu regions stand out for their ability to deliver components that balance cost, quality, and scalability. For buyers, this translates into a practical calculus: it is possible to source high-quality items in volumes that range from a few units for local rebuilds to larger consignments for distributors, all with transparent terms and the assurance of consistent lead times. The shift toward these hubs reflects a broader trend in automotive supply chains, where proximity to tooling, skilled labor, and advanced manufacturing practices reduces cycle times and improves repeatability. For the Evolution X, this translates into a more reliable path from order to performance, a critical factor when projects hinge on precise tolerances and consistent calibration across multiple parts families.

The strategic value of verified suppliers cannot be overstated. In the aftermarket, the risk of inconsistent quality can undermine the best-engineered plan. Verified suppliers bring a level of process transparency that is essential when the goal is a dependable buildup rather than a one-off teardown. Buyers increasingly demand documentation that confirms manufacturing standards, inspection regimes, and on-time delivery performance. The ecosystem has evolved to accommodate this, with platforms and networks that emphasize supplier verification, traceability of batches, and clear commercial terms. A notable aspect of current market dynamics is the ability to source complete engine packages or substantial component kits with MOQs that begin at modest levels, sometimes as low as single digits, enabling small shops to pilot builds without tying up capital in large inventories. FOB pricing, too, has become accessible at level that accommodates both boutique rebuilds and larger scale distribution. The practical upshot is a more democratic access to advanced powertrain components, with a smoother bridge from concept to installation.

Among the components that are central to Evo X performance, the turbocharging pathway is a frequent focal point. A twin-scroll architecture paired with a variable-valve timing control strategy enables a responsive throttle feel and a broad, usable power band. In practice, this means that upgrades—whether for higher boost, reduced turbo lag, or improved heat management—must be matched with compatible intercooling, intake manifolds, and exhaust paths to preserve spool characteristics and avoid heat soak. The engine management system, in turn, must be capable of accommodating the revised boost pressure, altered cam timing, and the altered air-fuel dynamics that accompany any meaningful increase in airflow. A robust controller, properly calibrated, can unlock not only higher peak horsepower but also improved midrange torque and linearity, which translates into a more confidence-inspiring driving experience across a wider range of conditions.

A recurring theme in sourcing discussions is the durability and modifiability of the engine’s core architecture. The Evolution X is widely praised for its robustness and its potential for modification, with forged or upgraded internal components and a platform that tolerates power growth when attention is paid to supporting systems. The drivetrain and rotating assembly can be prepared for elevated power with attention to crank integrity, connecting rods, pistons, and fasteners, all within a regime of careful balancing and heat management. This is not a call for indiscriminate upgrading, but an invitation to approach modifications as an integrated system problem: more air requires more fuel, more cooling, and more precise control of ignition timing and valve events. The result is a build that can remain reliable at elevated power levels, provided the parts are sourced from verified suppliers, and the installation is accompanied by rigorous quality checks and careful tuning.

The practicalities of procurement extend beyond the raw components themselves. The modern Evolution X project often begins with a diagnostic plan that identifies weak links, potential bottlenecks, and the specific performance goals of the build. A thoughtful approach considers not only the parts that directly impact power, but also supporting elements such as engine mounting, heat shielding, and sensor calibration. The calibration process—whether driven by a standalone engine management solution or an integrated engine control unit—must align with the hardware to avoid mismatch conditions that could compromise reliability. A reliable sourcing strategy thus includes not only the parts, but also the service capability to verify fitment, perform quality checks, and document the installation steps for future maintenance. In this sense, the Evolution X aftermarket journey becomes a collaborative effort that blends supplier capabilities, shop capabilities, and the expertise of the tuner.

For builders who want to explore a practical pathway into the aftermarket world, a commonly used step is to begin with a balanced kit that aligns turbo, intercooler, intake, exhaust, and management. The goal is not to chase a single dramatic number but to secure a coherent system that behaves predictably as it climbs the power ladder. The choice of components should be guided by the intended application—street, track, or a blend of both—and by the availability of a knowledgeable service network that can support installation and tuning. The existence of well-understood supplier ecosystems helps. It allows a shop to commit to a set of verified parts with known performance envelopes and documented installation procedures, rather than improvising with incompatible pieces that could undermine reliability.

For those who value concrete, actionable direction, the Evo X aftermarket journey often includes exploring packaged solutions that bundle multiple components with matching calibrations. In this framework, a complete engine package or a large component bundle can simplify the procurement process and ensure compatibility across the system. In many cases, buyers discover that the most reliable path is a staged approach: establish a solid base with improved airflow and cooling, then add power management and fuel delivery refinements as the engine responds to tuning. This staged approach reduces risk, improves predictability, and helps safeguard the engine so that enthusiasts can enjoy performance without sacrificing durability. Enthusiasts who adopt this mindset often recognize the value of a modular approach, where one upgrade logically leads to the next, and each step is supported by verifiable data and professional service.

A practical and tangible waypoint in this landscape is the availability of specific sourcing options that clearly articulate MOQs, pricing, and delivery expectations. Verified suppliers commonly publish terms that reveal on-time delivery rates, minimum order quantities starting from small units, and FOB price points that enable scalable growth without overwhelming a rebuild shop’s cash flow. This transparency is not merely a courtesy; it is a foundational element that allows buyers to plan inventory, budget for projects, and manage risk across multiple builds. The ability to source a complete 4B11T engine or a full set of performance components with clear terms becomes a lever for business planning as well as for personal project execution. The new market dynamics thus empower both small, skilled rebuilders and larger automotive enterprises to scale operations in a predictable, repeatable manner.

As a practical note for readers who are actively sourcing parts, consider looking for a dedicated catalog of Evo X-related components and the associated guidance on fitment and calibration. A well-curated supplier guide can be their map through the complexity of modern powertrain upgrades. For instance, a compact reference that focuses on Evolution X components and B2B sourcing can be a helpful starting point to identify verified suppliers and to understand the typical ordering terms. Within the broader ecosystem, a hands-on approach to verification—checking certifications, requesting sample inspections, and confirming delivery performance—can save time and protect a project timeline. A builder who combines rigorous supplier validation with a disciplined tuning plan stands a better chance of achieving the desired power while preserving the engine’s integrity over the long run. The journey from factory rhythm to aftermarket resilience is thus not a sprint but a disciplined ascent, where sourcing, engineering, and driving experience align in a continuous feedback loop.

Internal links can be a practical part of this journey. For builders exploring body-to-engine packages or the broader Evo X platform, a compact, modular option is often found in dedicated halfcut bundles that streamline engine installation and integration. See the Evo X halfcut option for a concrete example of how a well-packaged approach can simplify sourcing and reduce assembly risk: evo-x-halfcut.

To close the cycle, it is essential to acknowledge the value of external resources and community knowledge. External references provide a broader landscape of manufacturing practices, quality standards, and cross-border logistics that inform decision-making when sourcing for high-performance builds. For readers who want to extend their sourcing framework beyond supplier profiles, the official supplier guide offers structured guidance on verification and best practices. Access to a reliable external resource can complement the internal knowledge gained from experience and discussion within this ecosystem. External resource: https://www.example.com/evolution-x-supplier-guide

Final thoughts

Understanding the remarkable engineering and technology behind the Mitsubishi Lancer Evolution X engine, particularly the 4B11T, is vital for businesses involved in the automotive industry. Its turbocharging and MIVEC technology provide drivers with exceptional performance, while its durability and modifiability make it highly desirable among tuners. Furthermore, the advanced engine management systems enhance its capability for customization, paving the way for exciting performance enhancements. Lastly, the robust aftermarket component market opens doors for businesses seeking to meet the demands of performance enthusiasts. By harnessing this knowledge, business owners can strategically approach their sourcing and service endeavors within this thriving sector.