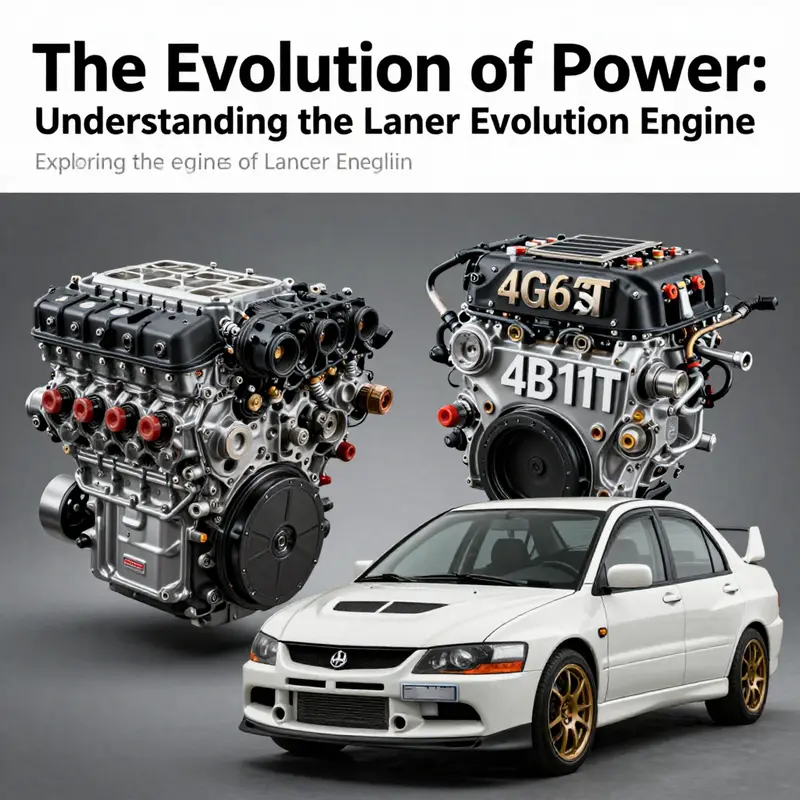

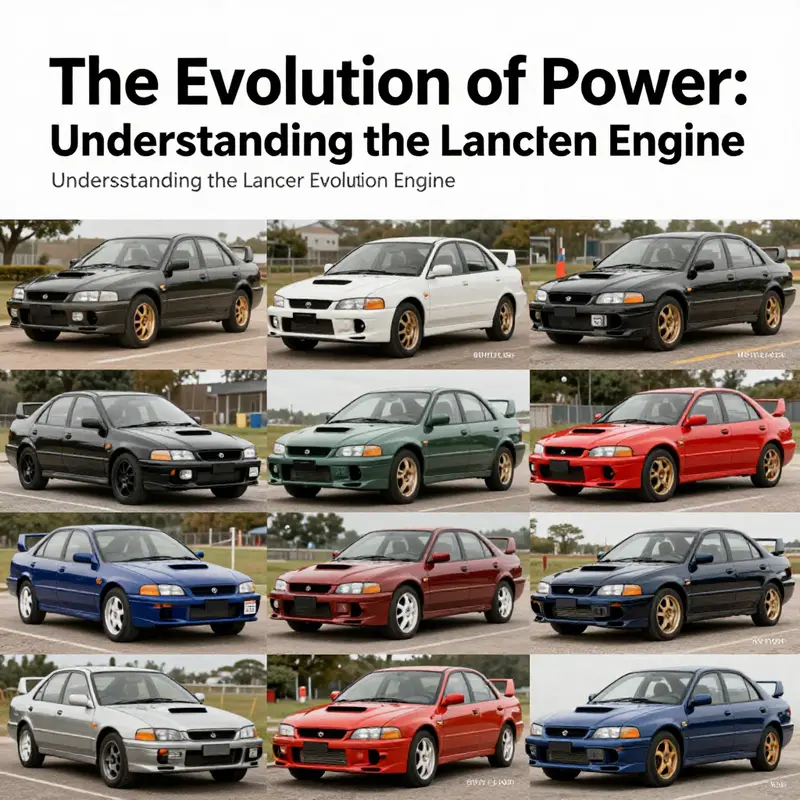

The Lancer Evolution series has seen remarkable transformations in its engine technology, marked by legends such as the 4G63T and the more recent 4B11T. These engines are not merely components; they are the heart of the Lancer Evolution’s identity, defining performance and driving experience. As we journey through the historical significance and advancements of the Lancer Evolution engines, we’ll explore how each iteration has set standards in the automotive industry, shedding light on their tuning potential, and previewing future directional shifts towards electrification. Each chapter will delve deeper into these engines, illustrating their engineering brilliance and the enthusiasts’ passion surrounding them.

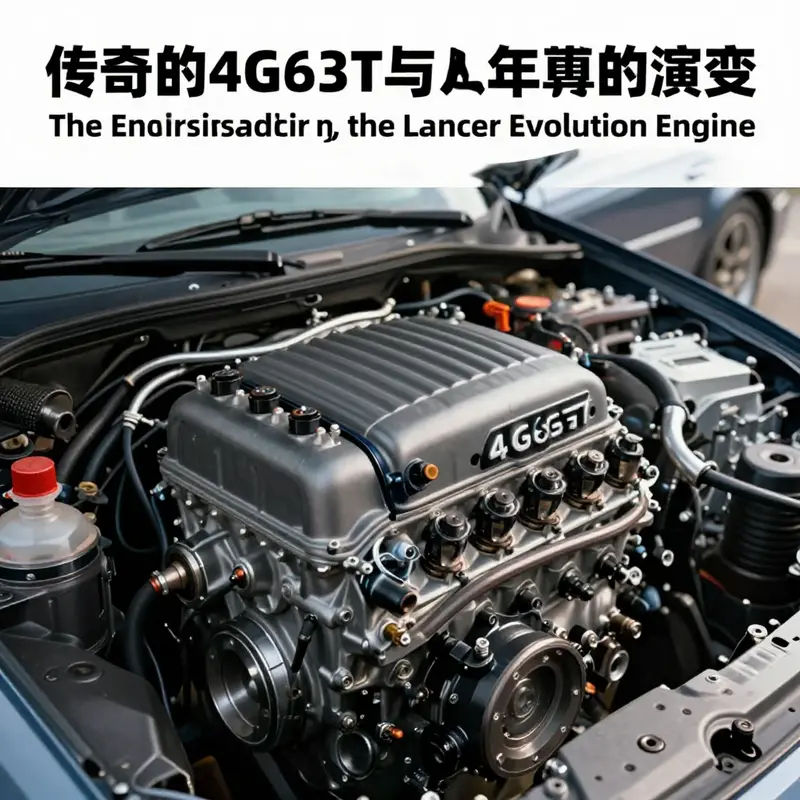

铸铁心脏的传奇:4G63T 在 Lancer Evolution 漫长进化路上的火花与极限

当谈及 Lancer Evolution 时,人们往往记得那一抹刺眼的红头盖、那份敏捷的操控,以及涡轮在转速表上跃动的金属脆响。然而真正推动这一系列向前的,是一个血肉铸就的心脏——4G63T。它不仅是技术的代名词,更是三菱在全球性能赛事中不断自我挑战的见证。4G63T 的诞生并非偶然,而是一次从拉力赛场直达街头的突破性跃迁。最早的形态来自铸铁缸体与涡轮增压的结合,经过 DOHC 16 气门的铸就,赋予这颗发动机顽强的耐用性与改装的无限潜力。此后,4G63T 的故事跨越了多代车型,成为改装圈里公认的“圣杯”之一,但它的意义远不止于数字的提升。它代表着一个时代,代表着机械与涡轮之间那种原始而强烈的情感——在拉力赛的残酷路面上,钢铁与铀色的火花不断碰撞,化作街头车迷心中的永恒回响。探索这段历史,我们不可回避的,是它如何从早期的铸铁缸体规训出强韧的结构基石,又如何在后续的技术演进中,保持着对高转速和低转速扭矩的双线追求。正因为如此,4G63T 不仅在街头传播成“改装圣经”,也在赛道上为 Lancer Evolution 奠定了可重复、可迭代的竞争优势。未来的走向也在这颗心脏的呼吸里继续延展。

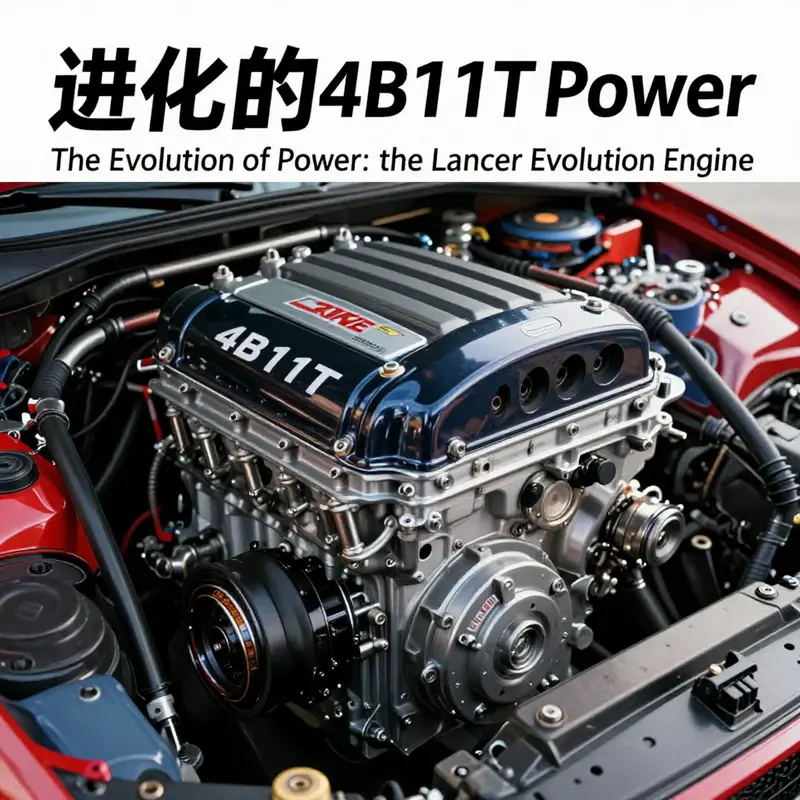

Redefining a Legend: The 4B11T Engine and the Evolution of the Lancer Evolution

When Mitsubishi introduced the Lancer Evolution X, the company faced a balance: honor a storied lineage of turbocharged four-cylinders while embracing a modern engineering discipline. The 4B11T engine at the heart of the EVO X was a deliberate move away from the iron-block designs of earlier generations toward a lighter, more rigid aluminum architecture. It used a forged crank, aluminum connecting rods, full-floating piston pins, and a four-bolt main-cap design to support high-torque, high-rev operation. The twin-turbo setup delivered broad, usable torque, aided by a water-cooled intercooler and efficient air-handling systems to keep the torque curve usable across a wide rev band. The compression ratio of 9.0:1 offered a workable compromise between power potential and reliability under boost, enabling strong performance without inviting excessive heat. The engine’s MIVEC variable valve timing and chain-driven cam train helped optimize response from low revs to the top end, pairing with the EVO X’s chassis and S-AWC all-wheel-drive to create a balanced, controllable performance.

From a tuning perspective, the aluminum block opened opportunities for weight savings and sharper chassis responses, while the platform rewarded thoughtful upgrades rather than simple power inflation. Though the 4B11T’s limits could be pushed with care—proper backing, lubrication, and component reinforcement—the engine’s strength lay in its ability to deliver predictable, scalable performance within a well-integrated system. As a result, the EVO X established a lasting impression: a modern performance sedan that could feel every bit as responsive on the road as it did on the track, without losing its daily-drive character.

In the broader arc of the Evolution lineage, the 4B11T represents a transitional moment: a bridge between the brutish efficiency of older turbo four-cylinders and a contemporary engineering philosophy that prioritizes weight, balance, and control. While future propulsion trends may explore electrification or hybridization, the core idea remains: power must be controllable, and engineering must align with the chassis to deliver a coherent, driver-focused experience.

From Iron Heart to Aluminum Pulse: The Evolution of the Lancer Engine and the Prospect of a New Era

The engine has long been more than a mechanical core in the Lancer Evolution narrative; it is the living heartbeat that carries the series through decades of refinement, competition, and now the question of what comes after. Across generations, Mitsubishi reshaped not just a powertrain, but the very philosophy of how a rally-proven platform could translate raw track discipline into everyday performance. The journey begins with an old, stubborn line: a 2.0-liter inline-four, housed in a cast-iron block, wearing a turbocharger as its crown and a lineage of engineering decisions that crowd the engine bay with more than just heat and noise. That iron block, resilient and forgiving, allowed the 4G63T to endure the onslaught of early tuning culture, where enthusiasts learned by trial and error how far a turbo can be pushed before the block or the valves call it quits. This reliability became a platform virtue. It gave the EVO a reputation not only for speed, but for a durability that encouraged countless experiments. The raw bones of the early engines were simple in concept, but they housed a complexity that could be coaxed into surprising performance with the right combination of boost, airflow, and fuel delivery.

In the earliest chapters of the EVO story, the 4G63T delivered horsepower that astonished the road-going performance crowd. Factory numbers hovered around the high teens to low two hundreds in practical terms, depending on the generation and the market. The mid-life era of the 4G63T saw the power curve rise as Mitsubishi refined the breathing, the boost response, and the way the engine managed heat under pressure. The key to this evolution was not merely adding more boost, but pairing turbocharger dynamics with a smarter valve strategy. The switch from a fixed cam timing approach to more sophisticated electronic control of variable valve timing opened a crucial door: better low-end torque and a more rewarding high-end presence. The result was a higher-speed, more responsive engine that still retained the rugged, tunable soul that made the EVO a favorite among drivers who loved to tweak and test boundaries.

As the line matured, the architecture began to reveal its limits in a new light. The iron block, while exceptionally durable, carried weight that challenged chassis balance and acceleration response. The balance shifted when Mitsubishi introduced a shift in the EVO’s broader engineering approach: a lighter, more modern engine family designed for a new era of performance. Enter the 4B11T, a true milestone that signaled a departure from the original blueprint while preserving the EVO’s core emphasis on torque, grip, and linear, tractable power delivery. The 4B11T sits in a modern chassis with all-aluminum construction, a move that reduced weight dramatically and improved rotational inertia, which in turn sharpened handling and response. Officially, the system delivers a robust mid-range surge paired with a confident top-end push. The engine’s architecture supports a quick throttle response and an efficient equilibrium between weight, heat management, and the ability to live at high revs for sustained periods. In practice, that translates into a track-ready, road-capable engine that keeps the EVO’s essence intact even as it steps forward into a more contemporary performance paradigm.

The 4B11T’s development did not simply add innovation; it reframed the whole engineering conversation around power, balance, and control. The all-aluminum construction reduced unsprung mass in a way that paid dividends across the vehicle’s dynamic envelope. The result is a platform that can accept more aggressive suspension tuning and fuel strategies without sacrificing daily usability. Power output at the factory level settled near the mid-300s in horsepower and torque that allows immediate, confident acceleration across a broad range. This is not merely a numbers game; it reflects an engineering philosophy that values predictable, repeatable performance at the limit. And because the engine is lighter, the vehicle can exploit that extra traction and cornering confidence to maintain momentum through complex driving sequences that would threaten heavier rivals.

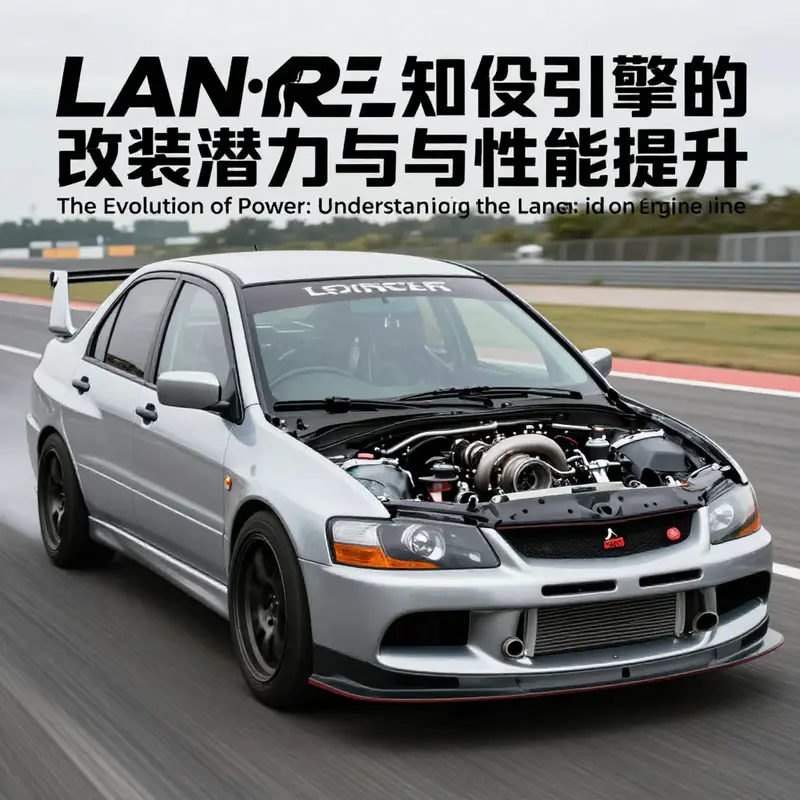

What follows then is a narrative of how this architecture invites both cautious reliability improvements and ambitious experimentation. For the enthusiast who seeks to ride the edge of the envelope within the limits of street-legal use, the 4G63T lineage remains a touchstone for ruggedness and ease of modification. The casting and machining tolerances that earned the 4G63T its reputation for resilience translate into a wide margin for tuning, given careful parts selection and management of heat, timing, and fuel delivery. Even within conservative bounds, bolt-on improvements—upgraded intake and exhaust paths, refined intercooling, and optimized ECU calibration—can push the power envelope far beyond stock while preserving the engine’s safety margins. And when the push becomes more intense, entering the realm of forged internals, refined crankshafts, and purpose-built connecting rods, the engine’s potential can appear almost limitless. In such configurations, power figures spring into a new class—where hundreds of extra horsepower are not merely numbers on a dyno sheet, but a tangible sense of acceleration, sound, and sheet-metal vibration that marks a car as a serious performance machine. In a culture that reveres the idea of “the thousand-horsepower badge,” the EVO’s foundations offer a platform capable of extraordinary transformation without erasing its fundamental identity. The story of these engines in the tuning world is a reminder that performance is not only about peak horsepower; it is about how power is delivered and how it integrates with chassis balance and driver control.

Yet the EVO’s evolution is not a story of one engine alone. It is a broader narrative about how a brand translates a track-tested concept into a road-credible performance system. The 4B11T era illustrates a different approach to achieving the same essential aim: more speed with better control. Aluminum construction and a modern architecture free the chassis to utilize more mechanical grip and more precise throttle modulation. It enables a more agile handling character, where the engine’s torque delivery can be exploited early in corners to maintain momentum without a surge that unsettles the chassis. In this sense, the EVO’s engine design is not only about raw numbers; it is about how those numbers translate into an experience—how quickly a car can exit a corner, how cleanly it can approach the limit, and how predictably it behaves when the driver pushes hard. This is where the engine’s fortitude becomes most apparent: it is not merely a power source but a driver’s tool for control, a partner in the pursuit of precision at the edge of traction.

The question of what lies ahead for the Lancer Evolution engine naturally turns to whispers of revival and reinvention. Industry conversations around a return point to a hybridized future, where a newer architecture could blend internal combustion with electric propulsion to maintain the EVO’s brand of explosive performance while addressing modern demands for efficiency and emissions. In the most expansive scenarios, a BEV configuration with multiple independent motors could deliver a level of torque vectoring and instantaneous response that redefines how the car meets the road. In a PHEV arrangement, a reliable gasoline engine could be paired with electric motors to deliver a cooperative performance that maintains the EVO’s instant torque feel while offering a cleaner, more flexible daily-driving footprint. Regardless of the exact packaging, the core challenge remains: how to preserve the car’s character—its willingness to surge, its confident steering feel, and its sense of orchestration between powertrain, drivetrain, and chassis—while embracing new technologies that redefine what a sport sedan can be.

In the meantime, the practical parts story continues to offer a path for those who want to respect the EVO’s heritage and still chase performance. The technical community recognizes a practical approach to increasing capability without abandoning the fundamentals. For example, beyond the basics of boost, air, and fuel, there is a growing interest in strengthening the block and rotating assembly to handle higher stress at elevated boost levels, yet while keeping the engine reliable over repeated sessions on the track. A billet block option for the 4B11T, for instance, represents a strategic choice for those who want to push the limits while maintaining a robust, repeatable platform. This direction embodies a careful balance: the desire to wring more power from the same philosphy, while protecting the engine’s long-term durability. If you’re exploring the 4B11T’s potential without changing the fundamental architecture, the billet-block route can be a meaningful reference point and is discussed in depth here: 4B11T billet block.

As the chapter closes on the engine’s current arc, it is clear that the EVO’s powerplant has always thrived on a blend of stubborn reliability, thoughtful engineering, and a culture that treats tuning as a dialogue rather than a battle. The move from iron to aluminum did more than shave weight; it rebalanced the car’s entire dynamic equation, allowing engineers and drivers to ask for more without sacrificing control. The future, while still unfolding in rumor and speculation, remains faithful to the EVO’s core: power that arrives with immediacy, chassis response that rewards precision, and a driving sensation that feels both raw and refined at once. Whether the new chapter arrives as a refined hybrid, a high-performance electric proposition, or a carefully evolved internal-combustion platform, the engine will continue to be the heart that keeps evolving, beating in a rhythm tuned to the pulse of the road and the track alike. And that is a legacy worth preserving: a commitment to extreme capability anchored in a philosophy that never sacrifices control for speed.

External reading and illustrative references can enrich this exploration. For a visual deep dive into the realm of extreme EVO builds and the kind of engineering that pushes these engines to extraordinary outputs, see a dedicated overview here: https://www.youtube.com/watch?v=examplevideoid.

从铸铁大心脏到全铝转折:Lancer Evolution 引擎的演化与未来电气化展望

Lancer Evolution 的发动机长期以来都是这部传奇故事的脉搏与灵魂。它不仅决定了每一代车型的性格,也见证了三菱在涡轮增压技术、材料运用与动力管理方面的持续进化。早期的4G63T以铸铁缸体为基底,承载着“耐用+改装潜力”的核心价值。那是一台2.0升直列四缸涡轮增压发动机,原厂输出在初代车系中就已接近195马力,而到了系列的中后段,尤其是第四代车型,功率上升至约250马力。这一路的跃迁并非单纯的 numbers 升高,更是对扭矩曲线、响应速度与耐久性的一次次精雕细琢。早期型号沿用传统的 DOHC 16 气门结构,仍以实现高转速输出为目标。随着时间的推进,三菱将可变气门正时技术引入后期机型,尤其是在第七代和第八代中,MIVEC 系统的应用让低转扭矩、低速响应与高转速功率输出之间的边界更加清晰,整车的线性动力输出也因此变得更具“即时性”。这一阶段,改装界对4G63T的热情与日俱增,铸铁缸体的耐受性使得改装件如涡轮、冷却、喷油系统及内部部件强化在极端工况下仍能稳定工作,推动了全球范围内的改装文化潮流。这样的耐受力与可塑性,使4G63T成为公认的“圣杯级”发动机,几乎成了追求极致性能者的共识起点。内部的结构设计也并非静止不变,随着代际的推进,涡轮增压的响应性与整体效率得到了显著提升。引入更精细的气门正时控制,意味着发动机在不同工况下都能够维持较高的效率与动力输出,提升了整车的实际驾驶体验,也让改装界对潜在马力极限的探求从理论走向了现实。

从铸铁心脏到电气化未来:Lancer Evolution 引擎对动力技术的长期影响

Lancer Evolution 的引擎不仅驱动车辆,也推动了汽车动力技术的边界。它把赛事上锻炼出的解决方案带入民用车领域,重塑了公众对四缸涡轮、高性能四驱和可控扭矩分配的认知。这个系列的引擎发展,从早期的铸铁结构到后来的全铝设计,再到今天讨论的电气化可能,体现了一个清晰的技术演变路径。每一步进化都在挑战工程师对重量、响应、耐久与精确控制之间平衡的理解。

最为人熟知的,是那台坚实的2.0升涡轮四缸引擎。它以耐久的铸铁缸体为基础,迎合了拉力赛对可靠性的苛刻要求。铸铁的抗疲劳性和热容量,使得这台发动机能够承受反复高温高压工况。这一点对耐力赛事和重度改装同样重要。工程师们通过合理的缸体刚性设计,保留了改装空间,而出色的可塑性则催生了庞大的后市场生态。爱好者可以在不重塑整机的前提下,提升涡轮、空气流动和喷油,达到远超出厂的性能水平。正是这种从出厂即具备强韧基础的思路,让一台量产发动机在私人改装手中产生出赛道级别的回响。

随着世代更替,材料与制造工艺的选择发生了显著变化。全铝发动机的引入,标志着对重量与响应性的强调开始占据主导地位。铝合金缸体与缸盖使得整机质量下降,车辆的质量分布和转向响应得以改善。减重不仅提升了直线加速,也让底盘在动态中显得更灵敏。与此同时,更轻的摆动质量提高了涡轮和曲轴的响应速度,让发动机在中低转速下就能表现出更直接的动力输出。这种材料转变,既是为了提升日常可用性,也是为赛道与快速路况提供更一致的力反馈。

在控制策略上,该系列引擎对可变气门正时和综合驱动系统的结合,带来了质的飞跃。可变气门正时技术改善了低速扭矩,同时在高转时保留了呼吸效率。与之配合的,是精细化的增压控制和中冷优化,使得涡轮迟滞被最大限度抑制,油门响应更线性。这些进步并非孤立出现。它们与全时四驱系统的扭矩分配策略紧密联动:当一缸或一轴输出特征发生改变时,车身动力管理系统便会重新分配驱动力。这样的协同设计,让车辆在湿滑和弯道中既能保持抓地力,也能保证驾驶员意图的直接传递。

真正令该系列在工程界产生影响的,是其对“量产车如何实现竞赛级控制”的示范。通过将主动偏航控制和高级四驱逻辑整合到出厂控制单元中,工程师把复杂的扭矩矢量化技术普及给普通买家。此前,精准的扭矩管理只在特定赛车级平台上可见。现在,普通车主也能在公路上体验近似的弯道稳定性与牵引力。这个范例促使其他厂商重新评估他们在四驱与动力控制上的优先级,从而在行业内形成一股重视软件与机械协同的趋势。

另一方面,改装文化对引擎开发也起到了反向推动作用。大批量的调校实验和极限使用条件,为工程师们提供了宝贵的数据。许多出厂零件的耐久极限,正是通过改装潮流暴露出来的。制造商在观察市场反应后,往往会把耐用零件的设计思路吸收到下一代产品中。举例来说,全新平台在缸体加强、冷却回路和润滑系统上的调整,很多灵感都来自业余与专业圈层对早期平台的极限试探。对于想在原厂基础上进行更深入升级的用户,后市场也提供了针对新型发动机的强化件,例如专用铝合金/钢化缸体替换件,帮助延展性能上限。4B11T billet block就是此类改装方向的一个标志性例子。

面对全球汽车动力系统电气化的浪潮,传统涡轮化设计并非只能淡出,它可以与电气技术共生。插电式混合动力可将内燃机的持续功率与电动机的瞬时扭矩结合。这样一来,驾驶者既能感受线性的涡轮推力,也能在需要时得到电动机的即时响应。比起单纯内燃机方案,这种混动架构还能在城市工况中大幅降低尾气排放。更激进的路线是纯电动动力,它能通过独立电机给每个车轮赋予独立控制的能力。四轮独立电驱不仅可以精准矢量扭矩,也能实现更高效的动力回收与动态稳定控制。

无论最终走向何方,新一代的动力系统都会承袭该系列核心理念:精准的驱动力管理、驾驶员意图的直接传递,以及对极限使用的硬件容忍度。重生并非简单复刻过去的符号,而是在新的动力矩阵中再现那种“可控的愤怒”。如果厂方在未来车型上继续强调四驱互动与可调动力曲线,那么这款车依旧有机会在新时代成为行业的参考样本。

这些技术演进的总和,说明了一个关键事实:引擎并非孤立的组件。它是车辆控制体系中的枢纽,需要与传动、底盘和软件紧密配合。Lancer Evolution 的引擎演化史,正是一个围绕这一理念展开的实践范例。无论粉丝期待的是纯粹的机械声浪,还是现代化的电气加持,真正的价值在于技术如何服务于驾驶体验本身。而这份以精确控制和极限耐用为核心的遗产,将继续影响未来高性能家用车的设计方向。

External source: https://www.autocar.co.uk/car-news/brand-news/mitsubishi-lancer-evolution-returns-2025

Final thoughts

The Lancer Evolution engines embody a legacy of automotive excellence, from the robust 4G63T to the advanced 4B11T, illustrating Mitsubishi’s dedication to performance enhancing technology. Looking ahead, the whispers of a potential return shift towards electrification promise to redefine what we understand as performance in this iconic series. Whether through nostalgia or innovation, the spirit of the Lancer Evolution will continue to inspire enthusiasts and shape automotive engineering for years to come.