Headlights play a critical role in any vehicle, particularly for iconic models like the 1995 Mitsubishi 3000GT. Business owners catering to the automotive market must leverage the right headlight solutions for their customers to enhance performance, safety, and style. As we delve into the diverse options available, we will explore aftermarket and OEM headlights, suitable replacement bulbs, and sourcing avenues for bulk and custom headlight parts. Each chapter will aim to equip business owners with the necessary insights to make informed decisions in this highly competitive market.

Seeing the Night Clearly: Aftermarket Headlights for the 1995 Mitsubishi 3000GT

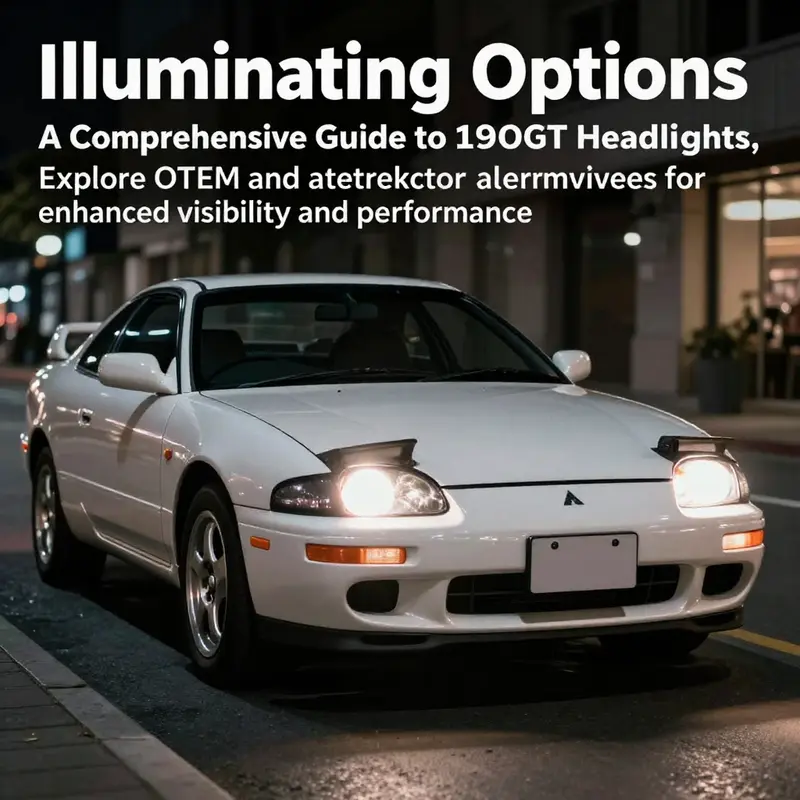

The 1995 Mitsubishi 3000GT has long stood as a bold statement of late-90s performance, its silhouette carrying a blend of aerodynamic purpose and mock-jet-age styling. Yet as with any classic performance coupe, the headlights—the eyes of the car—often reveal the tension between preserving a factory look and embracing an updated, more confident glow. The aftermarket landscape for the 3000GT’s headlights is not a clutter of fickle trends but a carefully balanced field between authenticity and modern visibility. For many owners, the decision to upgrade or replace hinges on three practical questions: fitment, legality, and how the change will harmonize with the car’s overall character. In this space, the options extend beyond simply swapping like-for-like units. They invite a reconsideration of how light meets road, and how a late-model Japanese icon translates its legacy into contemporary driving experience.

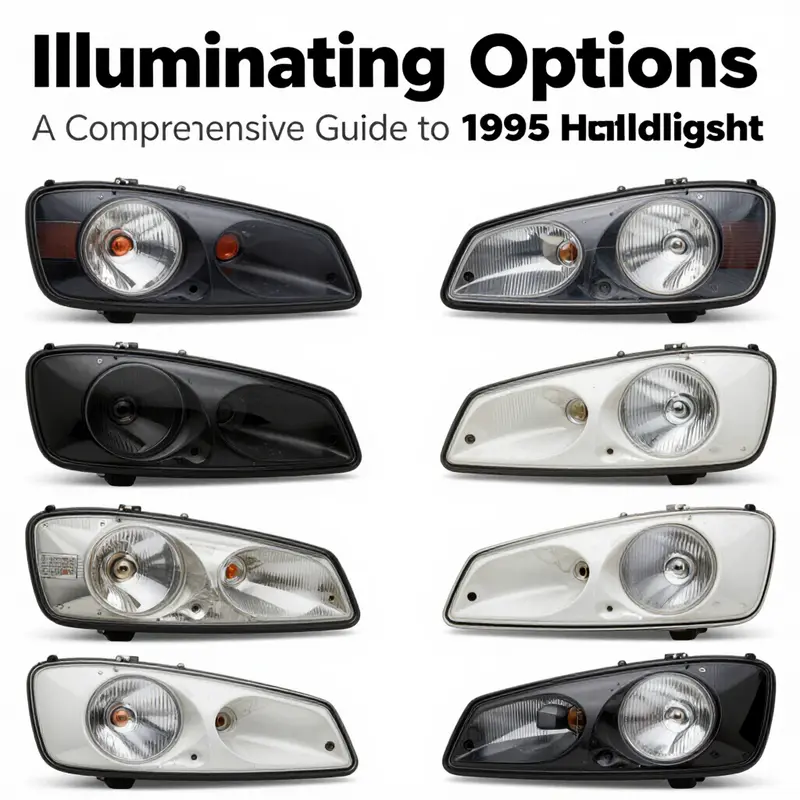

What you find when you search through marketplaces and parts catalogs is a spectrum that begins with complete headlight assemblies designed to align with the 1995 model year’s geometry and styling cues. You can choose driver and passenger side assemblies in a black housing to maintain the car’s shadowed, aggressive look, or you can opt for lighter, chrome or clear options that emphasize the geometry of the headlight lenses. The practical appeal is the guaranteed fit that many listings promise, which is an essential consideration for owners who want to minimize the guesswork that often accompanies older vehicles. The listings that surface on these aftermarket platforms frequently highlight compatibility with the 1994–1999 Mitsubishi 3000GT range, underscoring that the late-90s design language shared a common footprint across those model years. In many ways, the aftermarket market mirrors the car’s own ethos: a willingness to push the boundaries of what is possible while remaining respectful of the original design intent.

Price ranges on these complete assemblies illustrate the spectrum you can expect in the marketplace. A pre-owned left headlight assembly from the mid-to-late 1990s, for instance, might be listed around $148, a figure that makes a strong case for those restoring a keeper car whose budget must stretch across more than one subsystem. On the other end of the spectrum, there are bundled options that pair both left and right assemblies in a single shipment, often in a black finish, with shipping included and a price tag hovering around $739. The math here is straightforward: aftermarket assemblies are typically positioned as cost-effective alternatives to OEM replacements while promising the same essential fit and finish. For enthusiasts who are chasing originality on a budget, these figures can help frame a project plan that preserves the car’s lines without compromising on functional reliability.

Beyond the raw shell, the aftermarket ecosystem also speaks to a wider culture of light performance. For those who want to take the 3000GT into a more modern visual realm, aftermarket suppliers offer LED conversion kits or clear-lens assemblies. An LED conversion, properly implemented, can improve daytime visibility and cut through the night with a crisp, contemporary light profile. Yet this is one of those areas where prudence must accompany ambition. LED or HID upgrades must be matched to the car’s reflector geometry and beam pattern to avoid creating glare that frustrates oncoming drivers or, worse, fails regulatory scrutiny. It is not simply a matter of swapping in brighter components; it is a careful calibration of light distribution, color temperature, and beam cutoff. A commonly cited color temperature around 5500K sits at the cusp of a bright, daylight-like appearance without venturing into the purplish or excessively cool tones that can reduce contrast on the road. The risk of an improperly configured kit is not just poor aesthetics; it is a direct safety concern. Therefore, buyers should approach LED or HID upgrades with a plan that includes proper wiring, ballast management, and, if possible, an alignment check after installation.

The comparison between OEM authenticity and aftermarket practicality often centers on the balance between performance and authenticity. OEM-style headlight assemblies promise exact fitment and a look that remains faithful to Mitsubishi’s original design language. They typically come with glass or polycarbonate lenses that resist clouding for a longer period, and the internal components—reflectors, seals, and housings—are selected to withstand the car’s climate and typical road conditions. Aftermarket alternatives, by contrast, may emphasize performance-oriented updates such as intensified beam patterns, clearer lenses that reduce fogging, or aesthetic choices like tinted or blacked-out housings. The tension between these approaches is not merely about taste; it touches on road legality and safety. When you install any aftermarket headlight, you should verify that the part complies with local lighting regulations and that the beam pattern remains compliant with traffic laws. The last thing a restoration or upgrade project needs is a mismatch between a car’s bright new look and the practical requirement to illuminate the road safely for night driving.

The practical process of upgrading or replacing headlights on a 1995 3000GT also invites a broader view of where to source parts beyond the traditional auto parts store. Online marketplaces like those that host complete assemblies often provide a guaranteed-fit promise, which is particularly valuable for a model with a dedicated fan base and a precise aging of its bodywork. When you move to this level of sourcing, you begin to negotiate not just the right part, but the right parts ecosystem. This ecosystem includes vendor transparency, on-time delivery performance, and post-sale support, all of which matter when you are restoring a vehicle that you intend to keep roadworthy for years to come. Some practitioners in the space emphasize supplier reliability as a critical tier of the purchasing decision. A few industry peers highlight specific evaluative criteria that can help a buyer reduce risk: on-time delivery rates typically on the order of 98 percent or higher, clear technical specifications, visible warranties, and responsive customer service that can assist with questions about fitment and post-sale support. These criteria matter because the headlight is not a one-off purchase; it is part of a system that includes lenses, bulbs, wiring, seals, and alignment. A misstep in any one of those areas can cascade into misalignment, fogging, degraded light quality, or moisture intrusion.

As buyers weigh these considerations, the sourcing map expands to include not only Western marketplaces but also global manufacturers that serve restoration and bulk replacement programs. Alibaba and its network of suppliers have established themselves as key players in the broader 3000GT aftermarket ecosystem. For restoration shops or parts exporters, this channel offers breadth and scale—from CNC-machined components to remanufactured assemblies that can be priced competitively and delivered quickly. The provinces of Zhejiang, Guangdong, and Shandong, in particular, are noted for their advanced production capabilities and a robust supplier base. When evaluating suppliers in these channels, the criteria go beyond price: on-time delivery performance, technical transparency about materials and assembly methods, and post-sale support are critical to long-term success. In this sense, the headlight upgrade becomes less a solitary purchase and more a supply chain decision, with implications for project timing, quality control, and long-term reliability.

The practical theophany of this approach is that a well-chosen upgrade is not simply about making the car glow brighter. It is about preserving the car’s historical character while delivering daylight-like clarity that makes night driving safer and more enjoyable. It is about selecting a path that respects the vehicle’s original design language, yet accepts the modern engineering that has evolved since the car first rolled off the showroom floor. It is about balancing the car’s identity with practical daily driving needs. For owners who keep their 1995 3000GT on the road, this balance is not abstract; it translates to better visibility, improved safety, and a sense of confidence when negotiating a dark highway or a winding mountain road.

In evaluating options, a practical approach is to keep a clear record of what you want to achieve with your headlights. If your goal is a faithful reproduction of the stock look, you may lean toward OEM-style assemblies that preserve the original appearance and beam geometry. If your objective includes a brighter, more contemporary profile, you might opt for a black housing or a clear-lens design with a modern light source that complements the car’s sculpted linework. If you choose LED or HID upgrades, you must be prepared to address regulatory implications and to ensure a proper installation that maintains safe glare levels and beam alignment. In all cases, the installation should be conducted with attention to the car’s electrical system, moisture seals, and the potential need for a fresh headlight power harness or upgraded relays to handle higher-current demands. The overall result should be a car that looks as if it arrived from a later era of engineering while still carrying the grace and silhouette of a late-1990s performance icon.

For enthusiasts who want an explicit entry point into this spectrum, a dedicated resource on the available options for the 95-99 period can be especially helpful. This internal reference highlights a clear driver and passenger side headlight option that aligns with the SL/VR4 trim’s distinctive lamps. The page emphasizes how a proper set of headlamps can maintain the vehicle’s balance of performance and aesthetics, even as you upgrade lens clarity or housing finish. You can explore this specific resource here: 95-99 Mitsubishi 3000GT clear headlight assemblies. For many readers, this focal point serves as a pragmatic reminder that upgrading headlights is not just about brightness; it is about preserving the car’s identity while ensuring road safety.

Even as the community debates the best path forward, it helps to anchor decisions in the practical realities of modern road use. Halogen replacement bulbs, for example, remain a simple entry point for owners who want a straightforward improvement with minimal rewiring. Sources such as major retailers offer halogen bulbs in matched high-beam and low-beam configurations compatible with the 1994–1999 range. For these installations, the promise is straightforward plug-and-play compatibility, a tidy upgrade that can be installed with commonly available tools in a home garage. The result is a modest but meaningful increase in light brightness and color temperature, which can dramatically improve night driving comfort without the need to overhaul the entire headlight assembly.

The broader supply chain conversation also matters, particularly for shops or owners who are pursuing restoration or large-scale replacement projects. When you are dealing with bulk orders or ongoing service work, supplier reliability becomes crucial. In this context, the discussion naturally touches on supplier attributes that matter most: consistency in on-time delivery, transparency about production processes and materials, clear post-sale support, and the ability to respond quickly when a part does not meet expectations. These are not merely business considerations; they are essential to maintaining a steady workshop workflow, meeting customer expectations, and ensuring that the 1995 3000GT continues to command respect on the road. The goal is a seamless combination of aesthetics, performance, and reliability, one that honors the car’s heritage while embracing the incremental improvements modern lighting technology affords.

As this chapter exits the trench of raw choices and enters the broader conversation about headlights, it is worth recalling the implicit promise of aftermarket options: the ability to tailor light to a car’s personality without sacrificing safety or legal compliance. The 1995 3000GT is a compact example of this philosophy. It invites owners to choose a path that respects the car’s strong, sculpted lines while allowing for a more modern, practical illumination strategy. It invites restorers to balance the car’s historical significance with the realities of daily driving. And it invites enthusiasts to think not only about the glow that reaches the horizon but the clarity with which that glow reveals the world ahead.

External reference: https://www.ebay.com/itm/1995-1998-Mitsubishi-3000GT-BLACK-Left-Headlight-Assembly-LEFT/265579546672

Keeping the Look and Light Right: Choosing OEM or Aftermarket Headlights for the 1995 Mitsubishi 3000GT

Keeping the Look and Light Right: Choosing OEM or Aftermarket Headlights for the 1995 Mitsubishi 3000GT

The headlights are among the most defining features of a 1995 Mitsubishi 3000GT. Their flip-up presence, specific lens geometry, and original beam patterns contribute to the car’s identity. Deciding between original equipment and third-party replacements is not just about price. It touches preservation, safety, functionality, and long-term ownership cost. This chapter walks through that decision with practical detail, helping you choose a direction that matches your goals.

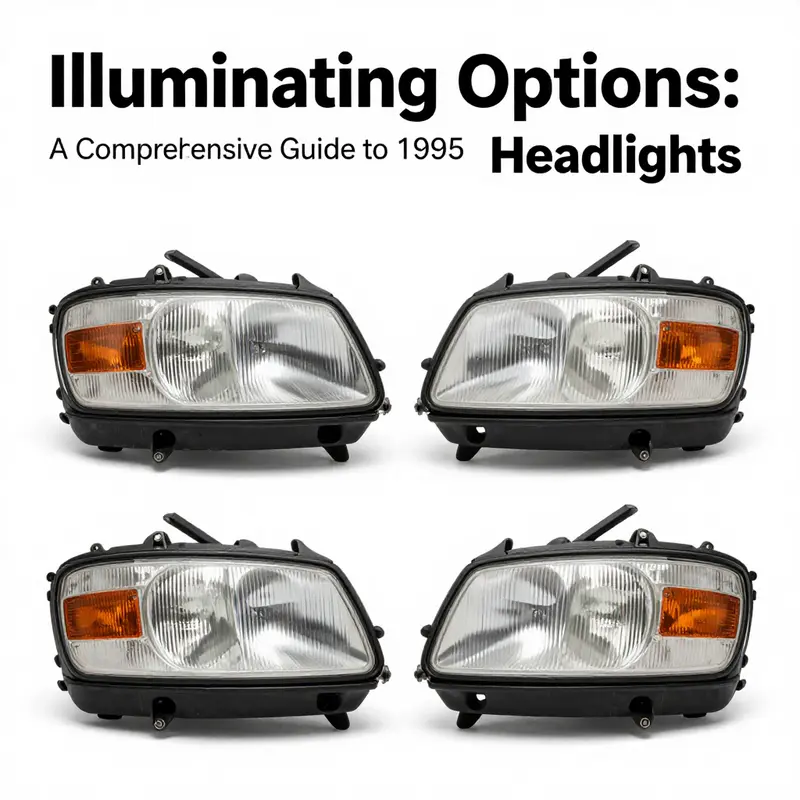

Authenticity matters when the goal is preservation. Original equipment units were designed to work with the car’s body lines, mounting points, and the flip-up mechanism. Their lenses and housings match factory tolerances. For collectors and owners aiming to maintain the car’s value, factory-correct parts avoid surprises during inspections or shows. An OEM assembly usually aligns precisely with the hood and fender, seals reliably against moisture, and produces the beam pattern the engineers intended. That beam pattern matters; reflectors and lens curvature combine to control cutoff, throw, and stray light. A correct beam keeps you legal and safe.

Cost is the counterweight. Genuine assemblies command higher prices. That difference reflects scarcity, original tooling, and the premium collectors place on authenticity. For some owners, the price is justified. For others, the budget and the need to get the car back on the road quickly make aftermarket options attractive.

Aftermarket headlights offer variety. They range from accurate reproductions to modern reinterpretations. Some replicate the flip-up look with near-OEM fit. Others replace materials, add LED arrays, or change lens color to a clear or tinted finish. Quality varies across manufacturers. Higher-end aftermarket units can be close to OEM in fit and finish. Lower-cost options sometimes use different plastic formulations, looser tolerances, or simplified sealing techniques. Those differences can lead to alignment issues, water ingress, or poor beam patterns.

Beam quality should be a primary concern. A headlight that looks right but throws light poorly compromises safety. OEM reflectors and lens profiles were tuned for specified bulb types. If you install a unit that changes the reflector geometry or lens optics, expect differences in how the road is illuminated. Misplaced hot spots, reduced range, or excessive glare to other drivers are common issues with poorly designed aftermarket lights. If you opt for non-factory optics, insist on units that meet recognized standards for street use. Check for certification stickers or documentation, and test beam patterns after installation.

Fitment is about more than bolts. The 3000GT’s flip-up mechanism introduces alignment variables commercial sedans rarely face. If the pivot points or the housing mounts are even slightly off, the headlight sits at an odd angle when raised or lowered. The result can be noisy operation, uneven gaps, and stress on the motor or linkage. OEM pieces, or high-quality reproductions, account for these tolerances. Budget parts sometimes do not.

Sealing and durability affect lifetime cost. Older cars are prone to aging seals and cracked housings. A replacement unit should resist UV, retain clarity, and keep moisture out. Moisture inside a headlight accelerates reflector corrosion and filament failure. Rebuilding the seals on an OEM assembly may offer the best long-term result at a lower immediate cost than buying a new aftermarket assembly. On the other hand, some aftermarket housings use advanced polymers that resist yellowing and are easier to restore if clouding occurs.

Bulb compatibility is another technical checkpoint. The 1995 Mitsubishi 3000GT originally used halogen bulbs in specified sizes. Replacement bulbs in the common 9005/9006 sizes are widely available and install with no rewiring. Many replacement halogen bulbs advertise a whiter output in the 5,500K range. That white tone improves perceived clarity, but color temperature alone does not increase illumination. If you upgrade to different light sources, ensure the housing and reflector are compatible. Converting a halogen-designed reflector to LEDs or HIDs without proper optics often causes beam scatter and glare.

Legal compliance cannot be overlooked. Different regions enforce standards for headlight beam patterns, brightness, and allowable modifications. An aftermarket assembly that is not certified for road use can create headaches during inspections or lead to fines. Keep documentation and verify local rules before fitting non-stock lights. If you plan to use the car in competition or off-road events, the rules differ; choose equipment accordingly.

Sourcing strategy affects both price and risk. OEM headlights for the 3000GT can be found through secondary markets. Their availability fluctuates, and prices reflect rarity. Third-party warehouses and specialists also remanufacture factory housings. For larger projects or supply runs, manufacturers in coastal Chinese provinces have developed competitive production lines for replacement assemblies. When buying in bulk or commissioning custom runs, evaluate suppliers on clear metrics: on-time delivery above 98 percent, transparent technical documentation, and reliable post-sale support. Inspect samples closely for fit and finish before large purchases.

Even when you choose aftermarket replacements, there is value in careful selection. Look for suppliers that provide measurement diagrams, material specs, and test beam shots. Ask about materials used for lenses and housings, and whether UV inhibitors are included. Request real-world fitment photos from vehicles of the same model year. A written warranty, clear return policy, and responsive technical support reduce risk.

Restoration-minded owners often find a middle ground. A salvaged OEM assembly can be fully rebuilt with new seals, fresh bulbs, and polished lenses. This approach preserves factory geometry while reducing cost. Rebuild kits for this model exist and include replacement gaskets, new motor linkage bushings, and sealing compounds. Polishing pitted plastic lenses restores clarity and keeps the original housings in place. That method suits a car intended to remain as original as possible, without paying top-of-market prices for untouched OEM pieces.

Installation tips matter whether you buy new, remanufactured, or rebuilt parts. Verify hinge and linkage condition before installing new housings. Replace worn pivot bushings. Check the motor operation and wiring for corrosion. Adjust headlight aim after installation using a flat surface and a known-distance target. Proper aim prevents dazzling other drivers and gives the best road illumination.

If you prefer modern lighting, evaluate complete, certified retrofit kits rather than piecemeal conversions. These kits often include matched optics designed to produce a legal beam pattern with LED or HID sources. They tend to be more expensive, but they protect against beam scatter and glare. Avoid plug-and-play claims without documentation. True safe conversions calibrate optics, not just swap bulbs.

For collectors, choice often comes down to provenance. An authentic assembly with documented history preserves market value. Even a restored OEM unit will generally be favored over a non-factory alternative. For daily drivers, the calculus shifts. Lower-cost, higher-performance, or easier-to-maintain aftermarket options may offer better value. Consider your driving patterns, typical climates, and whether the car will see winters when salt and road debris accelerate housing wear.

Practical comparisons help. If you require exact factory fit, original beam geometry, and a preserved aesthetic, allocate budget for OEM parts or a high-quality remanufacture. If the primary goal is safe, reliable driving with an acceptable aesthetic match, a vetted aftermarket option can be satisfactory. If you want modern brightness and appearance, choose a certified retrofit rather than improvising.

Finally, keep documentation. Save purchase records, warranty papers, and any test results. When selling or showing the car, this paperwork demonstrates care and authenticity. If the goal is long-term preservation, this paperwork can be nearly as important as the parts themselves.

If you want a quick place to start seeing available clear replacements for glass headlights on this model, review this reference: 95-99 Mitsubishi 3000GT clear driver/passenger headlights.

For a specific example of a factory-correct replacement listing, see this external reference: https://www.ebay.com/itm/94-98-Mitsubishi-3000GT-Dodge-Stealth-Driver-Passenger-Glass-Headlights/336238189049?hash=item336238189049&trkparms=amclen%3D107%26amcr%3D1%26utmcampaign%3Dv100048%26utmmedium%3Dmarketing%26utmsource%3Dshopee

Choosing between OEM and aftermarket headlights is a decision of priorities. Preserve originality to protect value. Choose tested aftermarket solutions for cost efficiency and functionality. Rebuild where practical to get the best of both worlds. Whatever path you pick, pay close attention to fit, beam quality, sealing, and legal compliance. Those factors determine whether your 3000GT lights the road clearly and keeps its signature presence intact.

Illuminating Choices: Replacing Bulbs in the 1995 Mitsubishi 3000GT Headlights

When a classic machine from the late 1990s returns to the road, its headlights are not merely a practical feature; they are a conduit between the car’s era and the present. For the 1995 Mitsubishi 3000GT, choosing replacement bulbs is more than a matter of brightness. It is about preserving the vehicle’s lines, ensuring safe night visibility, and maintaining the careful balance between originality and modern convenience. The headlight assemblies on early 3000GTs were designed to work within a specific electrical system and beam pattern. Over time, those systems can drift, and the bulbs that once came standard may no longer deliver the performance owners expect. That is why a well-considered approach to replacement bulbs matters as much as selecting a new seal or restoring the chrome trim.

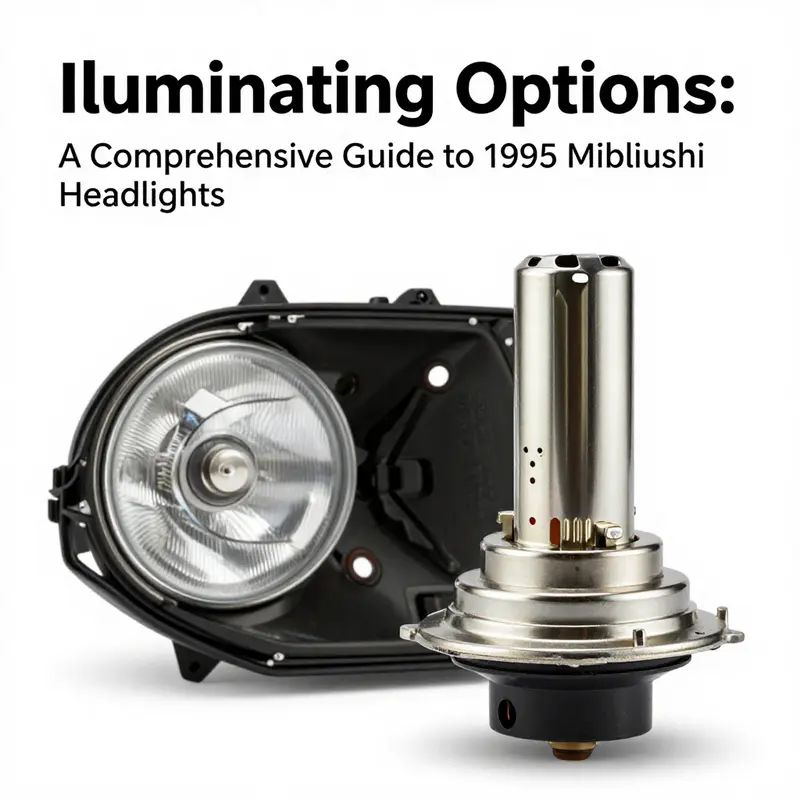

First, it helps to distinguish between the kinds of options available. The 1994–1999 window for the 3000GT shares a common spirit: a need for dependable, compatible lighting that does not disrupt the car’s wiring or its beam aim. Even when the goal is simply to restore factory behavior, the market today offers a spectrum of choices that can alter color temperature, brightness, and beam pattern in ways that affect nighttime visibility and on-road safety. The most straightforward route remains a halogen replacement that matches the original bulb type while ensuring plug-and-play compatibility. In many listings, the focus is on guaranteed fit and authenticity—attributes that reduce the risk of bulb misfit or electrical glitches. Yet the same space also hosts modern upgrades, including LED fog light and headlight bulb combos and even high-intensity discharge options. All of these possibilities weave into a broader restoration or preservation strategy: you want a solution that respects the car’s design intent while acknowledging the advantages of current lighting technology.

For the 1995 model year and its 1994–1999 siblings, the typical bulb formats you will encounter fall into a few broad categories. The simplest path is a direct-replacement halogen bulb designed to fit the vehicle’s headlight assemblies and socket configuration. This approach preserves the classic look and feel, delivering familiar warmth and color while improving reliability over aged stock. In parallel, there is a growing interest in color-balanced upgrades, notably LED-based options intended for headlight or fog-light duties. Some bundles advertised as LED fog light and headlight bulb combo kits aim for a 6000K appearance, a cool white with a hint of blue that modernizes the vehicle’s presence on dark roads. The intent here often leans toward the aesthetic—more than a radical engineering shift—yet such kits carry implications for beam quality, glare, and the car’s electrical load.

Within the marketplace, you will encounter listings that emphasize compatibility with the 1994–1999 3000GT range, sometimes highlighting a guaranteed fit or a specification sheet that notes OEM quality. The logic behind this emphasis is straightforward: when you are dealing with a vehicle that has a relatively compact headlight opening and a specific reflector geometry, convincing a bulb to illuminate in precisely the correct place is essential. A misfit bulb can scatter light, distort the beam, or even fail to seat properly. That is why many sellers stress fitment and authenticity, offering parts described as OEM-quality or OEM-style, intended to preserve the original appearance and function. The practical takeaway is to verify the exact bulb type for your car—whether the model uses H11, H4, or another common halogen format—and to confirm that the replacement will mate with the socket, connector, and any required wiring harness without triggering fault codes or electrical issues.

Beyond the standard halogen route, there is a current-driven interest in more audacious options. For those who want stronger forward illumination and a distinctive look, LED and HID upgrades are part of the conversation. A catalog of LED fog light and headlight bulb combos often cites a color temperature of around 6000K. The rationale is straightforward: a brighter, cooler light can improve visibility at night and give the car a contemporary appearance. However, the reality is more nuanced. LED and HID systems tend to demand additional hardware, such as ballast units for HID or drivers for LED assemblies, and they may interact with the vehicle’s electrical system or CANbus in ways the original bulbs did not. Installers who pursue these upgrades usually plan for potential ballast, resistors, or wiring modifications to ensure stable operation without triggering dashboard warning lights or causing intermittent faults. While the appeal is strong, the installer must balance the desire for a modern look with the need to maintain compatibility and long-term reliability.

As a practical example of the market, a typical listing in this space might offer a headlight bulb kit priced around mid-thirties. The value proposition in such listings often centers on a bundled package that includes both headlight and fog-light bulbs, designed to present a cohesive color balance across the front of the car. These kits can simplify the replacement process and reduce the number of separate purchases you need to complete a tidy upgrade. Yet price alone is not the sole indicator of suitability. A careful buyer looks for clear specifications about bulb base, size, and electrical requirements. The 3000GT’s headlight system spans a range of generations and configurations, so confirming that a given kit aligns with the vehicle’s year and trim is essential before purchase.

For drivers seeking a higher-performance route, the market also points toward xenon or high-intensity options that claim enhanced brightness and broader coverage. A notable entry in the high-performance space is a dual xenon projector assembly marketed for certain Mitsubishi configurations. While the product described clearly targets a Lancer Sport model, the underlying technology is transferable to other vehicles with compatible projector housing. The critical caveat is fitment: this kind of assembly must match the car’s dimensions, mounting points, and electrical connections. The price range for this kind of option, when available, sits in a mid-range bracket, reflecting the dual benefits of improved light output and the specialized manufacturing involved. For the enthusiast restoring a 1995 3000GT, such options present a tempting upgrade path, but careful verification of fit and electrical compatibility remains non-negotiable.

Across these considerations runs a steady thread: the essential need to confirm bulb type and electrical compatibility before committing to a purchase. The most common halogen configurations for a classic import-era headlight are variants of H11 and H4 in many markets, while some assemblies use different single-piece or composite sockets that require careful mapping to the car’s connectors. In any case, buyers should compare the bulb’s base configuration, wattage, and voltage to the factory specifications. A mismatch can lead to dimmer light, flicker, or even damage to the wiring or headlight switch. For a restoration project that seeks to mirror the original performance, there is a strong case for selecting a bulb that matches the factory specification as closely as possible, then considering upgrades only after the core reliability and beam alignment are settled.

The sourcing aspect of this journey matters as much as the technical fit. Reputable suppliers often emphasize not only product specs but service standards: on-time delivery rates, technical transparency about product composition, and post-sale support. In this ecosystem, a few suppliers have become reference points for the industry because they value consistent availability, clear specifications, and dependable customer service. When evaluating sources, a buyer should look for a demonstrated track record of reliability, transparent technical details, and a willingness to provide guidance if a bulb selection needs to be adjusted for a specific build or restoration plan. The goal is not simply to buy a bulb; it is to establish a reliable supply chain for ongoing maintenance or a broader restoration program that may require multiple replacements over time.

Within this context, there are practical steps a reader can take to navigate the choices with confidence. First, identify the exact bulb base type and the headlight assembly’s compatibility window. Then, determine whether the goal is period-correct illumination or modernized brightness. If the objective is a faithful restoration without electrical complications, the safe path is to select a verified fit halogen option that keeps the original color temperature and beam pattern intact. If the car’s owner has a broader restoration plan that includes improved visibility and a contemporary appearance, an LED or HID upgrade can be considered, but only after confirming that the car’s wiring and control modules can accommodate the change without adverse side effects. In this process, the internal decision points—fitment, color temperature, beam pattern, electrical compatibility, and the availability of post-sale support—should be weighed together rather than considered in isolation.

To ground this discussion in a concrete reference for understanding the realm of compatible headlights, consider a listing that specifically targets the 1995–1999 generation and offers checkable fitment for the 1995 model year. This resource provides a ready benchmark for what a trusted, period-appropriate option looks like in today’s market. For readers who want to see a detailed example of a replacement set that is compatible with the 1995 model year, the following internal link points to a widely referenced listing: 95-99 Mitsubishi 3000GT SL VR4 clear driver passenger side headlights glass. This source helps illustrate how a seller communicates compatibility and quality expectations in a way that supports informed decision making when restoration stakes are high.

When the time comes to install, a thoughtful approach to mounting and beam alignment matters as much as the bulb choice. Start with a clean, dry headlight housing and confirm that the gasket around the lens is intact to prevent moisture ingress. If you are upgrading to a brighter option, pause to re-check the headlight aim. A misaligned beam can blind oncoming drivers just as surely as a dim bulb can reduce forward visibility. The aim process is straightforward but precise: park on a level surface, measure the distance from the headlight lens to a vertical wall, and adjust the vertical and horizontal screws until the brightest hotspot lands at a precise point on the wall. This step ensures the beam pattern remains faithful to the vehicle’s original design intent, mitigating glare while maximizing road illumination. In a restoration context, such careful alignment preserves the classic driving experience, avoiding the common pitfall of upgraded lamps that look modern but throw light in the wrong places.

Within the broader arc of headlamp modernization, the 1995 Mitsubishi 3000GT sits at an interesting crossroads. The owner can choose to maintain the familiar, period-appropriate appearance or to pursue a more contemporary brightness profile. Either path can be rewarding when approached with attention to compatibility and installation details. Modern lighting technology offers improved reliability and a broader palette of color temperatures, but it also introduces complexity that must be managed to preserve the car’s historic character. For a collector or a weekend project car, that balance—between authenticity and upgrade—defines the satisfaction of a well-executed bulb replacement. And because the headlights are one of the few exterior features that most people notice at a glance, the choice has both a practical and an aesthetic payoff. The right bulbs illuminate the past without masking it, offering a clear line between the car’s original silhouette and its evolving road presence.

Incorporating a broader sourcing perspective, the landscape of bulbs and assemblies for this model year reflects a global supply chain that can support restoration work at different scales. For small, hands-on projects, the typical halogen replacement kit, chosen for compatibility and ease of installation, provides a reliable path forward. For larger operations or shops that handle multiple classics, the market’s mix of OEM-quality parts and aftermarket upgrades affords opportunities to standardize headlight components across a fleet without sacrificing quality. The key is to build a procurement approach that prioritizes fitment, documentation, and after-sales support. In practice, this means seeking suppliers who publish clear product specifications, provide substitution guidance when a bulb is not a perfect match, and stand behind their parts with consistent service levels. When those conditions are met, a restoration or maintenance program for the 1995 3000GT can progress with confidence rather than compromise.

As a practical reminder, the journey from bulb selection to beam alignment is not a single step but an interconnected sequence. The correct bulb type ensures a snug fit and a reliable electrical connection. The right color temperature aligns with the overall restoration aesthetic while maintaining road-legal clarity. And a careful alignment step guarantees that the beam lands where it should, protecting other drivers and maximizing the driver’s own visibility. In this sense, the chapter on replacement bulbs becomes a careful study of how a seemingly small component can influence the overall experience of owning and driving a classic car. The 1995 Mitsubishi 3000GT, with its distinctive headlights, rewards thoughtful maintenance that respects both the vehicle’s heritage and the demands of modern nighttime driving.

For readers who want to explore a representative example from the broader market, consider this internal reference to a trusted compatible headlight option for the era. The link directs to a product listing that consolidates fitment details and quality signals in a way that can help orient buyers who are new to classic-headlight shopping. By examining such listings, enthusiasts can learn how sellers communicate compatibility, performance claims, and installation considerations without wading through ambiguity. In the end, the right bulb choice is as much about reliable support and accurate fit as it is about the light’s color and brightness.

External reference: For a practical sample of replacement bulb options and pricing, see a representative listing on a major online marketplace. This external resource provides real-world context on what buyers encounter when shopping for 1995 Mitsubishi 3000GT headlight bulbs. External reference.

Strategic Sourcing for 1995 Mitsubishi 3000GT Headlights: Bulk, Custom, and Quality-First Procurement

Sourcing headlights for a 1995 Mitsubishi 3000GT at scale requires a practical mix of technical knowledge, supplier vetting, and logistical planning. Whether the goal is restoring a fleet of vehicles, supplying a specialty shop, or launching a small parts business, the decisions you make early determine cost, fitment accuracy, and long-term reliability.

Start with a clear specification. Document the exact model years, trim variations, and any desired finish options. The 3000GT line had small variations between years and trims that affect mounting points, wiring harness connectors, and lens shapes. Note lamp types and socket codes, for instance 9005/HB3 for high beams and 9006/HB4 for low beams. Record desired finishes such as black housings, clear lenses, or amber reflectors. Also specify whether you need complete assemblies, lenses, inner housings, or replacement seals. Clarity here reduces mismatches and saves negotiation time.

Next, map supplier capability to your technical needs. China’s regional manufacturing clusters have matured into highly specialized hubs. Provinces such as Zhejiang, Guangdong, and Shandong concentrate expertise in plastics molding, glass forming, optical coatings, and injection tooling. Factories there can move from prototyping to high-volume runs quickly. When evaluating suppliers, prioritize those with automotive-quality certifications and a visible track record in headlight production. Certifications signal a consistent quality system and help with regulatory compliance. Ask suppliers about their process control, quality inspections, and failure analysis procedures. A capable partner will discuss first article inspections, tooling wear limits, and material traceability.

Samples matter more than promises. Request pre-production samples and, if possible, a small pilot run. Inspect samples for dimensional accuracy, lens clarity, and reflector finish. Test electrical connectors for secure mating and correct pin orientation. Check the seal integrity to prevent fogging and moisture ingress. Confirm that bulbs seat correctly and that beam patterns align within legal tolerances. If you plan to offer aftermarket upgrades or performance-oriented optics, validate light output and beam cutoff against your standards.

Negotiate tooling and change control early. Custom components often require dedicated injection molds or lens tooling. These can be costly but are essential for long-term batch consistency. Clarify ownership of tooling, expected tool life, and maintenance responsibilities. Include a change-control clause specifying that any tooling alteration requires written approval. This protects you from sudden design shifts that could void previous fitment claims.

Define clear quality acceptance criteria in the contract. Establish defect rates, inspection sampling plans, and metrics for acceptable returns. Typical automotive suppliers target very low defect rates. For B2B sourcing, require a pre-shipment inspection and a batch-level certificate of conformity. Ask for material certificates for plastics and coatings, and require UV and salt-spray test results if parts will be exposed to harsh conditions. Insist on protection against common failure modes like lens yellowing, reflector corrosion, and cracked housings.

Address logistics and packaging with the same rigor. Bulk shipments need robust packaging to avoid damage in transit. Request nested packing options for assemblies or foam inserts for lenses. Clearly label each unit with part numbers, manufacturing dates, and batch codes. For high-volume orders, arrange pallet-level documentation and standardize carton sizes. This reduces handling time and warehousing costs. Also plan for lead time buffers. Chinese production lines can be fast, but tooling setup, holiday schedules, and shipping windows affect delivery.

Plan payment terms and risk mitigation. Typical arrangements include a deposit for tooling, followed by balance payments tied to shipment milestones. For first-time suppliers, consider third-party inspection or escrow arrangements to reduce risk. Use purchase orders that reference technical drawings and agreed acceptance tests. Retain a clause that allows for remedial production or credits for nonconforming batches. For repeat sourcing, negotiate progressive discounts tied to volume commitments or on-time performance.

Think about intellectual property and exclusivity. If you commission unique finishes or proprietary lens shapes, protect designs with clear agreements. Document what the supplier may reuse or sell to other buyers. For exclusive parts, include minimum order quantities and time-limited exclusivity clauses. If you plan to resell under your brand, ensure branding options on the housing or packaging are permitted and agreed upon.

Consider aftermarket fitment and guaranteed compatibility. Buyers of replacement 3000GT headlights value accurate fitment. Offer parts that are described with precise compatibility notes. Photos from multiple angles, measurements, and compatibility checklists reduce returns. If you plan to sell assemblies, include installation instructions and wiring diagrams. For lens-only or housing-only sales, list recommended seals and fasteners. Simple additions like trim clips or foam gaskets reduce installation friction and improve customer satisfaction.

Supplier communication and transparency make scaling smoother. Ask for production schedules, weekly updates, and photos of production runs. Prefer suppliers who provide engineering drawings, CAD files, and tooling images. This technical transparency speeds problem resolution. For complex custom work, arrange video calls during first prototypes. If language differences create friction, use a technical interpreter or a sourcing agent with automotive experience.

Manage compliance and shipping documentation proactively. Headlamp assemblies may carry regulations depending on destination markets. Check local requirements for beam patterns, lens markings, and reflective surfaces. Prepare documentation for customs, such as commercial invoices, packing lists, and origin certificates. For large shipments, work with a freight forwarder familiar with automotive components. They can advise on cost-effective shipping modes and customs facilitation.

Establish after-sales support and warranty terms. Define warranty periods, return procedures, and repair or replacement options. A fair warranty reduces buyer hesitation. For bulk buyers, offer tiered warranties tied to proper installation. Create a process for defective unit return and replacement, and specify responsibilities for shipping costs. Reliable post-sale support increases supplier trust and builds long-term relationships.

Factor in testing and certification costs. If you plan to market headlights as OEM-equivalent, allocate budget for independent testing. Photometric tests, ingress protection tests, and endurance cycles provide third-party validation. These tests also give you promotional data and differentiate your offerings. For performance-oriented optics, allocate time for road testing and validated adjustment procedures.

Leverage trade events and platforms for partner discovery. Trade expos let you meet multiple vendors and inspect capabilities in person. Online marketplaces provide a way to filter and shortlist suppliers quickly. Use reviews, fitment guarantees, and product photos on listing pages to narrow choices. After initial vetting, visit the plant or hire a trusted auditor to confirm capabilities.

Finally, build scalability into your sourcing plan. Ensure suppliers can increase capacity without compromising quality. Ask about alternate production lines, labor availability, and emergency tooling. Agree on escalation paths for urgent orders and define penalties or remedies for missed deadlines. A reliable supply chain for 3000GT headlights anticipates growth and protects against market fluctuations.

For direct reference while comparing listings and fitment claims, consult a broad marketplace catalog that aggregates compatible assemblies and parts. This resource helps confirm part variations and common seller claims: https://www.ebay.com/bhp/mitsubishi-3000gt-headlights

For parts such as replacement headlight glass and clear lenses specific to the 1995–1999 range, consider specialized product pages that show fitment details and visual references, such as the 95–99 3000GT driver and passenger side headlight glass resource.

Adopting these practices produces a predictable, quality-focused sourcing program. You gain better pricing through volume, but keep control through samples, clear contracts, and inspection regimes. A supplier relationship built on transparency and technical alignment reduces surprises. It supports restorations, repairs, and aftermarket upgrades for the iconic 1995 Mitsubishi 3000GT, ensuring parts fit well and perform reliably.

Final thoughts

In conclusion, the selection of headlights for the 1995 Mitsubishi 3000GT is wide-ranging, providing business owners ample opportunity to meet diverse customer needs. With a variety of aftermarket alternatives and authentic OEM options available, as well as suitable replacement bulbs, there is no shortage of ways to enhance vehicle safety and aesthetics. Furthermore, understanding sourcing avenues for custom and bulk parts can streamline business operations and improve customer satisfaction. Armed with this knowledge, business owners can confidently navigate the market of 1995 Mitsubishi 3000GT headlights, ultimately driving success for their enterprises.