A&F Auto Parts R Us Dismantling LLC stands as a crucial component of the automotive aftermarket in Tulare, California. This auto parts dismantling company not only specializes in remanufacturing automotive scrap parts but also plays a vital role in supporting local businesses by providing high-quality, recyclable, and reusable auto components. With operational efficiency and community engagement at its core, A&F aims to foster sustainability in the automotive sector. Each chapter reveals different facets of the company—its overall business strategies, operational hours, comprehensive services, economic impacts on the local community, and active community engagement, illustrating how A&F Auto Parts remains essential for business owners in the automotive industry.

Breathing Second Lives into Metal: A&F Auto Parts R Us Dismantling LLC and Tulare’s Auto-Reuse Ecosystem

The clang of metal and the hum of tires on pavement welcome visitors to A&F Auto Parts R Us Dismantling LLC, a salvage yard tucked along 3531 S K St in Tulare, California. In a landscape where repairs often hinge on the availability of specific parts, this operation occupies a quiet but essential niche: it dismantles and remanufactures automotive scrap into reusable components, stitching together a local supply chain that keeps older vehicles on the road without turning to brand-new parts. The address alone signals a practical center of gravity for the community’s maintenance needs: a place where the past lives on in the form of doors, bumpers, and engines that still have miles left to run, provided they are matched with the right vehicle and the right mechanism of fit. The business profile is straightforward by design, focused on salvage, testing, and distribution of used automotive parts that would otherwise contribute to a growing mountainside of waste. Yet beneath that straightforward outline lies a nuanced approach to sustainability, repair culture, and regional economy—a matrix of considerations that makes the yard more than a simple storefront.

What sets A&F Auto Parts R Us Dismantling LLC apart is its insistence on keeping a wide swath of the vehicle’s life cycle intact. Dismantling and remanufacturing are not merely about extracting a still-functional component and consigning the rest to disposal; they are about tracing a part’s journey from a vehicle that has reached the end of its life to a new life in another machine. This process requires precise knowledge, a careful eye for compatibility, and a level of transparency that customers notice when they call ahead to confirm availability. The staff’s reputation for being helpful and forthright is not incidental. It is the core operating principle that underpins trust in a market segment where misinformation and miscounts can lead to costly dead ends for the consumer. When a customer asks whether a particular alternator, radiator, or timing belt is in stock, the response is not a vague assurance but a concrete check of current inventory and compatibility with the customer’s make, model, and year. Such transparency reduces friction in the repair process and cultivates repeat visits in a community that values reliability just as much as affordability.

Operational hours, listed as 7:00 AM to 4:00 PM from Monday to Tuesday, set a predictable rhythm for both staff and customers. Those hours acknowledge the practical realities of dismantling work, where the morning hours are typically the most productive after parts have cooled from the previous day’s work. It is a rhythm that suits a town where many residents juggle multiple responsibilities, and it ensures that parts are readily accessible for local repair shops and do-it-yourself enthusiasts alike. The limited daytime window does not diminish the yard’s reach; rather, it concentrates effort, enabling the staff to perform meticulous cataloging, testing, and cleaning within a finite, predictable schedule. The surrounding community—well served by public transport—benefits from a central, accessible hub for automotive rehabilitation. In a region where miles matter, the ability to reach a salvage yard without lengthy detours matters as much as the availability of the parts themselves.

The dismantling process at the yard unfolds with a practical economy of motion. Vehicles arrive, and seasoned technicians identify components that can be salvaged, refurbished, or reconditioned for reuse. Metals are separated from plastics and composites, with an eye toward recycling where possible and reassembly where feasible. The remanufacturing angle comes into play when a component cannot be used as-is but can be upgraded or refurbished to meet safety and performance benchmarks. This creates a cascading value chain: a consumer or shop buys a used part at a price point that reflects its vintage, but not its obsolescence. The emphasis on reusability aligns with broader environmental concerns and a growing consumer preference for durable, repairable parts over disposable components. In practice, this stance translates into careful testing procedures, documentation of part condition, and a willingness to stand behind the quality of the components that depart the yard. Customers respond to that accountability with confidence, knowing they are choosing a sustainable option that also helps control repair costs.

Within this ecosystem, the human element matters just as much as the mechanical one. The staff at A&F Auto Parts R Us Dismantling LLC are described by customers as helpful, patient, and forthright about stock levels. This is not a one-way street of “sell now, figure out later”; it is a dialogue. A customer explains their need for a specific part, and the team responds with a clear explanation of availability, compatibility, and alternatives when necessary. The pricing structure reflects fairness: competitive enough to attract careful buyers, transparent enough to avoid surprises at checkout. In many small businesses, the human touch is a differentiator, and here it functions as a reliability signal. Buyers who walk into the yard with a vague memory of a part’s appearance often leave with the exact fit they need, sometimes after a brief inspection, sometimes after a short test to confirm electrical continuity or mechanical alignment.

The financial flexibility offered by the yard also matters. Credit cards are accepted as a payment method, which broadens access for customers who may not carry multiple cash denominations or require a streamlined transaction process when purchasing several components for a repair. This choice reflects a broader industry shift toward flexible payment options that accommodate both professional shops and hobbyists. It also dovetails with the location’s accessibility, as Tulare’s residents and nearby communities increasingly expect convenient, frictionless transactions. The combination of accessibility, inventory discipline, and a customer-first attitude creates a relational dynamic that extends beyond the sale of a single part. It supports a network of repair professionals who rely on steady, dependable supply lines and on a partner who can be counted on to salvage, verify, and deliver.

The social and economic ripple effects of the yard’s operations are subtle but meaningful. Local garages and independent repair shops benefit from a steady stream of affordable, tested components that allow them to compete with new parts without sacrificing quality or safety. For many vehicle owners, especially those with older models or vehicles with specialized configurations, salvaged parts can mean the difference between a costly repair bill and a practical fix that keeps a car on the road. The yard’s emphasis on transparency helps to prevent mismatch errors that would otherwise lead to returns, further expanding its value to the community. In a broader sense, the practice of dismantling and remanufacturing stands as a corrective to consumer waste, turning scrapyard remnant into viable alternatives and demonstrating that a local business can sustain itself while contributing to environmental stewardship.

The scholarly thread that runs through this operational portrait is simple: reuse is a legitimate manufacturing philosophy, even when the parts originate from a vehicle that has already served its primary life. A&F Auto Parts R Us Dismantling LLC embodies this philosophy through disciplined inventory management, a supportive customer experience, and a pragmatic approach to pricing and service. The business does not merely sell parts; it curates a micro-economy around repair and maintenance, cultivating trust with customers who recognize the value of a spared part that still carries a warranty of sorts—the warranty of tested performance and the assurance that the component has earned a second chance rather than being consigned to landfill. This approach resonates with a broader cultural shift in automotive care where the end of a vehicle’s first life is reframed as the beginning of another’s journey, a narrative that aligns with community resilience and responsible consumption.

For readers seeking a tangible sense of this yard’s footprint, the Google Maps listing provides a practical gateway to locate, verify hours, and read recent reflections from customers who have visited. The listing offers a geographic anchor to the story of how a small operation in Tulare supports a larger, interconnected system of repair and reuse. It also signals to prospective customers a level of legitimacy and accessibility that matters when coordinating pickups, drop-offs, or part inquiries. In this sense, the yard operates not just as a place to acquire a component but as a node in a local ecosystem that values transparency, reliability, and sustainable practice. Within this ecosystem, a single part—whether a salvaged bumper from a late-model sedan or a remanufactured alternator—can have a lasting impact on how people in the region approach maintenance, repair, and even the mindset of reuse.

To illustrate the breadth of resources that accompany such a business, one can find related discussions in automotive aftermarket channels, including specialized parts sources that highlight the kind of components that often pass through dismantling yards. A representative example that demonstrates the breadth of remanufacturing opportunities available to enthusiasts is a catalog entry for a specific Mitsubishi Evolution rear bumper in OEM condition. This example, while not a direct listing from the Tulare yard, reflects the same underlying principle: a salvaged part can meet exacting standards of fit and function, enabling a repair that preserves performance and value. See this reference for an illustration of the kind of precise compatibility that buyers often seek when sourcing used parts: 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM.

The story of A&F Auto Parts R Us Dismantling LLC, then, is not a single chapter about a local business. It is a lens on a community-wide practice that treats repaired and recycled parts as legitimate, dignified, and economically viable components of vehicle maintenance. It invites customers to participate in a more sustainable repair culture—one that recognizes the value of experience and the wisdom of reuse. And it invites the surrounding town of Tulare to see the salvage yard not as a symbol of scarcity but as a resourceful alternative within reach, a place where knowledge, transparency, and care translate into real-world savings and real-world reliability. As this chapter closes, the yard remains a practical, trustworthy partner for drivers and mechanics alike, a steady reminder that second lives can be practical, affordable, and environmentally meaningful.

External reference: https://www.google.com/maps/place/A%26F+Auto+Parts+R+Us+Dismantling+LLC/@36.175718,-119.522878,17z/data=!3m1!4b1!4m6!3m5!1s0x809e2a5f9c5d9f95:0x59b795d36724332e!2s3531+S+K+St,+Tulare,+CA+93274!3m2!1d-119.522878!2d36.175718!5m1!1e4?entry=ttu

Open Access and Practical Visiting Tips for A&F Auto Parts R Us Dismantling LLC

Visiting the Yard: Hours, Transport and Practical Tips

A&F Auto Parts R Us Dismantling LLC sits at 3531 S K St in Tulare, California. The yard operates on a regular weekday schedule, making it simple to plan a visit. Standard hours run Monday through Friday, from 8:00 AM to 5:00 PM. These hours are consistent across the most reliable sources, though a few listings show an earlier closing time. If precise timing matters, a quick call to (559) 509-4805 will confirm the day’s schedule.

Knowing the hours helps more than avoid an unexpected closed gate. The yard opens at a time that aligns with early trade traffic. Arrive soon after opening for the widest selection. Late mornings often bring new arrivals and freshly organized inventories. Midafternoon tends to be quieter, but parts can be harder to find then. Weekends are not an option; the facility is closed on Saturday. That makes a weekday plan essential for anyone needing parts or a consultation.

Accessibility begins long before you step into the lot. The address is on a main corridor in Tulare and is well served by local public transport. Buses and commuter routes stop near the area, and the short walk from a transit stop is convenient for those without a vehicle. For customers driving in, the property provides clear access from the main street, with space for short-term parking and loading. If you plan to haul a large component, consider coming with a trailer and a helper. The yard’s layout supports loading, but some parts need careful handling.

A practical visit starts with a call. Dialing (559) 509-4805 can confirm inventory, special handling needs, or workshop availability. Phone contact saves time. It helps the staff pull items ahead of your arrival or set aside specific components. If you are searching for a high-demand assembly, asking ahead can prevent disappointment. A short conversation also lets you confirm any temporary schedule changes.

When you arrive, have a plan. A list of the parts you need makes the search efficient. Include vehicle make, model, and year. If you have identification numbers such as part or engine codes, bring them. Clear, concise information saves time for both you and the yard staff. If you are unsure about a part’s compatibility, the staff can help verify fitment. They often handle a broad range of components and can check against common cross-references.

Payment and pickup are straightforward. The yard accepts typical on-site payment methods. If you are picking up bulky items, arrange how they will be loaded before purchase. Yard staff can advise on the safest way to remove parts. For heavy lifts, they may recommend equipment or extra help. If you plan to remove components yourself, bring suitable tools and protective items. Gloves, safety glasses, and a trolley can make the process smoother.

Traffic flow and timing matter. The best time to visit is early in the day, soon after the yard opens. This is when inventory is at its fullest and the site is least crowded. Midweek visits often yield better outcomes than Monday mornings, which can be busy with weekend returns and new stock processing. If you work standard weekday hours, plan an early departure or a late-afternoon visit. Calling ahead can sometimes allow staff to accommodate pickups outside the norm.

Accessibility also means physical and logistical readiness. The yard is navigable but can involve uneven surfaces and tight aisles. Wear sturdy shoes and durable clothing. If mobility concerns are present, call ahead. Staff can guide you to the most accessible areas or suggest alternate arrangements. Many customers appreciate a heads-up about heavy or awkward pickups so staff can prepare loading assistance.

For commuters or those without private transport, public transit connections make the yard easy to reach. Check local transit schedules to align arrival with yard hours. If a transit connection does not perfectly match your plan, consider a short taxi or rideshare ride from the nearest stop. The yard’s central location in Tulare means these short hops are often affordable and quick.

Inventory turnover and remanufacturing processes affect what you’ll find on a given day. Parts move quickly in a dismantling facility, and some components are prioritized for remanufacturing. If you require a reconditioned item, ask whether the yard has completed the remanufacturing process. Staff can advise on lead times for rebuilt parts and on the availability of core exchanges if needed. Planning ahead for reconditioned parts reduces downtime for vehicles waiting on replacement components.

Documentation is important. Bring proof of ownership for some larger parts if required. Some items may have legal or regulatory considerations. The staff will let you know when such documentation is necessary. A simple photo or a vehicle title snippet can clarify ownership and compatibility questions. Keeping records also helps if you plan to resell a recovered part later.

Safety and yard etiquette matter. Follow posted signs and staff directions. The facility maintains a working yard environment with machinery and tools in use. Keep children and pets secure and supervised. When examining components, be mindful of sharp edges and residual fluids. Ask staff about safe handling if you are unsure. They will point out hazardous areas and advise on safe lifting techniques.

If you travel regularly to dismantling yards, develop a short routine. Email or call before leaving. Verify opening times, ask about the specific part, and confirm any special arrangements. Arrive prepared with a list, tools, and a plan for transport. These small steps often cut hours of downtime and reduce multiple trips back and forth.

For enthusiasts and professional mechanics alike, the yard can be a valuable resource. It offers recyclable, reusable components that extend vehicle life. If you specialize in a particular vehicle, like a performance model, request parts specific to that line. For example, those hunting comprehensive front or rear assemblies might benefit from checking sources of half-cut units. An example of such a resource is the Evo X half-cut parts listing, which illustrates the type of assemblies people often seek from dismantling yards. Linking supply knowledge with the yard’s hours and accessibility helps customers plan targeted, efficient visits.

Finally, remember the human element. Yard staff handle a broad array of requests and often go the extra mile. Being courteous and precise with your needs fosters better service. A phone call, clear list, and punctual arrival usually guarantee the smoothest experience. When planning a visit to A&F Auto Parts R Us Dismantling LLC, use the weekday hours as your anchor. Combine that schedule with advance contact, practical load plans, and safe handling. The result is a productive, time-saving trip that gets you the parts you need.

For the most current operating hours and contact details, see the yard’s listing on Junkyards List: https://www.junkyardslist.com/locations/af-auto-parts-r-us-dismantling-llc-tulare-ca/.

Salvage for the Streets: How A&F Auto Parts R Us Dismantling LLC Turns Scrap into Reliable Aftermarket Parts

The story of A&F Auto Parts R Us Dismantling LLC unfolds in a city where the needs of drivers and the concerns of stewardship intersect. Nestled in Tulare, California, at 3531 S K St, this shop operates with a practical respect for the lifecycle of every vehicle that passes through its doors. From 7:00 AM to 4:00 PM on Monday and Tuesday, the business opens a window into how dismantling, remanufacturing, and recycling can sustain the after markets while reducing waste. The location’s accessibility—well-served by public transport—adds a connective tissue to a broader community of commuters, hobbyists, and professional technicians who rely on affordable, reliable components to keep fleets and daily drivers roadworthy. In this environment, the company’s work goes beyond part salvage; it is a philosophy of stewardship, making use of every usable bit of metal, plastic, and electronics that would otherwise wind up in a landfill. The result is not merely a shop that sells parts, but a small, tightly controlled ecosystem where dismantling meets instruction, where the customer encounter blends transparency with practicality, and where the idea of a circular economy gains tangible form on a shop floor.

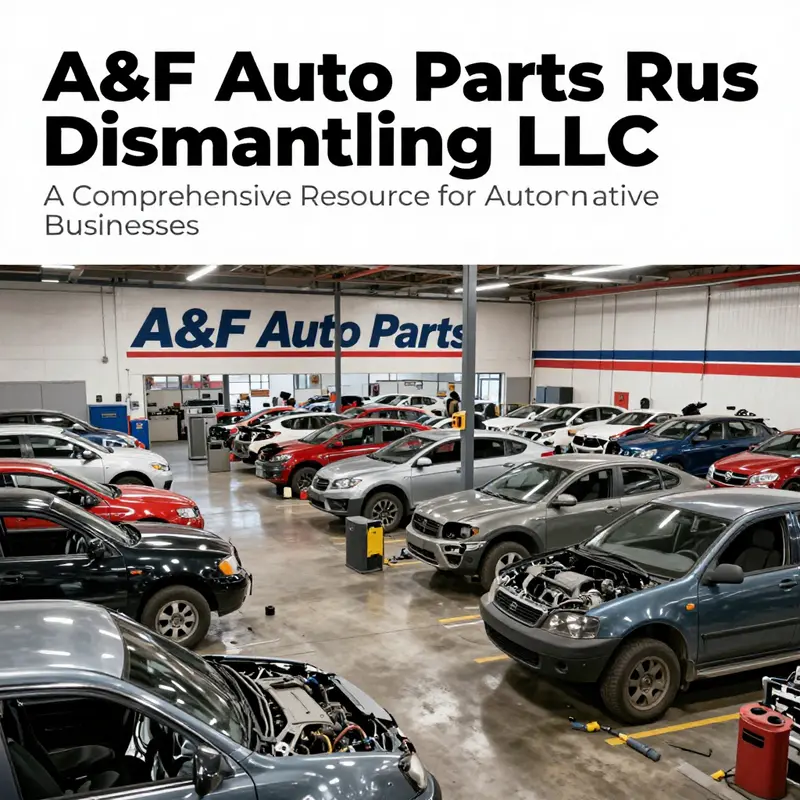

To understand how A&F Auto Parts R Us Dismantling LLC functions, it helps to follow the arc from intake to installation. Vehicles arrive with a range of conditions, from late-model sedans to older work cars, each presenting a different puzzle for the technicians who assess what can be salvaged, remanufactured, or reconditioned for reuse. The team performs a careful triage: safety-critical parts must meet strict criteria for reliability; components with a longer usable life rely on refurbishing processes that restore performance without compromising safety. This approach aligns with the broader aftermarket ethos that quality, accessibility, and environmental responsibility can coexist. In practice, customers walk into a space that is both busy and orderly, where the soundscape is punctuated by diagnostic beeps, the soft clink of metal parts, and the focused conversations of technicians guiding customers through options.

Among the core services that anchor this operation are precise testing and diagnostic capabilities that help separate the hopeful guesses from the certainties every technician seeks. Alternator and starter testing, for instance, is not just a quick spin of the pulley and a glance at a gauge. It is a procedure that evaluates a component’s ability to deliver consistent cranking power and steady electrical output under load. The goal is to determine whether a salvaged unit can meet the demanding standards of today’s vehicles, where systems rely on reliable voltage regulation to protect sensitive electronics and propulsion systems. In the same spirit, battery testing takes a close look at health and charge capacity, revealing whether a component can stably support daily starts and the energy demands of modern onboard electronics. These tests are more than routine checks; they are the gatekeepers of trust, building confidence that a remanufactured part will perform as needed without returning to the shop for repeated faults.

Diagnostics extend beyond charging systems into the realm of engine management. Check engine light reading is among the shop’s essential services, offering diagnostic codes that illuminate a vehicle’s internal status. Rather than guessing at the cause of a warning light, customers receive a structured, code-driven assessment that clarifies whether a fault stems from a sensor, a circuit, or a more complex subsystem. This clarity is crucial in a dismantling operation because it informs whether a salvage component can be a suitable substitute, what ancillary parts might be required, and how a given repair bill compares to the cost of a new part. By presenting a transparent diagnostic picture, A&F Auto Parts R Us Dismantling LLC helps customers balance cost, reliability, and the pace at which a vehicle must return to service.

In addition to diagnostics, the shop provides practical installation services that deliver immediate value. Wiper and bulb installation may seem small, but it is a reminder that quality maintenance is a sequence of targeted, reliable tasks that contribute to overall safety. A windshield wiper system that functions properly and lighting components that illuminate hazards at night are simple, daily assurances that reduce risk on the road. The staff’s availability for in-store pickup and shopping adds another layer of convenience. Customers who organize their day around family schedules or work shifts appreciate the option to select parts in person and retrieve them at a time that fits their itinerary. The ability to handle orders on site—whether for immediate pickup or future collection—speaks to a practical, customer-centric approach that values time as a resource and strives to minimize downtime.

The human and cultural dimensions of the business are also integral to the experience. Language assistance broadens access, ensuring that customers with different linguistic backgrounds can discuss vehicle needs, bargain for parts, and understand the implications of remanufactured options. In a field where miscommunication can lead to mismatched parts or unsafe repairs, this attentiveness to communication reduces friction and builds long-term trust. The financial aspect mirrors this emphasis on clarity and flexibility: the shop accepts a range of payment methods, including credit cards, debit cards, and NFC mobile payments. For customers who juggle cash flow with the unpredictability of car maintenance, such flexibility is not merely convenient; it is essential to sustaining ongoing access to reliable parts.

All of this takes place against a backdrop of environmental and economic considerations that are core to the dismantling enterprise. Salvaging components extends their useful life, blunts the demand for new manufacturing, and curtails the energy and material inputs associated with producing fresh parts. When a vehicle arrives, it is not just the story of a single machine but a catalyst for a broader calculation: how to minimize waste, maximize reuse, and pass savings along to customers who might be repairing a daily driver or maintaining a small fleet. The shop’s processes reflect a disciplined approach to remanufacturing, where each reclaimed component is subjected to testing and verification before it can be offered for resale. This discipline matters because aftermarket ecosystems rely on dependable parts that can endure the rough and varied realities of real-world use. In this way, A&F Auto Parts R Us Dismantling LLC becomes a hinge between the waste stream and the road, between the old life of a vehicle and its continued usefulness on today’s streets.

The practical synthesis of service, accessibility, and stewardship is what makes the Tulare operation more than a storefront. It embodies a philosophy that parts supply should be resilient, cost-effective, and environmentally responsible. For customers who are repairing a cherished vehicle or running a business that depends on reliable transport, the dismantling model offers a pathway to maintain uptime without breaking the budget. And for the broader community, it demonstrates a tangible commitment to reducing waste and extending the life cycle of automotive components through careful testing, refurbishing, and reinstallation. It is a reminder that the repair economy is not a brittle system built on scarcity; it is a robust, evolving network that reuses and reinvents, one part at a time.

For readers who are curious about the broader spectrum of aftermarket components and the kinds of parts that often travel through dismantling channels, consider exploring a representative example from related automotive hubs—an illustration drawn from a popular aftermarket resource. See the linked reference 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM to understand how a specific component category can be conceptualized, sourced, and validated within a similar supply ecosystem. This kind of reference helps illuminate the parallels between dismantling operations and the broader aftermarket landscape, where compatibility, fitment, and condition guide a buyer’s decision as much as price.

The chapter’s focus on the mechanics of the service mix—diagnostics, electrical testing, and practical installation—mirrors the essential competencies of a dismantling operation. It is not just about pulling parts from wrecks; it is about ensuring that each component that leaves the yard is fit for purpose, traceable, and supported by some reasonable expectation of performance. In this sense, the Tulare shop becomes a living case study in how small, locally anchored enterprises can contribute to a bigger narrative of sustainable transportation. It demonstrates that the value of a part is not only its price tag but its reliability, its readiness for reuse, and its suitability for a future that favors repair over replacement. For drivers and businesses alike, this philosophy translates into fewer delays, lower operating costs, and a smaller ecological footprint—all achieved through careful work, clear communication, and a steady commitment to service that respects the road and the planet.

External resource for readers who want to explore related carbon-fiber components and their role in lightweight, performance-oriented builds can be found here: https://mitsubishiautopartsshop.com/brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x/. This link offers a window into a segment of the aftermarket world that intersects with dismantling practices by illustrating how high-end materials and careful refurbishment contribute to performance-oriented reuse without excessive consumption. While the Tulare operation emphasizes a broad range of parts for everyday use, the underlying principle remains consistent: durable, test-verified components delivered to customers can extend a vehicle’s life and reduce the environmental impact of modern mobility.

The Quiet Engine of Reuse: A Tulare Dismantling Yard

In Tulare, California, a modest engine of reuse operates quietly on 3531 S K St, a site that speaks through steady hours rather than flashy signage. A&F Auto Parts R Us Dismantling LLC functions as a dismantling and remanufacturing operation for automotive scrap parts, a node in the circular economy that helps extend vehicle life by reclaiming components and recycling metals and plastics. The site hours, from 7:00 AM to 4:00 PM on Monday and Tuesday, reflect a lean, locally oriented work pattern familiar to many mid-sized regional firms. The surrounding community benefits in small but meaningful ways, including steady local employment, a supplier network that serves nearby businesses, and a practical example of environmental stewardship in action.

Yet this chapter starts by acknowledging data gaps. With publicly available information, there is no precise, authoritative measure of A&F’s direct economic impact on Tulare. Macro trends in the U.S. automotive value chain provide context, but they cannot substitute for local data. The automotive sector has seen changes in manufacturing share, automation, and supply chain complexity that shape opportunities and challenges for a single yard.

Nonetheless, even without exact numbers, one can discuss plausible channels of influence. Direct employment at the yard anchors incomes in a town where the labor market mixes agricultural and industrial activity. Jobs in dismantling facilities often pay above local minimums and offer skill development, with ripple effects on housing demand, retail activity, and school enrollment patterns. Indirect effects arise through local suppliers of tools, parts, vehicles, and maintenance services and through the foot traffic of workers and customers near the site.

On the environmental side, salvage and remanufacturing reduce landfill burden and the energy intensity of producing new parts. In California, environmental standards and consumer expectations further orient the industry toward sustainable practices. When parts are recovered and reused, they can shorten supply chains and support affordability in the aftermarket, keeping vehicles on the road longer. The local yard may become part of a regional ecosystem of distributors and repair shops that rely on affordable, reusable components.

Understanding the full local footprint requires granular data such as payroll totals, vendor spend, and tax receipts, which are not publicly disclosed for small private firms. The chapter suggests a framework for future study: collect payroll and procurement data, trace spending through Tulare’s supply chain, and assess environmental outcomes like tonnage processed and energy savings. Greater transparency would help residents gauge whether the dismantling operation contributes to resilience and sustainable growth.

For readers following the broader arc, Tulare offers a lens into how local players participate in national shifts. The case highlights the value of data transparency and coordinated regional efforts to foster workforce development and sustainable industry clusters. In short, the Tulare yard, properly supported and monitored, can serve as a modest but meaningful node in the circular economy, connecting end of life vehicles to renewed mobility, from waste to resource, and from local employment to community resilience.

Rooted Together: Envisioning Community Engagement for A&F Auto Parts R Us Dismantling LLC in Tulare

In a small California town, a dismantling and remanufacturing operation sits at a crossroads of economy, environment, and community well-being. The topic of community engagement for A&F Auto Parts R Us Dismantling LLC is not just a public relations concern; it is an ongoing practice of stewardship, local opportunity, and transparent operation. The absence of published programs invites a practical, imagined framework for how such a firm could engage neighbors, schools, workers, and local institutions through sustainability, transparency, and shared benefit.

Situated at 3531 S K St in Tulare, the site is more than a business address; it is a node in daily life and a potential collaborator with nearby schools, vocational programs, and service organizations. Accessible hours, safety demonstrations, and open days can invite neighbors to learn about scrap parts, recycling streams, and the safeguards that protect air and water quality. A robust plan might include listening sessions, internships, and site tours designed to meet local needs while maintaining safe operations.

A genuine engagement strategy starts with listening: mapping who benefits, who is at risk, and who can contribute. Local students and adults seeking skilled trades can connect with nearby vocational schools and community colleges for hands-on training in dismantling, sorting, safety, and remanufacturing. Apprenticeships, mentorships, and internship opportunities can create a local talent pipeline that supports better jobs and stronger community ties.

Transparency and dialogue help address concerns about noise, traffic, and environmental impact. Clear hours, posted safety practices, visible containment of hazardous wastes, and responsive neighbor feedback channels build trust. Open-house events, safety demonstrations, and guided tours can transform skepticism into shared understanding. Collaboration with neighborhood associations and local funders can expand educational programs and scholarships, further aligning the business with Tulare’s long-term wellbeing.

The circular economy lens makes these activities practical. Dismantling and remanufacturing keep components in circulation, reducing demand for virgin materials and lowering waste. A local workforce gains experience with quality control, recycling logistics, and compliance—skills that translate to broader regional opportunities. Apprenticeships and on-site training signal a long-term commitment to local livelihoods, helping stabilize the labor market and build community pride.

In partnership with schools and nonprofits, the site could host classroom visits, science fairs, and project-based learning around material science, sustainability, and industrial safety. While this narrative does not document a formal program for A&F, the model follows best practices: education-aligned experiences, scalable training, and measurable social impact. A listening tour could identify priorities, leading to a formal plan with quarterly open-house days, safety demonstrations, and joint recycling drives that bring residents and workers together.

Ultimately, a robust community engagement program would be measured by local employment and training outcomes, environmental benefits, and levels of neighbor participation. Public dashboards and annual reviews can reinforce accountability and invite constructive feedback. The town’s needs—education, safe neighborhoods, and environmental stewardship—are not separate from the business’s success; they are interdependent inputs to long-term viability. A well-implemented engagement strategy makes A&F a responsible neighbor, a teacher, and a steward of local resources.

For readers seeking broader context, related materials on sustainable materials management and community impact can illuminate how a dismantling operation can contribute to local resilience and economic opportunity.

Final thoughts

A&F Auto Parts R Us Dismantling LLC exemplifies how a dedicated auto parts dismantling business can significantly impact local economies while promoting sustainability. Through its operational efficiencies, extensive service offerings, and active community engagement, the company not only supports automotive businesses but also fosters a sense of community within Tulare. By choosing A&F for your auto parts needs, businesses can leverage high-quality components while contributing to an environmentally sustainable future.