A & P Auto Parts, based in Cicero, NY, has carved out a reputation as a key player in the automotive industry, focusing on the recycling of end-of-life vehicles and the sale of reusable parts. This article will delve into the multifaceted services offered by the company, unveiling its innovative business model that promotes sustainability through recycling. Furthermore, we will analyze the positive impact A & P Auto Parts has on the local economy and the broader auto industry, underscoring its significance as an environmentally responsible enterprise. Business owners and partners in the automotive sector will find valuable insights on how engaging with A & P can benefit their operations and contribute to a greener future.

How A & P Auto Parts in Cicero, NY Delivers Parts, Cash for Cars, and Recycling Solutions

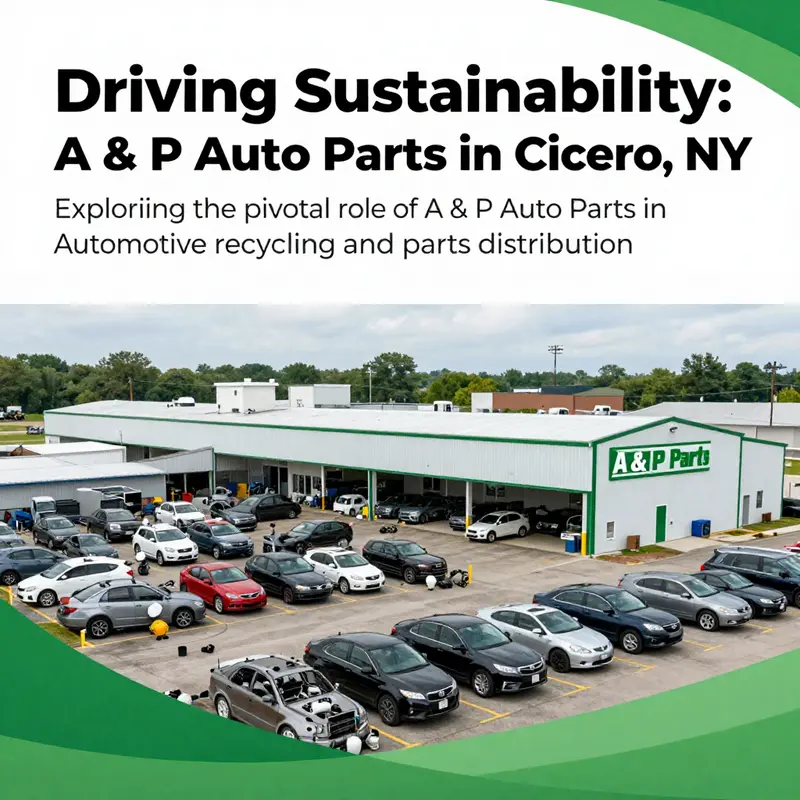

Overview of services and how they work

A & P Auto Parts in Cicero, NY operates as a regional hub for reused automotive components, vehicle dismantling, and responsible recycling. Their location at 8572 Brewerton Road functions as more than a lot of salvaged vehicles. It is an organized center where experienced dismantlers, parts specialists, and logistics coordinators work together. They serve homeowners, independent mechanics, and repair shops that need dependable, budget-friendly parts. They also handle end-of-life vehicles for owners wanting a fair cash offer and a clean, efficient disposal process.

The business model centers on reclaiming components from vehicles that are no longer roadworthy. Technicians assess incoming vehicles and identify reusable parts. Functional items go through cleaning and testing. Critical parts receive careful inspection and are cataloged. Once labeled, those parts are added to inventory and listed for sale through an online search platform. This method keeps the inventory moving and helps customers locate compatible parts faster. For repair shops, the streamlined search reduces downtime and helps projects stay on schedule.

Used parts provide a cost advantage without necessarily sacrificing reliability. Many reused components have long usable lives left. The Cicero center emphasizes parts that meet fit and function expectations. Assemblies like doors, engines, transmissions, and electrical components are evaluated for condition. Consumable items may be replaced and then included with the sale. Each item gets a record that notes fitment, condition, and any known issues. This record helps buyers make informed choices and reduces the risk of returns.

Customers interact with the inventory in several ways. A phone call to the toll-free line often starts the process. Staff can check the database, confirm part compatibility, and reserve items for pickup. The online platform allows customers to search by make, model, and sometimes VIN or part number. This saves time and avoids unnecessary trips. For those outside the immediate area, parts can often be shipped. Local buyers may choose curbside pickup to speed up the process.

A significant service is the option to receive cash for unwanted vehicles or parts. Owners who have a car that no longer meets their needs can bring it in for evaluation. The appraisers consider market demand for parts, the condition of key components, and salvageable materials. A transparent offer is provided based on those factors. If the owner accepts, the vehicle is processed with proper paperwork and the agreed payment is made. This option provides immediate liquidity while ensuring the vehicle will be used responsibly.

Processing a vehicle for cash goes beyond simple assessment. Fluids are drained and managed. Batteries are removed for recycling. Tires and wheels are inventoried for reuse or resale. Cells of salvageable metals are sorted and directed to the appropriate recycling streams. Hazardous materials are handled to comply with environmental regulations. The goal is to maximize the value recovered while minimizing environmental impact. Owners selling vehicles receive documentation that records the transaction and the vehicle’s final status.

Quality control plays a visible role at the Cicero facility. Technicians follow consistent steps when removing, testing, and storing parts. Electrical components are bench-tested where feasible. Mechanical assemblies are checked for obvious wear and damage. Windshields, lights, mirrors, and interior components are inspected for usability. Parts that fail inspection are either repaired or recycled for raw materials. This triage approach ensures that buyers receive items that meet reasonable quality expectations.

Pricing reflects part condition, rarity, and demand. Common components are often priced competitively, while rarer parts command higher prices. Customers benefit from lower-cost alternatives when compared to new, OEM counterparts. Repair shops frequently rely on these savings to keep labor costs manageable and projects profitable. For do-it-yourself enthusiasts, access to tested parts lowers restoration and repair expenses. The Cicero site supports both one-off repairs and larger sourcing needs for shops managing multiple vehicles.

Inventory management is both physical and digital. Each recovered part is photographed, described, and tagged. Technicians enter that data into the central database. The accuracy of this inventory is important for search effectiveness. When parts are claimed or sold, the database updates to reflect availability. This reduces cases of double-booking and helps maintain trust with repeat buyers. The system also enables staff to pull parts for customer holds and prepare them for timely pickup.

Because many buyers want assurance, return and exchange policies are clear. Commonly, parts sold in working condition may include limited guarantees for a short window. Non-functional or appearance-only items are sold as-is. The policies differ by part type and are explained at the point of sale. Transparent policies reduce misunderstandings and establish expectations before a purchase. Repair shops benefit from predictable terms when planning repairs around purchased used parts.

A & P Auto Parts’ role extends beyond the lot. They supply parts to a broader distribution network established over decades. This network allows them to locate rare or specific parts for customers who need them. The company’s infrastructure supports national distribution, which benefits local buyers through increased sourcing options. For customers in central New York, the Cicero location adds local access to that broader network, enabling faster solutions for many repair scenarios.

Sustainability is woven into the operations. Reusing parts reduces the need for new manufacturing and conserves embedded energy. Recycling fluids and metals prevents contamination and captures value from discarded materials. The center follows regional regulations for waste handling and recycling. That responsible practice benefits the community through reduced landfill use. It also aligns with repair shops’ interests in sourcing parts that reduce overall environmental impact.

Preparing to sell a vehicle for cash requires some simple steps. Owners should have the title and any necessary release forms. Clear identification helps speed the process. Removal of personal items and a brief description of the vehicle’s recent mechanical history also help. If large components like engines or transmissions have been recently replaced, noting that can affect the offer. Staff review paperwork and the vehicle to create a fair assessment that balances market demand and condition.

For buyers, a few practical tips help the search. Having the vehicle identification number or exact model year narrows the search. Photographs of the damaged area or part can assist staff in confirming fitment. For complex systems, bringing along the faulty part helps match connectors and mounting points. When in doubt, call ahead to reserve a part. This reduces wasted trips and gives staff time to pull and hold the item.

The Cicero operation also engages local repair shops in straightforward ways. Shops may call for parts availability or place standing requests for commonly used components. This relationship helps shops reduce lead times and maintain steady workflows. In turn, the parts center benefits from consistent, repeat business. Repair shops may also consign unusable components to the center for a small credit or disposal, creating a circular exchange of value.

Logistics and shipping options are designed to meet different needs. Local buyers get the fastest turnaround through pickup. For regional and national customers, shipping arrangements can be made. Packing and secure shipping are handled with care to prevent damage during transit. Costs vary by weight and distance, and staff provide estimates when asked. Shipping expands the practical reach of the Cicero inventory beyond the Syracuse area.

Seasonal variations influence what parts are in demand. Cold-weather seasons often increase demand for heating components, batteries, and suspension parts. Summer months see a higher need for cooling system components. That predictability helps both the parts center and repair shops plan inventory and purchases. Long-term, the center adapts to changes in vehicle populations and model lifecycles.

Safety and regulatory compliance are priorities during dismantling. Hazardous materials are identified and processed per law. Technicians wear protective gear and follow safe handling procedures. Documentation tracks the disposal of fluids and the recycling of hazardous components. This accountability protects the facility and the surrounding neighborhood. It also reassures vehicle owners that their end-of-life cars will not harm the environment.

The customer experience at the Cicero location is practical and direct. Buyers appreciate knowledgeable staff who can confirm compatibility. Sellers value fast, transparent offers for unwanted vehicles. Repair shops count on predictable inventory, sensible return policies, and helpful staff. The online search platform complements the in-person experience. Together, these elements make the location a reliable resource for parts and recycling in central New York.

As the company grows, so do opportunities for integration. Acquisitions and partnerships strengthen distribution channels. These expansions extend the range of available parts, which benefits both local and remote customers. The Cicero facility remains a crucial node in a broader network. That network provides redundancy and options when specific items are rare or in high demand.

For anyone considering using the Cicero location, expect a pragmatic approach. Calls and online searches yield quick answers. Bring documentation when selling a vehicle. Ask about testing results when buying electrical or mechanical parts. Confirm pickup or shipping details before leaving home. These steps keep transactions efficient and reduce surprises.

One example within the reuse economy is the availability of halfcut pieces. Listings like an evo-x-halfcut illustrate how partial vehicles can be sourced for extensive repairs. These halfcuts often include major assemblies that speed large restorations. They also highlight the kinds of inventory that salvage centers manage and distribute.

For immediate details on current inventory, operating hours, and the online search tool, consult the official website. The site provides the latest information and options for contacting staff directly. https://www.aandpautoparts.com

Recycling in Motion: The Circular Path of A & P Auto Parts in Cicero, NY—From Salvage to Supplying Reusable Parts

Nestled in Cicero, New York, A & P Auto Parts operates as more than a local dismantler; it is a practical demonstration of the circular economy in action. End-of-life vehicles are transformed into a reliable inventory of reusable parts, sourced, inspected, cataloged, and distributed to repair shops and DIY enthusiasts who value affordability and sustainability. This chapter traces the journey from intake to sale, highlighting how a regional network of dismantling centers, quality controls, and digital catalogs keeps parts circulating, reduces waste, and strengthens local repair ecosystems. By embracing safety, compliance, and data-driven operations, the business converts vehicles destined for scrap into lasting mobility and demonstrates how small firms can scale circular practices while supporting communities.

Local Circles, Global Flows: How A&P Auto Parts in Cicero Fuels Jobs, Sustainability, and the Automotive Supply Chain

When the phrase auto parts recycling is spoken in Cicero, it is easy to picture a yard of engines and a row of dismantled vehicles. Yet the deeper story behind A&P Auto Parts reveals a more complex, interconnected ecosystem. It is a company born in 1969 out of practical need and regional opportunity, refined through decades into a national distributor of used components and a robust dismantling operation. Its trajectory mirrors broader shifts in the automotive industry: a growing push toward sustainability, a demand for affordable repair options, and a logistics network that stitches together local repair shops with distant suppliers. In Cicero, the business is not merely a storefront or a salvage yard. It is a node in a circle that links households, garages, municipal fleets, and regional supply chains. The effect ripples beyond the fence line, reshaping how residents repair, reuse, and rethink the lifecycle of a car.

The most immediate and tangible impact is economic. A&P Auto Parts directly creates jobs across multiple fronts. In the retail portions of the operation, staff assist customers, manage inventory, and handle the coordination of parts across a sprawling catalog. Behind the scenes, skilled workers operate dismantling lines, safety systems, and sorting processes that ensure reusable parts move efficiently from end-of-life vehicles to shop benches. The employment story is not confined to the Cicero boundaries; the company’s reach extends into Syracuse and Rochester through its expanded footprint, widening job opportunities and offering more pathways for people to enter or elevate within the automotive sector. For the local workforce, this translates into steady incomes, skill development, and a clearer line of sight to long-term career prospects in a sector that constantly adapts to new technologies and regulatory requirements.

But the economic contribution does not terminate at wage supplements. A&P Auto Parts supports a wider network of local businesses by supplying affordable, reliable recycled parts that keep independent garages and repair networks operational. Mechanics who rely on used components are often small business owners or solo practitioners who must balance cost and quality to serve their customers. In many neighborhoods, the affordability of recycled parts makes essential maintenance accessible to a broader portion of the population. When a repair can be completed at a reduced cost without sacrificing safety or reliability, households have more discretionary income to spend in other areas, which in turn stimulates local commerce—from parts retailers to grocery stores to neighborhood services. The cost dynamics here are subtle but powerful. A steady supply of reused components helps shorten repair timelines and expands the capacity of repair shops to take on more vehicles, which can reduce downtime for car owners who depend on their wheels to commute, shuttle children, or run small businesses.

The influence of A&P Auto Parts on the local economy is inseparable from its role in supporting a resilient community. The dismantling center operates with a focus on safety and efficiency, always mindful of environmental responsibilities. Each vehicle that arrives for disassembly triggers a cascade of decisions: which components can be salvaged, which can be remanufactured, and which should be diverted from landfills. In this sense, the Cicero operation embodies a practical application of waste-reduction strategies that are increasingly essential across the auto industry. Salvaged engines, transmissions, and body parts are not just merchandise; they are a form of material reuse that reduces the need for new extraction, processing, and energy consumption. This approach aligns with a circular economy model in which products and materials are kept in productive use for as long as possible, slowing the rate at which valuable resources are depleted and minimizing environmental harm.

The environmental side of the story deserves equal weight. Recycling charges its own internal ledger, balancing the benefits of waste reduction against the energy and emissions that come with dismantling, cleaning, testing, and shipping parts. Yet the overall footprint is significantly reduced when a vehicle’s life is extended through reuse rather than replacement. Consider the garage that quietly relies on a lineup of dependable used components to keep customers on the road. The same garage can, with a consistent supply of vetted recycled parts, complete repairs more quickly, reduce the environmental impact of a single maintenance event, and pass savings along to customers. From a regional perspective, the impact compounds as the company strengthens its distribution network to cover Syracuse and Rochester, enabling faster delivery times and more predictable inventory for repair shops and retailers. The efficiency gains ripple through the supply chain: fewer new parts manufactured, less shipping congestion on congested corridors, and a more stable pricing environment for end users who often balance competing demands for affordability and quality.

In this light, the 2022 acquisition by Fenix Parts marks a turning point not simply for A&P Auto Parts but for the regional ecosystem in which it operates. The strategic expansion and integration of U-Pull U-Save into the network condensed a formerly fragmented landscape into a more cohesive, capable system. The acquisition strengthened the company’s position within the recycling and remanufacturing segment of the automotive supply chain and broadened its geographic reach, enabling more consistent sourcing of salvageable components and more robust service to customers. The effect is twofold: a deeper, more diversified inventory for customers and a more resilient platform for the workers who rely on steady demand for their labor. The synergy between dismantling capacity and distribution efficiency creates a feedback loop that enhances reliability and reduces the lead times that shops and dealers once had to navigate. In practical terms, a repair shop in Syracuse can access a broader catalog of tested, road-ready parts, while a shop in Rochester benefits from improved turnarounds on orders that would have otherwise required longer wait times or more expensive alternatives.

The market reach of A&P Auto Parts has grown beyond the immediate Cicero perimeter to serve a mix of vehicle owners, independent mechanics, and regional retailers. For car owners, the availability of recycled components translates into meaningful cost savings during routine maintenance and repairs. It is not merely about saving money on a single purchase; it is about preserving the ability to maintain and repair older or less common vehicles without fear of prohibitive funding. For repair shops, the steady supply of affordable parts supports a sustainable business model that can absorb fluctuations in new-car parts markets, especially when supply chains are under pressure from broader economic and regulatory shifts. The company’s approach also helps level the playing field for smaller operators who might otherwise struggle to compete with larger networks that can command more favorable terms from parts manufacturers. When a neighborhood mechanic can keep a vehicle on the road with a reliable recycled part, the customer experience improves, loyalty deepens, and the local economy keeps turning.

Beyond the direct economic and consumer advantages, A&P Auto Parts contributes to a broader cultural shift in how people think about vehicle lifecycles. The company’s emphasis on reuse challenges the assumption that a car must be replaced or heavily refurbished when components wear out. It invites a reexamination of maintenance norms, encouraging vehicle owners and repair professionals to consider what is possible within the realm of salvage-worthy parts. This mindset dovetails with ongoing conversations about resource stewardship, environmental accountability, and community resilience. The social value of such an approach is difficult to quantify in quarterly metrics, yet it resonates in the daily decisions of families who choose repair over disposal, in shops that extend the life of fleets, and in communities that appreciate how a local business contributes to both prosperity and sustainability.

The expansion in 2022 did not erase the need for careful navigation of the regulatory and competitive landscape. Environmental compliance, vehicle-recycling standards, and safety protocols govern dismantling and testing procedures, and these requirements are essential to maintaining trust with customers and partners. In Cicero and across New York State, the regulatory framework shapes the pace at which the industry can grow and modernize. The company has responded by investing in training, refining its processes, and adopting evolving best practices for handling hazardous materials, testing salvaged components, and ensuring traceability across the supply chain. This diligence protects not only the workers who operate on the floor but also the end user who buys a reused part and expects it to perform reliably on the road. The result is a business model that remains anchored to core values—safety, quality, affordability, and responsibility—while expanding its capacity to meet rising demand and to support a more sustainable automotive ecosystem.

As the industry evolves, so too does the way local economies measure success. It is no longer enough to count jobs or tax receipts in isolation. The true measure lies in the quality of those jobs, the capacity of local suppliers and repair networks to thrive, and the long-term environmental footprint of the region’s automotive activities. A&P Auto Parts demonstrates how a single enterprise can influence these dimensions in meaningful ways. By delivering affordable parts, supporting independent shops, promoting recycling, and expanding its regional network, the Cicero enterprise helps stabilize communities, empower small businesses, and push the broader industry toward a more circular, resilient model.

In practical terms, the customer experience at A&P Auto Parts blends accessibility with reliability. The company has made it straightforward for customers to inquire about parts, arrange the dismantling of end-of-life vehicles, or request specific components. A toll-free line and a dedicated website provide channels for information, pricing, and logistics that complement the tangible value of the parts themselves. The combination of a strong on-site operation and an expansive distribution network ensures that customers in the Syracuse and Rochester markets can secure needed components with minimal friction. For a repair shop or a vehicle owner, this translates into a smoother repair journey, lower downtime, and a better chance of keeping a vehicle in service rather than it being written off due to a lack of affordable parts.

The narrative of A&P Auto Parts in Cicero also raises important questions about the future of automotive maintenance and the role of local players in a national landscape. How can small and mid-sized recyclers compete with large-scale facilities while maintaining a personal touch with customers and communities? The answer lies in a combination of strategic expansion, emphasis on quality control, and an enduring commitment to environmental stewardship. The Cicero operation has shown that a local enterprise can leverage geographic advantage and a growing distribution network to deliver value not just in dollars but in capability and trust. In that sense, the company embodies a bridge between neighborhood economies and global supply dynamics, linking the day-to-day decisions of car owners and mechanics with the complex logistics of salvage, testing, and distribution that keep hundreds of thousands of vehicles in motion each year.

In closing, the story of A&P Auto Parts in Cicero is not simply about salvaged components or a regional dismantling center. It is about a living, evolving system that sustains livelihoods, enables affordable maintenance, and champions a circular approach to the automotive lifecycle. It reflects how local business leadership can adapt to change, expand its reach, and contribute to a more sustainable, interconnected industry. It also illustrates how a single enterprise, anchored in a place like Cicero, can influence the pace at which the broader automotive ecosystem moves toward more responsible production, consumption, and disposal patterns. The future remains dynamic, but the trajectory is clear: a locally rooted operation expanding its wings while remaining faithful to the values that have defined it for decades. For readers seeking more formal details about corporate milestones and market expansions, official communications from the acquiring company provide context and metrics that illuminate the path ahead. External references can help situate this narrative within the larger industry trajectory and underscore the ongoing evolution of salvage-based supply chains across the United States.

External reference: https://www.fenixparts.com/news/fenix-parts-completes-acquisition-of-ap-auto-parts-and-u-pull-u/

Final thoughts

In summary, A & P Auto Parts in Cicero, NY, not only leads in the recycling of automotive parts but also plays a vital role in the local economy and fosters sustainable practices within the auto industry. Its innovative services and commitment to environmentally friendly processes offer significant advantages to business owners seeking reliable and reusable parts. Engaging with A & P not only supports individual businesses but also contributes to a larger mission of economic growth and sustainability in the automotive sector.