The automotive industry is undergoing significant transformations, and the role of suppliers like Spark Auto Parts is pivotal in shaping its future. From their impact on retail dynamics to innovations in manufacturing, Spark Auto Parts stands out as a crucial component in the automotive ecosystem. In this exploration, we will delve into how Spark Auto Parts aids business owners, enhances global distribution, and revolutionizes maintenance practices, allowing for smarter decision-making in a competitive marketplace.

From Corner Counter to Global Line: The Role of Spark Auto Parts in Retail and Supply

Retail Identity and Manufacturing Reach

Spark Auto Parts occupies a unique position where neighborhood retail meets global manufacturing. The company’s long presence in Chicago gives it a clear local identity. Its storefront sits where customers expect to find knowledgeable help. For more than thirty years, the business has built trust through consistent service and an inventory that reflects real-world repair needs. That local reputation matters. It anchors relationships with independent mechanics, hobbyists, and everyday drivers. Those customers return because they can rely on experienced staff and parts that fit the task.

At the same time, affiliated manufacturing capabilities extend the brand beyond the store counter. A manufacturing arm focused on alloy and aluminum wheels illustrates that expansion. That division demonstrates the technical knowledge required to make critical components. It shows how a retail brand can move upstream and influence product design, material choices, and quality control. This vertical reach matters in two ways. First, it gives the retailer greater oversight of product quality. Second, it creates pathways for better margins and faster responses to market trends.

The combination of a community-oriented retail base and a technical manufacturing arm changes expectations. Customers no longer see the store as just a place to buy a part. They view it as a partner that understands where parts come from. That understanding translates into more informed conversations at the counter. It also shapes inventory decisions and how the store presents options for repairs and upgrades.

A critical part of this story is the shift toward blended sales channels. The company’s catalog is available beyond the physical street corner. Listings on an online marketplace expand reach to a wider audience. That channel increases visibility for specialty items and seasonal inventory. It also enables the business to serve remote buyers who value the store’s expertise but live outside the region. The result is a hybrid model. It keeps the strengths of local service while leveraging broader distribution.

This hybrid model puts supply chain choices under greater scrutiny. Sourcing strategies now influence both price and perceived reliability. For some components, global sourcing offers competitive cost advantages. For others, local supply reduces lead times and simplifies returns. The presence of competent in-house manufacturing gives the retailer leverage when negotiating with suppliers. It also helps maintain consistency across product lines when demand spikes.

Quality management sits at the heart of these decisions. Retailers that also control manufacturing can embed inspection criteria into production. That practice reduces variability and supports warranty policies. For mechanics who rely on consistent fit and performance, such reliability is crucial. It reduces diagnostic time and avoids repeat repairs. For consumers, it eases the purchase decision. A clear record of performance fosters loyalty and repeat business.

Operationally, the retail floor and the production line require different rhythms. Retail staff must balance immediate needs with stock planning. They handle walk-in customers and urgent requests. The factory side plans production cycles and governs material sourcing. Coordinating these functions demands clear processes and shared metrics. Inventory turnover, lead time, and return rates become key performance indicators that both sides watch closely.

Customer experience ties those metrics together. In the store, staff act as advisors. They translate technical details into actionable guidance. That human element remains valuable even as digital channels grow. Detailed product listings and accurate fitment data help online buyers. Still, many purchasers prefer confirming compatibility with a person. The retailer’s credibility depends on this nuanced service.

Reputation management also operates across platforms. In the local market, word of mouth and direct feedback build trust. Online, reviews and ratings amplify that reputation. The company’s longstanding presence has generated positive feedback across review platforms. That feedback functions as social proof. It reassures new buyers and supports higher conversion rates online.

Technology shapes how inventory and customer data are handled. Point-of-sale systems now often link to inventory management and supplier portals. That integration reduces stockouts and speeds reorders. It also enables more sophisticated planning. Predictive analytics can flag slow-moving parts and identify seasonal trends. When combined with manufacturing insight, those analytics point to opportunities for private-label offerings or targeted procurement.

In terms of product mix, a retailer like this balances commoditized parts with value-added items. Standard maintenance parts require reliable sourcing and clear fitment data. More specialized components, such as custom wheels, benefit from manufacturing experience. Those items carry higher margins but demand stricter quality control. The capacity to deliver both types of goods attracts a wider customer base. It also helps the retailer manage margin volatility that comes from price-sensitive commodity markets.

Regulatory and standards compliance also influence decisions. Parts that impact vehicle safety receive heightened scrutiny. Manufacturing facilities must meet applicable certifications and testing regimes. Retailers must ensure their supply chain respects these rules. Proper labeling and traceability become non-negotiable. For customers, assured compliance reduces risk. For professionals, it simplifies liability management.

Sourcing strategies must also adapt to market complexity. Some components are available from multiple global suppliers. Others have limited sources. The company’s procurement team evaluates suppliers based on cost, lead time, and quality. Building relationships with a diverse supplier base reduces exposure to single-source disruptions. It also opens the door to alternative spec options when markets tighten.

One arising trend is the growth of high-quality third-party suppliers who produce components compatible with major standards. These suppliers often operate in global manufacturing hubs. Retailers must vet them carefully. Third-party parts can provide cost savings without sacrificing performance. Still, they require rigorous testing and clear warranty terms. The presence of in-house manufacturing simplifies that validation. The production team can measure compatibility and performance against established benchmarks.

Service offerings round out the retail proposition. For professional users, the store supplies tools and technical accessories. For individual owners, it offers installation guidance and practical advice. Workshops and community events help bridge knowledge gaps. Such activities reinforce the store’s role as more than a parts supplier. They make it a local hub for practical automotive knowledge.

Financially, the dual model diversifies revenue streams. Retail sales produce steady, predictable cash flow. Manufacturing and online distribution introduce variable but potentially higher-margin opportunities. That mix can stabilize the overall business when one channel slows. It also enables investment in new capabilities, such as testing equipment or digital infrastructure. Smart capital allocation ensures the business can respond to supply shocks or seize market opportunities.

Human capital matters in both retail and production. Technicians, sales staff, and production managers bring different expertise. Cross-training helps. When retail staff understand manufacturing constraints, they set realistic expectations. When production teams understand customer pain points, they improve product fit. Investing in skills development creates a culture focused on reliability and innovation.

Finally, the brand’s community presence supports long-term resilience. Local engagement creates a loyal base that sustains the business during market fluctuations. That loyalty reduces sensitivity to short-term price competition. It also supports experimental offerings, like limited-run components or local pickup options for online orders. Those initiatives test new demand without heavy risk.

Throughout, the retailer-manufacturer model depends on balancing immediacy with foresight. Quick responses at the counter matter. So do multi-month production and sourcing plans. Success requires alignment across teams and clarity about priorities. When done well, the approach yields dependable parts, efficient service, and a reputation that spans neighborhoods and online marketplaces. That combination positions the company as a reliable resource for both DIY owners and professional shops alike.

For more context on how online listings extend a retail footprint, consult the store’s marketplace presence here: https://www.ebay.com/stores/spark-autoparts

For an example of wheel-focused aftermarket content that complements manufacturing knowledge, see this discussion of fitment for 17-inch rims: 17-inch rims for Mitsubishi Eclipse.

null

null

Wiring the World: The Hidden Architecture of Spark Auto Parts Trade

The phrase spark auto parts evokes a single component that ignites an engine. Yet behind that small, precise device lies a vast, interwoven system that stretches across borders, languages, and time zones. Engines start because a distributed set of creators, logisticians, and sellers cooperate as a single, living network. This chapter explores how that network operates, not just as a sequence of transactions, but as a dynamic ecosystem shaped by manufacturing prowess, digital marketplaces, regional logistics, and the careful choreography of OEM and aftermarket suppliers. It is a narrative about how a spark becomes a spark everywhere, carried along by a global choreography that keeps thousands of garages and fleets running every day.

To understand this architecture, we must begin with the manufacturing landscape that undergirds the entire enterprise. China has emerged as a central node in the production of ignition-related parts because its industrial ecosystems have matured to offer a delicate balance of scale, skill, and supply-chain discipline. In major provinces such as Zhejiang, Guangdong, Henan, and Fujian, clusters have formed that bring together raw material inputs, precision tooling, and a workforce trained for high-volume manufacturing. These clusters benefit from vertically integrated suppliers who can move from casting and machining to finish assembly within the same corridor of factories, reducing lead times and enabling tighter quality control. The result is a supply chain that can deliver consistent components at a lower marginal cost, while still meeting stringent international specifications that OEMs require for first-fit performance. The strength of this landscape lies not in a single factory, but in interconnected networks where tiered suppliers, metallurgical labs, and testing houses operate within hours of one another. This proximity fosters rapid iteration, rapid problem solving, and a level of resilience that is particularly valuable when a global disruption shifts demand patterns or interferes with logistics.

If manufacturing sets the stage, the next act unfolds through distribution channels that translate factory output into storefront stock and, ultimately, into repair bays. Global distribution for spark-related parts relies on a blend of direct OEM supply lines and robust third-party producers that specialize in aftermarket components. The OEM pathway ensures compatibility, longevity, and adherence to the original design intent, while aftermarket suppliers widen the field of options, pushing pricing, availability, and customization into sharper relief. The balance between these streams matters: OEM-aligned parts carry the weight of guaranteed interchange, whereas aftermarket components bring flexibility and innovation to meet diverse repair needs. Buyers—ranging from independent repair shops to large fleet operators—face a spectrum of choices that must be weighed against reliability, delivery timelines, and warranty terms. Digital marketplaces have amplified this complexity, enabling procurement managers to compare capacity, certifications, and production calendars across multiple suppliers in real time. The ability to access capacity on demand reduces inventory risk and helps shops respond quickly to sudden spikes in service demand, such as after a regional weather event or a large maintenance campaign.

In the modern marketplace, the distribution system is as much about information as it is about parts. Buyers seek proof of capability—production capacity, quality management systems, and traceability across batches. Certifications, testing reports, and recognized quality frameworks serve as signals that a supplier can be trusted at scale. In this environment, manufacturers in the leading clusters do more than just turn out parts; they publish data on process controls, materials, and test results that reassure buyers about consistency and repeatability. These signals are crucial when a retailer or a fleet operator must plan for recurring maintenance programs. The procurement narrative evolves from “can you supply this item when I need it?” to “can you sustain quality and availability over the long term, across batches and seasons?” The best suppliers answer with integrated systems that link production planning to inventory management, order fulfillment, and after-sales support.

A key component of this integration is the role of digital channels that connect producers to buyers. The global trade environment now accommodates sophisticated online sourcing mechanisms where buyers can evaluate suppliers on criteria that matter most in maintenance and repair ecosystems: performance consistency, geographic proximity, and the ability to scale. Platform-based sourcing enables buyers to filter by certifications, track record, lead times, and production capacity. It also helps buyers assess lifecycle costs, which include not just the price of a part but the cost of holding inventory, potential delays, and the risk of returns. In practice, this means a procurement manager can examine multiple suppliers in minutes, rather than negotiating through months of back-and-forth. The result is faster turnarounds and more predictable service levels for automotive service providers who depend on reliable parts to keep fleets on the road.

Logistics infrastructure underpins all of these activities. Modern auto parts warehousing has evolved beyond simple storage. Operators rely on dynamic space optimization, often using advanced racking and storage solutions that maximize space while preserving accessibility. Mobile racking systems, for instance, allow warehouses to adapt to varying product mixes and seasonal demand without incurring excessive building expansions. This flexibility is essential when a shop or distributor experiences peak maintenance periods. The ability to reconfigure storage layouts quickly translates into shorter pick times, reduced handling damage, and better safety outcomes. From a logistics perspective, the spark-related parts supply chain is a test case in efficient inventory management. It demonstrates how the combination of precise demand forecasting, agile warehousing, and synchronized transportation networks can shorten the distance between production and repair.

Transport networks themselves are layered and regionalized. Regional distributors maintain ample stocks within logistics hubs that provide rapid access to nearby repair shops and fleet depots. In many markets, intermodal solutions—where goods move seamlessly between road, rail, and port—become the backbone of timely deliveries. The goal is to minimize the time from the factory floor to a workshop’s shelf, ensuring a mechanic can locate the precise component quickly, test it, and install it without delay. This is particularly important for high-demand segments where even a few hours of delay can cascade into lost revenue for a service operation. The distribution network also includes reverse logistics channels that handle returns, warranty exchanges, and end-of-life recycling programs. These pathways protect value by recovering materials, reblending components for reuse where appropriate, and ensuring that waste streams are managed responsibly. In short, the trade mechanisms surrounding spark auto parts are not merely about moving units; they are about moving certainty—certainty of availability, certainty of quality, and certainty of cost.

Trade mechanisms themselves hinge on a tapestry of partnerships and governance. Manufacturers and distributors negotiate agreements that cover price, lead times, minimum order quantities, and service levels. They also develop risk-sharing arrangements to cope with volatility in currency markets, raw material costs, and shifts in regulatory regimes. The vibrant aftermarket layer adds another dimension: compatibility across different engine generations, the possibility of performance-oriented variants, and the need for clear warranty coverage. In such a setting, it is common for distributors to serve as intermediaries who consolidate orders from multiple shops and fleets, standardize packaging, and provide predictable delivery schedules. The objective here is not merely to supply a part but to deliver a service experience that shops can rely on for planning maintenance windows and scheduling dispatches. This requires sophisticated coordination, where order management, supplier performance data, and logistics visibility converge to produce dependable outcomes.

The global distribution and trade machinery also mirror the evolving expectations of buyers who operate in a digital-first environment. Buyers increasingly demand transparency—the ability to trace a part’s origin, verify its compatibility with an engine family, and confirm the authentication of the supplier. This demand has driven suppliers to implement robust supply-chain data practices, connecting production data with order status in real time. The result is not just a sale but a shared information corridor where both sides can anticipate issues, adjust expectations, and maintain continuity of service. Within that corridor, the interplay between OEM-aligned components and aftermarket options creates a rich spectrum of choices for repair professionals. Shops can select parts based on the specific service context—whether they are fitting a vehicle to original specifications or pursuing a performance-oriented upgrade. In both cases, the ability to source reliably from a single or a few trusted partners reduces administrative burden and accelerates the repair workflow.

In this expansive ecosystem, a single, well-chosen procurement decision can illustrate the broader logic of global trade. Consider how a regional distributor might source a batch of components to meet a rising servicing requirement. The distributor would weigh the scale advantages of a large Chinese manufacturing cluster against the assurance provided by suppliers with proven quality management practices and established after-sales support. They would examine transport routes, warehousing options, and the reliability of the supplier’s test data. They would also consider the broader implications for their own customers—the shops and fleets that rely on timely deliveries and consistent part availability. The outcome is a balance between cost, speed, and risk; between the assurance of OEM-fit and the flexibility of aftermarket options; between a transactional exchange and a collaborative, knowledge-sharing relationship. The modern spark auto parts network thrives when these trade decisions are made with visibility, governance, and shared incentives across the supply chain.

The real-world texture of this landscape is more nuanced than a simple map of factories and warehouses. It is a living system in which regional strengths shape global options. For example, the clustering of manufacturing in certain coastal and inland provinces creates time-zone advantages for cross-border coordination, while specialized labor pools support rapid tooling changes that accommodate new engine designs. The same system that enables mass production also allows for customization, such that a shop in one country can request a slightly altered component geometry to fit a locally popular vehicle variant without sacrificing the advantages of standardized manufacturing processes elsewhere. This capacity for nuanced adaptation is a cornerstone of resilience. It helps the supply chain absorb shocks—whether from trade tensions, port congestion, or a sudden shift in consumer preferences—while continuing to deliver reliability to service providers and end-users alike.

Embedded in this narrative is a practical reminder for anyone who manages maintenance and repair operations: the spark-related parts market rewards not just low price, but a holistic view of value. A supplier who combines scalable production with transparent data, reliable delivery, and responsive after-sales support offers a compelling proposition. A distributor who can harmonize orders across multiple shops, coordinate with regional logistics hubs, and provide consistent packaging and documentation reduces the friction that often accompanies repairs. The best partners contribute to a more predictable service economy, where repair and maintenance windows can be planned with confidence, and where the availability of high-quality parts translates into shorter downtimes and higher customer satisfaction. In this sense, the global distribution and trade mechanisms surrounding spark auto parts resemble a well-tuned engine themselves: every subsystem supports the others, and harmony among them produces smooth operation across markets and generations of vehicles.

To illustrate how these ideas connect to everyday practice, consider how a shop might navigate the online procurement landscape. Digital catalogs, supplier verification, and real-time stock checks become essential tools, enabling mechanics to assemble the right combination of OEM-compatible and aftermarket components for a given job. The process resembles a carefully choreographed supply chain dance, where an order placed in the morning might be fulfilled with a sequence of parts arriving by the afternoon, and the next-day service slot filled with confidence. This is the practical essence of the global distribution system at work: it translates macro-scale manufacturing efficiency into micro-scale service quality. And because the network is interconnected, a small decision by one participant—choosing a particular supplier due to shorter lead times or more favorable warranty terms—can reverberate through the entire chain, influencing inventory levels at partner warehouses and the speed with which service centers can respond to demand.

In acknowledging these dynamics, it becomes clear that the Spark Auto Parts ecosystem is not a single supply channel but a living tapestry of production clusters, distribution networks, and logistical practices. Its strength lies in the collaboration among diverse actors—makers, handlers, and keepers of service quality—who, together, ensure that a spark can light an engine wherever it is needed. This collaborative ethos is what sustains the reliability of maintenance in a world where vehicles travel longer, traverse more varied routes, and demand more frequent care than ever before. As the chapter closes on this exploration, the reader should appreciate two things: first, how regional manufacturing prowess and global distribution converge to support consistent, high-quality parts supply; second, how digital marketplaces and intelligent logistics turn that supply into dependable, timely service for every engine that requires a spark.

For readers seeking a concrete example of how niche markets organize around a specific catalog and a regional player, consider how a smaller, specialized retailer might curate its online presence to reflect both OEM compatibility and aftermarket flexibility. Such a retailer relies on a well-tuned mix of sourcing from capable manufacturers and offering a carefully verified range of substitutes that meet customer needs without sacrificing reliability. The approach echoes the broader principle described above: value in this space comes from the alignment of production capability, information transparency, timely delivery, and dependable after-sales support. In a world where engines depend on precise timing and perfect fit, the logic of global distribution becomes not merely a commercial strategy but a guarantor of performance across countless repair bays and service centers.

As we move forward in this article, the next chapter will deepen the discussion by examining how regional policy, environmental considerations, and evolving regulatory standards influence sourcing and quality assurance across borders. It will also explore how emerging digital tools are reshaping supplier evaluation, contract terms, and risk management, enabling all players to anticipate changes and adapt with greater agility. Until then, the underlying message remains clear: the spark that powers engines worldwide is sustained by a quiet, robust, highly coordinated trade system—one that blends the precision of engineering with the pragmatism of logistics, the certainty of OEM expectations with the creativity of aftermarket solutions, and the global reach of modern technology with the intimate knowledge of local repair needs.

Internal link reference (example of an internal resource): 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM

External resource for further reading: https://www.alibaba.com

How Spark Auto Parts Shape Maintenance, Diagnostics, and Repair Decisions

Spark auto parts are small components with outsized influence. They determine whether an engine runs smoothly or stutters, whether fuel is used efficiently, and whether emissions meet expectations. Because spark components perform the critical task of igniting the air-fuel mixture inside each cylinder, their condition and specification shape maintenance schedules, diagnostic workflows, parts sourcing, and repair economics. This chapter follows that influence from chemistry and wear to real-world repair decisions, showing how a single group of parts steers the larger practice of automotive maintenance.

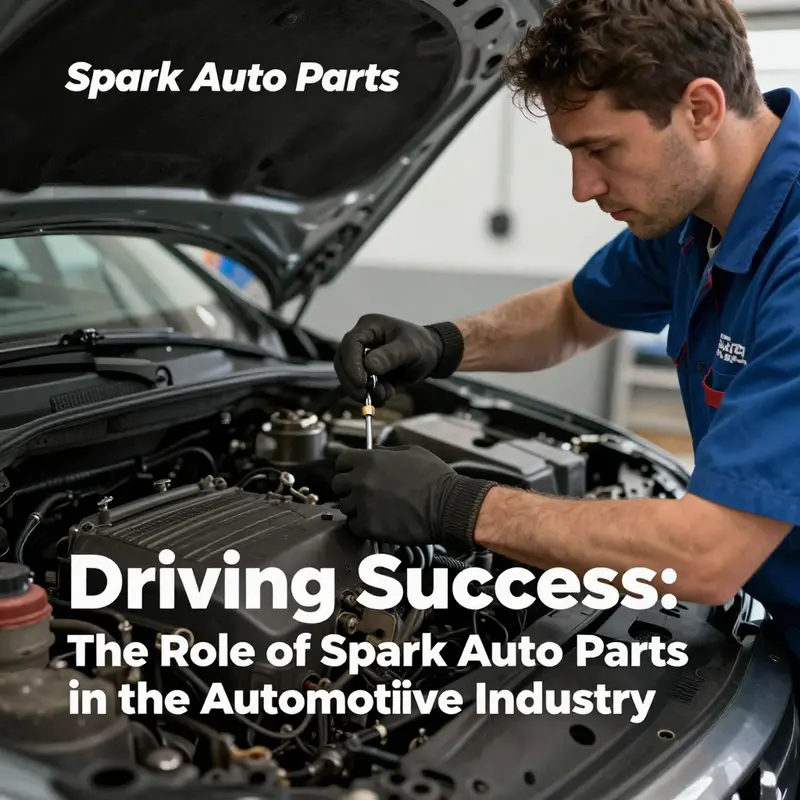

At the most basic level, the physical state of a spark component tells a story about the engine. Clean, correctly gapped electrodes indicate efficient combustion and proper fuel metering. Conversely, deposits, erosion, or insulating soot point to combustion irregularities, fuel system faults, or oil control issues. Those symptoms may present as rough idle, hesitation, or increased fuel consumption. Technicians learn to read deposits as clues. A black, sooty tip often signals a rich mixture or a weak ignition. An oil-fouled tip suggests worn valve guides, piston rings, or blow-by. A white, blistered electrode can mean overheating. Each observed condition directs further tests, informs the parts chosen for replacement, and narrows repair scope. In short, spark parts act as both functional components and inexpensive diagnostic sensors.

The choice between long-life and standard spark components has reshaped maintenance intervals. Modern materials and designs extend replacement intervals dramatically. Advances in electrode alloys and tip construction enable service lives measured in tens of thousands of miles. That reduces routine service frequency. Fewer replacements ease shop workload in the short term. Yet long-life components demand precise handling. Their fine electrodes can break if gapped improperly. Their longevity assumes correct installation torque and the right anti-seize practices in fragile cylinder heads. As a result, repairs once handled casually now require careful procedures and specific tools. Torque wrenches, proper gapping gauges, and attention to ignition coil boots become routine. For repair shops, this raises the bar for technician training and tool investment.

Selecting the correct component type affects repair outcomes. Original-equipment specifications guarantee fit, heat range, and electrode geometry that match the engine’s ignition timing and combustion profile. Aftermarket options offer variety and sometimes performance gains. Some designs dissipate heat faster, others present multiple electrodes to increase spark exposure. Those differences change how the engine tolerates ignition timing, compression, or fuel quality variations. Using an unsuitable option can cause pre-ignition, detonation, or chronic misfiring. That leads to repeat visits and deeper repairs. Thus, parts selection becomes a preventive choice. High-quality components reduce the risk of collateral engine damage and lower lifetime maintenance costs.

Diagnostics evolve with component technology. Advanced materials and new designs change failure modes. Multi-electrode tips and surface-discharge systems may show different wear patterns than traditional single-gap designs. Misfire codes can reference coil or injector issues when the root cause is electrode erosion. Modern vehicles often combine coil-on-plug ignition with long-life spark components. A failing part can damage ignition coils, or a weak coil may accelerate electrode wear. Technicians must integrate electrical diagnostics with visual inspection. Oscilloscope traces, coil resistance checks, and live misfire monitoring become routine steps alongside visual examination. That integration changes the repair sequence: instead of replacing components immediately, technicians often trace root causes through layered testing.

Inventory and supply chains also feel the effect. Shops once stocked many inexpensive, short-life parts in large quantities. Extended-life components reduce turnover, but they increase the cost per unit. Shops must balance inventory capital against quick access to the right specification. The rise of specialized manufacturers and regional producers complicates sourcing. A repair might require a specific heat-range variant or a part matched to a particular ignition coil design. When sourcing parts from outside traditional distributors, shops must vet quality carefully. Using lower-grade components to reduce immediate expense can increase warranty claims and labor costs later. Therefore, procurement strategies now favor verified suppliers and traceable parts, even if unit costs rise.

Maintenance strategies bifurcate into proactive monitoring and scheduled replacement. Frequent inspection of spark components during tune-ups remains valuable for older vehicles. For modern cars, technicians often rely on vehicle diagnostics and mile-based replacements. Yet relying solely on intervals has limits. Real-world driving and fuel quality vary. A vehicle operating under heavy load or with intermittent misfires may need earlier attention. Proactive monitoring, including compression checks and periodic ignition system scans, catches patterns that spark component inspection alone might miss. This combined approach keeps engines within design tolerances and prevents expensive downstream failures.

Repairs involving spark components frequently intersect with other subsystems. When spark parts show abnormal wear, the technician must inspect fuel injectors, compression, valve sealing, and the entire ignition system. Replacing spark components without addressing the underlying cause offers only temporary relief. For instance, a fouled tip from oil contamination often indicates worn piston rings or valve seals. Replacing the spark parts alone will not resolve oil consumption. Similarly, persistent misfires may require coil replacement or wiring harness repair. Successful repair plans often bundle services, which affects labor estimates, parts lists, and customer communication. Clear explanation of how spark part symptoms point to broader repairs helps customers understand necessary work and budgets.

Training and certification become more important as designs evolve. Technicians must remain current with torque specifications, gap tolerances, anti-seize recommendations, and the interaction between ignition coils and spark components. Workshops that invest in ongoing education reduce error rates and improve first-time fix rates. Tools that were once optional become standard. A quality torque wrench and a reliable gap gauge reduce the risk of damage and improve service consistency. Diagnostic scanners with live misfire analysis and waveform capture help isolate intermittent faults that previously required trial-and-error replacements.

For the do-it-yourself enthusiast, the shift to long-life components creates both convenience and complexity. Replacements are less frequent, but precision matters. DIYers need to understand heat ranges, correct gap procedures, and anti-seize usage. They should also know when to escalate to a professional, especially if multiple plugs show diverse fouling patterns. Misinterpreting symptoms can lead to unnecessary part purchases and failed repairs. Reliable reference information and careful documentation of the vehicle’s symptoms and recent service history improve diagnosis and prevent wasted effort.

Environmental and regulatory pressures magnify the importance of spark components. Proper ignition reduces unburned hydrocarbons, lowering emissions. A poorly firing cylinder increases particulate matter and NOx emissions. Municipal and national inspection regimes often use emission results as a proxy for engine health. A well-maintained ignition system helps vehicles meet stricter standards. This creates additional incentive for shops to prioritize correct parts and precise installation. It also provides context for consumers who face tests and fines related to emissions. Investing in quality spark components yields both performance and compliance benefits.

Looking forward, the role of spark components will change where electrification progresses. But for the vast fleet of internal combustion engines in service, their importance remains. Hybrid and high-efficiency combustion designs may demand new electrode materials or novel ignition technologies. Repair practices will adapt accordingly. Technicians will need to understand how emerging combustion strategies alter ignition stresses. For now, improved materials and precise engineering continue to extend service life while increasing the need for careful installation and diagnostics.

Practical examples clarify these themes. Consider a high-performance four-cylinder engine that returns uneven fuel economy and an intermittent misfire code. Visual inspection reveals one electrode with heavy leaded deposits, while the others look normal. That finding directs further inspection toward a failing injector or a localized compression problem. Replacing all spark components without checking injectors would likely fail to resolve the misfire. Another scenario involves swapping in a cheaper aftermarket component with a different heat range. Initially, the vehicle runs fine. Over months, the electrodes show accelerated erosion and the engine begins to knock under load. The repair then requires replacing pistons or addressing pre-ignition damage, multiplying costs. These examples underscore that spark parts are not isolated items. They integrate into a larger system of combustion, and they inform the decisions of technicians and owners alike.

Many repair shops now present inspection-driven service plans. Instead of recommending parts replacement by mileage alone, technicians document electrodes and coils, relate their findings to performance data, and propose a phased repair approach. This method reduces unnecessary parts replacement. It also builds customer trust through transparent reasoning. When replacement is required, shops select parts that balance longevity, compatibility, and cost. They also explain installation considerations, such as correct torque and gap settings. Clear communication curtails surprises and reduces the chance of repeated visits.

Finally, accessible resources help both technicians and owners make informed choices. Technical guides and authoritative articles outline specifications and installation best practices. For deeper technical reading on specifications and roles of spark components, an authoritative resource is available at: https://www.autorepair.net/repair-articles/spark-plugs/ .

For those seeking replacement engines or cores during major repairs, verifying component compatibility is essential. Reliable listings for engines and related assemblies can assist in sourcing parts that match ignition and compression needs. One example is a detailed engine listing that specifies core condition and related components. See this genuine engine listing for context: genuine JDM low-mileage 4G63T engine listing.

Throughout all these considerations, the central truth remains simple. Spark auto parts do more than strike a flame. They influence diagnostics, define repair sequences, affect inventory choices, and alter training priorities. Understanding their role is essential for effective maintenance and durable repairs.

Final thoughts

Spark Auto Parts serves as a vital player within the automotive sector, impacting various facets from retail to maintenance and manufacturing innovations. Understanding its multifaceted influence empowers business owners to make informed decisions that align with market demands. By leveraging quality parts and recognizing distribution effectiveness, businesses can not only enhance customer satisfaction but also ensure operational efficiency. As the automotive landscape continues to evolve, the significance of Spark Auto Parts will only grow, reinforcing its position as a trusted partner for automotive suppliers and practitioners alike.