Carbon fiber fenders have become a sought-after upgrade for Mitsubishi Lancer Evolution X enthusiasts, merging performance enhancements with stunning aesthetics. As the automotive market increasingly shifts towards lightweight, high-performance components, carbon fiber fenders stand out for their impact on vehicle dynamics and styling. This article will guide business owners through five key aspects: their performance benefits, various design options, installation considerations, legal and regulatory aspects, and a market analysis, ensuring a comprehensive understanding of why carbon fiber fenders are an essential consideration for anyone involved in Evo X upgrades.

How Carbon Fiber Fenders Transform Evo X Performance and Handling

Lightweight Efficiency That Changes How the Evo X Drives

Fitting carbon fiber fenders to an Evo X is more than an aesthetic choice. It alters the car’s dynamics in measurable ways. Carbon fiber composites deliver a high strength-to-weight ratio, so swapping steel or plastic fenders for carbon reduces mass where it matters. That reduction is most valuable when it lowers unsprung and rotational weight. Unsprung weight sits with the wheels, tires, brakes, and suspension components. Every pound removed there lets the wheels follow the road more precisely. The result is quicker response over bumps, improved traction, and a chassis that feels more alive to driver inputs.

Reducing mass up front or at the corners has cascading benefits. Less weight improves straight-line acceleration because the engine has less mass to move. It also shortens braking distances slightly, because brakes have less inertia to overcome. But the most noticeable gains often come through handling: reduced pitch under braking, less nose dive, and snappier turn-in. These are subtle shifts, but for a performance car bred for rally and track work, they are meaningful.

Stiffness, Feedback, and Chassis Behavior

Carbon fiber panels are stiffer than many aftermarket plastics and significantly stiffer than thin stamped steel of old designs. This stiffness helps maintain consistent panel geometry under load. When fenders do not flex as much, the suspension geometry remains more predictable during hard cornering. Improved predictability translates to steady mid-corner balance and more accurate steering feel. Drivers often report a crisper, more communicative chassis after such upgrades.

The damping characteristics of carbon also matter. Composite structures can absorb high-frequency vibrations differently than metal. That translates into reduced buzz and a more controlled feel at the contact patches. This does not make the car softer; rather, it refines the feedback presented to the driver, which can reduce fatigue on long track days.

Aerodynamics and Thermal Management

Carbon fiber fenders are frequently offered in ventilated or louvered designs. These are not only stylistic. Functional vents expel hot air from the engine bay and wheel wells. That flow reduces underhood temperatures and helps keep brake assemblies cooler under repeated heavy use. Cooler brakes maintain friction performance longer, delaying fade during sustained track sessions.

On the aerodynamic side, fender shape affects how air moves around the front wheels and down the car’s flanks. Carefully designed vents and smooth composite surfaces reduce turbulent flow that would otherwise increase drag. Wide fender designs, when executed correctly, allow for cleaner transitions between wheel arches and side skirts, stabilizing airflow along the car’s sides. The combined effect can improve high-speed stability and reduce lift, making the Evo X feel planted at speed.

Wide-Body Functionality: Grip, Clearance, and Tuning

One of the most direct performance advantages of aftermarket fenders is enabling a wider track and larger tire fitment. Wide-body carbon fenders create space for wider wheels and tires, wider offsets, and more negative camber where needed. Wider tires increase mechanical grip. They also modify slip angle behavior, giving the car more predictable limits before the rear steps out. For drivers chasing lap times, this ability to run wider rubber without rubbing is crucial.

Wider track width also improves lateral stability by lowering the lateral load transfer for a given cornering force. In plain terms, the car resists rolling and keeps more weight on the outer tires, extracting more grip. Pairing fenders that add track width with suspension adjustments—springs, anti-roll bars, and alignment—lets a tuner refine balance precisely.

Durability, Repair, and Real-World Considerations

Carbon fiber is strong, but its failure mode contrasts with metals. While steel bends and can be hammered back, carbon tends to crack or delaminate under certain impacts. For a track-focused Evo X, the tradeoff is usually worthwhile: composite panels withstand repeated stress without the fatigue issues of thin metals. Still, they require different repair techniques and can be more expensive to fix after significant damage.

Corrosion resistance is another practical benefit. Carbon does not rust, which helps maintain appearance and fit over years. This quality matters for owners in wet or salted-road climates, where metal panels may slowly degrade.

Fitment, Installation, and Setup

Performance gains depend on careful installation and integration. Carbon fenders may require slight bodywork, trimming, or fender rolling to clear larger tires. Mounting points need inspection; factory brackets sometimes require reinforcement or modification for a perfect fit. Poor alignment of panels can create aerodynamic drag or allow debris to enter critical areas.

Suspension tuning often goes hand in hand with new fenders. Because wider tires and altered track width change load distribution, reworking spring rates, dampers, and anti-roll bars optimizes the benefit. Engineers and tuners treat carbon fenders as part of a system. The payoff is a car that not only looks purposeful but also behaves that way on track.

Trade-offs: Cost, Legalities, and Everyday Use

Carbon fiber fenders represent a premium upgrade. Material costs and labor for accurate molds and finishes push prices higher than stamped metal or simple plastic alternatives. Buyers should budget for professional installation and paint matching if a painted finish is desired.

Some wide-body kits can exceed local regulations for vehicle width or for how far bodywork projects beyond the original silhouette. That impacts whether a car remains street legal in certain areas. Owners should check local laws before committing to aggressive flares.

Finally, consider daily usability. Very low-slung, race-inspired arches may collect road grime differently and necessitate more frequent cleaning. They can also change how the car behaves over speed bumps or steep driveways if not paired with proper ride height and fender-to-tire clearance.

Integrating Fenders Into a Coherent Performance Strategy

The real value of carbon fiber fenders emerges when they fit into a broader plan. Combined with wheel and tire upgrades, brake cooling improvements, aerodynamic addenda, and suspension tuning, they deliver cumulative gains. Aesthetics follow function; a wider, ventilated Evo X often looks purposeful because the modifications genuinely improve performance.

For owners considering a conversion, reviewing compatible wide front fender options helps align goals with reality. One useful resource covers a range of wide front fender choices and fitment styles for the Evo X: group-a-mitsubishi-evo-x-08-15-spec-v-wide-front-fenders. Use such references to compare profiles, venting strategies, and finish options.

Adopting carbon fiber fenders should be a decision based on intended use. For track-focused Evolutions, the handling, cooling, and weight benefits are tangible. For street cars, choose finishes and fit that preserve comfort and legality. In all cases, integrating the fenders with suspension, wheel, and brake upgrades unlocks their full potential.

End of chapter content.

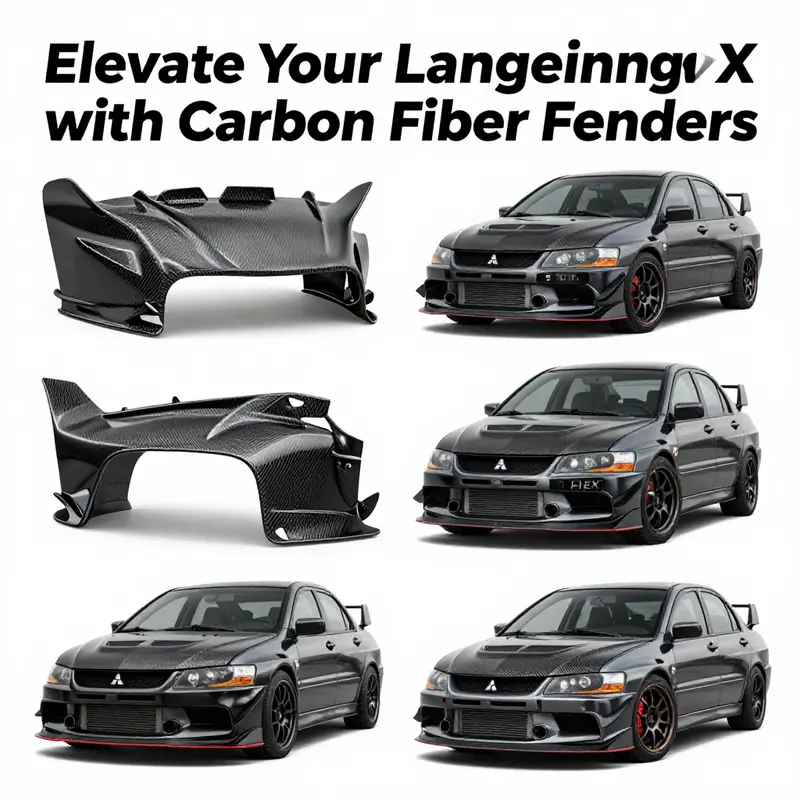

Bending Light, Steering Weight: Design Variations in Carbon Fiber Fenders for the Evo X

The Mitsubishi Lancer Evolution X is a machine that invites a conversation about balance—between stiffness and compliance, between raw aggression and refined efficiency. In that dialogue, carbon fiber fenders emerge not merely as components to swap in, but as deliberate statements about how a high-performance car can meet both track demands and daily usability. The three core design variations—OEM replacement, widebody, and ventilated or performance-oriented configurations—each carry a distinct philosophy. They shape not just the car’s silhouette, but its behavior in corners, its cooling pathways, and the way the chassis speaks to the road. To understand these variations is to appreciate how lightweight composites can preserve original aerodynamics while expanding potential in speed, stability, and even its visual language on the street or on the track. The Evo X becomes a canvas where engineering choices translate into tangible, measurable change, even if those changes happen on a scale that is surprisingly subtle to the casual observer.

OEM replacement fenders present a philosophy of integration. They are designed as a direct, one-to-one upgrade from the factory sheet, preserving the car’s original lines and the balance of its air flows. The fit is precise, the dimensions align with the bumper and doors, and the effect is a clean, almost seamless transition from stock to premium upgrade. What these fenders sacrifice in sheer drama they gain in predictability. They reduce weight compared to steel or heavier plastics, but they do so without altering the car’s footprint or the way the fender interacts with the underbody aerodynamics. This makes OEM replacement variants ideal for daily drivers, owners seeking an “OEM+” feel, or restorers who want to maintain authenticity while shaving off the inertia of heavier components. The result is a down-to-earth improvement: sharper response, quicker turn-in, and a more direct feel through the steering, all while preserving the Evo X’s familiar stance. This is the choice for purists who want a refined upgrade that respects the factory blueprint rather than rewriting it.

Widebody fenders, by contrast, announce themselves with a forceful stance and a widened stage for mechanical drama. Extending outward from the stock flares by several millimeters, these pieces push the track width wider, allowing for wider wheels and tires that can generate more grip and more decisive cornering. The functional payoff is not merely cosmetic. Wider tires can translate into greater lateral grip, more stable line entries, and a more confident exit from tight bends. Carbon fiber keeps the net unsprung weight down, so the suspension can respond more crisply to the road’s micro-variations. The visual impact is unmistakable: a car that looks ready for the circuit even when parked on the street. But it also demands careful consideration of fitment and geometry. The wider profile can affect fender-to-wheel clearance, the relationship with the brake ducts, and the need for precise alignment with the front bumper and side skirts. In this category, the fenders become an integral part of a broader aero strategy, underscoring the Evo X’s identity as a weaponized road car. The engineering challenge lies in maintaining structural integrity and paint quality across the larger surface while ensuring that the extension remains harmonized with the car’s lines rather than jarring the eye. Enthusiasts drawn to the most aggressive stance often select this path when their intent heads toward track days or show weekends where the car’s presence is part of the performance narrative.

Ventilated or performance-oriented fenders embody the interplay between cooling, airflow management, and aero discipline. These designs integrate functional vents or louvers that channel hot air away from the wheel wells, brakes, and, in some cases, components in the engine bay. The logic is straightforward: in sustained high-load use, heat is a performance enemy. By giving hot air a defined exit while controlling the path of incoming air, ventilated fenders can contribute to lower brake temperatures and more stable suspension behavior during repeated high-speed stints. Functionality here does not merely support reliability; it informs the car’s dynamic character. A fender with a purposeful vent can emphasize a race-inspired edge and communicates, even before the driver presses the accelerator, that this Evo X is built to endure the heat of spirited driving. Some advanced configurations go further, incorporating scoops that draw cooler air toward the engine bay, effectively integrating with the car’s overall cooling strategy. The trade-off, again, is a shift in appearance toward a more aggressive, performance-focused look. The shape and placement of vents influence not only aesthetics but the car’s drag profile and front-end stability. For track enthusiasts, ventilated variants offer a meaningful reminder that maintenance and performance are mutually reinforcing goals, especially when the car operates near the upper limits of its mechanical envelope.

The fusion of these design approaches with the Evo X’s existing architecture highlights an important truth: carbon fiber fenders are not simple add-ons. They are engineered to respond to a car that thrives on precision—precise steering feedback, deliberate throttle modulation, and a balance that rewards confident inputs. The layup schedules, resin systems, and the weave orientation used in carbon fiber fenders matter because they determine stiffness, impact resistance, and fatigue performance. The best implementations minimize added mass while maintaining structural resilience, a careful optimization that preserves the car’s nimbleness and its ability to accept aggressive suspension tuning. In practice, this translates to quicker turn-in, more linear weight transfer, and a smoother adaptation to varying road textures. It also means a more predictable behavior envelope at the limit, where drivers rely on consistent feedback to extract maximum grip. These are not merely cosmetic or even purely performance-oriented benefits; they are the product of thoughtful engineering that respects the Evo X’s chassis dynamics and the driver’s evolving expectations.

Real-world fitment and installation considerations shadow every decision about which fender design to choose. OEM replacement variants typically offer the simplest path to upgrade: minimal modification, straightforward alignment, and an outcome that mirrors factory geometry. Widebody options demand attention to wheel offset, fender mounting points, and possible trimming or rolling to accommodate a wider wheel and tire package. Ventilated designs, aside from their cooling advantages, can complicate the survey of airflow around the wheel well and the integration with other aero components. Paint and finish are rarely afterthoughts; carbon fiber requires proper prep, clear coats, and UV protection to retain gloss and prevent yellowing or micro-cracking over time. The goal remains consistent: to deliver a seamless, durable surface that stands up to daily exposure and the harsher demands of track use. It is also worth noting regulatory realities. In some regions, the extra width introduced by widebody fenders can trigger street-legal compliance issues, hinging on protrusion rules and overall vehicle width. Builders and owners who navigate these constraints must weigh the visual and performance gains against potential legal scrutiny and the broader implications for insurance and warranty coverage.

Aesthetics. The Evo X’s carbon fiber fender options allow owners to sculpt a unique visual narrative without sacrificing the car’s inherent aerodynamics. The weave pattern, the depth of the clear coat, and the harmony with the rest of the bodywork all contribute to a cohesive look. For many, the purpose is not to craft a mere statement but to forge a refined balance between form and function. When the fenders are correctly integrated with other attributes—bumpers, side skirts, rear wings, and diffuser components—the car’s silhouette becomes a coherent expression of purpose and engineering. In this sense, carbon fiber fenders are not just components; they are statements about how far a modern performance car can travel when its weight is carefully pruned and its air flows are consciously guided.

The decision process for Evo X owners is highly personal. Some seek the understated elegance of OEM replacement fenders, trusting that weight savings can be felt in daily driving while preserving a familiar sense of balance. Others chase a more provocative look and the tangible benefits of a broader track and heightened cornering stability that widebody designs offer. A final group prioritizes cooling and heat management, where ventilated variants provide a measurable advantage during extended sessions on a track or a scorching summer road course. In each case, the chain from design to road is a careful one, where understanding the vehicle’s goals, the driving context, and the budget matters as much as the aesthetic impulse. This is why the Evo X, even after years of evolution, remains a platform where these fender variations continue to spark dialogue among enthusiasts who value engineering excellence, weight efficiency, and a bold, race-inspired presence on both street and circuit.

For enthusiasts who want a bolder stance and optimized aero balance, there is a path through the Group A Evo X spec V wide front fenders. This option illustrates how a design can simultaneously push performance and shape identity, aligning the car’s mechanical edge with a striking visual statement. The broader lesson is clear: carbon fiber fenders are more than skin in the wind. They are a core design decision that invites a deeper conversation about how weight, aerodynamics, and thermal management come together to redefine what the Evo X can be in any given context. As owners weigh daily practicality against weekend adrenaline, the right choice becomes a personal calculus anchored in philosophy as much as in physics.

External resource: https://www.alibaba.com/product-detail/In-Stock-Evo-X-Carbon-Fiber-Fenders-Ventilated_1600794783162.html

null

null

Regulatory Roadmap for Evo X Carbon Fiber Fenders: Compliance, Risk, and Road Reality

The allure of carbon fiber fenders for the Mitsubishi Evo X is undeniable. Light as a rumor and precise as a racecar, these panels promise reduced unsprung weight, sharper steering feel, and a silhouette that telegraphs performance long before the car reaches the corner. Yet every upgrade of this kind sits at a crossroads where engineering ambition meets the rules that govern the road. To navigate this landscape with clarity, it helps to move beyond the glossy finish and into the regulatory framework that defines what can legally roam public streets, what must stay on the track, and how owners can balance performance goals with responsibility to safety, insurance, and other road users. The Evo X, a machine bred for dynamic capability, becomes even more compelling when you understand how its fenders fit into a broader system of compliance, testing, and oversight that shapes the practical value of these components.

From a legal standpoint, the majority of carbon fiber body components, including fenders and fender flares, are not typically classified as OEM or compliant parts in many jurisdictions. In the United States, for instance, regulatory bodies and building codes do not routinely recognize aftermarket carbon fiber panels as standard or street-legal replacements. This isn’t a blanket prohibition so much as a caution: in many regions, the absence of formal certification or explicit DOT/ECE approval can complicate vehicle inspections and even vehicle registration. Vendors often acknowledge this gap in their disclaimers, underscoring that these parts are primarily intended for track use, show cars, or off-road applications rather than daily commuter duty. The practical implication is simple: installation may alter the vehicle’s appearance and performance, but it could also affect compliance status at inspection time, complicating the path to a clean bill of road-worthiness during routine checks or compliance audits.

One of the most straightforward mechanical consequences of wider or oversized fenders is a change in the vehicle’s footprint. Many carbon fiber fenders are designed to widen the track or accommodate broader tires, sometimes by roughly 20 millimeters or more per side compared with OEM configurations. While this creates a more aggressive stance and can improve cornering grip, it can also push the vehicle beyond legal width limits in certain jurisdictions. The result isn’t merely a matter of aesthetics; it touches the safety envelope. Wider fenders interact with crash geometry, air flow, and wheel travel in ways that can influence stability, steering response, and tire contact with the fender under edge-of-limit conditions. In the worst-case scenario, noncompliant width can trigger enforcement actions, affect crash dynamics assessments, and complicate insurance coverage if an incident occurs.

A more formal consideration is safety certification. For a component to carry the stamp of street legality, it often must undergo safety and emissions certification to demonstrate that it meets recognized standards. In practice, many carbon fiber body parts produced by independent makers do not carry formal certification from major authorities such as the DOT or ECE. This absence of explicit certification does not necessarily imply subpar quality; rather, it means that the part’s compliance with every operating condition is not guaranteed by an established certification process. In some cases, manufacturers may provide fitment specifications and engineering analyses, but those do not replace the rigorous testing and approval pathways that street-legal components require. Without such certification, insurance providers can view the parts as a non-standard modification with uncertain safety validation, which raises the possibility of claim denial or adjusted settlements should an accident occur where unapproved parts contributed to outcomes.

These regulatory realities translate into real-world consequences for Evo X enthusiasts who crave performance upgrades. The decision to install carbon fiber fenders should come with a clear understanding of local regulatory expectations, as well as a plan for legally navigating inspections, registrations, and potential modification disclosures. It also means recognizing that the upgrade is not merely bolt-on hardware; it is a legally relevant alteration to the car’s body geometry, weight distribution, and airflow. The ownership experience becomes a balance between engineering ambition and civic responsibility.

For many drivers, the line between street-legal and track-ready is drawn not by a single regulation but by a mosaic of rules that can vary from state to state, and even between municipalities within a state. Some jurisdictions maintain strict width limits for street vehicles, others enforce more permissive standards depending on the vehicle class and vintage. In some regions, emissions and safety testing frameworks may be invoked for structural components that interact with the vehicle’s crash performance. The absence of formal certification can become a practical hurdle when these parts are installed. In such contexts, owners often choose to limit use to closed courses or sanctioned events, where the regulatory scrutiny is less intense and the performance benefits can be realized with reduced risk to compliance.

Professional installation and careful integration become more than a matter of fitment when legal considerations come into play. The process may require more than cosmetic alignment; it can entail fender rolling or trimming to maintain proper clearance, ensuring the panels do not rub on suspension components or tires during full suspension travel. Paint matching and finish durability assume heightened importance once provisions for road legality are in question. A misstep here is not merely an aesthetic blemish but a potential indicator of non-conforming installation to inspectors who examine overall vehicle integrity. The goal, then, is not simply to attach lighter, stiffer panels but to ensure that those panels are integrated in a way that preserves—or at least does not compromise—the vehicle’s lawful operating envelope.

For readers weighing the regulatory implications, the practical advice rests on due diligence and a staged approach. Start by researching local and state regulations governing vehicle width, aftermarket body components, and any required inspections. Speak with qualified body shops or tuners who have navigated similar projects and can document installation procedures, fitment tolerances, and required cosmetic or functional adjustments. Retain receipts and documents that verify the materials used, the thickness and weave of the carbon fiber, and the engineering notes that outline how the part interacts with the vehicle’s structure. This documentation can be invaluable if questions arise during an inspection or an insurance review.

If you are exploring the broader range of fender options available for the Evo X, you may encounter a wide-front variant designed to accommodate larger wheels or more aggressive tire packages. For readers curious about this option, an example of the wide-front design is described in community catalogs and shop pages that catalog how these fenders alter the vehicle’s stance and geometry. The specific path you choose should reflect not only your performance targets but also your willingness to navigate the legal landscape they inhabit. A careful balance favors a car that performs well and remains compliant or clearly categorized for non-street use, depending on your intentions and local rules. For those curious about a wide-front Evo X fender option in the catalog, you can explore further through the page group-a-mitsubishi-evo-x-08-15-spec-v-wide-front-fenders.

The question of insurance weaves in as a critical consideration. When a vehicle uses unapproved aftermarket parts, insurance claims can be constrained or denied if the insurer determines that the parts contributed to risk, or if the parts failed to meet safety expectations. The absence of standard certification means that coverage depends on how the policy language defines modifications and on the insurer’s risk assessment practices. Some drivers mitigate this by maintaining thorough records of professional installation, welding or drilling that may have occurred, and the protective measures used to preserve crash compatibility and occupant safety. Others opt to limit carbon-fiber fender use to non-public-road contexts, such as track days or private events, to preserve both performance gains and regulatory clarity.

In sum, Evo X carbon fiber fenders are a compelling engineering proposition that harmonize weight reduction with aggressive styling. They also demand a disciplined approach to legality, safety, and risk management. The decision to adopt such components should come with a clear plan for regulatory diligence, certification considerations, and robust documentation. It is not enough to be faster or more visually striking; the car must remain a responsibly operated machine within its jurisdiction. The integration of performance, aesthetics, and law creates a nuanced path that respects both the spirit of the Evo X and the frameworks that keep roads safe for everyone. For readers who want to see how this balance unfolds in a real-world context, the journey often starts with understanding the limits of street legality, followed by strategic choices about use cases, installation practices, and the insurance landscape, and ends with a vehicle that is as compliant as it is capable.

External perspective can help anchor these considerations. For a deeper dive into street-legal status and the certification landscape of aftermarket carbon fiber body components, see an external reference detailing certification and compliance considerations: https://www.ebay.com/itm/386752951436

Weighing the Edge: Market Realities and Material Truths of Carbon Fiber Fenders for the Evo X

In 2026, the market for carbon fiber fenders tailored to the Evo X sits at a crossroads where performance engineering meets consumer skepticism. The Evo X, a platform built for agility and aggressive handling, invites upgrades that promise real gains in balance and response. Carbon fiber fenders, when chosen with care, can reduce unsprung weight and sharpen the car’s throttle-to-turn feedback. Yet the premium price that accompanies genuine carbon fiber—especially in dry carbon formulations—means buyers must navigate a landscape fractured by mixed materials, dubious finishes, and a widening price spectrum. A recent cross-section of online marketplaces reveals a striking delta: some parts appear at a bargain-basement price, while others command a premium that reflects true material strength and precision manufacturing. This gap is not just about cost; it signals a broader shift in how enthusiasts define value in high-performance fabrications.

The core driver of this market is performance, but not performance alone. Enthusiasts are increasingly prioritizing a holistic sense of value that blends measurable gains with tangible material authenticity. The lightweight advantage is clear on paper: reducing front-end mass helps the Evo X breathe through corners, improves front-to-rear weight distribution, and enhances steering feel under aggressive load. In practice, the benefit depends on the part’s construction and integration with the car’s aero balance and braking regime. Carbon fiber’s strength-to-weight ratio remains its magnet, yet the true payoff is realized only when the component resists impact, maintains dimensional accuracy after track hours, and accepts comfortable repainting as part of a complete body-kit installation. The consumer’s mind shifts here from “look-at-me” carbon to “function-under-load” carbon, where credibility earned by material proof becomes the new premium.

Aesthetics still matter, perhaps more than ever. The dry carbon front pieces with their near-mirror surfaces convey an uncompromising, race-inspired identity that many Evo X owners crave. The craftsmanship is visible in the weave, the finish, and the absence of a thick protective coat. This purity—no surface layer to dull the weave—translates into a visual language about discipline and high-end engineering. In contrast, wet carbon products, while lighter than traditional plastics, carry a perception of compromise because their resin content and curing can introduce minor flaws if the process isn’t tightly controlled. Even when these parts look good at a glance, trained buyers examine grain alignment, edge quality, and the uniformity of resin pockets. The market’s refinement is echoing a broader automotive luxury standard: buyers expect not only performance but verifiable proof that what they’re buying aligns with the sport’s highest discipline.

The economics behind carbon fiber fenders reveal a spectrum that is as instructive as the technology itself. On one end, there are lower-cost experiences that imitate the look of carbon through FRP with a textured finish. These items might satisfy casual enthusiasts seeking a dramatic visual upgrade, but they carry the risk of degrading under UV exposure, heat, and road stress. On the other end lies true dry carbon—composed of pure carbon fiber fabric laid in a specific laminate schedule and cured in a controlled environment without a surface coating. The resulting weight reduction is meaningful, and the component’s elasticity helps it resist under-hood heat cycling during prolonged driving. This is where the real performance conversation begins: the material’s integrity under race-style stress, its compatibility with quick-release race stops, and its tolerance for minor surgical customization during installation. In the middle sits wet carbon, which delivers a compromise between cost and performance. Its resin-rich matrix makes it more forgiving to manufacture, yet denser and potentially heavier than dry carbon, which subtly shifts how the fender contributes to the Evo X’s overall dynamics.

Among buyers, the price landscape underscores a critical lesson: the market’s education curve is still steep. Market data indicate a price range from roughly three hundred dollars to well over two thousand four hundred dollars for Evo X carbon fiber fenders. That spread mirrors a broader dynamic: the proliferation of counterfeit or “pseudo-carbon” offerings versus authentic, specification-driven components. The elephant in the room is not just price, but provenance. True carbon fiber fenders carry documentation, including material certificates, curing standards, and engineering tolerances that align with OEM-like quality. In the absence of such proof, buyers risk a misalignment between expectation and performance, a mismatch that can complicate installation, compromise fitment, and erode confidence in the upgrade. The challenge is not merely to identify carbon fiber but to distinguish dry carbon from competitor-grade laminates, to recognize the absence of protective UV coatings that preserve weave integrity, and to understand how a fender’s geometry harmonizes with the Evo X’s front-end airflow and brake cooling.

The discourse around product types—dry carbon, wet carbon, and FRP faux-carbon—remains central to informed purchasing decisions. Dry carbon fenders offer the lightest weight and the best potential for performance gains because their mass is minimized and their surface is engineered for aerodynamic compatibility. They excel in track contexts where the front axle bears the brunt of aerodynamic and cooling demands, and where every gram matters for suspension tuning. Wet carbon, by contrast, presents a more accessible entry point for enthusiasts who want carbon-like aesthetics with a more approachable price tag. It can deliver meaningful weight savings over factory parts while avoiding the most expensive manufacturing steps, albeit with a higher resin content that can compromise stiffness and long-term drift resistance if not properly cured. FRP-based faux-carbon is the outlier in terms of performance potential. Its weight penalty and poorer long-term resilience under UV exposure tend to limit its appeal to casual show cars or temporary installations. The market’s wisdom increasingly revolves around the idea that value in carbon fiber is earned, not assumed, and that distinguishing between these materials requires both technical literacy and trusted sourcing.

Installations add a practical layer to market realities. High-quality carbon fiber fenders often demand professional alignment, a precise cut to fit over the factory bumper line, and careful paint-matching that preserves color continuity along the fender and surrounding panels. The process may involve fender rolling, edge refinishing, and sometimes minor changes to inner fender liners to maintain clearance with wheels and suspension knuckles. These steps are not merely cosmetic; they safeguard compound performance by preserving consistent airflow and preventing heat retention. The most discerning buyers recognize that a carbon fiber fender is an integrated component of the Evo X’s performance equation, not a standalone ornament. This recognition drives demand for brands and suppliers that offer complete packages—installation guidance, technical documentation, and after-sales support—rather than bare-part sales. In a market increasingly oriented toward “one-stop” solutions, the convergence of parts, service, and verification becomes a core differentiator. A brand that can demonstrate a material trail—from fabric roll to finished, painted fender—builds trust in a field crowded with visually similar, yet materially disparate, options. To address this need for clarity, a number of reputable forums and vendor portals emphasize transparent materials proof and standardized manufacturing practices, helping buyers make sense of the light-to-heavy spectrum in a way that aligns with their driving ambitions.

For those who crave a concrete touchstone within this evolving environment, one can look to a segment of the Evo X market that has embraced the wider stance as a functional performance path. The CS-speed-style wide fender approach, for example, illustrates how wider front fenders can accommodate larger wheels and tires while maintaining, or even improving, cornering stability at high speeds. This architectural choice is not just a matter of aesthetics; it signals a carefully engineered balance between track-ready grip and street-legal practicality. The link between wider front fenders and upgraded air management is a reminder that the best carbon fiber upgrades for the Evo X are those that harmonize weight reduction with intelligent airflow, tire clearance, and brake cooling strategies. For readers exploring this line of thought, a detailed look at wide-style, CS-speed-style wide fender options offers a perceptible blueprint for how design intent translates into real-world performance. wide-style, CS-speed-style wide fender for Evo X.

Looking forward, the industry’s trajectory points toward authenticity, verifiability, and service-oriented relationships. The most enduring brands will be those that couple high-grade materials with rigorous quality control, documented material provenance, and clear post-sale support. Consumers increasingly demand demonstration of compliance with mechanical and safety standards, predictable lead times, and the assurance that an upgrade will not compromise insurance or warranty frameworks. The market is moving toward a model where the upgrade is not a single purchase but a coordinated package: verified materials, expert fabrication, skilled installation, careful color matching, and a reliable aftercare program. In this context, the challenge for manufacturers and retailers is to articulate value beyond the initial price tag, translating weight savings and aesthetic drama into measurable performance returns on the road or track. The lesson for Evo X enthusiasts is simple: choose with intention, verify with documentation, and consider installation complexity as part of the total cost of ownership. The payoff is a more coherent integration of form and function that elevates the car’s character without compromising reliability.

External resource for deeper reading on material selection and market guidance: How To Choose The Best Evo X Carbon Fiber Fenders – Alibaba.com. This external reference provides additional context on material grading, supplier transparency, and the realities of market pricing that informed this chapter’s landscape.

External resource link: https://www.alibaba.com/product-detail/How-To-Choose-The-Best-Evo-X-Carbon_1600578956488.html

Final thoughts

The integration of carbon fiber fenders in the Mitsubishi Lancer Evolution X not only brings notable performance advantages but also enhances the car’s visual allure. As we have explored, the comprehensive benefits of these fenders—from performance gains to diverse design options and market considerations—highlight their important role in the automotive aftermarket industry. For business owners and enthusiasts alike, understanding the nuances surrounding carbon fiber fender upgrades can help in making informed decisions that align with both performance goals and legal regulations.