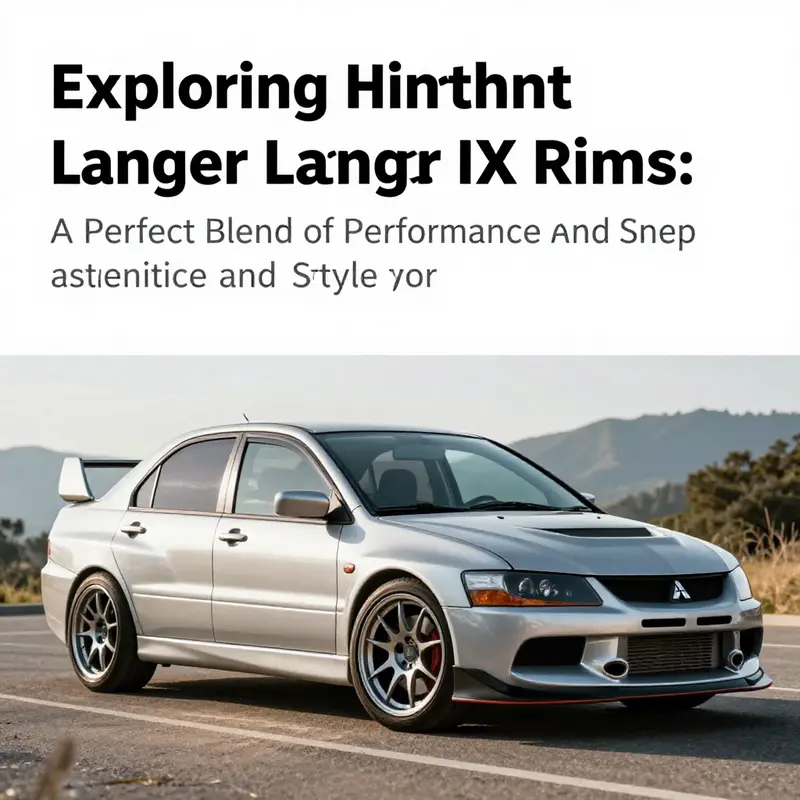

Understanding the wheels of the Mitsubishi Lancer Evolution IX (Evo IX) is essential for both enthusiasts and business owners in the automotive sector. The Evo IX is recognized not only for its unparalleled performance on the road and track but also for its aesthetic appeal. Original configurations feature striking 17-inch BBS rims, which serve as both a style and performance benchmark. Beyond the factory-installed wheels, various customization options are available that can enliven the performance metrics or visual presence of these vehicles. This article will delve into the stock configurations, popular aftermarket modifications, performance considerations, and current market trends that influence consumer preferences regarding Evo IX rims. Each chapter aims to provide business owners with a thorough understanding of how these rims can be an asset to their automotive offerings.

OEM Roots and Aftermarket Horizons: The Evolution IX Wheel Story

Wheels are more than just round metal components under a car. For the Evolution IX, they are a statement of balance—between what the engineers set out to achieve in mass production and what the enthusiast community seeks in handling, feel, and stance. The wheel package helps define how the car meets the road, how it brakes, how it corners, and even how it breathes at speed. In the Evo IX, this relationship is especially telling because the car was designed as a compact performance machine with a tight chassis, a responsive all‑wheel system, and a driver position that rewards precise input. The wheel choice, therefore, is not a cosmetic afterthought but an integrated performance decision. To understand the Evo IX’s wheel story means tracing a line from the official spec to the world of aftermarket options, where the diameter, width, and offset work together with tire technology and body design to create a distinct and purposeful driving feel.

The official configuration for the Evolution IX, as supported by multiple automotive references, centers on a wheel size of 18 inches in diameter and a width of 9.5 inches, with an offset of 22 millimeters. This combination has been consistently cited in reputable sources and reflects a careful calibration. An 18×9.5J wheel with ET22 is designed to maintain a balanced relationship with the car’s suspension geometry, brakes, and fender clearance. It offers enough room for a broad contact patch without sacrificing the ability to manage steering response, particularly when paired with a tire that complements the chassis dynamics. In practice, this spec supports a clean, flush look that preserves intended steering feel, allows adequate brake cooling, and helps keep the tire contact patch within the limits of the wheel arches. The result is a steady platform for confident acceleration, predictable cornering, and a harmonious balance between ride quality and lateral grip.

Yet the Evolution IX’s wheel story is not one-note. Some historical mentions point to a slightly different configuration for certain market-specific or edition-specific examples. In those cases, the footprint tends to shift toward a forged 17-inch wheel with a distinct finish and a different visual footprint, often paired with a particular body kit and lighting treatment that marked that model year or edition. It is important to acknowledge these variations because they illustrate how the Evo IX evolved as a living platform. The 17-inch variant is typically described in the context of limited editions or regional packages, where visual identity and ride comfort interact with warranty and chassis tuning. While these references exist, the baseline, widely corroborated spec remains the 18×9.5J with ET22. This baseline anchors the discussion and provides a reference point for both original owners and modern restomods. The OEM wheel’s form and function set the stage for how owners approach upgrades, including how much weight to add or subtract and how aggressive a tire package one aims to run without compromising the fundamental handling balance.

From a functional standpoint, the 18×9.5J ET22 wheel is a measured choice. The width of 9.5 inches supports a broad contact patch without inviting excessive scrub or rubbing in the stock chassis. The positive offset of ET22 places the wheel slightly inward relative to a high negative offset, which helps preserve steering feel and maintain the designed scrub radius. This matters when braking and turning at the limit, because the wheel’s position relative to the suspension components influences how the tire engages the road during dynamic maneuvers. With a properly matched tire, the wheel yields predictable behavior under throttle input, mid-corner load transfer, and mid-corner adjustments. The goal is to keep the handling balanced enough to inspire confidence while allowing the driver to exploit the car’s all‑wheel dynamics. In this sense, the OEM wheel size is a deliberate constraint that preserves a harmonious relationship with the braking system, the suspension kinematics, and the tire’s characteristics.

The aesthetic and functional identity of the Evo IX wheel package also hinges on how these dimensions translate into stance and road presence. In 18×9.5J with ET22, the wheel’s profile looks proportionate within the body’s fenders, producing a stance that is neither conservative nor aggressively tucked. This balance is crucial; a wheel that is too wide or too offset can push the tire beyond the intended contact area, which may degrade steering feel and mid‑corner stability. The 18-inch diameter keeps the wheel small enough to maintain adequate sidewall geometry with a performance tire, preserving ride compliance and road feedback. Meanwhile, the 9.5-inch width supports a tire that can deliver grip without overwhelming the chassis. For enthusiasts who crave a more aggressive aesthetic, the Evo IX’s wheel geometry becomes a canvas for modification—yet any departure from the OEM footprint must be approached with care to avoid upsetting the delicate choreography of power delivery, grip, and chassis balance.

Beyond the numbers, the Evo IX wheel story is about how a community interprets performance physics through form. The transition from OEM to aftermarket often centers on increasing the wheel diameter to 19 inches, which has become a popular direction for those seeking a more aggressive stance and broader tire options. A 19-inch wheel allows a larger tire footprint and a wider range of tires to optimize grip and braking capacity. It also enables designers to accommodate wider fenders and more aggressive body styling without compromising ramp angles or ground clearance. The amplified wheel diameter, when paired with wide tires, can shift the car’s feel toward sharper steering and a more immediate turn-in. However, this comes at a cost: higher unsprung weight, stiffer ride characteristics, and a greater likelihood of rubbing if the chassis is not updated with appropriate fender work or suspension adjustments. The interplay between wheel diameter, tire selection, and the car’s suspension geometry becomes a balancing act, where enthusiasts weigh the value of sharper responses against the comfort and daily drivability of the car.

In the aftermarket ecosystem, width often takes center stage. A common approach involves stepping to a 19×11 wheel with a negative offset to push the wheel outward and fill a widebody kit. When paired with a high-performance or semi‑slick tire in a 275-width class, this configuration creates a formidable contact patch and an expanded tire footprint. It is a classic recipe for enhanced lateral grip and a bold visual statement. But it also demands careful attention to alignment, fender clearance, and brake or knuckle clearance. The wheel’s offset and width must be harmonized with the car’s suspension travel, tire sidewall height, and the specific road or track environment the car will encounter. A deeper wheel can reveal more of the brake system, adding visual drama while also offering a practical window into how the braking hardware must coexist with the wheel’s inner clearance. The result is a package that, when balanced properly, delivers improved lateral grip, more precise turn-in, and a more planted sensation as the car carries speed through corners.

The practical realities of upgrading from OEM to a larger aftermarket wheel package are not purely about grip and looks. They touch the very essence of how a car communicates with the road. A heavier wheel, or one with a wider footprint, increases inertia and can dampen the immediate responsiveness that a lighter, smaller OEM wheel grants. This is part of the trade‑off that enthusiasts accept when choosing a 19-inch diameter with a broad tire. The weight penalty must be countered by selecting a wheel that uses advanced manufacturing techniques, often forged rather than cast, and by pairing it with a tire that provides torque distribution and sidewall stiffness aligned with the car’s suspension tuning. In practice, this means careful kit planning: a compatible spring and damper setup, possibly a revised sway bar geometry, and attention to braking performance, so the car remains predictable under braking and through turn transitions. The Evo IX, with its all‑wheel control logic and compact architecture, responds well to thoughtful upgrades that respect the platform’s intended balance.

As the wheel conversation evolves, it remains anchored by a few core ideas: size, weight, offset, and tire choice all converge to shape the car’s characteristics. The EVO IX’s wheel footprint, whether it sits in the OEM 18×9.5J ET22 configuration or in a broader aftermarket 19-inch setup, is a lens into the vehicle’s intended behavior. The 18-inch baseline helps preserve a comfortable ride while enabling solid grip and a balanced steering feel that aligns with the car’s chassis geometry. When the wheel diameter increases, the resulting changes in grip, steering response, and ride quality demand that drivers adjust expectations and, often, the rest of the chassis tuning. In this sense, the wheel is not merely a peripheral accessory; it is a central element of how the Evo IX integrates its performance potential with daily usability and weekend track readiness. The path from OEM specification to aftermarket experimentation reflects a broader ethos among Evo IX enthusiasts: the car invites exploration, but every modification must be read as a careful negotiation with the car’s fundamental dynamics.

For readers who want a practical starting point in navigating the Evo IX wheel landscape, consider exploring a resource that discusses OEM-style wheel options in a neutral, performance-focused context. This internal link provides a gateway to a catalog of wheel configurations that preserves the core geometry while offering alternatives that suit different goals. Accessing this page can help a reader understand how a change in wheel design—from diameter to offset to width—affects steering feel, tire choices, and overall balance. It also sets expectations for how a modern wheel upgrade interacts with the Evo IX’s distinctive all‑wheel architecture. OEM-style wheel options. The discussion that follows in subsequent chapters will unpack how these choices translate into real-world road and track performance, with attention to weight, inertia, and the tangible experience of handling under load. The Evolution IX wheel narrative is thus a blend of historical reference and practical guidance, a trajectory from the nuanced OEM footprint to the bold possibilities that define the modern interpretation of the platform.

沿着街霸轮廓的传承与进化:Evo IX轮毂改装的潜力与风格

三菱Lancer Evolution IX的轮毂,不只是轮胎的承载与地面联系的部件,更像是一枚承载历史与个人气质的载体。对于这代被称作“街霸”的车型,轮毂的选择往往在视觉冲击与性能需求之间寻求平衡。原厂在2006年的SE特别版上,推出了钻石黑涂装的铸造轮毂,配合整车的 HID大灯组,形成了系列收官版本独有的视觉与质感。这个配置并非仅仅满足日常使用的轮转需求,它还承担着让车主感受到厂商对稳定性、耐用性与美学高度统一的意义。走进改装市场,许多车主将目光投向更大尺寸的轮毂,以实现更强的路面张力与更具侵略性的外观。这里的趋势并非单纯追求数字上的放大,而是对轮毂材质、重量、偏移与轮胎组合的综合考量。更大直径通常带来更宽的轮胎,宽胎提供更稳定的抓地力和细腻的转向响应,但随之而来的是簇新体积与更高的扭矩需求、以及对制动系统与悬挂几何的再调整。因此,改装并非只是在轮圈上加上一层更亮的新装,而是一次关于整车动态极限的再定位。

车轮之道:为 Evo IX 平衡速度、操控与风格

Evo IX 的轮毂选择是一门综合工程学与视觉艺术。它既直接影响车辆的动态表现,也定义了整车的气质。选择合适的轮毂,必须在重量、刚性、散热、尺寸与偏距之间取得平衡。一个决定得当的车轮组合,能明显提升加速响应、制动稳定性和弯道反馈;反之,草率的换装可能损害底盘平衡,增加油耗并带来安全隐患。

铝合金与制造工艺是起点。相比传统铸造,高端锻造工艺能在更轻的重量下提供更高的强度和更好的疲劳寿命。对于以涡轮增压发动机和全时四驱平台著称的 Evo IX 来说,降低簧下质量能让悬挂更迅速反应路面变化,提高抓地力和方向盘的手感。锻造轮毂在赛道和激烈驾驶环境下尤为明显。它们在高应力循环下更不容易出现裂纹,能承受频繁的急加速与重刹车带来的负荷。

轮毂的直径与宽度需要与目标用途和车身结构配合。原厂相对保守的尺寸提供了一种平衡的舒适与性能表现。若追求更激进的外观与更宽的接地面,增大直径与加宽轮辋是常见做法。更宽的轮胎能提高横向抓地力,但这要求更精确的偏距(ET)控制与有时需配合轮拱调整。过度外扩会改变前后轮的轮廓投影,影响流体动力学特性与车轮间的互相作用,从而改变车身的中性转向表现。

偏距决定车轮在轮拱内的横向位置。一个合适的偏距可改善杠杆比,增强转向响应,并能保证悬挂几何在工作时不被强行拉扯。不合适的偏距会让轮胎过于靠外或靠内,导致胎肩早磨、避震杆干涉或转向回正力不足。安装更宽轮毂时,通常要同时微调偏距来维持原有几何边界。如果改装方案牵涉到宽体套件,设计师往往先通过外观设定目标,再由工程师反推合适的偏距与轮辋宽度。

轮毂的重量分布影响旋转惯量。细长而坚固的辐条设计有助于在保持强度的同时减少马力损失。较低的旋转惯量使发动机在加速时更省力。对 Evo IX 而言,这一点在赛道起步和连续弯道加速中尤为重要。合理的轮毂选择可以让涡轮响应显得更直接,传递出更强的动力连贯性。

散热是轮毂性能常被忽视的部分。激烈驾驶时,刹车系统的热量需要通过轮辋传导并散失到空气中。轮辋的开孔、辐条设计和表面处理都会影响通风效率。一个通风良好的轮毂能帮助制动器维持工作温度,减少刹车衰退风险,从而在比赛或山路驾驶情况下提供更可预期的制动表现。

除了金属与工艺,表面颜色和处理也会影响功能。不同涂层在高温环境下的耐久性不同。浅色或喷砂处理能在视觉上减少刮痕显眼性,而特殊涂层则能在盐分或石屑冲击下延长轮毂使用寿命。但任何外观升级都必须考虑实用性。抗腐蚀涂层与定期保养,远比单纯追求视觉效果更能保护轮毂的长期性能。

轮胎匹配是另一个关键环节。轮毂宽度直接决定可选轮胎剖面,进而影响接地形态和侧壁响应。低剖面高性能轮胎提供更直接的转向反馈,但牺牲一部分吸震性。相反,高剖面轮胎能改善日常驾乘舒适性。对 Evo IX 的使用场景需明确:若以赛道为主,选择更宽更低的组合;若以街道驾驶为主,则应兼顾转向灵敏与舒适性。

在追求外观极致化时,常见的是增加轮毂直径到更大规格。更大轮毂能带来强烈的视觉冲击,但也会改变滚动直径。保持接近原厂滚动直径对于保留变速器换挡逻辑和速度计读数很重要。如果直径变化过大,车辆的传动比和电子速度感应可能需要重新校正。换装前应计算轮胎外径差异并评估对底盘与动力传递的影响。

装配与调校流程不容马虎。从轮毂的偏心距标注,到中心孔的配合度,再到螺栓或螺母的规格,每一项都关系到安全。合适的安装扭矩、专业的动平衡、以及完工后的四轮定位,可以确保车辆在行驶中不会出现振动或不规则磨耗。安装大型轮毂时,检查制动卡钳与轮罩的间隙同样关键,避免在极端路况或全镇力制动时出现干涉。

外观层面,轮毂是车主表达风格的核心元素。通过颜色、辐条造型与轮辋饰面,轮毂能把一台 Evo IX 打造成复古风、战斗派或极简主义的街头作品。车身颜色、车身贴膜与轮毂色调之间的协调能增强整车的视觉语言。轮毂不再只是机械配件,它成为车主个人审美的延伸。

然而,美学不应以牺牲安全为代价。加宽轮毂与轮胎时,必须考虑转向器强度、轮毂螺栓应力与悬挂承载能力。轮辋宽度和偏距带来的杠杆变化会放大路面冲击力至懸吊部件,长期来看可能导致零件提前疲劳。因此,理想的改装是跨学科的工作。车主、轮毂供货方与改装技师应共同评估设计、材料与安装细节。

维护方面,定期检查轮毂的表面及内侧结构非常必要。高速行驶后的热循环会使金属微观结构发生变化。早期发现裂纹或腐蚀能避免灾难性失效。清洁时使用中性清洁剂与软刷,避免酸性化学物质侵蚀涂层。对于经常在潮湿或含盐环境行驶的车辆,采取防腐蚀措施尤为重要。

最终,选择轮毂是一次权衡与取舍。你可以以提升性能为首要目标,也可以将视觉冲击放在首位,但理想的结果应让两者互补。对 Evo IX 来说,最成功的改装往往不是极端的单点强化,而是通过精确计算与细致工艺,实现一个和谐且可靠的整体。这个整体能在弯道中更加从容,也能在街头吸引目光,而这一切始于对轮毂每一项参数的认真对待。

更多关于原厂与改装轮毂的选择细节,可以参考一则与轮毂相关的配件信息:brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans.

在接下来的讨论中,将把焦点延伸到与轮毂配合的制动与悬挂升级策略。那些调整能最大化轮毂改装带来的好处,并帮助你把一辆已被细心调校的 Evo IX,转变为既快且稳定的真正战车。

从传承到性能:Evo IX 轮毂市场演变与车主偏好解析

三菱 Lancer Evolution IX 的轮毂市场,既有对原厂意义的固守,也有对极致性能的不断追求。作为一款在车迷心中占据特殊位置的车型,Evo IX 的轮毂选择从一开始就不仅关乎外观。它同时决定了操控、刹车冷却、加速响应与整车的动态平衡。多年发展下来,轮毂领域的变化清晰地反映出改装文化与技术进步如何共同塑造车主偏好。

经典情怀依然存在。许多收藏者和忠实车迷倾向于保持原厂风格,或选择高度还原的替换件。这类需求通常不是为了追求极限性能,而是为了保值和历史完整性。原厂轮毂代表了车型设计时期的美学与工程理念。对于希望保留行驶手感与外观平衡的车主,原厂尺寸与偏距通常最为合适。若你需寻找与原厂相近的备件,网上仍有专门的原厂轮毂套件供应,可以作为恢复车辆出厂状态的首选,例如可参考原厂 R18 轮毂套件的相关资源。

与此同时,改装市场的主流方向已经从单纯的“看起来更大”转向“看得见且可量化的性能提升”。车主现在更注重轮毂带来的综合收益。几个明显的偏好体现了这一点:更大直径、更宽轮圈、轻量化材质和更严格的质量认证。更大直径和更宽轮圈可以提供更大的轮胎接地面积,从而提升机械抓地力和横向稳定性。但尺寸放大也带来代价,诸如更高的旋转惯性、可能的牵引力曲线改变,以及更高的悬挂传递力。成熟的改装者会在外观与力学需求间找到平衡,而不是盲目追求最大尺寸。

轻量化几乎成为不可逆的潮流。减少簧下质量能够改善悬挂响应与转向灵敏度,这对以弯道能力著称的 Evo IX 尤为重要。随着制造工艺的发展,流行的选择从传统铸造,渐进到高强度旋压工艺和锻造变形技术。旋压及锻造在保证强度的同时,大幅降低重量。这类轮毂在极限操控时,能显著缩短加速时间,改善制动力分配,并减少轮胎非弹性变形。因而,许多驾驶者愿意为这些工艺支付溢价。

但材料的探索并未止步于铝合金。高端玩家开始尝试碳纤维轮毂。碳纤维在减重方面具有天然优势。它能在更低重量下维持或提高强度与刚性。这对追求赛道表现的人群具有强大吸引力。缺点同样明显:成本高昂、生产一致性与抗冲击能力需严格检验。碳纤维轮毂在市场上仍属于小众选择,更多是为追求极限性能的用户准备。

品质认证如今成为购买决策的核心因素之一。轮毂不像普通外观件那样容忍失误。轮毂承载横向力和热应力,任一失误都可能带来严重后果。因此,车主在选购时会优先考虑通过权威认证的产品。认证不仅是质量保障的象征,也是对材料与制造工艺检验的证明。合格的认证可以减少长期使用中的失效风险,也能在出现事故或纠纷时提供重要依据。

设计趋势上,我们看到两条并行的发展。其一是“复古与尊重原型”——包括保留经典辐条、传统色系与原厂外观语言。其二是“功能化造型”——将散热、重量分布和应力路径纳入设计核心。现代表现形式常常是在辐条断面、轮辋内侧结构与通风孔设计上做文章。更好的散热能延长制动系统工作窗口,也能减少长时间激烈驾驶后的热衰减。

对 EVo IX 车主而言,轮毂的选择还要考虑制动器改装后的间隙问题。许多提升刹车性能的改装会使用更大的卡钳与更厚的刹车盘,进而需要更大的轮毂容积以保证避让。因而,轮毂的内凹度(offset)和刹车间隙成为重要参数。错误的偏距可能导致轮胎擦拭、转向牵拉或过度应力集中。专业的改装方案会同时调整轮距、轮圈宽度与偏距,确保动态表现与零件兼容性。

轮胎匹配是另一项常被低估的关键。轮毂更宽并不总是意味着更佳抓地力。匹配合适的胎宽、扁平比和结构,才能把轮毂优势转化为实用的抓地力与操控回馈。例如,过低的扁平比会降低乘坐舒适性并增加破损风险。轮圈与轮胎的组合必须考虑路面类型、用途与驾驶风格。许多硬核玩家会同时调整车轮定位角度、悬挂参数与轮胎气压,以求更精准的弯道表现。

市场教育也在悄然改变消费者期望。社群、车友会和赛事的传播,让更多车主了解轮毂的工程学意义。消费者不再单纯以视觉效果为导向。他们开始问及制造工艺、认证、材料规格与工程测试数据。愿意花更多预算的用户,通常有明确的目标。他们可能在赛道表现、日常可用性或平衡两者间做权衡。厂商与零售商也因此更加注重透明化信息的提供,列明轮毂的重量、负载指数与适配建议。

成本与回报之间的权衡始终存在。高端轮毂能提升车辆动态,但也带来保险、轮胎费用与潜在维修成本的上升。另一方面,原厂或复刻件在长期持有价值方面优势明显。许多车主会把轮毂选择作为车辆用途的直接反映。日常通勤者偏向稳妥、耐用与舒适优先的配置。周末赛道使用者则会偏好极致轻量与强刚性的轮毂方案。

未来趋势可以从两个方向预测。其一是技术下沉:曾经只在顶级套件中出现的制造工艺,会被更广泛地采用。成本下降后,更多车主将能负担得起高性能轮毂。其二是可持续与智能化:材料回收、生命周期评估与制造过程节能会成为行业讨论点。智能化则可能表现为轮毂结构与车载系统的交互,例如更精细的轮速监测与热管理策略。

最后,社区文化仍是推动市场的隐形力量。对 Evo IX 的偏好深受圈内意见领袖影响。一个令人信服的改装案例,往往能在短时间内成为流行趋势。那些既保留车型灵魂,又能在性能上带来实质变化的方案,更容易被社区采纳。因此,任何打算在 Evo IX 上改装轮毂的车主,都应在性能目标、车辆用途和预算间做出清晰判断。权衡这些因素,并优先选择有认证、适配良好、并能提供长期保障的产品,通常能带来最理想的驾控体验。

Final thoughts

The investigation into Mitsubishi Lancer Evolution IX rims reveals a landscape filled with both tradition and innovation. From the original BBS wheels that define the Evo IX’s character to the expansive array of aftermarket options available to cruise enthusiasts, the choices made in rim selection can dramatically affect the vehicle’s performance and visual appeal. Business owners should note the significance of catering to both stock restorations and custom modifications, as the demand for personalized aesthetics continues to rise. Standing out in the rigorous auto market requires an understanding of these trends, ultimately leading to stronger customer satisfaction and sales growth.