For business owners in the automotive aftermarket industry, understanding the intricacies of the Mitsubishi Lancer Evolution X front bumper is essential. As both an aesthetic and performance component, the choice of material directly affects the vehicle’s weight, aerodynamics, and overall durability. Each chapter of this article explores key aspects: from the leading material technologies like fiberglass, thermoplastic urethane, and carbon fiber, to the performance parameters that highlight weight reduction and aerodynamic efficiency. Additionally, we will discuss the critical considerations of durability and impact resistance, and conclude with insights on installation and fitment to ensure seamless integration. Together, these insights will enable you to better serve the needs of your customers and enhance their driving experience.

Under the Skin of Speed: EVO X Front Bumper Materials

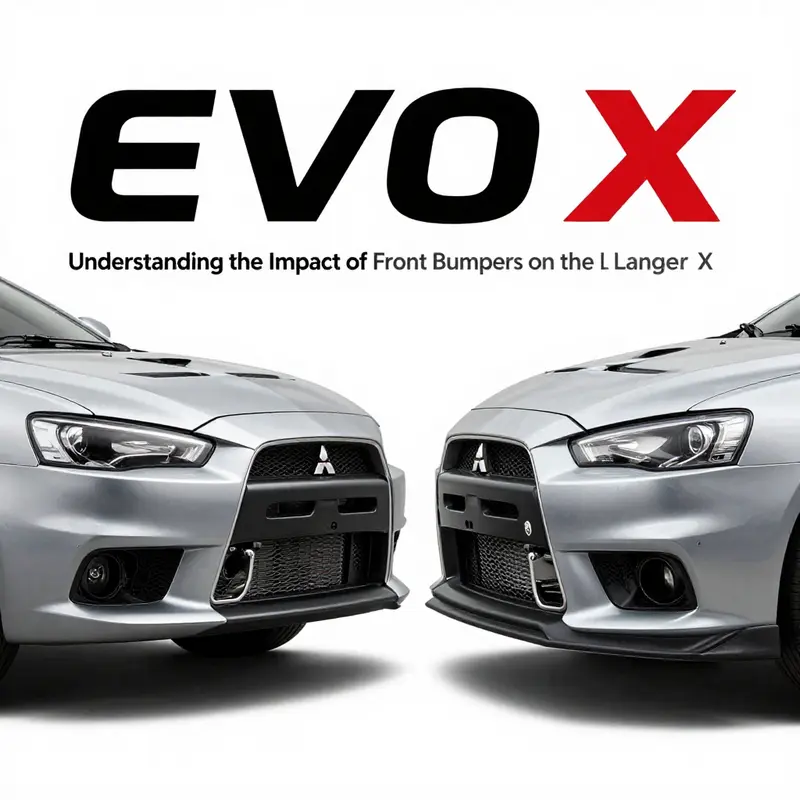

The EVO X front bumper sits at the intersection of aerodynamics, aesthetics, and impact resilience. It is more than a cosmetic cover; it is a shaping element for airflow, cooling, and energy management at the car’s wide front. In both stock and tuned contexts the bumper defines the vehicle’s stance, performance envelope, and daily practicality. The material choice—OEM-style plastics, FRP, TPU, ABS, or carbon fiber—dictates how the bumper behaves under heat, scuffs, and high-speed loads, and how easily it can be repaired or replaced. The following chapter surveys the material landscape for Evo X front bumpers, from accessible FRP and ABS options to premium carbon fiber and hybrid blends, highlighting trade-offs between weight, rigidity, cost, and fitment.

Raw materials and performance: FRP (fiberglass-reinforced polyester) is widely used in aftermarket bumpers for its balance of cost and moldability. It tolerates aggressive styling and complex shapes; with modern resins its durability can be tuned. TPU offers energy absorption and flexible impact resistance for urban driving, with slightly higher cost but improved scuff resistance. ABS provides a factory-like baseline—sturdy, paint-friendly, and predictable. Carbon fiber delivers weight savings and stiffness for weight-conscious builds; however, price, brittleness risk, and repair complexity demand careful design and protective load paths.

Hybrid composites blend carbon with fiberglass to balance weight and cost, enabling strong, resilient panels that still offer significant weight reductions relative to full FRP. Fitment and finish require careful manufacturing and quality control to ensure OE-like mounting points and consistent color matching. In practice, the bumper should work together with the car’s cooling system, shutter assemblies, and undertray to minimize drag and maximize stability. The supply chain, particularly East Asian composites hubs, can affect lead times and cost, making value-oriented choices important for enthusiasts and shops.

Conclusion: The material choice for the Evo X bumper is a function of intended use, budget, and tolerance for maintenance. Carbon fiber suits track or show cars; FRP and ABS fit daily driving with cost-conscious practicality; TPU adds impact tolerance for rough urban driving; hybrids offer a middle ground. The goal is to choose a panel that preserves OE geometry, fits cleanly, and integrates with the car’s aero strategy.

Aeroform and Edge: How the EVO X Front Bumper Channels Speed, Cooling, and Handling

The front bumper of the Mitsubishi Lancer Evolution X sits at a curious crossroads where aesthetics meet physics. It is not merely a face that grants the car its aggressive identity; it is a carefully engineered interface between the car and the air, an element that can tilt the balance of grip, cooling, and steering response when the speedometer climbs. In the most capable builds, the bumper becomes a performance actor, its design choices shaping how air travels around the front fascia, how heat exits from the engine bay, and how the car behaves at the limit. To understand its performance parameters, we begin with materials, because the way a bumper behaves under stress is as much about its composition as its shape. Options like fiberglass-reinforced polyester, thermoplastic urethane, ABS plastic, and carbon fiber each bring a distinct mix of weight, rigidity, impact resistance, and cost. FRP bumpers are common in the aftermarket world for a reason: they offer a strong curve of rigidity and impact resistance with relative ease of manufacturing. They deliver a predictable, solid response in everyday driving and sprint events alike, a reliable baseline that many enthusiasts use as a platform for further refinement. Thermoplastic urethane, by contrast, introduces notable flexibility. TPU bumpers absorb light impacts more gracefully and resist minor abrasions that occur in urban driving or in crowded staging areas on track days. ABS sits between these extremes, offering OEM-level compatibility in terms of fitment and painting, with a balance of durability and cost that appeals to many builders who want a clean, factory-like look without overpaying. Then there is carbon fiber, the lightest, sturdiest end of the spectrum. Carbon fiber bumpers can shave a meaningful amount of weight from the vehicle, often around a 30% reduction compared with traditional FRP parts. The structural integrity comes from the high-temperature tolerance and stiffness of automotive-grade carbon composites, which helps improve handling, reduce unsprung weight, and contribute to sharper throttle response and quicker steering on the track. Each material carries implications for the bumper’s performance envelope, but the real magic happens when form and function harmonize in the wind tunnel of real-world driving. Aerodynamic optimization begins with shaping that guides air smoothly around the corners of the bumper. EVO X front bumpers have been designed with curved profiles and integrated airflow channels that actively manage the boundary layer as the car accelerates. The goal is not to push air aside with brute force but to channel it in ways that reduce drag and generate downforce where it matters most. The reported performance gain in drag reduction can be as much as 15% compared with standard OEM bumpers in well-designed packages. That reduction translates to steadier high-speed stability, more predictable front-end behavior in crosswinds, and a more confident feel when the car charges toward the redline on a straightaway. The integrated channels also help keep the front tires planted by smoothing airflow over the wheel arches and around the fenders, which can lessen lift-induced separation at the front of the vehicle. This is not simply cosmetic optimization; it is a measurable shift in how the front of the car interacts with the air at speed, a key piece of the overall dynamic puzzle when the Evo X is tuned for track days or aggressive street use.

Cooling and thermal management emerge as equally critical in the narrative of performance. The EVO X front bumper typically features larger air intakes and strategically placed vents that draw cooler ambient air toward the radiator, intercooler, and engine bay. When the engine is pushed into high-demand situations—for example, during extended highway runs, track laps, or rally-style stages—engine temperatures climb quickly if air flow is not effectively managed. A well-designed bumper helps maintain a stable operating temperature by accelerating heat extraction from the front of the vehicle. In practical terms, the improved cooling can be quantified as a noticeable uptick in cooling efficiency, sometimes cited as up to a 20% improvement in engine cooling performance relative to OEM parts under strenuous driving. The cooling improvement supports more consistent power output and resilience during repeated high-load events, preventing heat soak that can shave horsepower and enclosure performance. The shaping of vents and ducts must also consider the surrounding components, including the intercooler positioning and the support structure behind the bumper. When these systems work in concert, the bumper becomes part of a thermal management strategy rather than a passive cover. The result is an integrated approach where aerodynamics and cooling reinforce each other rather than compete for space and airflow.

High-speed stability follows naturally from that combined emphasis on airflow management and thermal control. The EVO X’s performance ambitions are not only about cutting drag or extracting heat; they are about how the chassis feels as it traverses the late-gear corners at triple-digit speeds. A bumper designed with aero balance in mind works with the car’s other body kit components—spoilerc boards, side skirts, and underbody panels—to sculpt a cohesive airflow footprint. When the front end holds a clean, well-managed wake, the rear end receives less turbulent air, allowing the suspension to work more predictably and the tires to maintain grip with reduced yaw influence. The overall effect is improved stability that translates into steadier steering input and enhanced cornering confidence, particularly on a track where every percent of downforce and drag reduction translates into faster lap times. Yet this performance story is not a one-note tale of lightness and drag curves. It also hinges on durability and how the bumper handles real-world contact. Carbon fiber bumpers promise exceptional weight savings and rigidity, but their downside can be brittleness under heavy impact. In contrast, FRP and TPU bumpers tend to be more forgiving if a collision occurs, absorbing energy and reducing the risk of catastrophic failure. The trade-off shapes the decision for most enthusiasts: track-focused builds might prioritize carbon fiber for weight and stiffness, while daily drivers or street-oriented builds might favor FRP or TPU for durability and a more forgiving response when unplanned contact occurs. Installation and fitment considerations further influence the performance equation. Reputable aftermarket bumpers are designed around precise fitment, often marketed as easy installation with minimal modification requirements. The better the fit, the more consistent the performance outcomes, because gaps and misalignments can disrupt airflow paths and compromise both aero effectiveness and cooling. Given the complexity of a modern Evo X bumper, installers pay attention to the alignment of the bumper with the grille, fenders, and headlights, along with the mounting points that connect to the underlying crash structure. A precise fit ensures the airflow channels remain unobstructed and that the cooling ducts deliver uninterrupted air to the intended destinations. The question of durability complements the fitment narrative. While carbon fiber offers outstanding strength-to-weight benefits, the manufacturing reality demands careful design to avoid brittle failure on sharp impacts. Advanced FRP constructions can deliver a balanced profile of stiffness and resilience, while TPU can introduce a degree of flexibility that protects against minor impacts encountered in crowded city streets or parking lots. In the end, performance is a composite story—one where the bumper’s material choice, aerodynamic geometry, cooling strategy, and installation precision combine to determine how a car feels when the throttle is pressed to the floor and the road demands the most from its front end. The lure of an upgrade is not only the look but the promise of a more confident, composed, and connected driving experience. For those exploring genuine, OEM-leaning options, there is value in choosing a bumper that mirrors the design intent of the original while offering modern material performance. A genuine option tailored to the Lancer Evolution X platform preserves the alignment and fitment fidelity that enthusiasts rely on when dialing in aero balance and cooling efficiency. See for example a genuine front bumper option designed for the CZ4A Evolution X platform, which preserves the intended geometry and integrates with the car’s radiator and intercooler layout in a way that aftermarket variants sometimes approximate but seldom match in precise fit. Mitsubishi CZ4A Lancer Evolution X front bumper genuine. This kind of fitment fidelity, when paired with a carefully selected material strategy, helps ensure that the bumper’s performance parameters translate into real-world gains rather than theoretical benefits alone.

The discussion would be incomplete without acknowledging the broader ecosystem of validation and certification that supports these claims. Detailed supplier data from reputable marketplaces confirms that many Evo X front bumpers are designed to meet OEM standards for safety, durability, and performance. While the specifics vary by supplier and product line, the core message remains consistent: the combination of advanced materials, aerodynamic shaping, and precise manufacturing can produce a bumper that improves efficiency, cooling, and handling without compromising safety. These validations are essential for enthusiasts who want to push their Evo X beyond stock performance while maintaining reliable operation under track or rally conditions. The synergy between design intent and real-world performance becomes most apparent when the vehicle operates at the edge of its capabilities, where even small improvements in airflow, heat management, and structural integrity can yield meaningful, repeatable benefits.

As with any performance component, the choice of bumper should be guided by the intended use and the vehicle’s overall build. A track-focused Evo X benefits from the weight savings and stiffness of carbon fiber, which help with throttle response and front-end rigidity under high load. A daily driver or weekend warrior, however, may favor a FRP or TPU bumper for its forgiving impact characteristics and more straightforward repairability. In all cases the bumper is part of a system, not a standalone upgrade. Its performance is enhanced when it is harmonized with the front grille layout, intercooler routing, radiator sizing, and the underbody airflow management. When these elements are aligned, the Evo X front bumper does more than embellish the car’s silhouette; it becomes a critical contributor to stability, cooling resilience, and the driver’s confidence at speed. The narrative of performance parameters is thus not a single line of numbers but a spectrum of outcomes that emerge from material science, aerodynamic engineering, thermal management, and meticulous fitment. Enthusiasts who study this intersection often report a tangible sense of precision—how the steering responds to steering torque, how the car tracks mid-corner airflow, and how the cooling system maintains steady performance during sustained high-load driving. That sense of precision is what makes the Evo X front bumper a meaningful upgrade, offering a concrete channel through which aesthetics and performance negotiate their shared space on the road and on the track.

External resources and supplier data provide one path to validation, offering a window into the design principles that inform modern bumper construction. For readers seeking to corroborate performance claims or to explore OEM-aligned options, a trusted supplier page provides a useful starting point for understanding fitment, material options, and the real-world implications of different constructions. As with any aftermarket modification, due diligence is essential to ensure alignment with local regulations, safety standards, and the overall health of the vehicle’s performance envelope. The EVO X front bumper, with its combination of aerodynamic finesse, cooling capability, and material-driven dynamics, remains a compelling focal point for anyone seeking to elevate both the look and the capability of their car. When chosen with intention and installed with care, it becomes more than a cosmetic upgrade; it becomes a calculated improvement in how the car breathes, moves, and holds the road at speed.

External link: https://www.alibaba.com/product-detail/YH-FOR-LANCER-EVO-X-Carbon-Fiber_1601384752484.html

Forged for the Front Line: Durability and Impact Resistance in the Evo X Front Bumper

The front bumper on a Mitsubishi Lancer Evolution X does more than frame the face of the car; it is a first line of defense against road hazards, a key contributor to aerodynamic balance, and a keeper of the vehicle’s resale and daily reliability. In the Evo X, where performance is a blend of aggression and precision, durability is not just about surviving a curb strike or a low-speed scrape. It is about sustaining shape, function, and appearance through thousands of miles and a spectrum of climates. The material that forms the bumper becomes the deciding factor in how the component behaves when subjected to the everyday stress of urban driving, the occasional high-speed gust of track-focused driving, and the silent, invisible wear of UV exposure and thermal cycles. A strong bumper that performs reliably at the edge of engineering tolerance can maintain alignment with the headlights, ensure proper airflow to the intercooler and radiator, and preserve the intended aerodynamics that keep the car stable at speed. In a project focused on evo x front bumper construction, the durability and impact resistance of the chosen material are the quiet, consistent voices guiding design choices and owner expectations alike.

Material selection for the Evo X bumper is fundamentally a study in trade-offs. Among the most common options are ABS plastic, fiberglass-reinforced polyester (FRP), polyurethane (PU), and carbon fiber. Each material brings a unique set of properties that influence how the bumper will react when it is bumped by a curb, kissed by a parking-lot post, or pressed into by a stray piece of debris at highway speeds. ABS plastic is widely favored for its robust impact resistance relative to its mass, its easy repairability, and its stability across a broad temperature range. ABS can absorb minor impacts through a combination of its ductility and resilience, which helps prevent outright cracking in everyday collisions. For a street-driven Evo X, a well-engineered ABS front bumper provides a reliable baseline: it resists deformation, maintains color with proper UV protection, and lends itself to repair techniques that are accessible to typical workshop environments. Its thermal stability, while not as low in weight or as stiff as carbon fiber, offers a practical balance that reduces long-term maintenance headaches for daily drivers.

Fiberglass, or FRP, is another common choice because it delivers an attractive price-to-performance ratio. It has a stiffness that helps retain aerodynamic shape, which is essential for bumpers designed to manage airflow at speed. The trade-off with FRP is clear when it endures impact: it cracks more readily than ABS under low-speed encounters with concrete or curbs. This brittleness isn’t a fatal flaw, but it does complicate repairs and can necessitate more involved resin work, sanding, and refinishing to restore the original contour. In daily-use scenarios, a robust FRP bumper can perform exceptionally well, but owners must acknowledge that a sharper impact or repeated low-speed contacts can lead to progressive damage that is harder to patch than an ABS counterpart. From the perspective of durability, FRP sits in a middle ground: it offers strong rigidity and shape retention at a moderate cost, but its vulnerability to cracking in certain impact scenarios requires careful handling and, ideally, professional refinishing when damage occurs.

Polyurethane occupies a somewhat different niche. PU bumpers are celebrated for their flexibility and impact absorption. They are more forgiving of minor dings and scratches, and their resilience under temperature swings makes them well suited to varied climates. PU’s elasticity translates into a bumper that can deform slightly and then spring back, reducing the likelihood of cracking when minor collisions occur. For owners who live in areas with harsh winters, fluctuating temperatures, and frequent parking-lot maneuvers, PU delivers long-term maintenance advantages. It is also easier to repaint or touch up than FRP or carbon fiber, a practical consideration for those who want to preserve a factory-like finish without frequent refinishing. The durability narrative for PU, then, emphasizes a balance between cosmetic longevity and practical resilience in the face of daily use.

Carbon fiber stands at the high end of performance materials. The allure is unmistakable: a bumper that is significantly lighter yet capable of exceptional tensile strength. In the Evo X ecosystem, carbon fiber bumpers can reduce weight by roughly 30 percent compared with FRP equivalents, a meaningful delta when the goal is to lower unsprung weight and improve handling, braking response, and acceleration. In aerodynamic terms, carbon fiber bumpers are often engineered with performance-oriented contours that can contribute to modest drag reduction—up to about 15 percent in some track-focused designs—and enhanced downforce at high speeds, aiding stability and tire grip during high-G cornering. Yet carbon fiber’s strengths come with caveats. It is more brittle than FRP or PU under severe, sharp impacts, and its repair challenges can be more complex and costly. This brittleness is mitigated in high-quality, automotive-grade carbon fiber configurations through careful ply orientation and resin systems, but the potential for catastrophic cracking under severe impact remains a consideration for enthusiasts who intend to push the car to its performance limits. In high-speed or track environments, carbon fiber shines because its lightness and strength translate into performance gains that can be tracked and measured in lap times and fuel economy. For street use, the premium nature of carbon fiber must be weighed against the realities of road hazards and curb contact, where a tougher, more forgiving material can be preferred to minimize maintenance downtime.

The comparative durability narrative does not end with material properties alone. Real-world longevity depends on how the bumper is engineered, integrated, and maintained within the car’s overall system. Fitment matters; a bumper that aligns tightly with the bumper beams, radiators, and lip spoilers will distribute impacts more evenly and avoid stress concentrations that can lead to cracking or sagging over time. The installation methodology—whether it relies on OEM-style fasteners, brackets that maintain precise spacing, or compatibility with a quick-release system for easy access to the engine bay—directly influences durability in practice. Additionally, the finish and protective coatings play a role. UV exposure, chemical exposure from road salt, and thermal cycling can degrade surface coatings and underlying composites. A bumper with a robust protective coating or resin system will fare better over years of exposure, maintaining color, gloss, and impact resistance. These factors—fitment, installation, coatings—are the quiet determinants of durability that turn theoretical material advantages into real-world resilience.

Across the spectrum of use cases, the most durable Evo X front bumper is not simply the one with the highest strength in a static test. It is the one that maintains its shape, continues to fit precisely with the vehicle’s structural rails, and preserves its aerodynamic profile after countless encounters with everyday obstacles and occasional aggressive driving. For daily driving, polyurethane or ABS deliver a practical blend of toughness, flexibility, and ease of repair. If the aim is to optimize for track days or high-speed stability, carbon fiber offers meaningful benefits in weight and aerodynamic potential, provided the owner accepts the higher initial cost and the more challenging repair landscape. Fiberglass remains a viable option for those balancing cost and performance, but owners should anticipate the possibility of cracking in tougher impact events and plan for professional refinishing when needed. In every case, the durability story hinges on careful selection, thoughtful engineering, and honest assessment of driving habits and road conditions.

To connect this durability-focused discussion with concrete parts and options, consider the Evo X front bumper as part of a broader ecosystem of performance hardware. The front bumper does not exist in isolation; it is part of an integrated design that includes the bumper cover, the underlying bumper beam, and the aero elements that shape airflow and downforce. A front bumper designed for durability must harmonize with these neighboring systems, ensuring that an impact does not force the entire grille assembly or cooling ducts out of alignment. That is where the choice of material interacts with manufacturing precision. Advanced FRP products sometimes incorporate technologies like reinforced resins that help crack resistance, while high-quality PU formulations can offer improved flexibility without sacrificing rigidity. In the care and maintenance of these components, a routine inspection for microcracks, UV-induced chalking, or resin delamination can extend the bumper’s life, preserving both appearance and function.

For readers who want a tangible sense of a bumper option within the Evo X ecosystem, there is a distinct front-bumper choice that reflects this blend of performance and durability: Evo X front bumper option. This particular pathway emphasizes a balance of stiffness, impact absorption, and fitment that aligns with how most owners actually use their cars. The option is designed to accommodate the car’s frontal architecture while allowing for careful customization of intakes, canards, and lower lips that influence both aerodynamics and impact behavior. Choosing an option that emphasizes a robust, well-finished surface layer and accurate alignment with the bumper support structure will typically yield the most durable results for a wide range of driving scenarios. For an example of how such a choice can translate to the user experience, you can explore this Evo X front bumper option that reflects the balance between performance and practicality.

In closing, durability and impact resistance for the Evo X front bumper emerge from the interplay of material science, engineering design, and real-world driving. ABS provides a sturdy, repair-friendly base for everyday use, PU adds forgiving resilience for varied weather and parking-lot life, FRP offers a strong, shape-retaining option at a reasonable price, and carbon fiber elevates performance with significant weight savings and aerodynamic potential—though with heightened costs and a more demanding repair workflow. The most durable choice ultimately depends on the owner’s priorities: daily reliability, track-ready performance, or a balanced compromise. As a piece of the Evo X performance puzzle, the front bumper embodies how a carefully chosen material can translate into a more predictable driving experience, healthier aero performance, and a bumper that stays aligned with the car’s goals year after year.

For readers seeking broader context and dissenting viewpoints on material performance, the journey through durability continues with additional resources and real-world case studies that illuminate how different environments shape bumper behavior over time. External resources provide a wider lens on material behavior in automotive applications, complementing the Evo X-specific discussion with insights into long-term durability under diverse road conditions. External resource: https://www.alibaba.com/product-detail/YH-FOR-LANCER-EVO-X-Carbon-Fiber_1600435712237.html

The Front Bumper Equation: Fitment, Materials, and Aerodynamics in the Evo X

The front bumper of a Mitsubishi Lancer Evolution X is more than a cosmetic face; it is a carefully engineered interface between the car and the road. In the Evo X, the bumper plays a pivotal role in shaping aerodynamics, managing cooling, and guiding air to and around the front-wheel and brake assemblies. It also anchors the vehicle’s stance and attitude, contributing to the perception of speed even when the car is standing still. When a driver begins to upgrade, the bumper becomes a geometry that must harmonize with the chassis code CZ4A, the factory geometry that defines compatible years and variants. The process of choosing, fitting, and fastening a new bumper is a blend of engineering and art, where weight, stiffness, and airflow all dance in tandem with the car’s overall balance. The decision is rarely about chasing the lightest part alone or the most aggressive look; it is about preserving and enhancing the Evo X’s proven handling characteristics while unlocking the potential for a sharper footprint on the street and the track.

Material choice is the most visible decision, but it sits on top of a deeper conversation about how a bumper behaves in everyday driving and in the demands of performance. For enthusiasts who want a direct upgrade, the primary options fall into four broad families: fiberglass-reinforced polyester (FRP), thermoplastic polyurethane (TPU), ABS plastic, and carbon fiber. FRP represents a time-tested workhorse in aftermarket bumpers. It offers a solid mix of rigidity, impact resistance, and cost efficiency. It is relatively simple to repair after a scrape or a minor impact, especially when Duraflex-type enhancements are mentioned in the specification. These Duraflex-infused FRP composites are designed to resist cracking and to maintain structural integrity after jostling with curbs or road debris. TPU is the flexible cousin in this family. It absorbs minor impacts with a forgiving give that can shield the underlying structure and paint. In urban environments or rough roads where scuffs and light hits are common, TPU bumpers tend to perform better over the long haul because their elasticity can absorb energy without transferring it into the mounting points.

ABS plastic stands as a practical middle ground. OEM-style replacements frequently use ABS for its durability, impact resistance, and ease of painting to match factory tones. The material is known for predictable behavior across temperature changes and good compatibility with factory mounting points. It strikes a balance between price and performance, making it a reliable choice for street-driven Evo Xs that don’t demand the extremes of weight savings or aero-focused tuning. The most exotic of the four options is carbon fiber. Carbon fiber bumpers target weight reduction without sacrificing structural integrity. They can be engineered to withstand high-temperature environments while trimming unsprung weight, a critical factor for handling. Carbon fiber bumpers are typically lighter than their FRP counterparts by as much as about 30 percent, a difference that translates into tangible gains in turn-in feel, steering response, and compelled acceleration, especially as the center of gravity shifts slightly upward with a lighter front end. In the best configurations, carbon fiber work synergistically with aero shapes to improve downforce and reduce drag; the aerodynamic designs can contribute to drag reductions of up to 15 percent in high-speed regimes and help maintain front-end grip at corner entry. But there is more to the story than raw numbers. While carbon fiber offers impressive rigidity and weight savings, it can be more brittle than FRP or TPU if hit hard enough, so the choice demands a clear view of daily driving realities and expected use.

The Evo X is a car that rewards purposeful design. If the aim is aggressive aero that whispers to the wind and tames airflow around the corners of the bumper, the shape matters as much as the material. Aerodynamic efficiency is not only about the bumper itself; it is about how it integrates with the fenders, the grille openings, and the angle of approach of air toward the radiator and intercooler. A well-profiled bumper can reduce drag and improve downforce without forcing a change in ride height or a host of other structural changes. In a performance-focused build, a bumper that makes space for wider intake paths and optimized ducts can help maintain cooling efficiency at high speeds, a critical matter for track use. The front end, after all, is the first point of contact for air, and the bumper’s geometry can influence how effectively air is directed to the cooling system and how that air then exits the underbody and around the wheels. These considerations create a chain reaction: lighter materials can reduce inertia, aerodynamic refinements can improve stability, and all of it comes together to alter how the Evo X negotiates a corner and returns to straight line flow.

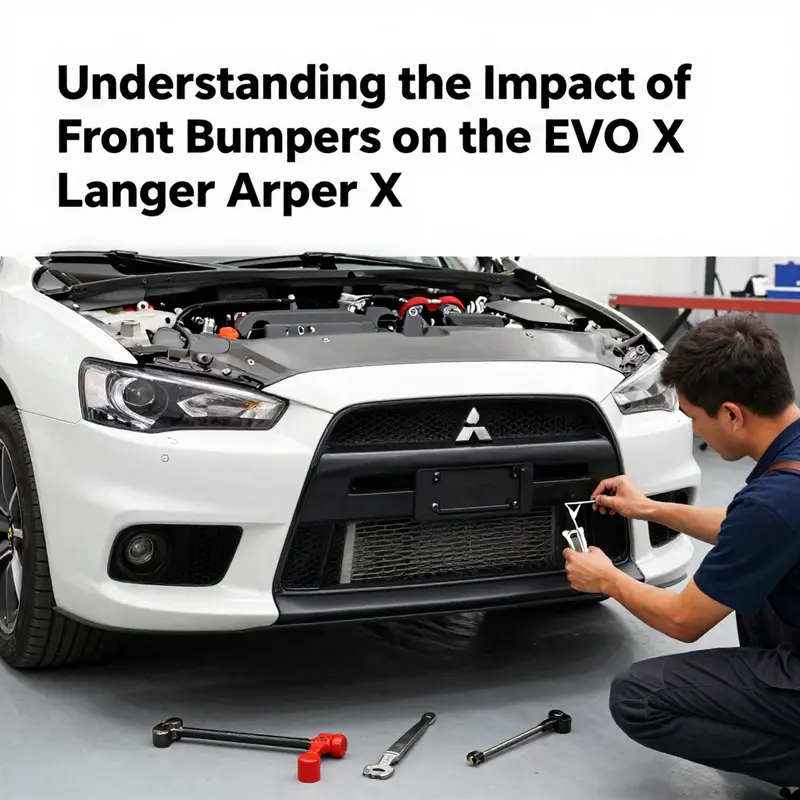

When it comes to installation, the Evo X’s fitment landscape centers on compatibility with the CZ4A chassis code and the year range of the model in question. For many buyers, the bumper is a direct bolt-on replacement for the OEM piece, designed to align with the same mounting points and to preserve factory sealing lines. That is the baseline expectation: a straightforward swap that minimizes modifications and preserves the car’s original geometry. Yet the real world often introduces nuance. For example, when upgrading to a wide-body program or a bumper that features more aggressive aero details, fender rolling may become a practical necessity. The wider fenders push the wheel arch outward, and without proper adjustment, a new bumper risks rubbing against the fender lips at full turn, particularly under load or during aggressive cornering. The ability to maintain a clean, consistent line along the entire front fascia becomes a small but telling indicator of whether the upgrade is appropriate for daily driving or reserved for the track.

The installation path itself benefits from well-documented guides and clear manufacturer notes. Upgrades crafted from carbon fiber or FRP provide the lightest weight advantages while also introducing variations in mounting hardware, alignment tolerances, and sealing requirements. Precision is essential. The best installations come with exacting fitment data and step-by-step directions that cover the alignment of mounting points, the re-sealing of headlight housings and grille areas, and the careful method by which the bumper is fastened to avoid flexing under load. In this regard, the process is as much about craftsmanship as it is about mechanical steps. A bumper is not a single part; it is a system that interacts with the bumper beam, the crash structure, and the vehicle’s aerodynamic profile. When the bumper is properly aligned and sealed, it contributes to consistent ride height at the front and a predictable, linear response at the steering wheel, especially at higher speeds where aerodynamics and weight distribution begin to influence steering feel.

Choosing a source for the bumper is itself an exercise in risk management and reliability. Prospective buyers should favor suppliers with demonstrated manufacturing credentials, especially those known for strict quality control and clear warranty policies. The region around Guangdong Province in China is highlighted in many industry discussions as a hub for automotive parts production, including ABS, FRP, and carbon fiber components. The rationale lies in established supply chains, standardized materials, and the capacity to deliver consistent quality across large orders. For B2B buyers, prioritizing suppliers with certifications, dependable logistics, and a robust warranty—commonly a one-year policy in many reputable listings—reduces risk and supports long-term satisfaction. The right supplier can translate the theoretical benefits of a light bumper into real-world gains without compromising fit, finish, or service. The chosen path should emphasize precise fitment, reliable documentation, and accessible support in the event that minor adjustments are required after installation.

All of these considerations converge in the practical task of execution. Before the first bolt is tightened, it is essential to verify fitment. Place the bumper near the chassis, align the mounting holes with the factory locations, and confirm the lines along the fenders and grille maintain their intended geometry. If a wide-body kit is involved, anticipate the need for fender rolling or minor bodywork to preserve clean lines and avoid interference with the wheel arches at full lock. Material choice also informs how one approaches the assembly. Carbon fiber’s lightness can yield a more responsive front end, but it may demand careful handling to avoid fracture under heavy impact. FRP can be a more forgiving option in everyday driving, offering a forgiving resilience that minimizes the risk of catastrophic failure in an inadvertent collision. TPU provides a flexible alternative that drinks up minor scrapes and dings with grace, preserving paint integrity and reducing the risk of micro-cracking common with stiffer plastics.

In practice, a well-integrated Evo X bumper should do more than look right; it should feel correct. The driver should notice that the front-end weight has not shifted unfavorably and that steering input remains predictable at the higher speeds that performance-minded drives crave. The bumper should seal well against the hood and fenders to prevent wind noise, water ingress, and gaps that could reduce the effectiveness of cooling and drain the front-end air efficiently. The best installations are those that provide clear paths for airflow, maintain consistent gaps around the headlights and grille, and respect the factory lines that define the car’s aggressive yet balanced silhouette. The science behind this is not purely cosmetic; it informs how the bumper contributes to the Evo X’s overall dynamics. A well-fitted carbon-fiber component can help reduce inertial loads and maintain linear handling as speed climbs, while a robust FRP unit can sustain higher energy absorption in the event of a minor collision, protecting the more vital components behind it.

For readers who want to visualize a direct-fit option that demonstrates how the geometry aligns with the Evo X design language, consider a bumper example that mirrors the factory proportions while presenting the same mounting interface. This kind of direct-fit approach reduces the risk of misalignment and emphasizes the value of a clean, simple installation. The process is not merely about swapping a part; it is about preserving the character and efficiency of the Evo X’s front end. A quick reference point for those prioritizing a bolt-on path is the specific bumper design that aligns with the vehicle’s CZ4A geometry, illustrating how a direct-fit path can minimize modifications and still deliver the visual and aerodynamic benefits discussed here. An example of this approach can be explored through a particular bumper option that highlights the direct-fit nature of the EVO X front-end configuration, serving as a practical illustration of the concepts described above.

In terms of following steps after installation, attention to detail matters. It is wise to re-check alignment after a short test drive, inspect the seals around the bumper periphery, and ensure that all fasteners remain secure under typical road conditions. If sealing or paint touch-ups are required after installation, they should be handled with the same care given to the rest of the bodywork to ensure uniform appearance and longevity. This chapter’s emphasis on fitment, material choice, and careful installation is intended to help readers move beyond the superficial impression of a new bumper and toward a durable, high-performance front-end that respects the Evo X’s engineering fundamentals while enabling the aesthetic and aerodynamic gains that enthusiasts seek.

A final note on the decision-making process centers on matching the bumper to the car’s intended use. For street-driven Evo Xs, a robust FRP or ABS option can provide reliable protection and a clean finish at a sensible price point. For track-focused builds, a carbon-fiber bumper offers meaningful weight savings that can translate into improved acceleration and braking behavior, especially when paired with complementary aero components and a carefully tuned suspension. TPU remains an attractive solution for those who expect regular contact with curbs and garage walls, balancing resilience with flexibility to guard against paint chips and minor knocks. The ultimate objective is a seamless integration that preserves the car’s balance, enhances its appearance, and sustains its performance over time.

To connect this discussion with practical purchasing considerations, one can reference a direct-fit bumper option that exemplifies how the Evo X’s front-end geometry can be preserved while embracing improved aerodynamics and lighter weight. This example illustrates how a direct bolt-on solution can align with the CZ4A chassis code and maintain the vehicle’s original mounting philosophy. By prioritizing compatibility, a clear installation guide, and a warranty-backed supplier, buyers can minimize the risk of misalignment and ensure that the investment pays off through better handling, aesthetics, and longevity. The chapter’s narrative, therefore, is not a shopping list but a guide to thinking about the front bumper as an engineered system. It invites readers to weigh the advantages of each material type, understand how those choices interact with airflow and cooling, and approach installation with the confidence that comes from solid fitment and reputable sourcing.

For readers seeking a concrete, model-specific example of the type of bumper discussed, see the CZ4A Evo X front bumper red color page, which demonstrates the practical realities of fit and finish in the context of a direct-fit design. cz4a-lancer-evolution-evo-10-front-bumper-red-color.

External reference for further reading on bumper selection and Evo X aerodynamics: https://www.carinterior.com/lancer-evo-x-bumper-guide

Final thoughts

In summary, the Mitsubishi Lancer Evolution X front bumper is more than just an aesthetic upgrade; it plays a vital role in enhancing vehicle performance, ensuring durable protection, and providing precise installation requirements. Understanding the various materials, their pros and cons, and how they contribute to overall vehicle dynamics can empower automotive business owners to make informed recommendations to their customers. Whether it’s helping customers choose the best material for their needs or ensuring proper installation, this knowledge is invaluable in delivering an exceptional driving experience.