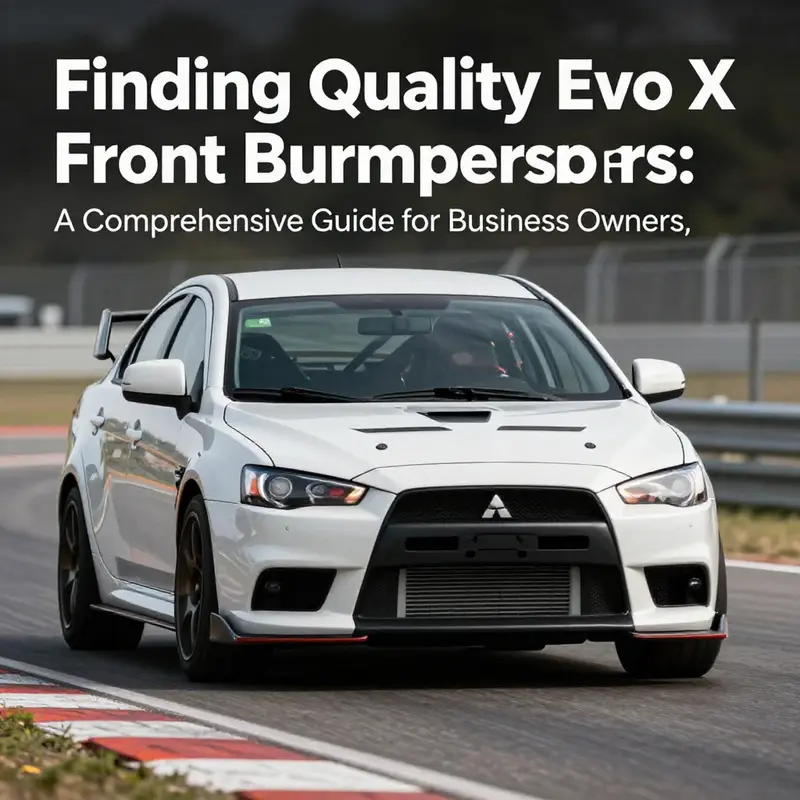

As the Mitsubishi Lancer Evolution X gains classic status among automotive enthusiasts, the demand for high-fidelity OEM front bumpers continues to surge. This article unpacks the essential aspects of sourcing these parts from the global hub of automotive manufacturing—Guangdong, China. We will explore why this region stands out, the differences between OEM and aftermarket options, key criteria for supplier evaluation, and the best platforms for procurement. Each chapter deep dives into these facets to equip business owners with actionable insights, promoting informed decision-making in their pursuit of quality components.

Forged on the Coast: How Guangdong Becomes the Global Forge for Evo X OEM Front Bumpers

The front bumper is more than a shield for the nose of a high‑performance sedan; it is the interface between engineering precision, aesthetic intent, and real‑world durability. When the Evo X—an emblem of mid‑2000s performance refinement—requires a replacement that preserves factory geometry, materials, and the exacting fitment that enthusiasts expect, the search often leads to a single geography: Guangdong. This southern Chinese province, and more specifically the Guangzhou region, has matured into a global hub where OEM‑style front bumpers for this car are conceived, produced, finished, and prepared for international shipping with a level of integration that rivals any global supply chain. The story of this hub is less about a single factory and more about an interconnected network that spans design studios, resin labs, precision toolmakers, automated painting cells, and distribution channels that can deliver a kit from bench to driveway with remarkable speed. It is a story of clusters that work in concert, a logistics spine that keeps pace with demand, and a manufacturing philosophy that emphasizes fidelity to the original element while adopting modern practices for consistency, safety, and cost containment.

At the heart of Guangdong’s dominance is a vertically integrated ecosystem built around material science, precision tooling, and a culture of process discipline. The composites and plastics landscape in this region has evolved into an environment where raw material choices—whether virgin ABS, polypropylene, or thermoplastic olefin—are matched to exacting resin systems and UV stabilization recipes. For bumper shells, the choice of material is not simply a matter of cost or weight; it is a decision that influences dent resistance, color stability, and long‑term appearance after exposure to sun, road salt, and wash cycles. ABS remains a workhorse for OEM‑styled exterior components because it delivers the balance of rigidity, impact resistance, and surface finish that factory parts depend on. PP and TPO offer lighter, cost‑efficient paths for non‑critical sections, while FRP—glass fiber reinforced plastic—finds use in performance applications where stiffness and reduced weight are valued. Carbon fiber, the premium option, is reserved for high‑end iterations that demand peak stiffness and a very light touch on overall mass, often in conjunction with aero elements like canards or integrated splitter systems. The capability to work across these materials within a single cluster reduces steps, speeds up iteration cycles, and minimizes the risk of dimensional drift between CAD models and the finished product.

The raw material pipeline feeds into a network of facilities that cover the full spectrum of production processes. Injection molding cells churn out the bulk of the bumper shells in matched tolerances, while surface finishing shops take care to replicate the factory texture and joint lines that seasoned technicians know by feel. Paint shops, equipped with color‑matching capability, ensure that the final finish can blend onto the vehicle with the same seamless transition you would expect from a factory component. In this ecosystem, the paint layer is not a cosmetic afterthought; it is a critical element of match integrity that plays directly into the perception of OEM fidelity on the road or track. Alongside these traditional processes, specialized units handle FRP and carbon fabrication, where layups, resin infusion, and curing cycles are tuned to the specific performance profile of the bumper or its aero components. The result is a family of parts that can be ordered with consistent quality across batches, a milestone for buyers who demand repeatability in a global market.

Beyond the bench and the barn, Guangdong’s advantage extends to the cradle of logistics. The province’s strategic position near major ports such as Guangzhou and Shenzhen provides a direct line to air, sea, and rail networks that weave through Asia, Europe, North America, and beyond. Proximity to these hubs lowers landed costs and slashes transit times, a practical benefit that translates into shorter lead times for restorers and racers who need a bumper in the right shade, with the same mounting points as the original. The regional trade ecosystem is reinforced by regulatory frameworks that align with international standards, including the convergence of automotive quality and safety practices that North American, European, and Japanese markets expect. Suppliers here frequently align to ISO/TS 16949 or IATF 16949 standards, translating into predictable processes and auditable quality trails that B2B buyers can trace from first quote to final receipt.

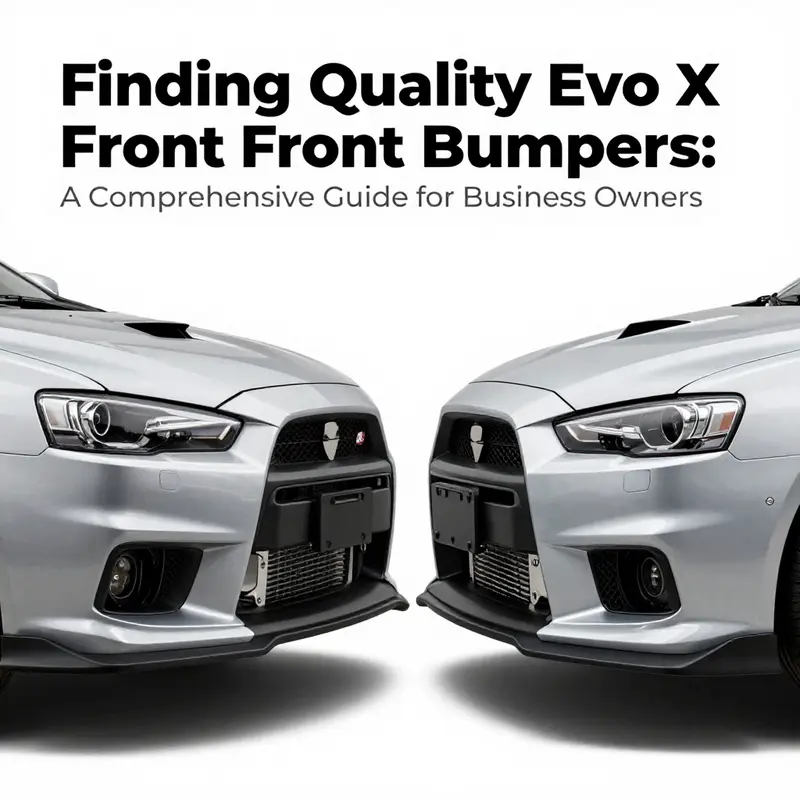

To the outsider, the distinction between OEM and aftermarket bumpers may appear subtle; to a restorer or a race team, the difference is existential. OEM front bumpers are designed to mirror the original’s geometry, fitment interfaces, and integrated features such as fog light housings, air intake grilles, and sensor cavities. The aim is seamless integration with the factory electronics and body panels, ensuring that factory lines, impact absorbers, and mounting points align without further modification. Aftermarket performance bumpers, by contrast, often emphasize bolder styling cues, larger air intakes, or aggressive aero kits. They may offer weight savings or enhanced cooling performance but can require trimming, rework, or even relocation of certain hardware to achieve a proper fit. This is not a condemnation of aftermarket parts, but a reminder of the context in which OEM‑style components hold value: maintain factory aesthetics and fit without sacrificing the integrity of the original system.

Buyers evaluating a source for the Evo X’s OEM‑style front bumper rightly weigh several pillars of due diligence. Material consistency sits at the top of the list; virgin‑grade resins with UV stabilization and proper impact modifiers are non‑negotiable for long‑term appearance and behavior in sunlight. Fitment accuracy is another pillar; many buyers request CAD files or physical samples to confirm that exterior contours align with mounting surfaces, and that all cutouts line up with lights, grilles, sensors, and parking aids. Certification compliance follows, with buyers seeking proof that the part adheres to OEM quality standards and that the supply chain can demonstrate traceability from resin to final packaging. Packaging and logistics are not afterthoughts either; protective films, branded packaging, and reliable shipping terms help ensure the bumper arrives in pristine condition, ready to install, without requiring rework on a carrier’s end. Finally, warranty and post‑sales support can be a differentiator; a credible supplier will back the part with at least a year of coverage and prompt assistance if fitment or finish issues emerge.

The purchasing landscape in this space is further shaped by the emergence of reputable platforms that connect buyers with verified suppliers. On the direct B2B front, Alibaba and similar marketplaces host listings that emphasize OEM‑style compatibility, with claims around weight reductions through carbon components, aerodynamic optimization, and warranties that mirror factory expectations. In parallel, curated marketplaces offer OEM‑certified bumpers from trusted sellers, combining competitive pricing with efficient delivery. For a deeper dive into the kind of supplier guidance that informs global procurement decisions, consider resources that synthesize the automotive OEM supply dynamics in this region. The insight from Global Sourcing Insights highlights how OEM‑style components for Evo X models are produced and distributed at scale, underscoring the catalysts behind Guangdong’s prominence in this niche market. This broader perspective helps procurement managers understand how regional specialization translates into consistent product performance across continental markets.

Within this framework, the Evo X OEM‑style front bumper is more than a replacement part; it is a calibrated interface between a car’s purpose and its appearance. It is designed to integrate with the vehicle’s original design language, to preserve the intended aesthetic while maintaining the mechanical handshake that exists between the bumper, the lighting system, the sensor suite, and the underlying crash structure. The Guangdong cluster’s ability to deliver a part that meets factory alignment curves, mounting hardware tolerances, and paint color fidelity is what elevates the purchase from a simple replacement to a restoration of the vehicle’s intended character. For many buyers, order quantity is a practical consideration as well. Suppliers in Guangzhou and nearby zones are increasingly comfortable with MOQs that begin at a single unit for prototyping or low‑volume orders, a signal of how the market has evolved to support enthusiasts and small shops as well as large fleets. This flexibility is critical for restorers who must test fitment on a sample bumper before committing to a broader replacement program.

To illustrate how this ecosystem translates into real‑world sourcing, buyers often rely on a trusted route: a well‑documented product page that asserts compatibility, followed by a direct inquiry for CAD files and a physical sample to verify dimensional accuracy. Once the fit is confirmed, the next step is to review packaging standards and shipping timelines, ensuring that the bumper’s arrival aggravates neither bodywork schedules nor workshop workflows. The Guangdong advantage also means a rapid response to technical queries, with suppliers able to provide material specifications, UV stabilization data, and warranty terms in a form that supports due diligence and risk assessment. In practice, this makes the region not only a supplier of parts but a partner in the care and maintenance of a coveted performance sedan heritage. It is no accident that the global community of Evo X enthusiasts finds itself returning to this corridor for components that promise factory integrity and predictable performance under track conditions and road use alike.

For readers who want a concrete link to a supplier that emphasizes genuine factory alignment for the Evo X’s front bumper, a notable reference can be found here: genuine CZ4A Lancer Evolution X front bumper. This resource exemplifies the type of documentation buyers seek—clear indication of genuine alignment with the CZ4A platform, visible in the mounting geometry, finish, and compatibility with the vehicle’s light and sensor housings. It also embodies the broader ethos of Guangdong’s OEM ecosystem: a focus on fit, finish, and fidelity, delivered through a coordinated supply chain that can scale while maintaining the meticulous standards that enthusiasts expect of original equipment. The emphasis on genuine parts is not merely about brand status; it is about preserve‑and‑protect philosophy—preserving factory fit and color, protecting resale value, and ensuring that the overall balance of performance and aesthetics remains true to the model’s design intent.

The journey from factory under one roof to driveway or racetrack under another is a reminder that the automotive aftermarket thrives when supply chains are resilient, transparent, and specialized. Guangdong’s position as a global hub reflects more than cost advantages or manufacturing muscle; it mirrors a sophisticated understanding of how modern automotive parts must perform under scrutiny—from ISO‑compliant production floors to the rigors of cross‑border logistics. Enthusiasts and professional buyers alike derive confidence knowing that the front bumper capable of preserving the visual identity of a coveted model is manufactured in a way that respects the original engineering choices and the car’s safety architecture. In this sense, the Guangdong corridor is not merely a production zone; it is a living system that connects design intent with practical realities, enabling owners to keep their Evo X projects authentic, reliable, and compelling on every mile of their journey.

External resource for broader context on OEM bumper supply chains and supplier guidelines: https://www.global-sourcing-insights.com/evolution-x-oem-bumpers-supplier-guide

OEM or Aftermarket Front Bumper: Navigating the Evo X in a Global Framework of Authenticity and Performance

The Evo X front bumper is more than a shield; it is a critical interface for crash energy management, aerodynamics, and the vehicle’s visual identity. The choice between OEM and aftermarket affects fit, cost, compliance, and long-term value. Over the years the Evo X has built a global following that is reflected in a mature aftermarket ecosystem. In Guangdong province and the surrounding clusters the production of bumper components has become a capability hub for OEM style replacements and related exterior parts. This regional specialization supports tight tolerances and faster cycles from concept to customer.

OEM bumpers are built to Mitsubishi original design specifications and are aligned with automotive standards and the car CAD data. They provide color matching, consistent gloss, and predictable fitment that aligns with the rest of the vehicle architecture. The trade-off is cost and lead time, with OEM parts typically commanding higher prices and longer delivery windows.

The Guangdong based aftermarket path offers flexibility through small batch production, rapid prototyping, and customization options that extend beyond factory parity. Common materials include ABS for durability, polypropylene and TPUs for cost and weight, and in high end builds carbon fiber or fiberglass reinforced options. Quality control rests on validated CAD data, UV stabilization, precise tolerances, and robust surface finishing to resist scratches and weathering. The proximity of tooling shops, paint facilities, and assembly lines in Guangdong shortens feedback loops and supports fast color matching and texture adjustments.

From a procurement perspective the decision is not binary. OEM helps preserve vehicle value and provides a clear path for warranty alignment and regulatory documentation, while aftermarket options excel in project based work, low volume orders, or performance focused builds where weight savings or improved airflow matter. Guangdong suppliers often advertise standard black bumpers, factory color finishes, or color matched coatings along with documented warranties and quality certifications such as ISO or IATF aligned programs.

Quality and compliance anchor both routes. OEM parts carry the design and testing footprint of the original manufacturer, with auditable crash and fitment data. Reputable aftermarket suppliers close the loop with validated CAD data, rapid prototype iterations, testing protocols, and clear warranty terms. Buyers should request dimensional samples and material certifications to verify tolerances and color stability before committing.

The supply chain reality in Guangdong emphasizes end to end capability. Injection molded bumper covers, FRP or carbon variants for performance variants, and paint shops capable of color matching to factory or customized finishes are common. Proximity to major ports reduces transit times and total cost for overseas buyers. Buyers should evaluate material consistency, supplier certifications, and the ability to provide ongoing support.

Buying workflow considerations start with objective setting. For warranty service or factory retained fleets OEM remains attractive, but for show car builds or prototyping the aftermarket path can deliver near OEM fit and faster iteration. Suppliers should provide samples, credible certification, packaging standards, and verified logistics options. MOQs may be low in Guangdong facilities, enabling rapid development cycles.

Ultimately the choice comes down to intent, model year, and project budget. OEM offers the strongest alignment with regulatory compliance and long-term value retention, while the Guangdong aftermarket ecosystem provides competitive fit and finish with advantages in customization, lead times, and price. The best decision aligns supplier capability with the buyer’s goals, ensuring the entire bumper lifecycle from CAD alignment to finished part and post-sale support.

Overall authenticity and performance can be achieved through multiple paths. With careful qualification of suppliers and clear documentation, a decision can balance value, risk, and timing without compromising safety or aesthetics.

From Guangdong to Garage: OEM-Grade Evo X Front Bumper Sourcing in a Global Market

The Mitsubishi Lancer Evolution X remains a benchmark for compact performance, a sedan whose chassis discipline and aerodynamic intent still spark fascination among restorers, track enthusiasts, and weekend drivers. When the front bumper sustains damage or ages beyond cosmetic repair, buyers weigh factory fit against aftermarket options that promise aggression at the expense of exacting OEM geometry. OEM grade Evo X front bumpers—whether genuine or OEM style replicas—are more than parts; they are links to the original engineering intent designed to integrate with the car’s lights, grilles, sensors, and air management systems.\n\nThe main sourcing thread runs through Guangdong, a province that has evolved from manufacturing hub to integrated ecosystem for automotive exterior components. The districts that host injection molding, FRP shops, and carbon fiber facilities lie within a few kilometers of each other, enabling faster iterations, lower lead times, and the ability to source multiple material variants under one roof. For B2B buyers, proximity translates into traceability and shared standards that help ensure the bumper aligns with the Evo X’s geometry and crash performance expectations.\n\nThe materials used reflect a balance of cost, weight, and stiffness. ABS is common for OEM styled shells, with PP and TPO blends offering lighter covers and robust impact behavior. Enthusiasts chasing a lighter, race oriented build may opt for FRP or carbon fiber variants, noting higher costs and more demanding UV and resin controls. Color matching by Guangdong paint shops, with UV stabilizers and clear coats, remains critical to final appearance.\n\nCompliance and quality systems also shape outcomes. ISO 9001 and IATF 16949 certifications signal disciplined processes, traceability, and post production testing. A bumper produced within a well managed Guangdong cluster can avoid many delays that plague fragmented supply chains. For buyers planning larger orders, high on time delivery rates and robust packaging standards provide confidence in meeting project deadlines. Ultimately, OEM grade bumpers are designed to fit with the Evo X’s mounting points, sensors, and trim configurations with minimal modification, while aftermarket options may require adjustments to surrounding panels or hardware.\n\nIn practice, the best partners combine material integrity with proven manufacturing expertise and a proven track record of dimensional precision. Request CAD based verification or physical samples to check fit against the Evo X mounting geometry. Consider MOQs that suit prototyping or low volume runs to test fitment across different trim variants. The Guangdong cluster’s integrated tooling, rapid prototyping, and transparent processes make it possible to source bumpers that preserve the car’s lines and aerodynamic balance. The end result is a front bumper that functions as a genuine extension of the Evo X, not an afterthought that undermines the car’s performance envelope.

Frontline Fidelity: Sourcing OEM-Grade Evo X Front Bumpers from a Global Supply Network

The Mitsubishi Lancer Evolution X has earned a reputation not just for its rally-bred performance but for the way its front end presents a precise synthesis of function and form. The bumper is more than a cosmetic panel; it is a critical component that governs aerodynamics, impact energy management, sensor alignment, and the seamless integration of lighting and grille elements. When a factory replacement is required—whether from a collision, aging, or restoration—the decision to pursue an OEM front bumper, rather than a generic aftermarket substitute, becomes a choice about fit, finish, and long-term reliability. In the current market, the supply chain that delivers these OEM-style parts has coalesced around key automotive clusters, with Guangdong Province in China emerging as the global hub for Evo X bumper production. This is not happenstance. It reflects an ecosystem built to support OEM-grade fidelity from design to final polish, all while meeting international standards and keeping pace with global demand.

To understand why OEM front bumpers for the Evo X continue to command attention, one must first appreciate the difference between OEM replacement and aftermarket performance pieces. An OEM front bumper for the Evo X is expected to mirror the original in material, thickness, mounting points, and finish. It is designed to accommodate the factory fog lights, grilles, air intakes, and any vehicle-specific features such as active aero elements or integrated sensors. In contrast, aftermarket performance bumpers often emphasize bold styling cues, larger air intakes, or added canards and spoilers. While these enhancements can improve visual impact or track performance, they can also introduce fitment challenges or require bodywork adjustments. The decision to source OEM-grade parts is thus a balancing act between authenticity, compatibility, and the end use of the vehicle, whether it is a showroom restoration, a daily driver that must blend with factory cues, or a track race car where precise geometry matters for predictable aero behavior.

The Guangdong region’s leadership in Evo X bumper production is anchored in a vertically integrated industrial cluster that supports every stage of part creation. Injection molding facilities yield consistent, virgin-grade plastics with UV stabilization to resist sun exposure over years of exposure to the elements. In the Evo X context, ABS remains a staple for cost-effective, rigid bumper shells that resist impact while maintaining a high-quality surface finish. For performance-oriented builds, there are options in reinforced materials such as FRP or even carbon fiber composites, which reduce weight and can contribute to improved suspension dynamics and braking performance by shaving mass at the vehicle’s front end. The cluster’s proximity to paint shops with color-matching capabilities coupled with seasoned finishing specialists ensures that factory-looking satin, gloss, or matte finishes can be matched with precision to the vehicle’s original color code. The same ecosystem houses tooling experts who maintain the tolerances required for exact fitment, so the bumper aligns with the chassis mounting points and the surrounding body panels as the factory intended.

A crucial factor in sourcing OEM-style bumpers is the material science that underpins long-term durability and safety. In practice, buyers should verify material consistency and the presence of UV stabilizers and impact modifiers. Virgin-grade ABS or PP, selected for their proven resistance to thermal cycling and impact, are the baseline for OEM replacements. For weight-sensitive builds, buyers might consider lighter materials or carbon fiber components for canards, splitter lips, or decorative elements, but these choices should be evaluated against the potential need for rework to achieve correct alignment with sensors, fog lights, and the intake tract. In addition to the body panel itself, the packaging and protective measures matter. Proper damping inside the shipping crate, moisture barrier films, and careful labeling help preserve finish and prevent micro-scratches that can undermine color-matching during installation. The Guangdong clusters also benefit from a robust logistics framework, with waterways and ports such as Nansha and Shekou providing efficient routes for international customers. Reduced transit times translate into faster project timelines for restorers and race teams alike.

For buyers pursuing OEM-grade replacements, a methodical supplier evaluation is essential. First, material consistency is non-negotiable; request documentation that confirms virgin-grade plastics and additives used for UV stabilization. Second, fitment accuracy should be verified through CAD files or, ideally, physical samples that map to the Evo X CZ4A chassis code. Third, certification compliance matters. Reputable suppliers will reference OEM-related standards and, where applicable, ISO or IATF certifications that demonstrate consistent quality management practices across production batches. Fourth, packaging and logistics should be scrutinized. A reliable supplier should offer branded packaging, protective film, and options for fast shipping—whether through traditional channels or modern platforms that provide traceability. Fifth, warranty and post-purchase support are meaningful signals of a supplier’s confidence in their product. A practical benchmark is a minimum one-year warranty with responsive after-sales service that can assist with color matching guidance, installation tips, and replacement parts for mounting hardware or fasteners if needed.

Navigating the procurement landscape also means choosing the right purchasing channels. For direct B2B sourcing, platforms that host verified Evo X bumper manufacturers provide access to a broad catalog of materials and finishes. Alibaba.com is commonly used by global buyers to connect with verified suppliers that operate from major automotive hubs in Guangdong and Zhejiang. Buyers can search for those labeled OEM compatible or OEM replacement and verify supplier credentials such as Gold Supplier status, Trade Assurance, or Verified Supplier badges. Importantly, these platforms often allow customization, including color matching and even logo imprinting for fleet or dealer applications. For smaller-scale buyers or enthusiasts seeking quick replacements, marketplaces with strong buyer protections, such as eBay, can offer OEM-style bumpers with clear condition indicators and user feedback. The key is to approach each listing with a critical eye for fitment notes, material specification, and return policies.

Within this sourcing framework, a concrete example can help illustrate how an OEM-guided choice might unfold. For those who want to see a representative OEM-compatible Evo X front bumper option, the CZ4A Evo X front bumper red color page provides a real-world reference for how a supplier describes fitment, material, and color match options. For a direct, verifiable instance of a listed product tailored to the Evo X, one can explore the dedicated listing that features carbon fiber front bumper components and associated accessories. Such pages often detail the materials (carbon fiber or FRP), surface finishes, weight considerations, and the specific mounting points that align with the Evo X’s structural geometry. This is the kind of documentation that helps procurement teams compare CAD data against actual parts and ensures that the replacement aligns with the car’s original design intent.

The Evo X’s chassis designation, CZ4A, remains a useful anchor for compatibility checks. When evaluating potential matches, buyers should confirm that the bumper is intended for CZ4A variants from 2008 to 2015. This ensures that the mounting geometry aligns with the factory bumper’s attachment points for the radiator support, crash bars, and energy-absorbing structures. It also helps guarantee that the bumper integrates with the vehicle’s lighting systems, air intakes, and sensor housings. If a vendor cannot confirm CZ4A compatibility, the risk of misfit increases, potentially triggering additional bodywork, repainting, or revision work that defeats the purpose of purchasing a precise OEM-style piece.

Another practical consideration is volume and lead time. For prototypes or low-volume restorations, Guangzhou-based suppliers frequently accept MOQs as low as a single unit. This flexibility supports testing, color verification, and early-stage assembly without tying up capital in large lots. For distributors or workshop fleets, the ability to secure larger quantities with consistent lead times helps stabilize project planning and inventory. In any case, engaging a supplier with clear turnaround estimates, transparent serial tracking, and post-shipment support can mitigate delays and ensure that a project remains on schedule. The global nature of the Evo X aftermarket means that buyers must balance the desire for authenticity with the realities of cross-border logistics, currency fluctuations, and varying warranty policies across jurisdictions.

Ultimately, the decision to source an OEM-style Evo X front bumper from a global network rests on a few decisive questions: Will the part fit precisely with the factory components and sensors? Is the material specification consistent with factory intent and long-term durability? Can the supplier provide credible documentation, samples, and a warranty that stands up to inspection? Do packaging and shipping practices minimize risk during transit and storage? And does the supplier offer responsive after-sales support if color matching or mounting questions arise after installation? Answering these questions requires a thorough, collaborative approach between buyer and supplier, one that respects the Evo X’s engineering heritage while embracing the efficiency and reach of a modern procurement ecosystem.

As the Evo X community continues to evolve, the central role of OEM-style front bumpers remains a testament to how enthusiasts balance authenticity with practicality. The best parts come from partners who understand the chassis, the market, and the standards that define high-fidelity replacements. In that sense, sourcing is not simply a transaction; it is a careful alignment of expectations, specifications, and timelines that keeps the Evo X look and feel true to its factory legacy while allowing owners to push the limits of performance and appearance. External resources and verified supplier listings can help frame that alignment, offering both reassurance and a path to a precise, factory-compatible front end.

For a concrete example of an OEM-compatible option, see the cz4a-lancer-evolution-evo-10-front-bumper-red-color page, which showcases how a supplier communicates fitment and finish within the Evo X framework. This kind of reference point can be invaluable during supplier evaluation and CAD-to-part validation. And for those who want a broader view of the sourcing landscape, an industry guide to supplier evaluation can provide a structured framework for assessing technical performance, quality control, and logistics across the supplier ecosystem.

External resource: https://www.alibaba.com/product-detail/YH-FOR-LANCER-EVO-X-Carbon-Fiber_1600579384434.html

Final thoughts

In conclusion, sourcing an OEM front bumper for the Mitsubishi Lancer Evolution X requires an understanding of the manufacturing landscape, particularly the prominence of Guangdong as a production hub. With clear distinctions between OEM and aftermarket components, and an established set of criteria for supplier evaluation, business owners can make informed decisions to meet their needs. Utilizing verified platforms for procurement ensures quality and efficiency, ultimately enhancing both the restoration and performance aspects of the Evo X community. Success in this venture not only requires knowledge but also strategic partnerships that meet quality and compliance standards.