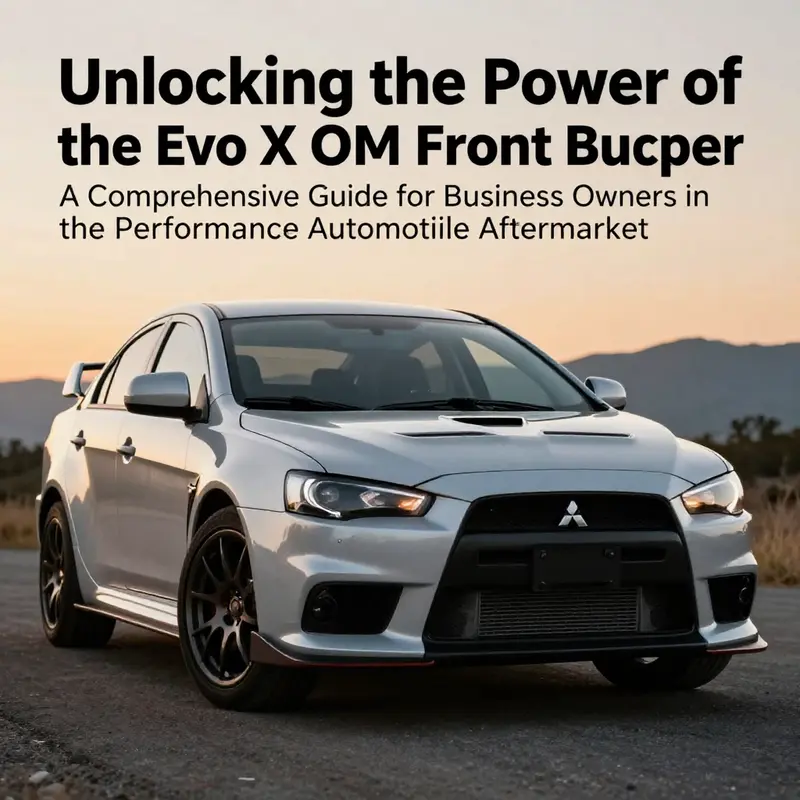

The Mitsubishi Lancer Evolution X, celebrated for its high-performance pedigree and rally-inspired heritage, continues to captivate automotive enthusiasts and business owners alike. Central to its allure is the OEM front bumper, which balances aesthetics with functionality, making it a prime target for aftermarket suppliers. This article will dive deeply into five critical chapters: the design and functionality of the Evo X OEM front bumper, the materials used in its production, the market dynamics surrounding its manufacturing, the performance enhancements that the design enables, and key considerations for purchasing and selecting suppliers. By the end, business owners will have a thorough understanding of not just the component itself but also its significance within the broader performance automotive landscape.

Shark Nose Precision: EVO X OEM Front Bumper

The Evolution X’s front end signals its intent with a shark-nose profile and a purpose-built bumper that blends form and function. The OEM piece isn’t just a styling cue; it is a carefully engineered interface between aero performance, cooling airflow, and crash safety. The large, diagonally meshed grille guides air to the radiator and intercooler while shaping the flow over the hood and fenders to minimize buffeting at speed.

Beyond looks, the bumper integrates brake-ducts and openings that support cooling for the brakes and engine bay, helping maintain consistent performance under track use or spirited canyon driving. Materials are chosen for a balance of weight, durability, and cost; most OEM bumpers are ABS, with FRP or carbon fiber options in specialist builds. The OEM piece offers predictable fitment and compatibility with the car’s sensors and lighting, preserving the Evolution’s handling characteristics and overall balance.

In sourcing and warranties, the OEM bumper benefits from established manufacturing pipelines and support networks, ensuring reliable replacement and predictable service life. For those prioritizing authenticity and resale value, keeping the factory front bumper aligned with the rest of the bodywork remains a straightforward, high-value choice.

null

null

null

null

Engineering The Factory-Fit Edge: How OEM-Style Front Bumpers Shape Evo X Performance

The Evo X front end is more than a styling cue; it is an engineered interface that balances aerodynamics, cooling, and chassis stability. An OEM-style front bumper mirrors factory geometry with precise tolerances, delivering authenticity and function in one package. When readers imagine a bumper that looks like it came straight from the assembly line, they picture a component that is not just a cover but a carefully sculpted piece of the car’s performance puzzle. The Evo X benefits from a bumper design that manages air as much as it shapes the vehicle’s visual stance, helping the chassis stay balanced at speed.

The aerodynamic profile of an OEM-style bumper guides airflow efficiently around the front of the car. At highway speeds or on windy roads, the shape minimizes drag and feeds air toward the radiator and intercooler. This is crucial for maintaining performance during repeated high-rpm operation or spirited laps, preventing intake temperatures from rising. By steering the air with intention, the bumper contributes to front-end stability and predictable handling.

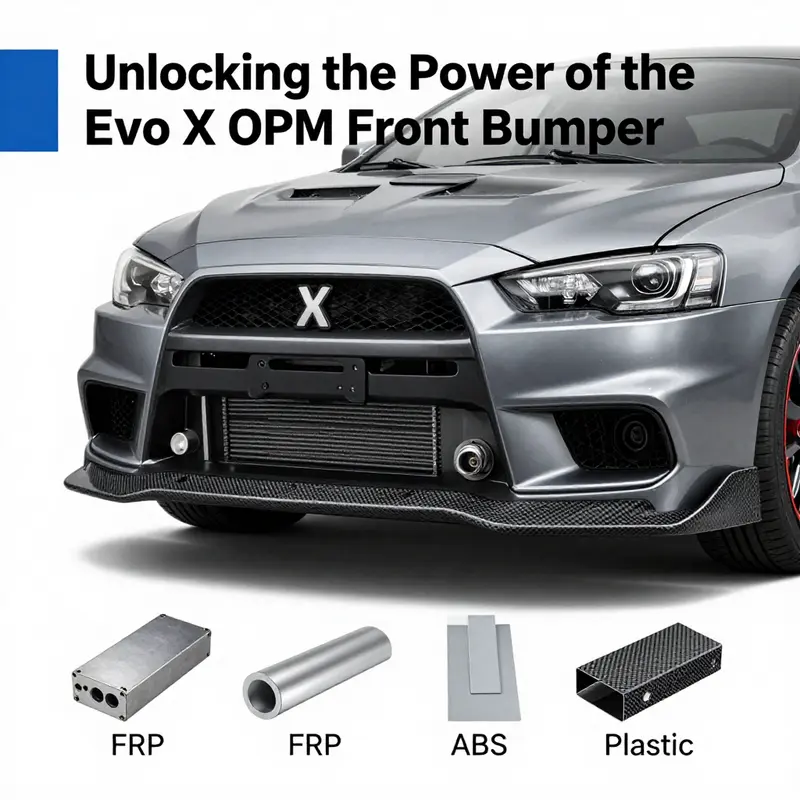

Material choice lies at the heart of the bumper’s performance envelope. Injection-molded polypropylene (PP) remains common for its precise fit, impact resistance, and durability. For lighter weight, carbon-fiber variants exist, offering potential gains in responsiveness but at a higher price. FRP and ABS options provide trade-offs between cost, weight, and rigidity. Each material brings a different texture to the car’s front end, influencing finish durability, stone-resistance, and ease of repair after track use.

Beyond material, the bumper’s tolerances are a quiet but critical factor in performance. OEM-style bumpers align with fenders, hood, and grille with factory-like precision, ensuring that air dams, splitters, and lower surfaces maintain their intended gaps. Proper fit reduces turbulent flow and preserves the engineered balance engineers designed for high-speed regimes. In practice, that means less post-install alignment drama and more confidence in the car’s dynamic behavior.

Sourcing and supply-chain realities shape the Evo X bumper story. Reputable suppliers in major manufacturing hubs offer OEM-style bumpers that reproduce factory geometry while allowing choice of materials. The advantages are faithful fitment and the ability to tailor weight, stiffness, and heat management through material selection. Carbon fiber options deliver meaningful weight reductions, while FRP or ABS variants offer accessible options with reliable fit and finish. When evaluating options, consider certifications, warranties, MOQs, and proximity to transit hubs to ensure predictable delivery times.

Ultimately, the OEM-style front bumper represents a conscious engineering choice rather than a mere surface swap. It integrates with the car’s cooling system, weight distribution, and aerodynamics to sustain Evo X performance and aggressive stance. For enthusiasts who view the car as a single, coherent system, the OEM approach offers authenticity without compromising the engineering fundamentals that keep the car performing at its best across diverse driving scenarios.

Authenticity and Precision: Navigating Suppliers for the Evo X OEM Front Bumper

The front bumper on the Evo X is more than a shield at the nose; it is a carefully engineered interface that governs cooling, aerodynamics, and crash safety while preserving the car’s distinctive profile. When a B2B buyer approaches the market for an OEM-style front bumper, the decision landscape is not about choosing between a handful of options but about threading a path through authenticity, fitment precision, and reliable logistics. The Evo X’ s design lineage makes this journey particularly exacting: factory alignment with panels, sensors, and airflow channels must be preserved to avoid compromising performance, warranty coverage, or resale value. In this context, the supplier ecosystem matters as much as the bumper itself. Guangdong’s manufacturing corridor in southern China has emerged as the nerve center for performance-grade automotive components, driven by dense clusters of injection molding, fiberglass fabrication, painting capabilities, and tooling expertise. This region’s integrated production model enables rapid prototyping, scalable output, and competitive pricing, all of which are critical for fleets, restorers, and dealers who rely on consistent, factory-accurate parts that won’t trigger misalignment alarms with body panels or radar-equipped safety systems.

Critical considerations begin with the question of authenticity. Genuine OEM bumpers come from the original equipment manufacturer or authorized partners who replicate factory geometry, maintain the same mounting points, and preserve engineered tolerances. The difference may be subtle to the untrained eye, but it translates into perfect fit, seamless integration with lighting units, and unaltered aerodynamics. For buyers who must adhere to rigorous standards—whether for a professional restoration, a fleet maintenance program, or a market-compliant resale—the distinction between OEM-quality and merely OEM-appearance is consequential. Industry guides consistently stress that OEM bumpers deliver unmatched compatibility, while replicas can introduce fitment gaps or compatibility issues with safety sensors and camera arrays that are increasingly standard on modern platforms. In practical terms, this matters at the rail and the curb—on the track days and the showroom floor alike.

From a materials perspective, OEM-style bumpers are typically offered in a spectrum of polymers with different weight, impact resistance, and cosmetic outcomes. FRP and ABS plastics remain common choices, prized for their balance of stiffness, cost, and formability. Carbon fiber variants enter the conversation when weight reduction and high-speed stability are prioritized, especially in performance-focused applications. Such options can shave weight and improve downforce, but they also demand rigorous quality assurance to maintain structural integrity under load, exposure to heat cycling, and long-term durability. For buyers evaluating material trade-offs, it helps to quantify the practical implications: lighter carbon fiber can marginally improve front-end responsiveness, yet it may command a premium and require careful inspection for resin-rich regions or microscopic delamination if not properly cured and finished. The overarching goal, regardless of material, is to secure a bumper that threads into the Evo X’s aero balance without introducing mismatch in gaps with fenders, headlights, or the under-hood intake routing.

Sourcing strategies reflect this complexity. Buyers are advised to leverage platforms that connect directly with verified Chinese manufacturers who specialize in Mitsubishi Evo X parts, enabling transparent pricing, flexible MOQs, and dependable logistics. A robust supplier network often offers a vertically integrated workflow—from injection molding and fiberglass work to high-quality painting and packaging—so that prototypes and production runs can be validated quickly. Price is never the sole measure; price stability, lead times, and post-sale support can determine the difference between a smooth project and a stalled build. Because many buyers operate on project-driven timelines, proximity to major ports becomes more than a convenience; it is a strategic advantage for reducing transit times and safeguarding against unplanned delays. But this advantage only bears fruit when combined with credible supplier practices.

One practical path to credibility is engaging with suppliers who provide verifiable documentation. Material composition reports, dimensional accuracy certifications, and evidence of adherence to established quality-management standards offer a factual basis for due diligence. ISO-based or industry-aligned quality programs, alongside third-party inspection options, provide independent reassurance that the bumper not only fits on day one but maintains its integrity after installation and long service life. In an environment where counterfeit or substandard components can pose safety and compliance risks, a transparent chain of custody—covering origin, processing, and testing—gives buyers confidence to commit to a specific supplier and to scale orders with predictable outcomes. The most reliable suppliers also employ digital tools for design validation and real-time quality monitoring. This technological edge supports traceability, enables faster design iterations, and reduces the risk of surprises when the bumper meets the car’s exacting tolerances.

For buyers seeking to validate supplier credibility and access OEM-grade options, verified supplier programs on major sourcing platforms provide a structured starting point. These programs filter by certifications, export experience, and customer feedback, and they help buyers separate genuine OEM paths from look-alike alternatives. On the marketplace landscape, there exists a resource dedicated to validating supplier credibility that can orient procurement decisions: a verified supplier hub with pre-screened manufacturers known for automotive component exports. Access to such a hub streamlines due diligence and can shorten the path from inquiry to quotation, accelerating both prototyping and bulk production cycles. As a navigation aid, the platform’s filterable data helps buyers compare eligibility for export controls, warranty provisions, and post-purchase support—factors that matter when a part must perform under demanding track or showroom conditions.

Within this context, the practical act of sourcing becomes a disciplined workflow. Buyers should begin by outlining the desired specifications: OEM-fitment geometry, exact mounting hole spacing, and compatibility with the Evo X’s lighting assembly and sensors. They should then shortlist suppliers who present clear evidence of OEM-grade production lines, stable material sourcing, and transparent quality controls. A prudent approach includes requesting sample parts for fitment checks, followed by on-site or third-party audits where possible. Audits can verify the supplier’s facility capabilities, equipment calibration, and adherence to quality protocols, all of which help mitigate the risk of counterfeit components slipping into a production line or a dealership’s inventory. The most reliable suppliers maintain a digital thread that traces every bumper from raw material batch to finished product, with batch-specific test results and warranty documentation.

As part of the sourcing narrative, a concrete step for buyers is to engage with verified Chinese manufacturers that offer flexible MOQs—from single prototypes to full-scale production runs—while maintaining reliable logistic support and proximity to ports such as Nansha and Shekou. This proximity translates to shorter lead times and easier returns or replacements if fitment issues arise. Buyers should also assess the supplier’s ability to provide finishing options, including blank white finishes suitable for custom paint jobs, or pre-painted surfaces that match a particular palette. The demand for authentic aesthetics—not merely visual similarity—will often push buyers toward suppliers who can honor precise surface finishes and color-matching tolerances across batches.

One practical touchpoint for this chapter’s readers is the option to explore listings that explicitly emphasize genuine OEM-grade fitment and documented compatibility with the Evo X’s bodywork and safety systems. While the market offers a spectrum of options, the path toward reliability lies in deliberate verification, factory-aligned engineering, and a posture of cautious skepticism toward parts that claim OEM likeness without verifiable provenance. For buyers who want to ground their decisions in a concrete example of credibility, an established supplier listing dedicated to genuine Evo X front bumper components provides a compelling reference point. See the listing that focuses on genuine Evo X front bumper fitment and documentation here: mitsubishi-evo-x-front-bumper-genuine. This internal reference points to a live, verifiable source that embodies the standards discussed above, including factory-aligned geometry and a traceable production lineage that aligns with OEM specifications.

In parallel with supplier evaluation, buyers should consider leveraging external resources to expand their understanding of supplier credibility and export-readiness. A well-known global marketplace offers a Verified Supplier Program that helps identify automotive-component manufacturers with proven export experience and customer-reported performance. This external resource offers a broad framework for assessing capabilities, certifications, and post-sale support, complementing the more focused diligence performed on individual suppliers. While the specifics of each supplier will vary, the shared emphasis remains constant: authentic OEM fitment, rigorous quality assurance, and dependable logistics that keep projects on schedule.

Ultimately, the Evo X front bumper procurement journey is a test of how well the buyer translates engineering precision into procurement discipline. Authenticity, fitment accuracy, and lifecycle reliability are not optional extras but the core criteria that determine whether a bumper will perform as intended on the street, on the track, or in a showroom cube. By combining vetted supplier partnerships, documented quality control, and strategic logistics planning, buyers can assemble a supply chain that delivers true OEM-grade integrity without compromising on the agility required for modern automotive programs. The result is a front bumper that preserves the Evo X’s aggressive stance while integrating seamlessly with the car’s cooling strategy, aerodynamic balance, and safety systems—an alignment of engineering and procurement that stands up to the demands of professional restorations, performance builds, and discerning showrooms.

External resource for further reading: https://www.alibaba.com/suppliers/verified

Final thoughts

As the demand for the Mitsubishi Lancer Evolution X continues to thrive, understanding the intricacies of the OEM front bumper becomes paramount for businesses in the automotive aftermarket. With its sleek design, diverse material options, and significant performance enhancements, the Evo X OEM bumper represents a vital component in enhancing both vehicle aesthetics and functionality. By staying informed about manufacturing dynamics and making wise purchasing decisions, business owners can position themselves favorably within this lucrative market. Ultimately, whether for replacement or performance enhancement, the Evo X OEM front bumper remains a cornerstone of quality and innovation in the automotive industry.