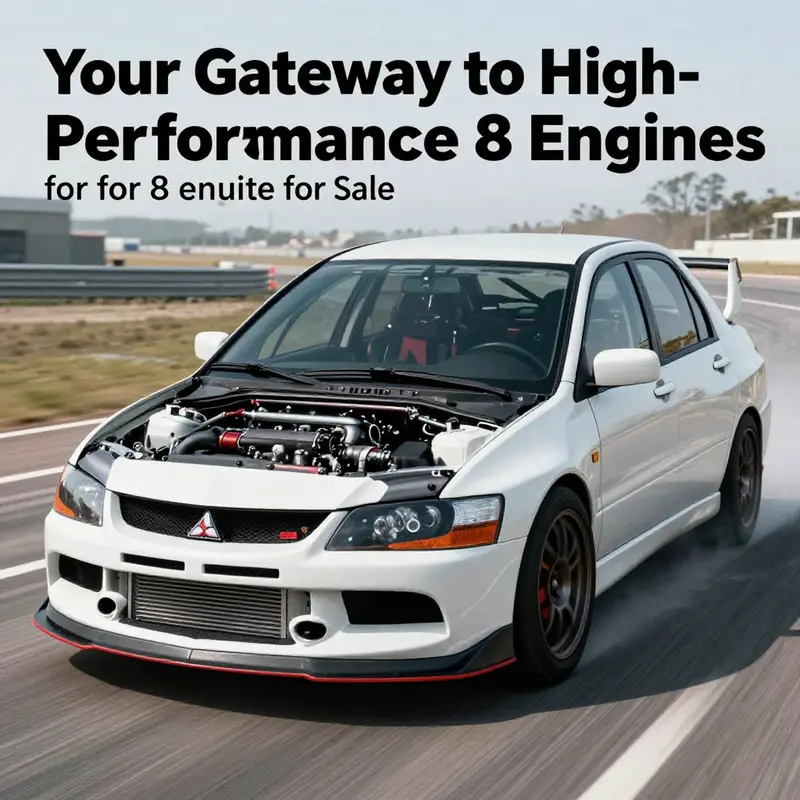

The Mitsubishi Lancer Evolution VIII is renowned for its remarkable performance capabilities and enthusiastic following among car enthusiasts. As business owners in the automotive industry, understanding the demand for Evo 8 engines and components can open new avenues for profitability. This comprehensive guide explores the various aspects of Evolution 8 engines for sale, from new components to high-performance modifications, and purchasing options to maintenance considerations. With insights into benchmarking modified engines, this article equips business owners with valuable knowledge to capitalize on this niche market.

New Frontiers in Evo 8 Sourcing: Building Modern Powerplants from a Classic Foundation

The Mitsubishi Lancer Evolution VIII engine remains a benchmark for how a compact four-cylinder turbo powerplant can blend compact efficiency with race-bred torque and linear response. In the current market, the conversation around the Evo 8 has shifted from simply swapping a blown unit to composing a complete, modern powertrain package built around new or rebuilt components. The appeal is straightforward: owners want the reliability, consistency, and tunability that come with technically validated parts, while still preserving the distinctive character of the Evo 8’s shared-breathing, high-spirited performance. What unfolds is less a restoration project and more a carefully engineered upgrade path that treats a classic as a living platform rather than a museum artifact. This shift matters because it reframes how enthusiasts and professional builders assess value. Instead of chasing the latest factory crate, they seek cohesive systems—engine blocks, rotating assemblies, cylinder heads, and control electronics that have been designed to work together, tested under real-world conditions, and validated on dynos that simulate street and track use with the same rigor every other modern performance engine demands.

To begin, the geography of sourcing plays a decisive role in both the timing and the quality of parts. Across Asia, dense clusters of precision machining, metallurgy, and automotive engineering services exist in regions where engineering traditions run deep and logistics networks run efficiently. The practical outcome is a pipeline that can deliver new or rebuilt Evo 8 components with a consistency that used to be the domain of OEM supply chains for contemporary models. Buyers who plan to assemble a high-performance Evo 8 powertrain often find it advantageous to locate partners in areas where workshops provide end-to-end capabilities—block casting or machining in-house, crankshaft balancing, and flow bench testing, all integrated with a calibration workflow for the ECU. This vertical integration reduces risk by minimizing handoffs between suppliers and eliminates timing gaps that could otherwise introduce misalignment between the mechanical and electronic systems.

From a technical standpoint, the value of a supplier’s in-house capability cannot be overstated. A credible partner should demonstrate more than catalog depth; they should show tangible, in-house competencies that directly impact engine reliability. CNC block machining creates precise bore geometry and deck heights, which set the baseline for reliable compression and head seal integrity. Head porting, when performed in coordination with combustion chamber design refinements, can unlock airflow improvements without sacrificing durability. Crankshaft grinding and dynamic balancing protect bearing life and reduce vibrational energy that translates into wear, noise, and degraded performance over time. The most important proof, however, lies in the testing regime. Thermal cycling tests push components through repeated heating and cooling to reveal weak points. Leak-down measurements verify that piston rings and valve seals maintain compression across many cycles. Cold-flow bench data demonstrate how fuel and air behave at different operating states, informing calibration strategies for injectors, pumps, and the ECU. These are not cosmetic checks; they are the fingerprints of a rigorous engineering process that translates into predictable performance on the road and on the track.

In the marketplace, crate engines and turnkey component packages have grown increasingly common as a solution for Evo 8 builders who want speed-to-start without sacrificing reliability. A well-engineered crate engine, for example, should deliver a harmonized set of parameters: a block that can withstand heat cycles, a rotating assembly that remains balanced under load, a cylinder head with porting that does not compromise cooling, and a fuel-and-ignition system calibrated to the same end goals as the turbo and exhaust layout. The test bench then confirms that this integrated system achieves the promised performance and that it remains robust after repeated dyno runs across different ambient conditions. It is easy to underestimate how much a cohesive system matters until a mismatched combination of parts forces an ECU to compensate in ways that reduce efficiency or shorten component life. When the pieces are designed to fit together, the result is a broader, more dependable performance envelope—torque that comes in smoothly, a throttle response that remains linear as boost rises, and a power band that holds confidence through cornering and braking alike.

Market demand for Evo 8 components has been reinforced by a broader trend toward performance modernization across the internal combustion segment. Carmakers continue to invest in high-output engines that deliver exhilarating performance, driven by a willingness to push power density and precision engineering to new levels. This environment signals to builders that the road to enduring power is paved with robust hardware and disciplined testing. It is not about chasing the loudest horsepower figure in isolation; it is about creating a powerplant that can sustain high-performance use with repeatable results. For Evo 8 enthusiasts, this means that the most reliable route to higher power is not a single upgrade but a coordinated program that aligns crank, block, head, and management software to a shared objective. The result is a platform that remains responsive to tuning, tolerant of daily driving, and capable of performing consistently under a wide range of temperatures and fuels.

Another practical consideration is the procurement path itself. Buyers increasingly favor sources that can offer full-cycle production capability, from initial machining to tested assembly and engine dyno validation. This approach—where the same workshop handles the core metal work, the assembly, and the final performance verification—reduces miscommunications, ensures traceable quality, and establishes a credible warranty framework. It also supports a more predictable lead time, which is essential for project sequencing. In addition, buyers must approach with a clear sense of the required specifications: the target displacement, bore and stroke choices, the preferred gearing of the rotating assembly, and the calibration goals for the ECU. The more precise the early specification, the less time is wasted in development and rework. And because Evo 8 projects often involve turbo systems that push the limits of turbine efficiency, the matching of the exhaust manifold, intercooler sizing, and fuel delivery becomes a shared concern across the mechanical and electronic teams. A well-integrated package thus becomes a blueprint for a reliable, track-ready machine that remains friendly to road use.

The sourcing narrative also raises questions about the lifecycle support for Evo 8 components. Enthusiasts who invest in new components are not merely purchasing parts; they are entering into a relationship with suppliers who can provide documentation of the fabrication path, a transparent trace of material provenance, and post-sale support should maintenance be required. A responsible supplier will offer more than a price quote; they will present a documented bill of materials, machining photos, and a dyno run that demonstrates repeatable results under controlled conditions. That documentation matters because it forms the basis for long-term ownership—future upgrades, ECU recalibration, and consistent results after service work. While the allure of reduced downtime is strong, the long-term payoff is a powertrain that maintains performance integrity across seasons, not just a single demonstration run.

To connect these ideas with practical steps, buyers should focus on building a disciplined inquiry process rather than chasing aggressive up-front pricing. A cautious but curious buyer asks for detailed process documentation, a clear warranty stance, and access to test results that are traceable to individual components. They compare vendors not only by price but also by how well the supplier can articulate the engineering rationale behind each choice, how the components were validated, and how after-sales support is structured. In short, the Evo 8’s new-component journey is as much about process integrity as it is about horsepower. The best outcomes come from partnerships where engineering rigor, transparent testing, and reliable support intersect, enabling builders to push for more power without sacrificing durability, reliability, or the ability to enjoy the car on public roads.

For readers who want a concrete touchpoint during their search, a practical example is the availability of OEM-grade illumination components that must meet precise tolerances and thermal specifications—an area that often mirrors the care taken with powertrain components. You can explore a listing here: brand-new OEM customized HID headlights for Lancer Evo-8-9. This kind of item illustrates the broader principle: high-performance platforms rely on parts engineered with the same level of discipline as the core engine. The lighting system, like the powertrain, demands predictable behavior, stable performance across temperature fluctuations, and robust construction to endure long-term use. The parallel emphasizes an overarching truth: a well-executed Evo 8 upgrade is not a patchwork but a harmonized system where every component, no matter how small, contributes to the whole.

As the search continues, the broader takeaway is clear. The Evo 8 powertrain remains a dynamic platform for modern engineering. The opportunity to acquire fresh components or to assemble a careful, integrated kit from reputable manufacturers makes power a feasible target rather than a distant dream. The reward is a drivetrain that responds with linear torque, maintains smoothness across a wide range of speeds, and delivers dependable performance across diverse driving scenarios. The strategic focus on integrated, validated hardware, supported by transparent documentation and ongoing calibration, transforms the Evolution VIII into a platform that can evolve with the times while preserving its distinctive driving character. External resource: Made-in-China’s catalog of Evo 8 engine components provides a broad sense of the types of parts and precision services available through large-scale manufacturing ecosystems. Explore the catalog here: https://www.made-in-china.com/products/34915724514.html

Turbocharged Pathways: Navigating High-Performance Kits for the Evolution 8 Engine

The Evolution 8 engine, with its 4G63T 2.0-liter turbocharged heritage, sits at a crossroads where daily usability meets track-ready potential. In markets around the world, enthusiasts approach this platform not merely as a means of transportation but as a canvas for performance exploration. The appeal lies in a chassis that can respond to a careful blend of airflow, fuel delivery, and suspension tuning. This chapter examines the spectrum of high-performance modification kits designed for the Evo VIII era, not as a catalog of shiny parts, but as a practical guide to understanding how the right combination can transform a street car into a formidable on-track companion. The goal is to map out the pathways available to buyers and builders who seek to balance power, reliability, and drivability while respecting the inherent limits of aging components, cooling capacity, and the need for precise tuning.

At the core of any Evo VIII upgrade is the turbocharged heart. Upgrading the turbo system is not just about pushing more air into the engine; it is about managing that air with a matched intercooler, refined intake routing, and a calibrated fueling strategy. A typical plan starts with a larger compressor unit paired with a more efficient intercooler to reduce heat soak and to preserve spool characteristics across a wider RPM range. This is followed by a redesigned intake path and a thoughtfully engineered exhaust route that minimizes backpressure without compromising flow velocity. The objective is to achieve quick turbo response, stable boost delivery, and a broad, linear power curve that practitioners can tune toward higher performance without over-stressing the engine’s rotating assembly or cooling system. In practice, such upgrades require more than parts; they demand a coherent tune that respects fuel, ignition timing, and the engine’s thermal envelope. When executed well, the result is not a single horsepower spike but a usable increase across the entire rev range, with predictability on the throttle and consistent performance on a hot day or a long stint on the track.

Beyond the turbo kit, the intake and exhaust ecosystem plays a critical role in shaping the engine’s breathing. A high-flow intake and a mid-to-high-flow exhaust, designed to synergize with the turbo’s characteristics, can unlock meaningful gains. The emphasis is on reducing intake restrictions while maintaining filtration and reliability. A robust exhaust path lowers back pressure, allowing the turbo to spin up more readily and respond to throttle inputs with improved immediacy. When paired with ECU tuning, these components help smooth the power delivery and sharpen throttle response, turning a quick car into a responsive instrument for corner entries and overtakes. Yet, the ecosystem is not just about raw flow; it is about sonic character as well. For many owners, the sound of a well-balanced system—a crisp intake note blended with a controlled exhaust tone—becomes part of the driving experience’s emotional appeal, not merely a performance metric.

Fuel and injection systems form another pillar of the Evo VIII upgrade philosophy. As boost targets rise, so does the demand on fuel delivery. A boost-controlling device coupled with properly sized injectors and a capable fuel pump becomes essential to maintain safe air-fuel ratios under load. The tuning challenge here is to provide sufficient fuel at higher boost pressures while avoiding lean conditions that can threaten the engine’s longevity. In practical terms, this means selecting a fuel system capable of delivering stable volume across the operating spectrum and balancing it with a sophisticated ECU calibration. The tuning process is iterative and data-driven, often requiring road and dyno sessions to refine injector flow, pump supply, and timing. When managed correctly, these adjustments support not only higher peak power but also improved mid-range torque, which translates into more usable performance in everyday driving and more confidence on the road courses.

Message boards and shop walls alike highlight upgrades to the drivetrain and suspension as the bridges between horsepower and usable handling. A robust drivetrain, featuring reinforced transmission components and a reliable differential control system, helps translate increased power into forward momentum without compromising durability. Upgrades to the suspension, including performance-oriented dampers and geometry tweaks, are equally critical. The goal is to preserve stability under braking, maintain grip through cornering, and provide a predictable, communicative feel through steering inputs. These elements work in concert with chassis bracing and bushings to reduce flex and wheel hop, particularly when the car is driven aggressively for multiple laps. It is this alignment of power, grip, and chassis feedback that often defines the line between a weekend warrior and a car capable of sustained high-performance performance.

A complete performance package can offer a one-stop pathway for enthusiasts who prefer a turnkey solution. In this space, the emphasis shifts from piecing components together to selecting a cohesive set of upgrades designed to work in harmony. Complete packages aim to optimize airflow, fuel delivery, cooling, and chassis dynamics in a coordinated fashion, reducing the risk of incompatibilities that can arise when different vendors’ parts are mixed. The outcome is often a more coherent powertrain feel, with a more linear response and balanced performance that remains predictable across road and track conditions. In all cases, the value of a complete package lies in its integration: a tuned balance that respects the Evo VIII’s fundamental strengths—its light weight, its eager turbocharged engine, and its chassis that rewards precise handling—while pushing the envelope of what a street-legal car can do.

For buyers navigating the market, several practical considerations help separate viable upgrades from speculative ones. Compatibility remains a central concern. The Evo VIII’s 4G63T platform can be sensitive to mismatched components, especially when it comes to fueling and engine management. A thoughtful approach begins with a clear plan: identify your target use case—street, track days, or occasional events—and then build toward a cohesive package rather than chasing the highest advertised horsepower figure. Cooling capacity is another critical factor. Higher boost and greater airflow demand more robust intercooling and radiator capacity. Without cooling headroom, power can sag as heat builds, and the risk of detonation increases. Skilled tuners will emphasize thermal management as much as airflow and fuel delivery, ensuring that the engine remains within safe operating temperatures during sustained performance driving.

The procurement path for Evo VIII performance upgrades often traverses global marketplaces and specialist shops. If a buyer is exploring a fresh assembly of components, it can be advantageous to begin with a broad search on reputable platforms that cater to performance enthusiasts. This approach increases the likelihood of finding parts designed for the Evo VIII and compatible with the vehicle’s era and specifications. A careful evaluation of part condition, compatibility notes, and return policies is essential, particularly when sourcing used or refurbished components. For those who seek a more direct route, some markets offer one-stop upgrade programs from manufacturers and workshops that emphasize integration and support. In such cases, the value lies not only in the parts themselves but also in the accompanying installation guidance and post-purchase tuning services.

As performance ambitions deepen, many builders also consider aerodynamic and cosmetic upgrades that complement the powertrain work. Front-end components and body panels that optimize airflow can reduce lift and improve high-speed stability, while interior ergonomics and weight management contribute to a more engaging driving experience. A practical touch used by many is pairing functional aero with protective and aesthetic elements that endure under heat and vibration. Such decisions reinforce the sense that the Evo VIII, properly upgraded, is not merely a faster car but a more focused instrument for precise, confident driving.

In this context, one practical tip sits at the intersection of form and function. When evaluating a bodywork upgrade, consider a front-end piece that integrates with existing cooling strategies and aerodynamics. A well-chosen piece can offer both functional gains and a visual identity that suits the car’s performance character. For those who want to explore that option further, an example from the marketplace exists under a listing described as a front bumper with carbon lip designed for the Evo VIII and nearby Evo IX models. This is not a recommendation but a representative touchpoint for how aero and aesthetics can converge on this platform. You can explore a representative option here: evo-8-9-varis-front-bumper-with-carbon-lip.

For readers who want to broaden their knowledge beyond individual components, a curated catalog of Evolution VIII performance parts can provide a useful reference point. These catalogs summarize categories, compatibility notes, and general performance expectations across multiple upgrade families, helping buyers form a holistic plan before spending. An external resource that offers such a catalog can serve as a helpful starting point for comparison and budgeting. External resource: https://www.jdmparts.com/mitsubishi-evolution-8-performance-parts. This reference can guide readers toward a structured understanding of what to demand from a coordinated upgrade and how to gauge which upgrades are most appropriate for their goals without getting lost in supplier hype.

The overall message is clear: the Evolution 8 engine for sale is not a static relic but a living platform whose value comes from thoughtful, coordinated upgrades. When the parts, tuning, and cooling align, the result is a car that breathes with purpose, responds with immediacy, and remains capable on both the public road and the race circuit. The choice of upgrades should reflect not just horsepower targets, but also the driver’s discipline, the intended use, and the car’s ability to sustain its performance under real-world conditions. By approaching the Evo VIII upgrade path with a plan that prioritizes compatibility, cooling, and a cohesive tuning strategy, enthusiasts can unlock a meaningful, reliable performance that endures beyond the thrill of the first dyno pull.

Markets in Motion: Sourcing Evolution 8 Engines for Sale—Balancing Authenticity, Power, and Practicality

The market for Evolution VIII engines in the mid-2020s moves with a pace that matches the cars themselves: deliberate, technical, and increasingly global. A combination of tightening emissions norms, aging but beloved mechanical platforms, and a rebirth in interest from rebuild specialists has transformed how enthusiasts and shops think about where power comes from, what it costs, and how reliably it can be delivered. Authentic OEM components from the original era still hold a premium for those chasing exacting restoration criteria. They offer proven compatibility, documented history, and the reassurance of factory engineering. Yet their scarcity and price can slow even the most determined build, turning a straightforward swap into a prolonged hunt across continents and years of production timelines. Buyers, therefore, navigate by weighing the weight of genuine parts against the speed and practicality of alternatives that arrest the clock and still deliver the roar and responsiveness that define the Evo VIII experience.

Beyond the OEM perch, remanufactured or rebuilt engines present a mid-path that appeals to a broad spectrum of builders. They promise a balance of authenticity and cost control, with warranties and documented remanufacturing processes designed to restore power bands and reliability. The value proposition rests on more than just the initial price; it hinges on predictable performance, the leverage of modern testing practices, and the ability to integrate with aftermarket components without repeated surprises. In markets where OEM parts have grown scarce, these options become practical lifelines for projects that aim to hold the essence of the Evo VIII’s character while embracing contemporary machining tolerances and improved quality control. The challenge is to discern rebuild quality from generic assembly, ensuring that the base block, cylinder heads, and rotating assemblies have undergone the kind of scrutiny that gives long-term confidence during street and track use alike.

A third path expands the horizon even further: crate or complete engine packages sourced from regional manufacturers that operate with a higher degree of vertical control. In certain regions, workshops and metrology networks offer end-to-end production, including block casting, balancing, head porting, ECU calibration, and dyno validation. The promise here is coherence—an integrated approach in which all stages of assembly are aligned toward a target specification. Buyers who pursue this route often seek engines that not only meet original specifications but also come with enhanced tolerances or tuned components that better respond to aftermarket hardware, from turbochargers to high-flow intakes and performance exhausts. The trade-off, of course, is scrutiny: an engine built away from the original supply chain demands rigorous evaluation of build data, test results, and performance evidence before committing to a purchase.

In 2026 the market has shown a notable uptick in demand tied to a global shift toward powerplants that temper emissions while preserving the mechanical drama that fans crave. The 22 percent year-over-year rise in sales of authentic, high-fidelity components mentioned in recent market analyses reflects a broader appetite for engines that can be rebuilt to factory intent, or better, to a calibrated modern standard. This demand is not simply about horsepower numbers; it is about reproducibility, warranty coverage, and the ability to map performance to controlled dyno outcomes. Enthusiasts are increasingly asking not just how much power a build can produce, but how repeatable and serviceable that power will remain as miles accumulate and regulatory pressures intensify. The result is a market that rewards buyers who couple technical acumen with disciplined sourcing practices, where the easiest choice is not always the best one for a given project.

A careful sourcing strategy becomes essential when evaluating the three broad options. OEM parts from the era still sit atop the authenticity ladder. They are most compelling for restoration-grade builds or competitions that demand unfailing originality. Yet their limited availability means that practitioners often accept longer lead times and higher budgets, sometimes adding logistics complexity and import duties into the total price of ownership. Remanufactured engines from Western suppliers present a balanced alternative. They can offer warranties that reduce risk, while still delivering power and reliability that perform well in daily driving and weekend track days. The risk with remanufactured units lies in the variability of source material, the depth of refurbishment, and the clarity of testing documentation. Builders must probe the provenance of the core, the precision with which components were re-machined, and the transparency of performance data such as leak-down results or cold-flow bench testing. Without such data, even a seemingly cost-effective option can become a maintenance headache in the long run.

Crate engines produced in other regions introduce a different calculus altogether. To the extent that these options are viable, the core advantage is coherence and supply chain control. A manufacturer that runs its own block casting, cylinder head work, and ECU calibration, backed by dyno validation, can offer engines with consistent tolerances and a well-defined warranty framework. For buyers, though, due diligence remains essential. The minimum checks should include an engineering dossier that documents the machining tolerances, the thermal cycle testing performed to simulate real-world conditions, and an objective leak-down or compression profile that demonstrates integrity at start-up and under load. Informed buyers look for evidence of dynamic balancing of rotating assemblies, careful attention to bearing clearances, and a thermal management strategy that aligns with the intended operating envelope.

The evaluation criteria extend beyond raw specs and into the logistics of sourcing itself. A credible supplier network should present transparent, science-based data rather than glossy marketing claims. Buyers expect to see evidence of CNC block machining, precise bore alignments, and consistent gasket sealing behavior under pressure. They want to review test data that shows how the engine behaves across a range of temperatures and RPMs, as well as documented bench results that corroborate claimed horsepower parity with original hardware. When such data exists, it becomes a foundation for a more predictable build plan, enabling performance targets to be set with a higher degree of confidence and enabling clearer budgeting for related components such as fuel, intake, and exhaust systems. The decision then becomes not only about the price tag but about the likelihood of meeting endurance goals without repeated tinkering or mid-build surprises.

In practical terms, a builder facing these options can think in terms of goal-oriented sourcing. If restoration fidelity and originality drive the project, the path toward OEM parts and carefully curated remanufactured units may be the safest course. If the objective is to balance cost with performance enhancements and faster project completion, a well-chosen crate engine with robust documentation and a reputable support structure can deliver the most predictable workflow. If, instead, the emphasis is on preserving classic driving dynamics while pushing the envelope on power with aftermarket modifications, a crate option that explicitly aligns with a performance-focused build might be the best path, provided the accompanying ECU, sensor calibration, and fueling strategy are coherently integrated.

To illustrate a practical option within the crate-engine landscape, a complete compact package that includes a short motor can serve as a compelling reference point. This kind of package embodies the core virtues of modern sourcing: controlled specifications, a clear assembly lineage, and a defined set of engineering tests that reassure buyers about repeatable outcomes. When considering such an option, it is essential to request comprehensive build records, validate the reliability metrics, and confirm the compatibility of the crate with the rest of the drivetrain and transmission family in a way that mirrors the original platform. The compatibility story matters just as much as the horsepower figure, because a mismatch here can undermine the entire efficiency of the build even before it begins to encounter the road.

For readers who want a concrete example of this approach without navigating multiple brands or platforms, a representative crate short-motor option can be a helpful place to start. It provides a tangible reference point for what a tightly controlled, engineered package looks like and how it should perform under controlled testing conditions. complete 4G63 short motor package serves as a practical anchor in discussions about sourcing. It is not the only path, but it crystallizes how a complete package, assembled with in-house precision processes and validated by testing, can align with specific build goals and timeframes. Buyers can use this reference to shape their questions to potential suppliers, ensuring they demand the right documentation, the right warranty terms, and the right post-sale support that will preserve both performance and peace of mind as miles accumulate.

The broader conclusion remains consistent across channels: the Evo VIII engine for sale exists in a marketplace defined by choice, discipline, and the engineering rigor behind each option. Authenticity carries tremendous value, but it is only one dimension of a multi-faceted decision. A well-drafted sourcing plan that aligns with a clear performance goal, a disciplined testing regime, and a realistic maintenance program will outpace a purely price-driven approach. As regulations tighten and the technical bar for reliability rises, the market rewards buyers who treat engine acquisition not as a one-off purchase but as a carefully curated, long-term investment in the car’s character and its future on the road and the track.

External reading: For broader supplier listings and additional context on Evo 8 engine availability, see this original source: https://www.made-in-china.com/products-search?keyword=Evo+8+engine

Between Power and Precision: Installing and Maintaining an Evolution VIII Engine Ready for Sale

The moment a buyer encounters a performance engine touted for a late-model, all-wheel-drive icon, the landscape of possibilities unfurls with equal parts excitement and caution. An Evolution VIII engine for sale represents more than a raw power source; it is a carefully engineered package that, when integrated with the right supporting systems, can transform a daily driver into a focused track companion. The engine’s legacy rests on a turbocharged four-cylinder backbone that rewards precise tuning and disciplined maintenance. Yet that same configuration demands a disciplined approach to installation and ongoing care. The journey from listing to road-ready power is not simply a swap of one component for another; it is a choreography of systems that must sing in harmony to avoid detonation, overheating, or sudden drivability issues. The core idea is clear: to unlock reliable performance, you must treat installation as a system-wide undertaking and maintenance as an ongoing craft rather than a one-time task. \n\nInstallation begins long before the engine is bolted in. It starts with a plan that respects the vehicle’s existing architecture while acknowledging the higher stress the engine will endure once boosted. A professional install is not optional when you are dealing with a performance engine intended to operate well beyond stock parameters. The technician must understand how the intercooler interacts with charge air temperatures, how the fuel delivery system feeds the turbo under load, and how the exhaust flow shapes spool and response. The basics—proper engine mounting, precise alignment, and secure harnessing of sensors and lines—are not mere formalities; they are prerequisites for predictable drivability. In practice, this means selecting compatible mounting hardware and ensuring the engine and the chassis share a common performance language. If the installation involves upgrading the turbocharger, intercooler, or fuel injectors, those choices should be coordinated with the ECU strategy. The goal is to maintain a balanced air-fuel ratio and a stable timing map across the engine’s operating range. In many setups, achieving a reliable 350–450 horsepower, as suggested by experienced builders, requires more than bolting on a bigger turbo. It demands a holistic approach that includes upgraded intercooler plumbing, robust fuel delivery components, and careful ECU remapping that respects the engine’s thermal and mechanical limits. The integration task also extends to the exhaust system. A well-matched exhaust not only contributes to power gains but also preserves exhaust scavenging that helps the turbo respond consistently under varying loads. The relationship between backpressure, turbo lag, and exit velocity becomes part of the installation calculus. A mismatched exhaust can melt the gains achieved by other improvements and create drivability headaches. In short, the install is a study in system compatibility rather than a simple part swap. The technician’s attention to detail—correct gasket sealing, precise torque specs, and verified sensor readings—serves as the first line of defense against future failures. Even with a fresh install, the engine’s early life should be treated as a study period. The owner’s tolerance for minor tuning quirks, such as turbo surge at certain RPMs or slight idle fluctuations, must be balanced against the engine’s long-term health. It is during these initial miles that the fueling curve, boost targets, and ignition timing are tuned to match the specific vehicle weight, aerodynamics, and cooling capacity. The practical takeaway is simple: a well-executed installation reduces the risk that high-performance ambitions will outpace the car’s fundamental reliability.\n\nMaintenance, meanwhile, is the mirror image of installation. It is the ongoing discipline that keeps the engine’s performance envelope from sliding into unsafe territory. Routine oil changes with high-quality synthetic lubricants are not luxuries but necessities. The turbocharged four-cylinder operates at elevated temperatures and pressures, especially under hard driving. Clean, correctly profiled oil not only reduces friction but also provides critical cooling for hydraulic lifters, variable valve timing gear, and the turbocharger’s bearings. A meticulous change interval—more aggressive than stock schedules—helps preserve ring seal integrity and minimizes carbon buildup in the cylinder head. The intercooler, a vital line of defense against detonation, deserves periodic attention. Leaks or blockages in the intercooler circuit can allow charge temperatures to climb, eroding knock resistance and threatening engine integrity. The maintenance routine should include a methodical inspection for leaks, pressure test results, and a check of hoses for softening or cracking. As boost levels rise, the importance of airflow management becomes more pronounced. Compressor efficiency can decline at higher RPMs if intake piping or air filters restrict flow. Upgrades to the intake tract—while not strictly necessary for every build—often provide a more consistent, repeatable performance and reduce the risk of lean conditions that inflame detonation. If modifications extend beyond the engine’s basic configuration, fueling and cooling must advance in lockstep. A remapped ECU paired with enhanced fuel delivery and improved cooling is not optional—it is a fundamental requirement for maintaining engine health when the boost is elevated. The engine’s thermal stability, in particular, deserves close attention. Sustained high load and elevated temperatures can promote detonation if the timing advances too aggressively or if fuel quality varies. This is why, even after the installation, a schedule of periodic checks on ignition timing, knock sensors, and booster maps is essential. The best practice is to treat tuning as an iterative process, not a single event. Small, well-documented adjustments over time yield the most reliable results and help preserve the engine’s longevity under spirited driving.\n\nAnother pillar of maintenance concerns the engine’s mechanical wear components. Even with a fresh build, the camshafts, valve springs, and connecting rods endure higher thermal and mechanical stress after a boost is introduced. Regular compression or leak-down tests can reveal subtle issues before they become catastrophic. Head gasket integrity deserves particular vigilance, as any failure in a boosted application can cascade into coolant and oil contamination, complicating repairs and increasing downtime. The transmission and drivetrain deserve equal attention. A robust torque transfer system, clutch assembly, and driveshafts must be matched to the engine’s output. Inadequate clutch grip or insufficient differential cooling can undermine acceleration or, worse, lead to driveline shock during full-throttle shifts. The practical upshot is that maintenance buys reliability. It protects the investment behind the engine and the labor that brought it into the vehicle. It also preserves the owner’s confidence in the car’s daily-miles-to-track-days balance.\n\nFrom a purchasing perspective, the path to acquiring an Evolution VIII engine for sale invites prudent scrutiny. Used engines, in particular, must be evaluated with care. Verifying the engine’s history—prior rebuilds, mileage, and any signs of turbo or head gasket service—helps set expectations for the level of refurbishment that may be required. A comprehensive professional diagnostic is non-negotiable before committing to a purchase. Even engines that arrive with a clean bill of health benefit from a careful initial break-in and data logging to confirm that oil pressures, fuel trims, and boost targets remain within designed ranges. When considering a broader upgrade strategy, many enthusiasts browse a spectrum of aftermarket components within a coordinated plan. This approach recognizes that the engine’s performance envelope expands most safely when the supporting systems—fuel, cooling, intake, exhaust, and engine management—are upgraded in a coherent, test-driven sequence rather than piecemeal. In this way, the buyer can mold a build that aligns with the car’s intended use, whether that is daily driving with occasional track sessions or concentrated weekend performance. The acquisition is not simply about horsepower numbers; it is about the engine becoming part of a reliable, well-regulated system that maintains everyday drivability while delivering the thrill of higher-lift performance.\n\nFor those who seek a broader upgrade path beyond the core engine, the ecosystem of parts and accessories offers a spectrum of choices. In practical terms, this means considering options for auxiliary systems and aero-related enhancements that help manage the car’s new performance profile. A front bumper upgrade, for instance, can play a strategic role in airflow management, reducing lift at speed and providing a more aerodynamic package that complements engine performance. This is a case where a single purchase becomes the gateway to a coordinated, whole-vehicle transformation. Engaging with reputable suppliers who offer compatible components is essential. The key is to ensure that these add-ons are designed to harmonize with the engine’s output, rather than create conflicting demands on the vehicle’s control systems. For instance, when coupling upgraded body components with a high-performance engine, it is prudent to verify that mount points, weight distribution, and cooling capacity remain balanced. In practice, a well-considered upgrade plan preserves handling, braking, and stability while enabling the engine to deliver its full potential. Finally, for readers who want a more grounded technical reference, a trusted source provides a detailed overview of the Evolution VIII’s engine architecture, performance characteristics, and maintenance practices. The article offers a robust framework for understanding how the engine behaves under boost, how to interpret fuel and timing strategies, and how to approach maintenance with long-term reliability in mind. External reference: https://www.motortrend.com/cars/mitsubishi-evolution-8/ \n\nAs a closing note that threads through every practical decision, the overarching philosophy is clear: an engine intended for sale and installation represents a shared commitment between seller and buyer. It is a commitment to documentation, to professional service, and to a maintenance cadence that respects the engine’s stress points. The goal is a seamless fusion of performance and reliability, where the thrill of faster acceleration and sharper responses is matched by predictable daily drivability and a transparent maintenance trail. When the installation is executed with care, when supporting systems are upgraded in a thoughtful, coordinated way, the Evolution VIII engine for sale becomes not just a piece of hardware, but a well-planned pathway to a vehicle that can be driven with confidence and enjoyed at the limits. For readers exploring the practical realities of such a project, the sentence above captures the essential balance: power deserves precision, and precision protects power. The result is a car that can deliver the sensations enthusiasts seek without compromising on road manners or long-term durability. For a broader technical context and deeper performance considerations, the referenced article provides a comprehensive foundation that complements the hands-on guidance outlined here.

From Garage to Dyno: Navigating the Market for a Modified Evo 8 Engine

The appeal of a modified Evolution 8 engine sits at the intersection of raw ambition and practical know-how. Car enthusiasts who chase big power on a 2.0-liter turbocharged heart are drawn to Evo 8 engines because they promise a feeling that sits somewhere between a rocket and a road racer. Yet as the market for Evo 8 engines and their supporting parts grows, so does the need for methodical evaluation. Buyers often face a balancing act: the thrill of more horsepower against the realities of reliability, fuel system demand, and the cost of professional installation. Understanding this balance means following not just the headline figures but the story behind them—the hardware that makes the numbers possible, the conditions under which they were achieved, and the expertise required to keep such builds running in the real world of street and track. Within the Evo 8 ecosystem, the core engine platform centers on a compact four-cylinder block paired with a turbocharging setup that can be tuned to shift the entire vehicle dynamics. For many, the entry point is a stock or near-stock engine with upgraded supporting components rather than a blank slate build. The reason is simple: power without control is a recipe for unreliable performance. When you start stripping away the stock calibration and installing forged internals, upgraded fuel delivery, and enhanced cooling, you begin a chain of dependencies. The engine’s fuel system must feed higher demands, the cooling system must dissipate extra heat, and the ECU must be tuned to harmonize air, fuel, and ignition under a wider range of operating conditions. This is not only a question of parts but of a cohesive build plan—a map that connects the turbo kit, intercooler, exhaust path, fuel rails, injectors, and the engine management software into one reliable system. On the sourcing side, the market reveals a broad spectrum of options. Some buyers look for complete new or rebuilt cylinder heads and engine assemblies that claim factory-fresh status on platforms that facilitate bulk buying. Price ranges can vary widely, with complete head assemblies or other major components offered at seemingly accessible levels. The appeal of a complete package is obvious: a known starting point that reduces some guesswork in the build. Yet the caveats are equally important. The provenance of such components, the presence of proper machining specifications, and the history of the part must be verified. In this context, marketplaces that enable direct supplier-to-buyer transactions can be valuable, especially for those who want to compare multiple options quickly. But diligence remains essential. Buyers should require third-party diagnostic data and realistic load testing results rather than relying solely on manufacturer claims. The difference between a piece that merely looks capable and a part that withstands race-level stress is often found in the documentation, the test results, and the installer’s level of experience. Among the practical routes to market, there is also knowledge embedded in the stories of successful builds. A compelling example documented by enthusiasts describes a Evo 8 that became a virtual benchmark after a comprehensive upgrade: an evolved turbo system, a tuned intercooler setup, a bespoke exhaust path, enhanced fuel delivery with tuned injectors, and a carefully developed ECU map. The result was horsepower numbers that breached the 400-hp line on a dyno, while the car maintained a level of drivability required for road use and the durability needed for repeated track sessions. This kind of outcome is possible, but it rests on choosing compatible parts, an unbroken chain of professional installation steps, and ongoing maintenance. The same story also emphasizes the necessity of verifying the modification lineage—each component’s origin, the quality of the installation, and the alignment of the build with the vehicle’s cooling and lubrication strategy. Without those elements, the gains risk becoming short-lived heat sources rather than sustained performance. For buyers formulating a plan, the question becomes not only what to buy but how to buy it. The Evo 8 market rewards a clear understanding of where power comes from and how it is sustained. Upgrades that dramatically increase flow through the intake and exhaust, when paired with a robust cooling solution and a calibrated ECU, create the conditions for real, track-worthy performance. But there is a practical dimension to consider as well: the vehicle’s daily usability. A well-tuned high-hp Evo 8 engine can be a joy on a weekend road course, yet it may demand more attentive maintenance, higher fuel costs, and specialized service compared to a more modest but reliable build. The ownership experience, therefore, is a negotiation between the speed you want and the predictability you can tolerate. In all cases, a rigorous maintenance routine, quality lubrication, and attentive diagnostics remain non-negotiable. The engine itself is a collection of systems that must work in concert; neglect any one of them, and the entire performance objective can be compromised. Relevant guidance for anyone entering this space is to approach the market with a plan that includes documentation, verification, and a clear sense of how far you want to push the peak numbers. If your goal is to achieve a high-12 to low-13 second quarter-mile capability or a 6-minute track day companion, you should set expectations accordingly. High-quality components—such as upgraded turbochargers, more efficient intercoolers, a properly sized fuel system, and a tuned ECU—are critical, but so is the surrounding infrastructure: a dependable clutch setup, a robust short-block when required, and a cooling system that can handle the extra thermal load. The data points from field testing and performance labs suggest that with the right combination, you can surpass the 400-hp threshold while keeping the package streetable and durable, provided you maintain rigorous service protocols. In this sense, the Evo 8 engine for sale is not a single bargain but a pathway built from decisions about components, installation quality, and long-term upkeep. To illustrate the practical path of exploration, one can examine a gear-driven upgrade concept that is well documented in performance circles. A full sequential gearbox upgrade, when married to an Evo-class engine, unlocks a level of drivability that suits both aggressive road driving and controlled track sessions. This topic, while not the central focus of every sale listing, is a reminder that performance is never just about raw horsepower. It is also about how the power is delivered, how quickly the drivetrain can respond, and how reliably the system can endure repeated shifts at the edge of grip. For readers curious about how far a drivetrain upgrade can go in real Evo 8 builds, a deeper look is available at the gear-specific resource linked below. full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x. This resource reinforces the principle that a robust performance project depends on coherent integration across engine, fuel, cooling, and transmission systems. With those ideas in mind, the decision framework becomes clearer. If you are evaluating an Evo 8 engine for sale, start by outlining your performance target and your intended usage—street driving, occasional track days, or a competition setup. Then request a complete modification history and third-party validation where possible. Ask for weathered but accurate dyno sheets, not just peak numbers. Confirm that forged internals, upgraded fuel delivery, and cooling enhancements were installed by qualified shops and that the ECU mapping is tuned for the specific parts in the car. If the seller can provide diagnostic reports or a credible track-side data printout, you gain a higher level of confidence about longevity and reliability. Finally, ensure you have access to a support network of qualified technicians who can service the build and a budget that accounts for maintenance, insurance, and the inevitable future upgrades. In the end, the Evo 8 engine for sale becomes not just a power unit but a carefully engineered platform that requires skill, patience, and ongoing attention to keep delivering the performance you expect on the road and beyond. External reference for deeper context on verified performance benchmarks and decision frameworks is included here: How To Choose The Best Evo 8 Engine For Your Performance Build. https://www.performancecar.com/how-to-choose-the-best-evo-8-engine-for-your-performance-build

Final thoughts

Understanding the market for Mitsubishi Lancer Evolution 8 engines, along with their components and potential modifications, equips business owners with the tools necessary to excel in this competitive landscape. By leveraging the insights shared throughout this article — from new components to performance enhancements and essential maintenance — you can align your offerings with the evolving demands of automotive enthusiasts and maximize your profitability. Embrace the Evolution 8 engine marketplace, and set your business up for success in an industry that thrives on performance and innovation.