The Mitsubishi Lancer Evolution series has long been a beacon for automotive enthusiasts seeking performance and style. Among its key components, the front bumper stands out as both a visual focal point and a critical element in the car’s aerodynamic profile. As the landscape of automotive modifications evolves, business owners in the aftermarket parts industry must stay informed about consumer preferences, production trends, and innovative designs. This article delves into three pivotal aspects affecting front bumpers for Mitsubishi Lancer Evolutions: the lightweight construction and competitive advantages of the Evo 7 bumpers, the industrial production trends that highlight China’s manufacturing capabilities, and the cutting-edge design innovations featured in Evo X bumpers. Together, these chapters will provide a comprehensive overview of the evolving landscape of front bumpers in the performance automotive market.

Front Bumper Evolution: Aerodynamics, Materials, and the Identity of the Mitsubishi Lancer Evolution VII

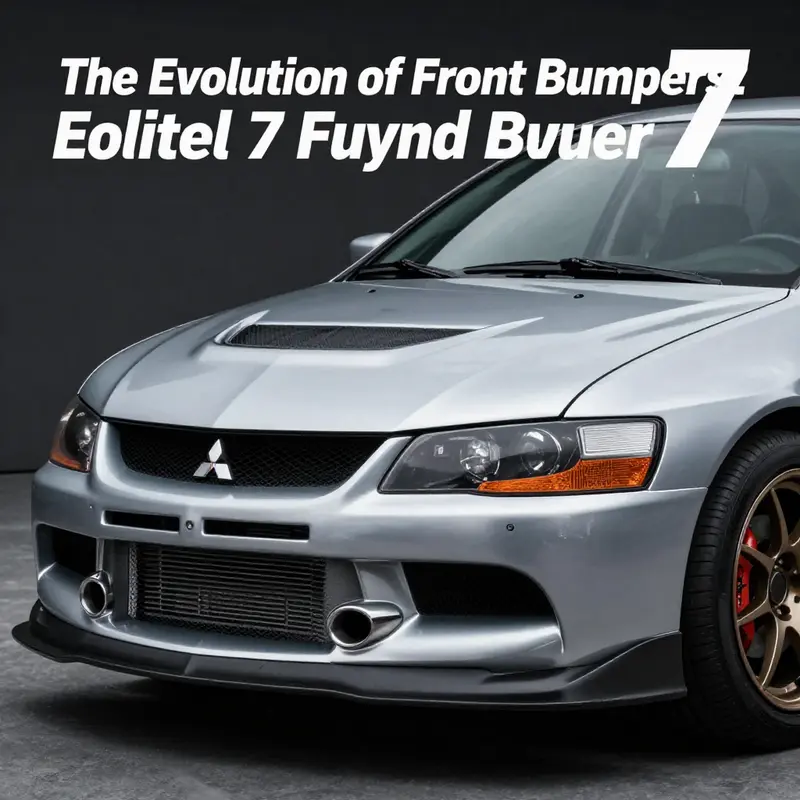

The front bumper of the Mitsubishi Lancer Evolution VII is more than a protective shell. It is a statement of intent, a functional argument written in air and under the hood. From the moment the car is seen in profile, the Evo VII announces a philosophy: form follows function, and function demands air. The most striking feature of this bumper is the oversized central air dam. It is not merely a stylistic flourish; it is a carefully calibrated duct, designed to funnel cool air to the engine bay and, critically, to the brakes. In high-speed driving, where every degree of cooling and every gram of drag counts, the central intake serves as the heartbeat of the cooling system. It feeds the radiator and, through carefully arranged internal passages, channels air toward the brakes to keep them from fading during extended laps or spirited street sessions. The left and right side openings work in concert with the center, guiding airflow across the car’s face to minimize lift and to stabilize the body at high velocity. This is not a bumper that sits passively in front of the car; it is an aerodynamic instrument, a component whose geometry has been honed in wind tunnels and on the road alike to sculpt the way the Evo VII meets the air.

The design language of the Evo VII’s front end is aggressive, with sharp lines and deep contours that convey a sense of weaponized intent. The bumper’s silhouette creates a sense of forward propulsion, as if the car is leaning into the air rather than being pushed by it. This attitude is not superficial. It reflects a period when engineers and designers began to treat the entire front end as an integrated aero platform. The bumper does not exist in isolation; it works with the hood line, the fenders, and the lower front splitter to manage how air enters, how it exits, and how it interacts with the underbody. The goal is to reduce pressure buildup in front of the car, which translates to lower drag and improved high-speed stability. In practice, the Evo VII’s bumper helps generate a clean separation of airflow around the vehicle’s front corners, reducing turbulent wake that could otherwise buffet the chassis at speed. The wind tunnel studies that informed these decisions reaffirmed that the combination of the large central intake and the side ducts provides a balanced distribution of pressure that keeps the nose planted during high-speed acceleration and cornering.

Beyond raw aerodynamics, the bumper is a study in integration. It houses the fog lamps in a knock-on fashion that preserves the overall geometry while adding practical lighting for poor weather driving. It includes the lower valance, a separate feature that is often overlooked but plays a crucial role in directing air along the underside of the bumper. This arrangement ensures that cooling air is not diverted away from the radiator and brake components during dynamic driving. The valance also contributes to the visual continuity between the bumper and the rest of the front fascia, reinforcing the car’s aggressive stance without appearing clumsy or disproportionate. When you observe the Evo VII from head-on, you witness a purposeful orchestration of elements that are more than the sum of their parts. The bumper’s integrations—fog lamps, grill openings, and lower diffuser-like elements—work together to create a coherent system where cooling, airflow management, and aesthetics are one.

Material choices for this bumper reflect a balancing act between stiffness, weight, and durability. The original equipment manufacturer (OEM) or high-quality aftermarket front bumpers for the Evo VII tend to be fashioned from robust engineering plastics, such as high-strength ABS, or, in performance-oriented builds, reinforced composites including glass fiber. ABS offers a practical mix of impact resistance and lightness, which translates to lower weight without compromising structural integrity. The glass fiber-reinforced variants push the weight down further and improve rigidity, which is especially appealing for track-focused builds. In either case, the bumper is engineered to absorb and dissipate minor collision energy, helping to protect the underlying structure while maintaining a weight distribution favorable to handling. The material science here is not merely about saving a few pounds; it is about enabling the car to respond more predictably in demanding driving situations. A lighter bumper lowers unsprung mass and helps the suspension respond more quickly to road imperfections, which translates to more precise steering feedback and improved ride quality in aggressive driving scenarios.

The Evo VII’s bumper is also a portal to the broader ecosystem of the car’s performance culture. While the bumper is fully functional in its stock or OEM-style form, it is commonly seen as a foundation, a starting point for a broader aero program. The more committed enthusiasts use the Evo VII as a chassis onto which a suite of aerodynamic upgrades can be mounted—front lips, canards, side skirts, and diffuser components that work in unison to shape the vehicle’s aerodynamic footprint. The bumper becomes the anchor for this ecosystem, a stable platform that preserves OEM fitment while allowing for modular enhancements. The ability to mount additional aero elements without sacrificing integrity or safety is a key attribute of a bumper that has matured through multiple generations of Evo platforms. It is a testbed for the idea that performance can be improved without sacrificing daily usability or reliability, a balance that is central to the Evo’s enduring appeal.

In considering the Evo VII’s evolution, it is helpful to think about how the aftermarket and the OEM designers view the bumper. For many, the goal is not only to replicate the factory aesthetics but to improve on them in ways that can be integrated into the daily-driving experience. Weight reduction is a recurring theme, as is the pursuit of enhanced cooling efficiency. The bumper’s geometry is often adjusted to align with updated intercooler routing, radiator inlets, and brake cooling pathways that may have evolved in parallel with other performance components. It is a reminder that the front bumper is not a static ornament; it is a living part of a dynamic performance system, one that has to adapt to evolving engines, tighter cooling requirements, and more capable braking hardware.

To appreciate the Evo VII’s bumper in its contemporary context, one must also consider the global supply chain that supports its production and upkeep. The modernization of the car’s front-end components has paralleled the maturation of a robust automotive parts industry in places like Guangdong Province, China. In the era of the Evo VII’s peak popularity, the region’s clustering of injection molding, fiberglass fabrication, painting, and tooling facilities meant that high-quality bumpers could be produced and finished with a level of precision that once would have required long, expensive supply chains. This geography of manufacturing created efficiencies that benefited both OEM and aftermarket suppliers, allowing for rapid iteration and consistent quality assurance. The proximity of these facilities—along with established export logistics—helped suppliers meet the growing demand from North America, Europe, and Asia. It also meant that many of the aftermarket front bumpers available for the Evo VII could offer realistic OEM-inspired aesthetics with reliable performance parity. The specialization in precision molding and surface finishing offered a practical pathway to deliver bumpers that not only looked right but performed as expected under real-world conditions.

As the Evo line expanded into the later generations, the concept of the front bumper as an aero instrument remained central, but the execution evolved. For the later Evo X, the industry increasingly stressed OEM-specific fitment and more integrated aerodynamic systems. Bumpers began to feature more complex air intakes, venting for engine and intercooler cooling, and even more sophisticated lower lip configurations designed to minimize drag while maximizing cooling capacity and high-speed stability. Yet the Evo VII’s bumper remains a touchstone in this evolutionary arc. It represents a moment when the balance between aggressive styling and functional aerodynamics became a design language that reverberated through the entire Evo community. The aftermarket landscape followed suit, offering variants that preserved the core geometry while exploring materials like advanced glass fiber composites and, in some cases, carbon fiber accents for selective upgrades. In this sense, the Evo VII’s front bumper is not a relic but a living reference point—a reminder that the road to greater performance is paved with decisions about weight, airflow, and the tactile feel of a car that truly wants to cut through the air.

For enthusiasts who crave a modern look with a nod to the classic identity, the current market offers options that maintain the familiar silhouette while integrating contemporary performance features. Some high-end aftermarket versions emphasize air management with more aggressive channels and vents, while still preserving the essential central dam and side intake architecture that define the Evo VII’s frontal face. When discussing these upgrades, it is important to consider not only aesthetics but safety and OEM certification. The best options are those that maintain crashworthiness and structural integrity while enabling a performance-oriented driver to push the car to its limits without compromising protection. The Evo VII’s bumper thus stands as a baseline for evaluating how far a modern front-end package can be pushed while respecting the vehicle’s original intent.

From a practical perspective, the Evo VII’s bumper embodies a philosophy that resonates with many performance-minded owners: optimize the path of least resistance through air while preserving a level of reliability that makes the car a capable daily driver. The bumper’s design supports cooling, visibility, and protection in a cohesive, well-integrated package. It is a reminder that in performance cars, beauty often lies in the quiet efficiency of a component that does its job so well that you hardly notice it—until you push the car to its limits and feel the difference a well-tuned front end can make. The evolution is ongoing, but the Evo VII’s front bumper remains a crucial reference point in understanding how Japanese performance engineering translated into real-world aerodynamics and everyday usability.

In the spirit of ongoing refinement, the conversation about front bumpers cannot ignore the broader ecosystem of suppliers and builders who shape the Evo’s aerodynamic identity. For those who want a contemporary, visually aggressive extension of the classic design, aftermarket options—such as the modern Varis front bumper family—demonstrate how air management, weight, and aesthetic aggression can be reimagined without sacrificing compatibility or safety. A notable example from the current catalog highlights how a modern forward fascia can balance aggressive lines with precision fitment, leveraging advanced composite materials to reduce weight while preserving rigidity. This aligns with the Evo VII’s core principle: a bumper should be more than a shield; it should be a loud, efficient statement of how a car meets the wind.

As readers consider upgrading or restoring an Evo VII, the bumper’s role becomes a lens through which to view the vehicle’s evolution as a whole. The front end, with its defining air dam and carefully shaped intakes, encapsulates a design approach that marries track-tested air handling with the daily practicality that fans and owners demand. It is a reminder that the Evo’s identity is built not just on its engine or chassis, but on the way every component—down to the bumper—contributes to performance, reliability, and the driving experience. The Evo VII’s bumper is more than a component; it is a chapter in a longer story about how airflow, materials, and manufacturing excellence coalesce to create a car that continues to captivate enthusiasts nearly two decades later.

Internal reference and further reading: For a contemporary exploration of aero upgrades in the Evo family, see the discussion of the Evo 8/9 Varis front bumper with carbon lip, which illustrates how modern materials and design innovations extend the lineage of performance-focused front-end engineering: evo-8-9-varis-front-bumper-with-carbon-lip.

External reference: To glimpse how global marketplaces present OEM-inspired front bumpers for performance cars, see this listing that highlights the market context for front bumper components: https://www.alibaba.com/product-detail/Mitsubishi-Evo-7-Front-Bumper-High-Quality_1600853954248.html

From Guangdong’s Molds to Global Roads: The Industrial Pulse Behind Evolution Front Bumpers

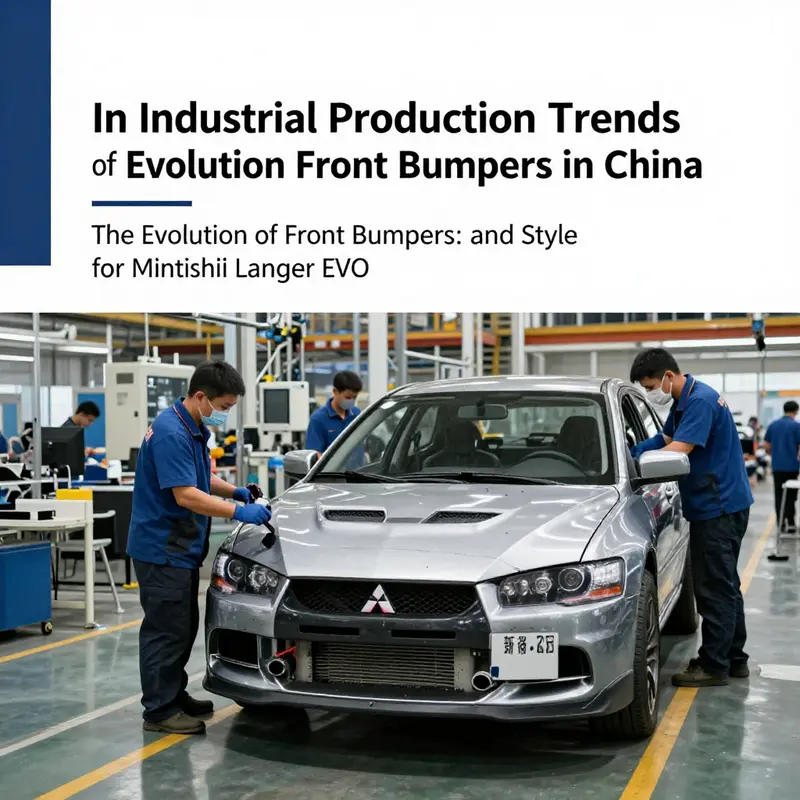

The front bumper is more than a decorative face on a performance car; it is a carefully tuned interface where aerodynamics, impact resistance, and weight converge with the realities of mass production. In the global market for evolution front bumpers, the Chinese industrial landscape has emerged as a pivotal nervous system for design, manufacturing, and distribution. The chapter you are about to read follows that pulse—from the design tables where engineers test airflow and crash energy to the sprawling clusters in southern China where plastics become the shapes that slice through wind and debris at 150 miles per hour and beyond. The numbers alone tell a story. The China car front bumper market is projected to reach about USD 10.82 billion by 2025, and it is expected to grow at a robust CAGR of roughly 11.8 percent from 2026 to 2033. This is not a fad; it is the steady expansion of a supply chain that supports both OEM components and the aftermarket enhancements that enthusiasts crave. Behind these figures lie choices about materials, process, and geography that determine how a bumper performs in daily driving, on track days, and in the long arc of a vehicle’s life cycle.

Material choice sits at the core of any bumper’s performance and longevity. The conventional baseline remains a family of engineered polymers, where polypropylene and thermoplastic olefins (TPO) offer a blend of impact resistance and light weight. Reinforced polymers add stiffness and fatigue resistance, enabling complex forms and integrated features such as air intakes, cooling ducts, and subtle aero devices. ABS has long been favored in many evolutions for its durability, gloss retention, and predictable behavior under impact. Yet in the higher-end segments, builders push toward glass fiber composites and other advanced fiber-reinforced materials. In the Evo culture, weight reduction is not a mere preference; it translates to better handling, improved acceleration, and more predictable crash performance. Glass fiber, in particular, provides a compelling combination of strength and lightness that makes a performance edge feasible without sacrificing robustness in everyday use. The result is a spectrum of front bumpers that can be tailored to the customer’s needs, whether it is a daily driver seeking durability and lower running costs or a track-focused build aiming for peak aero efficiency and aggressive styling.

The geographic distribution of production within China reveals a clear pattern: Guangdong Province dominates the arena. The city clusters around Guangzhou and Shenzhen have cultivated a mature, vertically integrated ecosystem. Here, the journey from raw resin to finished bumper can pass through multiple stages in a compact geographic footprint: injection molding to form the basic geometry, surface finishing to achieve the smooth, paint-ready surface, UV-resistant coatings to withstand sun exposure, and rigorous final inspection to ensure uniformity across thousands of units. This proximity is more than a convenience; it acts as a brake on production bottlenecks and as a stimulus for rapid iteration. When design teams adjust a vent size or modify an air duct, the line can pivot quickly, with changes moving from drawing board to showroom floor in a fraction of the time required in more dispersed supply networks. The capability to deliver OEM-equivalent aftermarket parts with consistent quality makes this region a hub that not only meets domestic demand but also supports North American, European, and Japanese markets that demand reliability and traceability in a global supply chain.

But Guangdong is not the sole actor in China’s bumper saga. Zhejiang, with its emphasis on scalable production and export readiness, represents a complementary strength: the ability to scale up production volume while maintaining tight cost controls and logistics efficiency. Liaoning, too, has carved out a niche by focusing on regional markets that extend into neighboring markets such as Russia, Mongolia, and Korea, where price sensitivity and local regulatory requirements shape the offerings. The broader Chinese ecosystem is strengthening its sustainability posture and its adherence to global standards, with suppliers investing in energy efficiency, waste reduction, and responsible sourcing throughout the manufacturing chain. In practice, this means tighter process controls, better calibration of color and finish to ensure uniformity across batches, and more robust packaging that protects sensitive surfaces during long shipments.

The supplier landscape reflects a parallel evolution: a shift toward consistent compliance with international standards, a growing emphasis on sustainability, and a keen focus on speed-to-market. The modern bumper supplier in this space is not merely a mold-maker; it is a factory-within-a-factory—an operation that can align resin selection, molding temperature, paint chemistry, and assembly sequencing to deliver turnkey products that meet exacting expectations. This level of integration matters because the market’s demand profile extends beyond simple form and fit. Brands and buyers are seeking a product that not only looks right in the showroom but also survives the rigors of time, weather, and highway speeds. When a bumper is designed to withstand UV exposure and to resist cracking from minor road impacts, the total cost of ownership for the vehicle owner decreases—fewer repairs, less maintenance, and a longer window before a replacement is needed. In many cases, the materials chosen for a bumper influence every subsequent decision in the vehicle’s exterior program, including paint adhesion, surface hardness, and even adjacent panels that share adhesive bonds and mounting interfaces.

In the realm of customization and performance, the market has grown adept at translating global demand into tailored solutions for a wide spectrum of vehicles. Manufacturers cater to specific design and fitment requirements, ensuring that a bumper not only aligns correctly with the body lines but also preserves the original aesthetics and functional airflow characteristics. This is particularly important for high-performance builds where cooling efficiency and aerodynamic balance can affect engine reliability at high speeds. A bumper is not just a front face; it is a carefully engineered channel for air that must cooperate with the radiator, intercooler, and cooling fans, while also offering the structural resilience needed in the event of a minor collision. The most refined offerings can be customized to include integrated air intakes, vents, and even aerodynamic lips that extend a few millimeters to influence the local flow field. Customization is also about manufacturing practicality: blanks can be produced in white or unpainted finishes, enabling owners to apply unique paint schemes or decals that reflect their personal identity while preserving the bumper’s structural fidelity.

Within this customization landscape, a front bumper can travel from design concept to customer installation with an efficiency that mirrors the speed of automotive innovation itself. Model-agnostic features such as precise fitment, retained mounting points, and compatibility with existing sensors and tow hooks are crucial; yet the ability to adapt a design to a specific platform without courting excessive retooling costs is a strategic advantage. The industry’s push toward OEM-grade fitment in aftermarket products—ensuring that a non-OEM bumper matches the engineering tolerances of the original design—has accelerated investment in high-precision tooling and process controls. In practice, this means tighter cylinder pressures in molding machines, more stable resin blends to minimize color deviation, and paint lines that reproduce factory hues with excellent repeatability. The result is a bumper that can maintain its appearance across years of exposure to sun, salt, and road debris, while also preserving the vehicle’s structural integrity and crashworthiness.

The evolution front bumper market does not exist in isolation. It thrives on a global feedback loop that links research labs, color laboratories, and track days with the factory floor. A notable aspect of this ecosystem is the attention to certification and safety compliance. Reputable suppliers align their products with recognized safety standards to guarantee crashworthiness and durability. This is particularly important when a bumper includes features such as energy-absorbing elements, reinforcement ribs, and integrated air channels that must perform predictably in an impact. The Chinese production clusters have invested in quality assurance regimes that echo international expectations, reinforcing trust among overseas buyers who demand consistent performance. That trust translates into recurring orders, longer-term partnerships, and the ability to forecast demand with greater confidence—an essential element for any business seeking to navigate the volatility of aftermarket cycles and seasonal demand.

Beyond the shop floor and the paint booth lies the broader story of logistics, export readiness, and the ability to respond quickly to shifting demand across continents. Guangdong’s cluster-driven model means that raw materials, processing, finishing, and packaging can be synchronized with a supplier’s logistics network, reducing lead times and enabling just-in-time delivery to distributors and retailers around the world. The value proposition for buyers in North America and Europe rests on more than price; it rests on reliability, traceability, and the assurance that the bumper they order will fit as promised, arrive in pristine condition, and maintain performance over time. The industry’s forward trajectory suggests a continued emphasis on rapid prototyping, digital design-to-manufacture workflows, and more intelligent inspection technologies to catch any deviation before it leaves the factory floor.

For industry professionals and enthusiasts alike, the implications of these trends are both practical and aspirational. Practically, they translate into a broader range of options, better quality control, and shorter lead times for those seeking to upgrade their cars with high-performance front bumpers. The aspirational aspect is the democratization of advanced materials and engineering—where weight savings, improved aerodynamics, and enhanced crash protection can be realized not only by factory teams but also by hobbyists and weekend tinkerers who want a show-ready, race-inspired aesthetic without compromising everyday reliability. The Guangdong-based ecosystem makes this possible by lowering barriers to entry for new suppliers and enabling mature players to scale while preserving consistency across thousands of units.

Throughout this development, one notable thread is the balance between performance and practicality. A bumper designed for high-speed stability might add aggressive styling, but the best implementations deliver a net gain in handling and cooling without imposing extra maintenance burdens. The goal is to create a component that contributes to an overall design that feels cohesive—where the bumper, the grille, the lighting, and the surrounding body panels work as a single aerodynamic unit. It is a design philosophy that recognizes that in high-performance contexts, every millimeter of clearance, every vent, and every shaping feature can influence heat management and wind forces around the front of the vehicle. In this sense, the evolution bumper becomes a microcosm of modern automotive engineering, where lightweighting, material science, manufacturing science, and global supply-chain dynamics converge to produce a product that is as much about reliability as it is about speed.

The chapter closes not with a definitive end but with an invitation to understand how the evolution of front bumpers, driven by Chinese industrial prowess, informs the broader dialogue about performance culture. It helps explain why a front bumper from a Guangdong cluster can be both a practical upgrade for daily drivers and a strategic choice for track-oriented builds. It sheds light on how advanced materials, when combined with precise tooling and integrated finishing lines, yield products that meet exacting standards while still offering room for personalization and experimentation. It also points to a future where the supply chain continues to tighten, where sustainable practices become the default, and where customization remains a hallmark of a community that values both form and function in equal measure. For enthusiasts and professionals, the message is clear: the front bumper is not simply a cosmetic piece but a critical performance element whose evolution mirrors the global pace of automotive engineering. The road ahead will see even smarter materials, even tighter integration with the vehicle’s thermal and aerodynamic systems, and even faster pathways from design to delivery, all anchored by the robust manufacturing heartland that has long made southern China a world leader in automotive components.

External resource for broader market insight: https://www.linkedin.com/pulse/china-car-front-bumper-market-trends-2025-application-george-dong-zjyqk/

Internal reference for further reading: evo-8-9-varis-front-bumper-with-carbon-lip.

Carbon, Track Width, and Air: The Evolution Front Bumpers That Redefined the Evo X Era

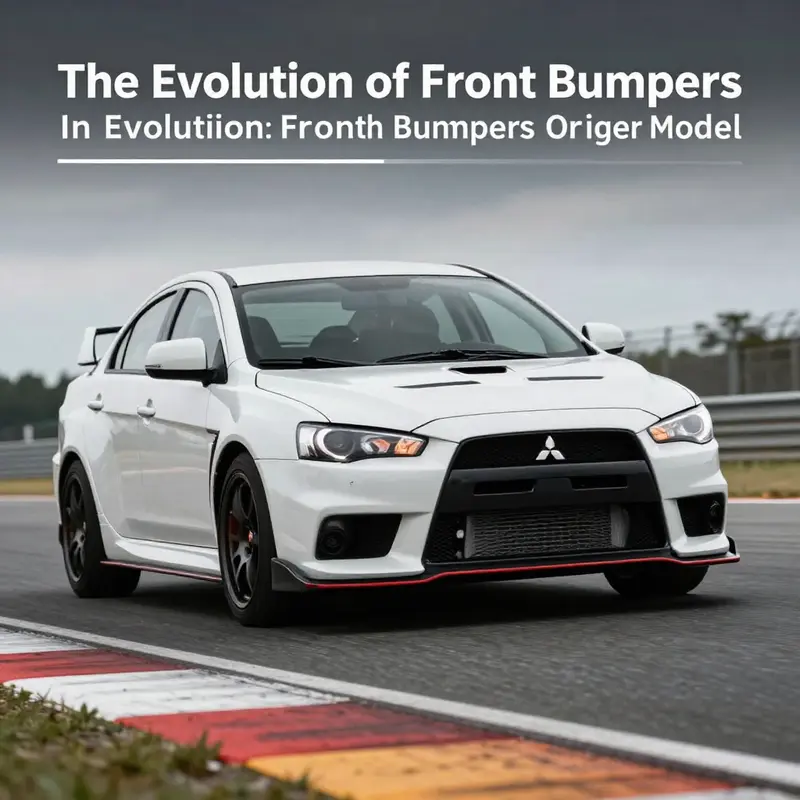

The front bumper on a performance car is rarely just a cosmetic panel; on the Evo X, it functions as a conduit for cooling, a shield against road debris, and a key element in the chassis’ balance at high speeds. As the Lancer Evolution lineage matured into the Evo X generation (2008–2015), the design language of the front end shifted from purely aggressive styling toward a more purposeful synthesis of aerodynamics, weight management, and modular customization. The bumpers that emerged for the Evo X did not simply imitate the factory look. They reflected a broader engineering philosophy that prioritized precise fitment, materials that could withstand demanding driving conditions, and production systems capable of turning innovative concepts into readily available parts for street and track use. In this sense, the Evo X era of front bumpers stands as a case study in how aftermarket aero evolved from a niche accessory into a sophisticated, performance-focused component that could integrate with the car’s cooling architecture, chassis width, and overall handling envelope. The shaping of air around the vehicle was not merely about creating an intimidating silhouette; it was about managing flow in a way that stabilized the car’s attitude on entry and exit, across a range of speeds and road conditions, while keeping maintenance practical for daily driving.

The most conspicuous and widely talked about innovations in Evo X bumpers revolve around two intertwined goals: weight reduction and aerodynamic efficiency. Weight is a constant constraint in performance engineering, and every gram saved on the front end is a potential improvement in steering response and acceleration. One of the defining shifts during this period was the increasing use of real carbon fiber components in high-end, track-focused bumper assemblies. Carbon fiber had earned its reputation in motorsport for its exceptional stiffness-to-weight ratio, fatigue resistance, and cladding that could be engineered to withstand impacts from road debris without sacrificing the structural integrity of the bumper system. In the Evo X context, real CF found its place primarily in front-end lip configurations and supplementary lip extensions—elements that could be integrated with the core bumper body yet delivered meaningful weight savings and improved aerodynamic performance. In practice, these CF components contributed to a lower overall weight and a more rigid front frame when the bumper was bolted to the vehicle. The result was a more responsive front axle behavior, particularly under aggressive throttle modulation and mid-corner transitions, where a stiffer front end helps the tire to maintain contact with the surface and to transmit steering inputs more directly to the chassis. This is a nuance that resonates with drivers who track their car or push the limits on winding roads, where the difference between a stable line and a twitch can come down to the front-end package.

What makes the carbon fiber approach especially compelling in the Evo X era is not just the raw weight delta, but the way CF interacts with other performance-oriented elements of the bumper system. The lip, for example, is not a passive trailing edge; it actively manages the separation of the boundary layer and directs high-velocity air to areas where it can cool the intercooler and radiator cores more efficiently. In real-world terms, aCF lip integration can reduce stagnation and recirculation pockets at high speed, which translates into more consistent cooling performance during extended sessions on a race track or even during spirited hot laps on a mountainous road. The technology is not merely about reducing drag, either. A well-designed CF lip can help generate a modest but meaningful amount of downforce at the splitter, improving front-end grip without imposing a dramatic lift-induced penalty elsewhere on the vehicle. For drivers who value a balanced, communicative feel through the steering wheel at the limit, this can be a decisive advantage.

This emphasis on weight and aero efficiency sits alongside a broader trend toward aerodynamic fine-tuning that extends into the bumper’s geometry. The Evo X front profile saw a deliberate broadening of the overall track footprint through bumper modifications that extended the front fascia laterally. This widening effect, achieved through carefully engineered extensions and mounting points, is more than a cosmetic flourish. It translates into a deeper distribution of mass, a more stable front-end footprint, and increased susceptibility to aerodynamic downforce at higher speeds. The practical upshot is improved cornering stability and more predictable drift or push behavior when entering a corner at speed. While the track-day enthusiast will appreciate these gains, the street driver still benefits from enhanced high-speed stability, which translates to more confident highway cruising and a more planted feel during aggressive lane changes.

An important strategic context for these innovations is the manufacturing ecosystem that makes such advanced front-end kits feasible at scale. The Evo X bumpers benefited from a mature, localized manufacturing network in southern China, notably the Guangdong Province, where a dense cluster of automotive parts suppliers developed around Guangzhou and nearby hubs. This cluster optimized precision molding, surface finishing, and complex assembly processes—everything from injection molding of ABS or polypropylene composites to post-mold painting, finishing, and packaging. The proximity of these capabilities created a seamless pipeline from design concept to ready-to-ship product, slashing lead times and enabling rapid iteration in response to customer feedback or new aerodynamic insights. The advantage of this ecosystem is not simply speed. It also supports a consistent tier of quality that keeps aftermarket bumpers aligned with OEM certification standards. In other words, a bumper kit designed for the Evo X can deliver reliable crashworthiness and durable performance while remaining cost-effective for distributors and end users alike.

In this context, material science remains a central pillar of the Evo X bumper story. ABS and polypropylene composites were widely used for their balance of stiffness, impact resistance, and weight. ABS, in particular, offered a robust, impact-tolerant shell that could stand up to urban road hazards without cracking under minor collisions or road debris strikes. The molding processes used in Guangdong’s automotive clusters were refined to produce smooth surfaces that accept clear coats with uniform thickness, resisting peel and micro-cracking even after repeated thermal cycling. These surface qualities matter, because the bumper’s appearance—dragged across a car carrier or scratched during installation—affects not just aesthetics but the perceived value of the kit. A flawless surface finish reduces post-purchase service concerns and makes color-matching easier for owners who want to maintain factory tones or blend their custom paints with the bumper’s blank-primer finish.

The Evo X’s aerodynamic strategy also embraced integrated air intakes and venting to support engine cooling and intercooler efficiency. The front bumper’s geometry could be tuned to channel air toward specific core areas, with careful attention paid to the geometry of the intake ducts and their lips. When air is directed efficiently, it feeds intercoolers and radiators with cool air while maintaining high-energy flow at the vehicle’s leading edge. The interplay between bumper geometry and the car’s cooling system is a subtle dance. A bumper that directs air too aggressively may cause cooling losses at certain speeds, while one that is too passive could allow overheating under track workloads. The Evo X designers and aftermarket engineers aimed to strike a balance that would be forgiving on the street but capable on a track—an outcome that required precise aerodynamic modeling, empirical testing, and a manufacturing system that could reproduce these designs consistently across batches.

Another layer of sophistication in Evo X bumpers concerns their compatibility with OEM aesthetics and fitment. The demand from B2B buyers and procurement managers has always included a strong emphasis on precise fitment; a bumper that does not align with the factory mounting points can become a source of ongoing maintenance headaches. The modern bumper kits for Evo X have tended to emphasize OEM-specific fitment, ensuring that mounting tabs, crash bar connections, and fastener points align with the car’s original structure. This reduces installation time for technicians and minimizes the risk of misalignment, which can compromise both safety and performance. In addition, the most capable kits offer a modular approach to air intakes or venting pieces so that an owner can tailor their array of cooling inlets to the climate in which they drive. The ability to customize these features within the framework of a certified, properly engineered kit is what makes the Evo X front bumper ecosystem a compelling choice for both daily drivers who want performance and enthusiasts who want a track-ready edge.

The Evo X’s front-end evolution did not occur in isolation. It sits within a broader context of materials science and manufacturing ecosystems that shaped not only how the bumper looked, but how it behaved. In Guangdong’s clusters, the end-to-end process—mold design, resin selection, surface finishing, and packaging—was optimized for rapid turnover. Suppliers began offering flexible production models, moving from single-piece prototyping to medium-scale runs and even larger commercial productions. This flexibility reduces time-to-market for new aero variants, allows for frequent design adjustments in response to feedback, and provides distributors with more consistent inventory replenishment. The supply chain discipline that underpins these processes is what enables a high-end carbon fiber lip to be paired with a reinforced ABS bumper shell without introducing prohibitive lead times or quality concerns. It’s a delicate balancing act: maintaining the premium characteristics of CF while ensuring the bumper kit remains accessible to a wide range of customers.

Crucially, these innovations have not sacrificed safety or compliance. Reputable suppliers adhere to international standards for safety, crashworthiness, and durability. Even as enthusiasts push the envelope with weight-reducing CF components and wider track modifications, the underlying engineering standards ensure the bumper’s performance remains predictable in the event of a collision. For buyers and technicians, this combination of structural integrity and lightweight performance is a compelling reason to consider an Evo X bumper kit that integrates carbon elements and aero improvements within the bounds of safety and reliability.

The Evo X’s front bumper narrative also underscores a broader principle in modern car customization: the importance of cohesive system thinking. The bumper does not operate in isolation; it works in concert with the hood, fenders, grille, and bumper mounts to deliver a harmonious front-end package. When a kit is designed with this systemic mindset, it can maintain visual alignment with factory lines while introducing a subtle aggression that communicates the car’s intent. The result is not merely a new look; it is a front end that breathes with the rest of the car’s geometry and weight distribution, preserving the wheelbase’s balance and the steering feel that enthusiasts covet. For the Evo X, this meant adopting a front-end language that spoke to the era’s performance priorities—weight efficiency, cooling reliability, and a front-end silhouette that conveyed both purpose and panache.

Within this narrative, the Evo X bumpers also reflect a shift in how performance upgrades are sourced and evaluated. The market became more sophisticated, with B2B buyers asking for detailed specifications, precise fitment data, and quantifiable performance metrics. They look for front-end kits that can deliver a predictable drag profile, robust air intake behavior, and consistent color and finish across large orders. The Guangdong-based manufacturing milieu, with its robust process controls and scalable production lines, has been instrumental in meeting these expectations. It enables suppliers to offer a spectrum of configurations—from simple lip extensions to more elaborate, CF-enhanced assemblies—without sacrificing the ability to ship timely, well-packaged products to distributors around the world. The outcome is a more accessible but still performance-conscious ecosystem where Evo X owners can choose a bumper setup that matches their goals, whether that means a daily driver with a strong street presence or a track-prepped machine with strategic CF components.

Looking ahead, the Evo X bumper conversation foreshadows the next wave of evolution: a more nuanced integration of new materials, smarter aerodynamics, and even more modular construction that can adapt to evolving regulatory environments and changing consumer preferences. The interplay between lightweight materials, track-ready geometry, and reliable manufacturing will continue to define how front bumpers are conceived, tested, and sold. The story of Evo X bumpers is, at its core, the story of how a generation’s appetite for performance—paired with advances in materials science and supply chain efficiency—transformed a simple piece of plastic into a strategic performance asset. It is a reminder that even the smallest components can influence the car’s behavior at the very edge of its capability, and that the pursuit of better aero, better weight, and better integration is a continuous process, not a fixed endpoint.

For readers who want to explore the practical side of sourcing and evaluating Evo X bumpers, a deeper dive into supplier capabilities and material specifications offers valuable context. See the detailed supplier guide linked in the external resources for insights into how modern Evo X bumper programs are evaluated, certified, and delivered to distributors worldwide.

Internal link note: To see a genuine option for the Evo X front bumper in the CZ4A lineage and understand how OEM-aligned fitment is achieved, you can review the specialized Evo X front bumper listing here: CZ4A Evo X front bumper. This reference illustrates how a bumper designed around factory mounting strategies can simplify installation while preserving the visual cues that enthusiasts expect from the Evo X’s front end.

External resource: For a broader view on supplier capabilities and material specifications in this niche, consult the Global Sourcing Insights Evo X bumper guide at https://www.global-sourcing-insights.com/mitsubishi-evo-x-bumper-supplier-guide-2025.

Final thoughts

The front bumper for Mitsubishi Lancer Evolution models serves as a prime example of how automotive elements can evolve in response to both aesthetic appeal and performance demands. The Evo 7, with its lightweight design, offers practical benefits for daily driving, while the industrial trends in China reveal the importance of sophisticated manufacturing in meeting global market demands. Moreover, the Evo X models showcase innovative enhancements that align with enthusiasts’ desires for quality and performance. For business owners in the aftermarket sector, understanding these trends and innovations is crucial for positioning products that resonate with consumers, ultimately leading to enhanced satisfaction and brand loyalty.