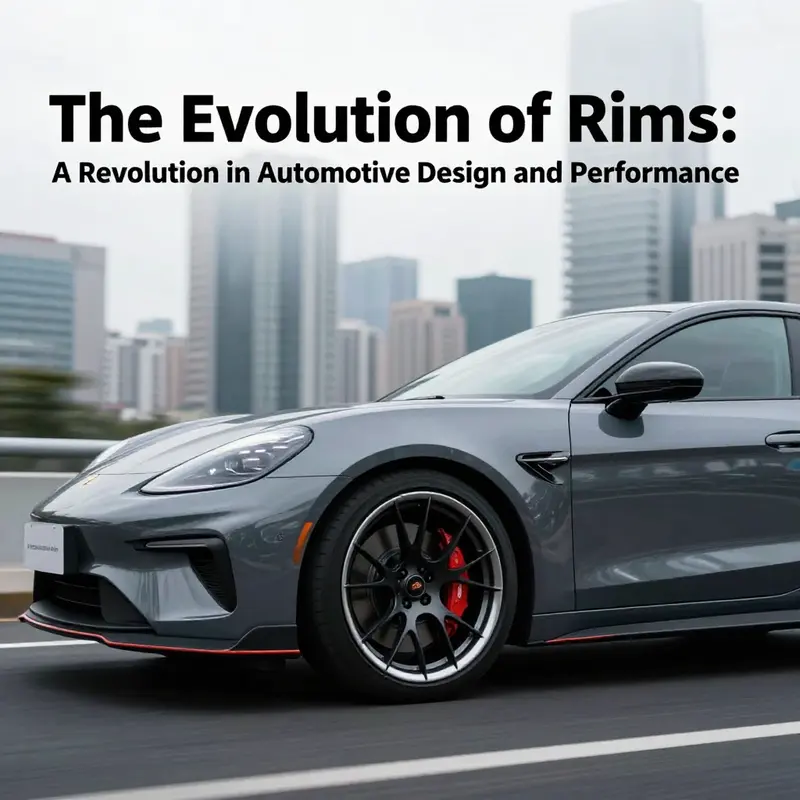

The automotive world is witnessing a significant transformation in rim technology, with evolution rims leading the charge. These high-performance components go beyond mere aesthetics; they encapsulate the continuous advancements in design, material science, and functionality. As business owners in the automotive sector, understanding these changes offers insights into market trends and consumer demands. This article dissects the evolution of rims through five critical aspects: design evolution, material advancements, functional applications, aesthetic innovations, and performance enhancements, equipping you with comprehensive knowledge to make informed decisions and potentially leverage these insights to enhance your business.

Rim Evolution: The Unfolding Arc of Design, Material Science, and Functional Craft

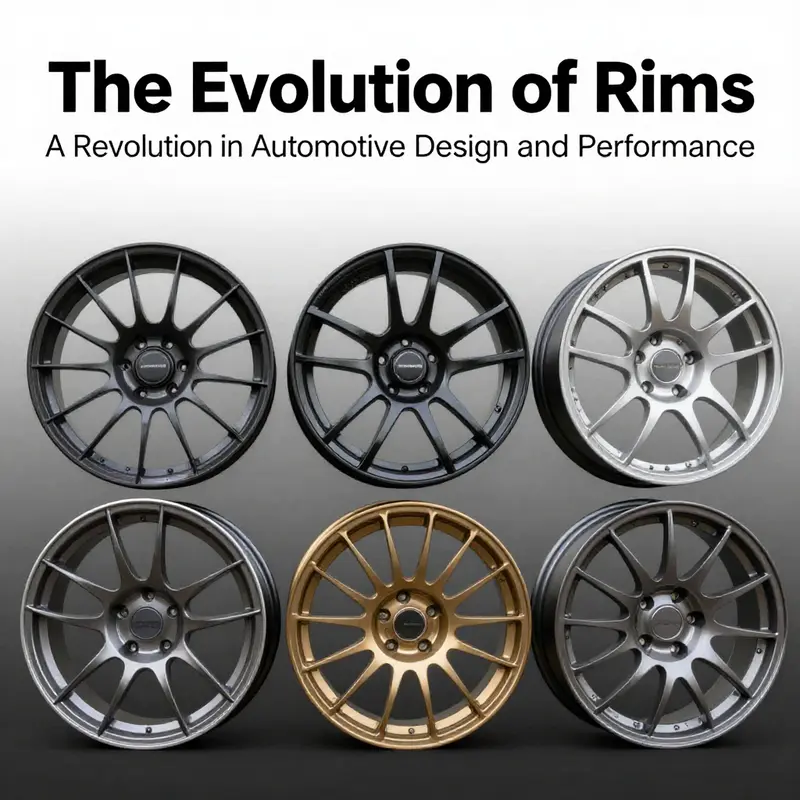

The concept of evolution rims mirrors a broader story—one where wheels are no longer simple round assemblies but outcomes of a long continuum that blends design ambition, material science, and engineering discipline. In this chapter, we trace how rims have progressed from basic steel foundations to complex, purpose-built components that balance aesthetics, safety, and performance. This evolution is not a single product line but a trajectory that reveals how every generation of rim technology inherits the constraints and opportunities of its predecessors while pushing toward lighter weight, greater strength, and richer visual language. The core idea is straightforward: evolution rims represent continuous improvement across three intertwined dimensions—design geometry, manufacturing materials and processes, and functional resilience in real-world driving contexts. Even as the market embraces more dramatic looks and higher-performance targets, the ultimate measure remains the same: how a rim contributes to the vehicle’s handling, durability, and identity without compromising safety or reliability.\n\nFrom a design perspective, the arc of rim evolution has moved from simplicity to complexity in geometry and finish. Early wheels were functional round forms with relatively uncomplicated spoke patterns. As tastes and performance requirements evolved, designers embraced more elaborate geometries—multi-spoke, Y-spoke, and split-spoke configurations—that create an impression of motion even when the vehicle is standing still. The visual drama of these geometries is not merely cosmetic; it directly influences how load is distributed across the wheel, how air flows around the brake package, and how the rim tolerates the forces generated during cornering, acceleration, and braking. The rise of larger diameters in the wheel market only amplified the importance of forming stresses and torsional rigidity through intelligent spoke layouts. A well-executed split-spoke design, for instance, can offer enhanced structural support while optimizing weight distribution and aerodynamics. The net effect is a wheel that communicates performance through its silhouette while delivering tangible engineering benefits under load. In this sense, the aesthetics of evolution rims are inseparable from their engineering logic.\n\nMaterial science marks another landmark in the evolution narrative. The shift from conventional casting toward forging represents a central hinge in rim technology. Forged rims—produced through high-pressure forming—produce a denser, more uniform grain structure than their cast counterparts. This densification translates into higher tensile strength, which allows wheels to be both lighter and stiffer. Lighter rims reduce unsprung weight, an essential factor in a vehicle’s suspension responsiveness and steering precision. Stiffer rims resist flexing during aggressive cornering, contributing to more predictable steering feel and improved brake heat management because the wheel itself plays a role in heat dissipation. Durability also benefits from forging, as the refined microstructure tends to be more resistant to fatigue under repeated loading. The net result is a class of rims capable of delivering sporty handling, enhanced dynamic rigidity, and longer service life under demanding driving conditions. As materials science pushes toward even lighter alloys and advanced composites, the evolution continues, with new forging technologies and post-processing methods enabling tighter tolerances and more uniform finishes. In practical terms, the shift to forged rims is one of the clearest markers of evolution—an identifiable leap in performance potential that scales with the expectations of high-end drivers and performance-focused builds.\n\nBeyond the core materials and geometry, the way rims are finished and protected has become a crucial dimension of evolution. Automobile environments can be harsh: road salt in winter, high heat from brake systems, and the general wear of daily use. To address this, manufacturers and aftermarket producers have developed coatings and protective layers that extend rim life without compromising appearance. Protective coatings can shield rims from corrosion and pitting, while specialized finishes—ranging from matte to gloss to chrome-like appearances—offer durable aesthetics that endure brake dust, cleaning, and road debris. Finishes also serve as a vehicle’s visual signature. For owners who demand a unique look, nuanced color accents or two-tone treatments can create depth and contrast, adding a sense of depth and unity with the vehicle’s bodywork. The design language here is not merely about catching the eye; it is about engineering coatings that stay aesthetically stable through climate cycles and road conditions, thereby reinforcing confidence in the wheel’s long-term performance and value.\n\nFunctionally, evolution rims have grown more capable of supporting modern performance envelopes. The trend toward higher-performance vehicles—luxury SUVs, high-output sedans, and enthusiast-grade coupes—has driven a parallel shift in wheel design toward configurations that optimize weight distribution and aerodynamics while maintaining robust load-bearing capacity. In SUVs and heavier platforms, split-spoke designs can offer superior stiffness and load pathways, helping to manage torque and cornering forces without a noticeable increase in weight. In lighter, performance-oriented builds, engineers may emphasize minimal mass in rotating components to improve acceleration and braking response, while still ensuring enough rigidity to retain precise steering feedback. The balance between weight, stiffness, and durability is at the heart of evolution rims. This balance informs decisions about rim thickness, the choice of spoke geometry, hub compatibilities, and even the method by which the wheel mates to the vehicle’s brake system and suspension geometry. The practical upshot is a wheel that is not simply an aftermarket accessory but a critical component that interacts with tires, brakes, and chassis dynamics to define the vehicle’s overall character.\n\nIn the broader ecosystem, OEM-focused and aftermarket designers alike have pursued authenticity and precision in fitment. Some efforts emphasize replicating or aligning with original equipment manufacturer (OEM) designs to preserve a model’s visual language and factory tolerances. Such fidelity matters for fit, brake clearance, and the seamless integration of wheel and body lines. It also speaks to a reality that evolution rims live in: a dialogue between heritage aesthetics and modern engineering standards. This fusion allows for a “heritage-inspired yet modern” look that satisfies enthusiasts who crave a faithful nod to the past while requiring contemporary performance capabilities. The result is a wheel family that can honor automotive lineage without sacrificing the predictability and safety demanded by today’s road conditions and regulations.\n\nFrom a practical standpoint, evolution rims also reflect a growing appreciation for how design can address real-world needs. In climates with harsh winters, for example, rims may feature protective coatings and corrosion-resistant alloys that extend their useful life. For drivers who prize a bold stance or a distinctive presence, designers can craft finishes and color integrations that create visual depth, without compromising durability or balance. The story of evolution rims is thus a story of convergence: diverse technical threads—geometry, metallurgy, coatings, and fitment practices—converging to produce wheels that are more capable, more beautiful, and more reliable across a broader spectrum of driving contexts. The design language that results from this convergence speaks to an era when wheels are considered essential performance partners, not mere accessories.\n\nAn illustrative strand in this evolution is the exploration of color depth and visual unity that can subtly elevate perception without overt branding. A representative half-rim concept, which adds a color accent to the inner rim edge, demonstrates how such details can create a coherent visual narrative when paired with the vehicle’s paint and brake finishes. This approach blends fashion with function—adding depth and cohesion to the wheel design while preserving the wheel’s core mechanical attributes. It highlights a broader tendency in rim design: to treat color and geometry as integral components of the engineering package rather than as superficial adornment. In this sense, evolution rims embody a philosophy that design choices should reinforce performance goals and aesthetic ambitions in equal measure.\n\nWithin this evolving landscape, the idea of authentic fitment remains central. For a growing cohort of drivers, there is value in rims that replicate or closely mirror OEM aesthetics, ensuring that wheel arches, brake calipers, and fenders maintain proper clearance and a natural, factory-feel alignment. This attention to fitment fidelity reinforces safety, ride quality, and consumer confidence when upgrading wheels. It also reflects a pragmatic recognition that the most compelling rim solutions are those that respect the vehicle’s original design intent while delivering enhanced materials performance and refined engineering. The evolution thus becomes a collaborative process between design exploration, material science, and manufacturing discipline, underpinned by a practical commitment to fitment integrity and real-world usability.\n\nFor readers who wish to explore a concrete example of how these themes translate into lifecycle considerations, consider the broader context of fitment and restoration-minded upgrades. The rim’s evolution is not isolated to new builds alone; it informs how enthusiasts approach restoration and period-correct customization—how a classic silhouette can be reimagined with modern forging techniques, or how a heritage-inspired geometrical motif can be realized with tight manufacturing tolerances and durable finishes. The narrative remains coherent: evolution rims are about stronger, lighter, more visually compelling components that still honor the vehicle’s engineering fundamentals. This is why the conversation around rim evolution continues to resonate with both performance-focused drivers and those who simply want a more expressive, integrated visual statement for their car.\n\nFor readers who want to connect this broader discussion with hands-on examples, a close reading of market offerings and design studies can reveal evolving patterns in OEM replication, protective coatings, and advanced finishing techniques. Such patterns suggest a future in which rims increasingly function as integrated performance packages, where the design of the rim geometry, the choice of material, and the surface treatment are choreographed to optimize ride quality, braking performance, and long-term durability, all while providing an unmistakable surface for personal expression. The ongoing evolution, then, is not a dramatic upheaval but a carefully calibrated sequence of improvements—each generation learning from the last, each design iteration refining the balance between form and function. In this light, evolution rims become less about chasing novelty and more about delivering a mature, coherent approach to wheel engineering that can adapt to shifting driving needs and evolving aesthetic standards.\n\nExternal resource for further reading: for a deeper dive into half-rim design innovations and their implications for both form and function, see the Dynamic Dawn 2.0 press kit. This source offers a concise window into how a nuanced rim concept can alter depth perception, color interaction, and overall unity with vehicle design. https://www.dynamicdawn.com/presskit/dynamic-dawn-2-0-press-kit.pdf\n\nInternal resource note: in discussions about authentic fitment and OEM-inspired approaches, industry examples sometimes emphasize alignment with factory geometry and tolerances. A representative example from the aftermarket ecosystem or dealer networks can illustrate how a brand-new original rims set emphasizes precise dimensions and finish consistency to maintain the intended driving and visual experience. For readers seeking a tangible case study in OEM-style fitment, you may explore a related option that demonstrates how authentic fitment is achieved in practice, such as the discussion around rim assemblies designed for high-precision mounting on a popular sedan platform. [brand-new original BBS rims set of 4 R18 rims for Lancer sedans] to see how traditional brands approach exacting fitment, finish quality, and consistent tolerances across a full wheel package.

Forging Ahead: Material Breakthroughs and Craftsmanship in Evolution Rims

Rims have long been the unsung backbone of a vehicle’s performance and personality. In the evolving language of wheels, evolution rims signify more than a new silhouette or flashy finish. They represent a dialogue between design aesthetics, material science, and manufacturing discipline. Lighter weight often means sharper handling and better efficiency, while stronger materials and precise fabrication extend durability across driving contexts. The story where engineering and artistry blur, and where every choice—from alloy composition to finishing treatment—has a tangible performance implication.

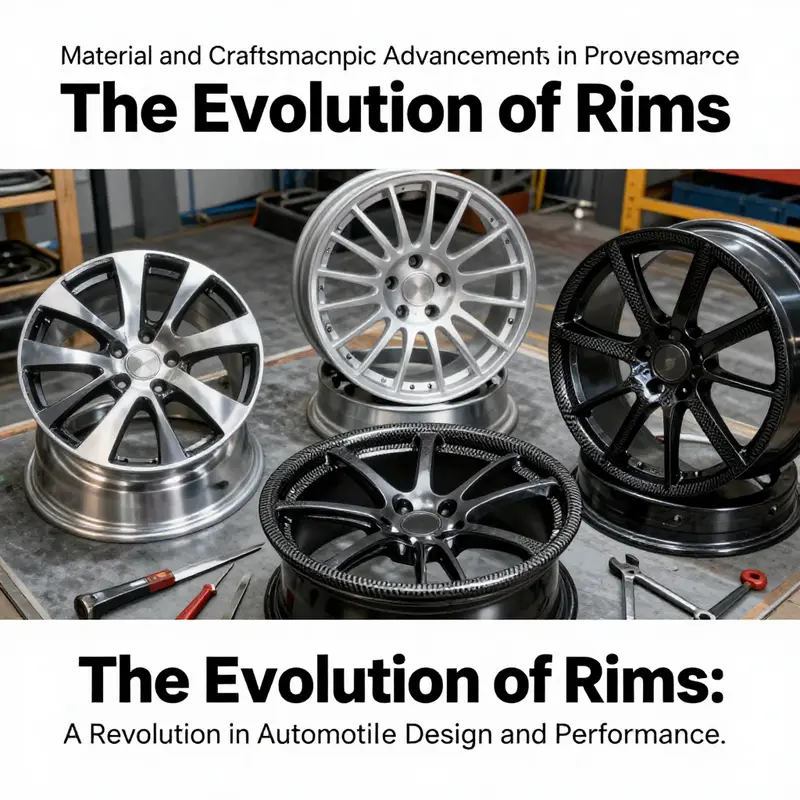

Material choices anchor this evolution. Modern rim production leans on high-strength aluminum alloys, often alloyed with magnesium or zinc. These combinations alter the metal’s microstructure, enabling tighter tolerances and exacting finishes. Casting supports complex geometries, while forging rearranges grain structure through high-pressure forming, yielding a stronger weight ratio. Forged rims are prized for stiffness and resilience, resisting deformation under load and offering precise steering. Yet they carry a premium and can crack if energy exceeds tolerance. This trade-off is central: performance gains come with costs, and the best choice depends on vehicle intent and driver expectations.

Design and material evolve together. The move from single-piece rims to dynamic spoke architectures—radiating spokes or split-spoke patterns—optimizes load paths and maintenance. In larger diameters, designers experiment with spoke geometry to redistribute stress while delivering an aggressive visual language. The wheel becomes an interface between chassis and road, translating power into trajectory with confidence rooted in material and geometric discipline.

The realm of finishes shows how coatings extend the wheel’s life and appearance. Protective layers resist corrosion, abrasion, and chemical attack, while finishes like durable clears and powder coatings shield against salt and road grime. Chrome plating offers high-gloss aesthetics but requires maintenance and balance with durability. Finishes influence longevity by reducing micro-damage that could propagate into cracks under stress.

Non-traditional materials appear in niche applications, such as high-strength plastics in BMX rims to trim rotational inertia while maintaining identity. These mag rims echo lighter metal wheels and illustrate how material science pushes the design space. The principle remains: weight reduction without sacrificing stiffness or durability, expanding options for evolving performance targets.

At scale, the story intersects supply chains and standards. The market features reliability, customization, and international compliance. Regions like China, with provinces such as Henan, Guangdong, and Shandong, reflect a mature ecosystem where manufacturers coordinate through long-term partnerships rather than price raids. For fleets, this translates into predictable quality and delivery, reducing downtime and ensuring consistent wheel performance.

On the consumer side, steel rims remain affordable and rugged, especially in winter or rough conditions, while higher-end alloys offer improved handling and braking response for those who seek style and performance. The trade-offs include increased unsprung weight and higher replacement costs after pothole encounters.

The future lies in deeper integration of advanced materials and precision craftsmanship—lighter weight, higher strength, and refined aesthetics—while maintaining safety and practicality. As road conditions and powertrains evolve, rims must rise as a critical enabler of vehicle dynamics.

From Form to Function: The Evolution of Rims in Modern Vehicles

Rims are more than a visual accent on a wheel. They are an engineered interface between road, chassis, and braking system. The concept of evolution rims captures a lineage of advances that began with simple, sturdy forms and has progressed toward innovations that balance lightness, stiffness, durability, and style. When we trace the arc of this evolution, we see rims moving from basic supportive components into sophisticated, performance-driven parts. This transition mirrors the broader trajectory of automotive engineering, where every gram saved, every stress path optimized, and every surface treated for corrosion or heat can translate into measurable differences in handling, braking response, and even tire life. The chapter ahead threads together design shifts, material breakthroughs, and manufacturing refinements, then connects these elements to real-world driving dynamics. What emerges is a picture of rims that are not simply passive shells but active contributors to a vehicle’s behavior and its character on the road.

The first meaningful shift in rim design is observable in the shape language itself. Early, monolithic hub-and-spoke configurations prioritized simplicity and load-bearing efficiency. As performance demands grew, designers experimented with spoke topology to manage how loads traverse the wheel during acceleration, cornering, and braking. This design evolution culminated in radiating spoke patterns that amplify visual depth while distributing stresses more evenly across the rim body. The development did not stop there; a notable iteration is the split-spoke concept, where spokes bifurcate toward the rim’s outer edge. This structural choice creates a perception of lightness and speed, yet it often yields a more robust load path at high cornering loads and under braking. In larger diameters—twenty-two inches and beyond—these patterns become even more consequential. The split arrangement can help maintain rigidity as the outer rim grows heavier and the moment arms lengthen, mitigating the risk of flex that can translate into steering feel changes under aggressive inputs. In sum, design evolution for rims is a continuous exchange between aesthetics and measurable performance outcomes. The eye-catching silhouette of split spokes is not merely decoration; it signals a refined balance of stiffness, load distribution, and lateral strength that modern driving requires.

Material science is the second axis of evolution. The shift from traditional cast rims to forged rims marks a watershed moment in wheel engineering. Forging, especially high-pressure processes, rearranges the metal’s grain structure, producing a rim that is inherently more uniform and stronger for a given weight. The weight savings are not trivial: reducing unsprung weight improves the wheel–tire assembly’s ability to respond to road irregularities, allowing the suspension to do its job with less gyroscopic inertia hogging the dynamics. A lighter rim reduces the energy required to alter the wheel’s rotational state, which in turn can lengthen tire life and improve acceleration response and braking prowess. These gains come with a caveat: forged rims price and production complexity can be higher, but the performance dividends often justify the investment for enthusiasts and high-performance road cars where every increment in stiffness translates into tangible handling benefits. The material conversation also touches coatings and finishes. Beyond metal choice, rims benefit from protective layers that shield them from the twin assaults of road salt and brake dust. For winter driving or off-road use, protective coatings, sealants, and specialized oxide layers help sustain structural integrity and aesthetics over time. Chrome-plated or similarly treated finishes offer a striking look but require more meticulous cleaning regimens to preserve the reflective surface and to minimize corrosion in crevices where moisture and road grime accumulate. The evolution here is practical as much as it is cosmetic: coatings reduce maintenance friction, extend service life, and support the long-term performance story of high-end rims.

Manufacturing innovations also shape what rims can do. Advances in CNC machining, heat treatment, and balancing techniques enable tighter tolerances and more precise weight distribution. The manufacturing process determines how well a rim resists flex under lateral loads and how consistently it responds across a spectrum of speeds and cornering forces. Tighter tolerances produce more predictable rotational dynamics, which can improve steering precision and feedback through the steering wheel. This is particularly important when a vehicle relies on precise suspension geometry and calibrated brake performance to achieve a desired dynamic profile. The broader implication is that manufacturing refinements enable rims to perform consistently across a wide range of temperatures, road conditions, and driving styles. They also enable more complex geometries—such as multi-plane machined features or intricate cutting patterns—that enhance both stiffness and heat dissipation, a critical consideration when braking systems operate at sustained high speeds or during aggressive driving.

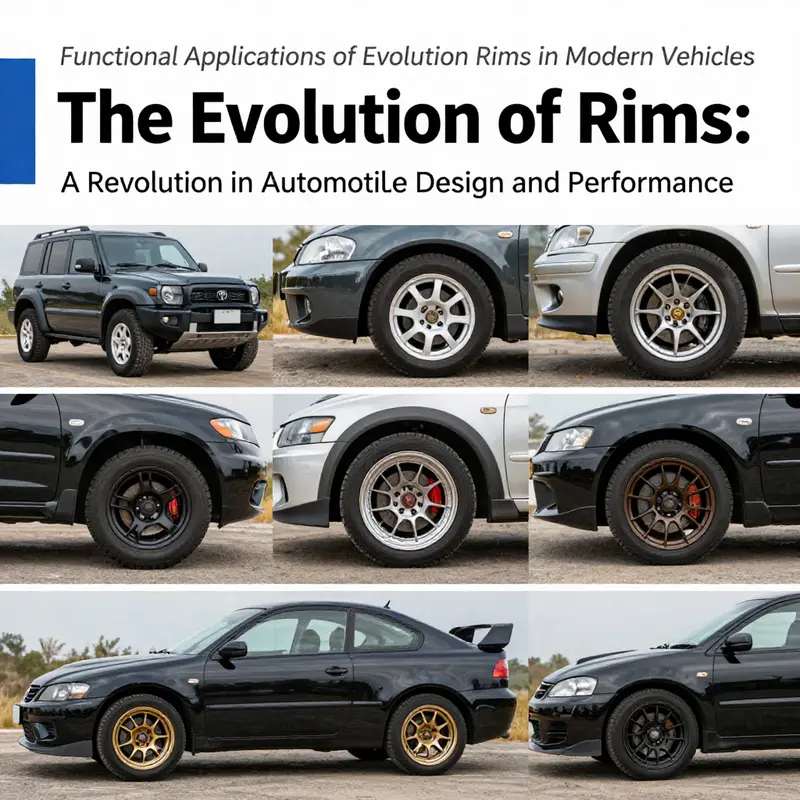

As functional demands evolve, rims increasingly serve multiple roles at once. A contemporary evolution rim is designed to support not only load-bearing and inertia management but also thermal management and aero considerations. In high-performance or luxury SUVs, for example, rim designs may incorporate features that promote more efficient brake cooling, reducing the likelihood of brake fade on long, spirited drives or on demanding road courses. Similarly, rim shapes can contribute to aero efficiency by reducing turbulent wake behind the wheel, which, in turn, can marginally affect fuel economy at highway speeds. These functional aids sit on the edge of aesthetics, where the rim’s silhouette—its depth, the curvature of the spokes, and the way the rim catches light—aligns with a vehicle’s overall presence. The interplay between function and form becomes a hallmark of evolution rims: they must attract the eye while delivering real, measurable improvements in handling, stability, and safety.

The discussion would be incomplete without acknowledging trade-offs that accompany innovation. The most visible friction point is weight. While forged rims can trim weight compared with their cast counterparts, certain advanced designs—especially those with elaborate spoke patterns—can increase mass. The net effect on fuel economy may be modest but not negligible for daily drivers. More importantly, a heavier wheel changes the dynamics of steering feel and suspension tuning. For drivers chasing ultimate straight-line speed, the broader image is that lighter rims usually deliver quicker responses and more agile turning, but this must be balanced against the risk of reduced durability in some environments. Maintenance represents another practical consideration. Complex spoke geometries, while aesthetically appealing, can trap brake dust and road grime, demanding more frequent cleaning to prevent corrosion and to preserve the intended finish. Fitment is a final, practical caveat. Large-diameter rims require careful selection to ensure sufficient clearance for brake kits, calipers, and suspension travel. In addition, tire availability can become a limiting factor as wheel sizes grow; the spectrum of compatible tires narrows as rims approach the outer limits of what a given chassis can accommodate. These trade-offs do not detract from the value of evolution rims; they simply remind us that every technical gain sits within a broader system of vehicle design and maintenance.

In applications, evolution rims have found homes across the spectrum of modern vehicles. They suit performance-oriented builds where sharpening handling, reducing unsprung mass, and achieving a clean, aggressive stance matter most. They also appeal to luxury SUV owners who seek a sporty, upscale aesthetic without sacrificing durability or ride quality. The ability to combine visual impact with measurable improvements in load distribution and structural integrity makes them compelling for drivers who want both daily usability and a hint of track-ready character. Performance, aesthetics, and durability are not mutually exclusive in this context; they are complementary dimensions of the same design philosophy. The ongoing refinement of spoke geometry, hub connectivity, material selection, and protective finishes suggests a future where rims can be tailored with even greater precision to the driver’s intent, whether that intent centers on spirited driving, long-distance comfort, or a blend of both.

For readers who want to explore how rim choices relate to real-world geometry and handling, a useful reference point is the broader conversation around rim sizes and their effects on dynamics. See the discussion of 17-inch rims for Mitsubishi Eclipse wheels (2018–2023) for a concrete case study of how a specific size class interacts with vehicle architecture and brake styling. This contextual lens helps bridge the gap between theory and practice, showing how design intent translates into feel on the road. As the field continues to evolve, the search for new materials, refined processes, and clever geometries will push evolution rims even further toward a seamless blend of function and form.

External resources can deepen understanding of standards, grades, and performance characteristics that underlie these practical choices. For a deeper dive into standards and performance dimensions of larger rim sizes, see an in-depth guide to red 22 inch rims: https://www.wheelbase.com.au/blog/in-depth-guide-to-red-22-inch-rims-standards-grades-performance. This resource complements the narrative of evolution rims by anchoring the discussion in established evaluation criteria and real-world performance benchmarks, offering a framework for technicians, enthusiasts, and engineers to assess the trade-offs and benefits of different rim architectures. Readers who want a more technical perspective on load paths, stiffness-to-weight ratios, and corrosion resistance will find that guide particularly instructive. In this way, the exploration of evolution rims becomes not just a curated tour of designs and materials but a practical map for making informed choices that align engineering insight with driving expectations. The journey from a purely aesthetic statement to a performance-oriented, durability-conscious component is ongoing, and it invites ongoing attention to how each new iteration quietly shifts the balance between grip, stability, and elegance on the road.

null

null

Engineering the Edge: The Performance Evolution of Automotive Rims

Rims are more than wrappers for tires; they are active parts of a vehicle’s dynamic system. Over the decades, rim technology has evolved from simple steel disks to engineered aluminum alloys and advanced manufacturing methods that reduce unsprung mass, improve braking cooling, and enable new aerodynamic strategies.

The shift from steel to aluminum increases strength-to-weight ratio and offers greater design freedom. Forged rims deliver high strength with lower mass but at higher cost; casting and hybrid processes now close the gap for many applications. Design choices—from spoke geometry to hub flange and rim bed contours—balance stiffness, weight, and heat management while shaping visual identity.

Aerodynamics matter: vented spokes and precise rim shapes help channel air to cool brakes and reduce drag. Heat management remains central: better thermal paths and venting reduce brake fade and extend pad life. Finishes and coatings extend wheel life in adverse environments while influencing heat dissipation and appearance.

The practical effect for drivers is sharper handling, quicker responses, and more consistent braking under demanding conditions. In the end, rim evolution reflects a broader trend in automotive engineering: lightweighting, precision manufacturing, and integrated design that harmonizes form with function. This is not a single product but a continuum of innovations that keep pushing the wheel system toward higher performance and reliability.

Final thoughts

The journey through the evolution of rims underscores a beautiful interplay of art and science, demonstrating how dynamic innovations in design, materials, and functionalities are reshaping automotive engineering. Business owners in this sector must embrace these advancements not just to keep pace but to lead in a competitive marketplace. Evolution rims are not simply about aesthetics; they are foundational to delivering superior vehicle performance and safety, ultimately informing consumer choices in the years to come. Understanding their implications can empower your business strategy and enhance your offerings.