The front bumper of the Mitsubishi Lancer Evolution X is an emblematic feature, merging high-performance engineering with aesthetic appeal. Its design plays a crucial role in aerodynamics, enhances braking performance, and symbolizes the sportiness of the Evo X. For business owners, understanding the intricacies of the Evo X front bumper—from its aerodynamic qualities to aftermarket modifications—can drive competitive advantages. This article dissects its structural elements, explores available aftermarket options, examines materials influencing performance and cost, dives into manufacturing dynamics, and highlights performance enhancements through modifications. Each chapter contributes to a comprehensive understanding of the Evo X front bumper, enlightening stakeholders on its significance in today’s automotive market.

Shaping the Wind: How the Evo X Front Bumper Balances Aerodynamics and Character

Shaping the Wind

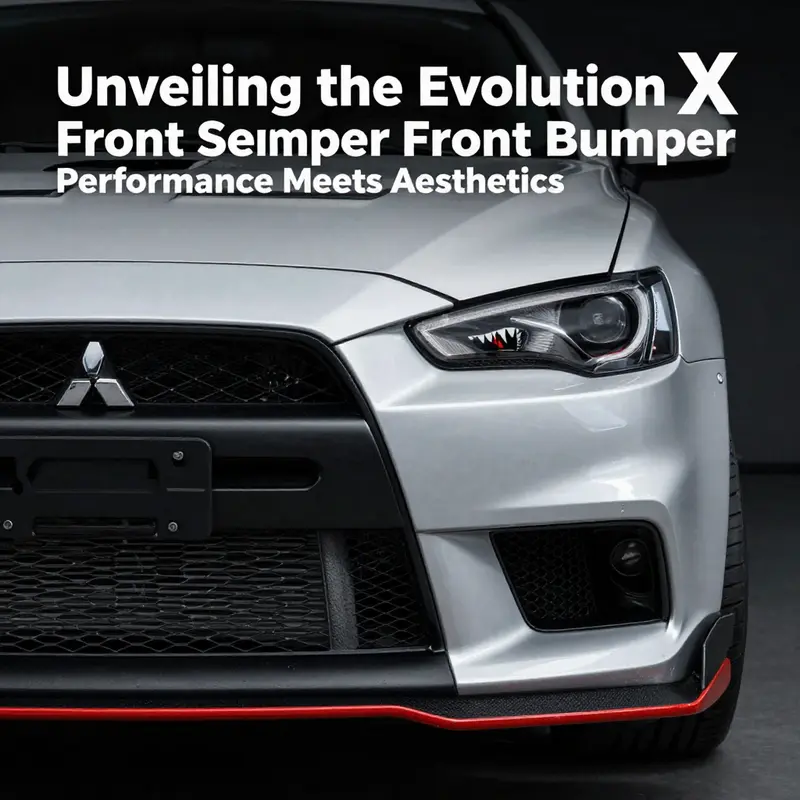

The front bumper on the Evolution X is more than a styling statement. It is a deliberate aerodynamic tool, a cooling corridor, and a visual promise of the car’s intent. Designers folded function into the sharp lines of the fascia to manage airflow, cool critical systems, and create a recognizable profile. Every inlet, lip, and duct on the bumper works with the car’s overall aero package to reduce drag where it matters and generate stability where it counts.

At the heart of that approach is airflow management. The bumper’s geometry channels air in controlled paths: some is guided through the central intake to feed the radiator and intercooler, some is split to sweep cleanly around the wheel wells, and some is directed through side ducts to cool the brakes. This division of air paths reduces turbulent wake behind the bumper and helps maintain high-speed composure. Engineers achieve this by shaping the lips and openings to create pressure differentials that coax air into desirable routes rather than letting it buffet the car unpredictably.

The larger forward openings are a practical response to thermal needs. High-performance engines and forced-induction systems generate heat that must be shed efficiently. The front bumper’s trapezoidal intake and its mesh pattern are sized to increase airflow into the cooling stack while presenting minimal frontal obstruction. The mesh pattern itself is a compromise between openness for cooling and surface area to dissipate energy and protect internal components from debris. This balance keeps temperatures in check without opening the car to excessive drag.

Brake cooling is another area where the bumper’s design is intentionally precise. Ducts placed on each side of the bumper are routed to deliver cool air directly onto the discs and calipers. By aiming a concentrated stream of air at those components, the system controls pad and rotor temperatures, reducing fade during sustained or aggressive driving. These ducts are small in appearance but large in effect; they reduce the need for oversized, heavy brake hardware by helping the existing system perform consistently under load.

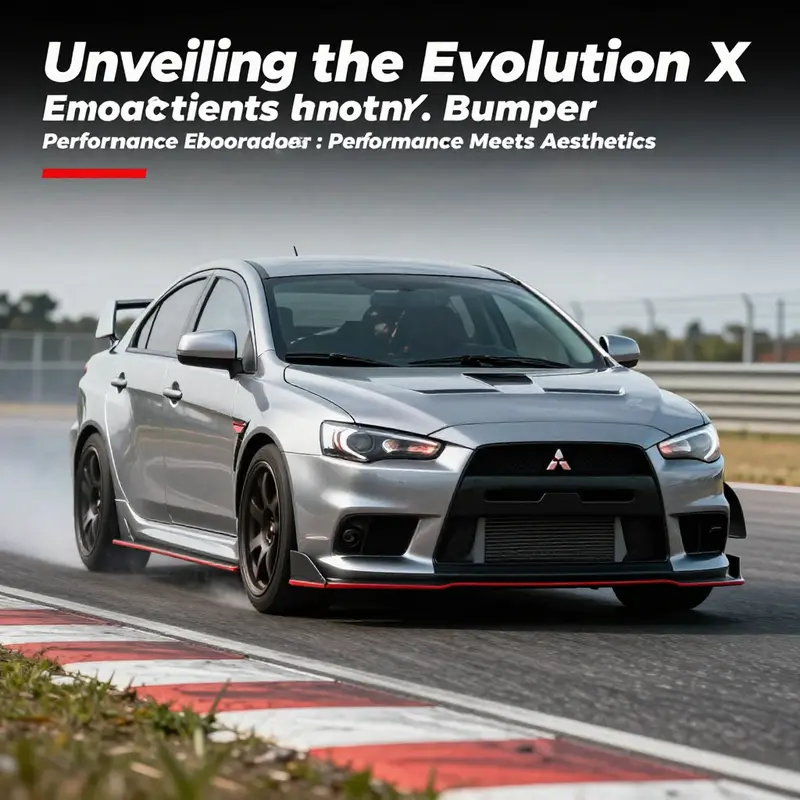

Wind tunnel testing and computational fluid dynamics underpinned many of the shaping decisions. Engineers used scaled models and full-size prototypes to observe how small changes to the lip angle, undercut depth, or duct entry altered pressure fields and flow separation points. The result is a front bumper that finds a mid-point between minimizing frontal drag and producing useful aerodynamic loads. At speed, that translates to a steadier front end and improved high-speed tracking without a significant penalty to top-end velocity.

Those same design decisions produce the Evo X’s signature presence. The sculpted nose, aggressive intakes, and visible ducts communicate performance. Yet these visual cues are not merely decorative. They hint at the underlying aerodynamic principles: flow redirection, pressure management, and localized cooling. This synergy between form and function is why the bumper remains a defining element of the car’s identity.

Aftermarket options support owners who want to push the aerodynamic envelope further. Some replacements widen intake apertures, deepen lips, or integrate sharper splitters. Carefully designed add-ons can increase front downforce and refine airflow to the cooling system. But those gains come with trade-offs. Larger or more protruding elements can increase vulnerability to curb strikes and low-speed contact. More aggressive lips may lift easily over bumps and require careful alignment to avoid creating new sources of turbulence. Installation precision becomes critical; small misalignments alter the pressure balance and can negate expected benefits.

Material choice influences both performance and durability. Thermoplastics like ABS and polypropylene offer resilience to everyday impacts and lower cost. They are forgiving in minor contacts and retain shape well. Fiber-reinforced plastics provide a stiffer structure and can be shaped into more complex aerodynamic forms, but they may crack under severe impact. Composite blends that combine fiberglass stiffness with polymer flexibility aim to capture the best of both worlds, offering weight savings and a degree of impact tolerance. The right material depends on how the car will be used: daily driving, spirited street work, or track-focused applications.

Trade-offs also appear in aerodynamic tuning. Increasing intake size improves cooling but can raise drag and disturb the laminar flow at the bumper’s edges. Adding a pronounced splitter can create front downforce but requires careful consideration of ride height and approach angles. Brake ducts optimize thermal performance but, if oversized or poorly shaped, can act as parasitic inlets that increase overall resistance. In short, every modification must be considered in the context of the entire vehicle package.

Fitment and integration with other bodywork also matter. The bumper does not act alone; it interacts with the hood profile, undertray, fenders, and side skirts. A cohesive aero strategy aligns the bumper’s exit flows with the underbody and side-flow devices to prevent flow collisions that would raise drag and produce lift. When replacing or upgrading a bumper, attention to these relationships is essential. A mismatched bumper can undermine the balance the original design established.

Practical considerations shape owners’ choices as much as aerodynamic theory. Durability in daily use, the likelihood of damage from road debris, and installation complexity influence decisions. Professional fitting ensures proper alignment and secures ducts and fasteners so airflow paths remain as intended. It also helps maintain the car’s structural relationships and prevents rattles or misalignments that might arise from a DIY installation.

For those seeking a direct replacement that preserves factory aerodynamics, there are genuine bumper units intended for the Evolution X platform. These preserve the original inlet sizes, duct locations, and mounting interfaces, helping to maintain the car’s intended aerodynamic balance. For options that push performance further, careful selection and testing are recommended to ensure gains are real and not merely visual. For a straightforward replacement, see this genuine CZ4A Evo X front bumper for a factory-correct fit and preserved aero behavior: https://mitsubishiautopartsshop.com/mitsubishi-cz4a-lancer-evolution-x-front-bumper-genuine/

The front bumper of the Evolution X is a lesson in measured design. It marries heat management and braking support with aerodynamic stability and branded character. Modifications can amplify specific traits, but gains are only meaningful when the entire vehicle is considered. Understanding the airflow highways the bumper creates—and how they tie into cooling and chassis balance—lets owners make informed choices that honor both performance and longevity.

Source: https://www.autoblog.com/2026/01/28/lancer-evo-x-front-bumper-guide/

Selecting and Sourcing Aftermarket Front Bumpers for the Evo X: Practical Choices and Trade-offs

A unified look at options, fitment, and sourcing for the Evo X front bumper

The front bumper of the Evolution X is more than styling. It defines airflow, cooling, and the car’s presence. Aftermarket options span exact factory replacements to dramatic race-inspired conversions. Choosing among them requires balancing aesthetics, performance, durability, and procurement realities. This chapter walks through those choices and the practical trade-offs owners and buyers face.

At the simplest level, buyers pick between direct-fit replacements and purpose-built enhancements. Direct-fit replacements mirror the original shape. They preserve the factory mounting points and the front sensor, fog light, and grille interfaces. For drivers prioritizing a factory appearance and straightforward installation, this remains the lowest-risk path. These units are usually made from flexible thermoplastics like polypropylene or ABS. Those materials resist minor impacts and return to shape fairly well. They also accept paint easily and integrate with existing hardware.

Beyond direct-fit parts lie performance-oriented kits. These designs reinterpret the Evo X’s shark-nose character with enlarged intakes, sharper splitters, and more pronounced ducts. The intent is to increase front-end downforce, guide cooling air to the intercooler or brakes, and reduce airflow separation at high speed. In practice, these gains depend on the entire vehicle setup. A well-designed bumper that increases front downforce must match the rear aerodynamic balance, suspension geometry, and tire contact patch. Otherwise, handling may become unsettled.

Materials and construction methods shape both function and cost. Injection-molded thermoplastics offer repeatable fit and consistent finish. They are common for direct-fit replacements and mid-range kits. Fiber-reinforced plastics, including glass-fiber composites, can give sharper shapes and lower weight. Hand-laid composite parts sometimes need more trimming and fitting than molded pieces. Carbon fiber or carbon-look components appeal visually and reduce weight, but they typically cost more and can be brittle under impact. Splitters and canards may use a mix: a durable plastic base with composite cosmetic overlays. When evaluating materials, consider how the part will be used. Daily-driven cars benefit from tougher plastics. Track cars may favor composites for weight savings and stiffness.

Fitment and installation are where many projects stall. Even parts labeled compatible with the Evo X can require trimming, filler, or bracket fabrication. Widebody or conversion kits often demand cutting of inner fenders and relocating mounting points. Alignment must be precise to maintain panel gaps and to avoid rubbing with tires on full lock. Expect to source new fasteners, clips, and sometimes inner-brace supports. Professional installation is advisable when structural modifications or precise aerodynamic function matter. For buyers who intend to resell the car, preserving the ability to revert to stock is worth planning.

Cooling function is a key technical consideration. The Evo X front bumper isn’t merely ornamental; it routes air to the engine bay, intercooler, and brakes. Aftermarket ducts must align with brake hardware and the brake backing plates to actually deliver cooling. Similarly, radiator and intercooler airflow paths need proper sealing and scooping. A visually large intake that bleeds air around internal components may deliver less cooling than a modest intake paired with proper ducting. Ask potential suppliers for photos of installations and flow diagrams showing where air exits and enters. That evidence distinguishes style work from engineering work.

Durability and finish quality vary widely. Mass-produced molded parts can have consistent paint prep and smooth surfaces. Hand-finished composites may show weave, pinholes, or filler lines unless properly prepared. Look for factory-quality prep, such as even primer, consistent gelcoat, and sanded transitions. UV stability is another factor; some coatings fade or chalk on sun-exposed cars. If sourcing from overseas manufacturing hubs, verify paint standards and curing processes. Ask for sample photos of finished parts that have aged in real-world conditions.

Sourcing and procurement bring separate constraints. Manufacturing clusters in certain regions offer a fully integrated supply chain. That integration shortens lead times and reduces logistics complexity. Suppliers there commonly support mold design, prototyping, finishing, and packaging under one roof. For procurement managers, this compact footprint simplifies communications and speeds production adjustments. Yet price alone should not be the deciding factor. Evaluate a supplier’s technical capability, quality assurance processes, and certifications. Insist on sample validation, dimensional checks against an approved master, and clear after-sales support channels.

Quality controls are practical. Request inspection reports showing dimensional tolerances, material certificates, and tensile or impact test results if available. For larger orders, ask to witness a first-article inspection or receive detailed photos and measurement charts. Confirm packaging standards to prevent shipping damage. Minor cracks or scratched paint on arrival add unexpected cost and delay projects.

Customization is appealing, but it raises complexity. Conversion kits let owners radically transform the Evo X face, sometimes borrowing cues from other models. These projects require fabrication skills and a plan for integrating sensors, lighting, and crash structures. Consider legal and safety implications. Some jurisdictions have rules on headlights, fog lamps, and pedestrian safety. Check local compliance before committing to a dramatic conversion.

Finally, plan for integration with other upgrades. A new bumper that increases cooling and downforce pairs well with upgraded brakes, intercooler, and suspension tuning. Conversely, a mismatched bumper can expose other weaknesses. If you are sourcing a direct-fit replacement for a collision repair, matching paint codes and preserving OEM mounting points smooths the process. If you are building a track-focused machine, allocate budget for professional fitting, ducting, and validation testing.

For owners seeking a factory-style replacement, consider viewing genuine front bumper listings to compare fit and finish. One useful resource shows authentic CZ4A Evo X front bumper options available through a parts shop. For deeper procurement guidance and supplier evaluation, refer to this buyer’s guide on aftermarket front bumper sourcing: https://www.autosupplyinsights.com/mitsubishi-lancer-evo-x-front-bumper-supplier-guide

Choosing the right Evo X front bumper is a decision about priorities. Decide whether you want seamless factory replacement, targeted performance gains, or a complete restyle. Match materials to use, plan for fitment work, and validate supplier capabilities. With careful selection, the front bumper will enhance both the car’s performance and its enduring presence on the road.

Shark Nose, Light Mass, and Quiet Power: The Materials Driving the Evolution X Front Bumper

The Evolution X front bumper sits at a crossroads of form and function. Its characteristic lines—an assertive, shark-nose silhouette and a broad trapezoidal intake—are more than design cues. They are calibrated pathways for air, cooling, and downforce, tuned to extract the most from a car that lives on the edge of grip and speed. The bumper’s mesh, the precise geometry of its ducts, and even the texture of its surface all contribute to a single goal: to manage the air that greets the Evo X at high speed. In a way, the bumper is a microcosm of the car itself—engineered to balance aggression with reliability, performance with practicality. The way it moves air around the radiator, interlaces with brake cooling, and reduces frontal lift matters as much as its visual impact when the car is parked or approaching a set of traffic lights. So, when we talk about the Evolution X bumper, we’re talking about a living system rather than a single component. The bumper is a shield, a guide, and a statement all at once, and its material makeup is what makes all those roles possible.

The options for material choice are a short but potent menu: ABS plastic, fiberglass reinforced plastic (FRP), and carbon fiber. Each material carries a distinct philosophy of performance, durability, weight, and cost. ABS, a workhorse of modern automotive body panels, is prized for its impact resistance and flexibility. In everyday driving, that translates to a bumper that can absorb small bumps and minor scrapes without cracking. It is tough enough to endure routine use while still accepting repairs with relative ease. The resilience of ABS makes it a sensible default for daily drivers who want a bumper that can take the punishment of city streets, parking lots, and occasional track days without demanding constant maintenance.

FRP, by contrast, leans into rigidity and cost-conscious performance. Fiberglass-reinforced plastic can be molded into complex aerodynamic shapes, offering the opportunity to craft aggressive lines and intricate air channels. For builders and enthusiasts chasing a bold look and a measurable aero edge, FRP is a compelling option. Yet its brittleness remains a caveat. A hard impact can cause cracks where a more ductile material would yield, and repairing FRP often requires specialized care. For those who measure value not only in price but in the ability to push a design toward its aerodynamic ceiling, FRP presents a strong case where a budget-minded, appearance-focused upgrade is the priority.

Carbon fiber represents the premium path. Its promise is lightness paired with stiffness. A bumper built in carbon fiber trims unsprung mass at the front of the car, a small but meaningful advantage for handling and acceleration, particularly on a track or fast road. The weight savings ripple into steering response and braking behavior. The downside is equally tangible: cost is high, and repairs after damage are challenging and expensive. Carbon fiber in practice tends to be reserved for high-performance builds where every gram counts and the owner is prepared for the ongoing maintenance and financing that a carbon-focused setup entails. The material choices thus map directly onto a driver’s goals, from practical daily usage to serious performance or show-piece ambitions.

The Evo X’s approach to cooling and aerodynamics reinforces this material narrative. The front bumper’s design does more than look aggressive. The large intake and the diamond-mesh pattern are engineered to optimize engine bay airflow and to reduce boundary-layer separation at speed. Adjacent to this central function, specialized brake cooling ducts on either side capture air to minimize brake fade and maintain pedal feel during repeated high-speed stops. The ducts’ efficiency is not a trivial enhancement but a necessary complement to the car’s overall performance profile. Where carbon fiber might grant a weight advantage, the durability and reparability of ABS or FRP can compensate if the front end is likely to see frequent contact with gravel, curbs, or minor collisions. The bumper, in its totality, becomes a living platform for how a vehicle translates raw speed into controlled motion.

Crucially, the material decision affects not only weight and cooling but also fit and longevity. OEM-grade ABS bumpers are designed to integrate with the car’s existing structural and mounting geometry. They tend to maintain consistent tolerances, ensuring that the bumper aligns with adjacent panels and sensors. In the aftermarket space, the same material choice often governs ease of installation and the quality of surface finish after painting. FRP bumpers, though adaptable for bold shapes, require careful finishing to minimize surface imperfections that can reveal themselves under sun or after a few cycles of heat and cold. Carbon fiber assemblies demand exacting layup quality and resin control; otherwise, the promised strength-to-weight gains may be compromised by misaligned seams or resin-rich pockets. The practical consequence is that sourcing decisions must consider not just the sticker price but also the supplier’s quality control practices, whether the part has been validated against OEM specs, and how well it will hold up under the real-world conditions that Evo X owners encounter—from daily commutes to weekend track sessions.

These considerations lead to another layer of complexity: the procurement landscape in which Evo X bumpers are produced and traded. For buyers and distributors seeking performance upgrades, the origin of the bumper matters almost as much as its material. In major manufacturing clusters across China—particularly in provinces known for automotive composites and body components—foundries bring together the full spectrum of capability, from mold design to finished painting and packaging. The advantage of such an integrated ecosystem is not merely cost. It is speed, flexibility, and the ability to support prototyping in small batches or scale to larger orders with shorter lead times. That is essential for a model like the Evolution X, where a bumper may need to accommodate various trim levels, sensor placements, and bumper-to-body interfaces across model years. A buyer who can pair design intent with a supplier’s technical capability and an ISO-certified quality system can navigate beyond price alone to secure parts that truly match OEM standards. In practice, this means evaluating a supplier’s sample validation processes, their traceability, and their after-sales support—factors that ultimately determine whether a high-performance front end is reliable enough for daily use or reserved for selective track applications.

From a design and engineering standpoint, the choice of bumper material also interacts with the car’s weight budget and its front-end geometry. Carbon fiber’s role in reducing mass at the bumper edge can contribute to a slightly more agile front end, especially when paired with a stiffer frame and well-tuned suspension. ABS and FRP, while heavier, can still be engineered to deliver respectably low inertia and good crash energy management. In all cases, the bumper must integrate with the car’s cooling ducts, sensors, and mounting points without introducing misalignment or excessive gaps. The front fascia’s surface finish matters as well, particularly for owners who contend with long-term exposure to sun and weather. A high-quality finish resists cracking or crazing and can hold color and gloss across seasons. The market for Evo X bumpers reflects this mix of performance and practicality. For those who prioritize aesthetics and a bold stance, FRP may be the most attractive route; for those who emphasize reliability and DIY repair friendliness, ABS stands out as the balanced choice; for those pursuing maximum performance and show-ready weight savings, carbon fiber remains the aspirational option.

To connect these design considerations with real-world sourcing, it helps to think in terms of a lifecycle approach. A bumper begins its journey as a concept, moves into tooling and mold design, and then transitions into production. The mold’s precision impacts both fit and surface quality, and paintability hinges on the resin system and surface preparation that follows. Once in production, ongoing quality control—checking for dimensional accuracy, paint thickness, and surface integrity—becomes the backbone of a reliable supply. For buyers, that means a carefully designed evaluation framework that looks beyond the unit price. It means validating supplier capabilities, ensuring that samples meet OEM-style tolerances, examining their document control and material certifications, and confirming that after-sales support will be available if fitment or finish issues arise. In this sense, the bumper becomes less a single item and more a node in a wider ecosystem of parts, processes, and people working together to keep the Evo X’s front end both visually striking and functionally capable.

For readers seeking deeper context on specific genuine front bumper options within the Evo X ecosystem, a representative resource offers detailed specifications and compatibility notes. Mitsubishi CZ4A Lancer Evolution X front bumper (genuine) provides a technical touchstone for understanding how a genuine front bumper aligns with the chassis geometry and sensor layout, while illustrating how OEM-grade parts stay true to the car’s original engineering intent. This kind of reference complements the broader discussion of materials by anchoring the conversation in a concrete example of fit and finish. External references can also illuminate broader market dynamics. For instance, a major online supplier’s catalog highlights how raw material choices and manufacturing workflows translate into bumper options across price points and performance goals. External reference: https://www.alibaba.com/product-detail/Upgrade-Your-Mitsubishi-EVO-X-Front-Bumper1600849174568.html?spm=a2700.galleryofferlist.poffer_list.1.7d2b1e7cXHnLJf&urlHash=1600849174568

The Evolution X bumper is more than a plastic shell with a logo. It is a carefully chosen interface between air, weight, and load paths. Its material makeup dictates how entry-level enthusiasts experience reliability and how dedicated racers experience the potential to shave seconds off a lap time through mass reduction and improved brake cooling. In the end, the bumper’s material story—ABS for everyday resilience, FRP for bold styling and rigidity, carbon fiber for peak performance—mirrors the chorus of possibilities that the Evo X invites. It is a reminder that even within a single component, decisions about materials ripple through handling, cooling efficiency, serviceability, and the car’s overall character. As the evolutions on the road and track continue, this bumper remains a focal point where engineering nuance and personal preference converge, guiding builders, racers, and enthusiasts toward choices that fit their ambitions as much as their budgets.

Shaping Speed: The Global Manufacture and Supply Chain Behind the Evolution X Front Bumper

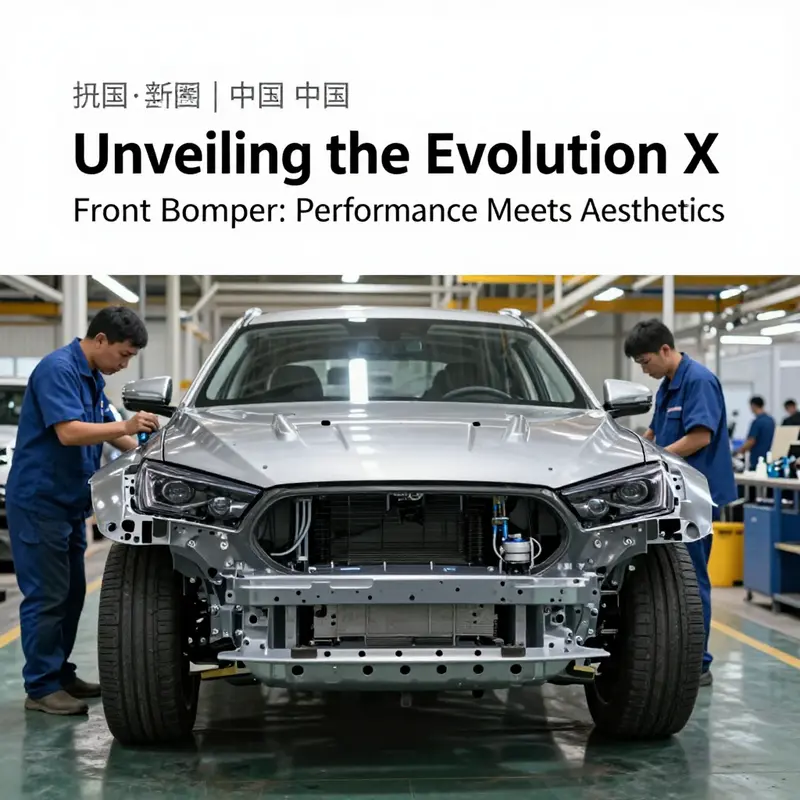

The Evolution X front bumper is more than a cosmetic fascia; it is a carefully engineered interface between aerodynamics, cooling, and the sensory experience of driving a high-performance sedan. From the characteristic shark-nose silhouette to the bold trapezoidal intake and the diamond-mesh pattern, the Evo X front fascia embodies a philosophy: form must enable function at speed. The larger opening isn’t merely for looks; it is a carefully calibrated portal for engine breathing, helped along by brake-cooling ducts tucked into the side, which impinge on the discs and calipers as the car rushes toward redline. In the world of performance parts, those design cues carry significance beyond aesthetics. They set the tone for how a component is manufactured, sourced, and delivered to a buyer who expects OEM precision and aftermarket flexibility in a single package. The manufacturing and supply chain dynamics that produce this bumper—threads that braid together mold makers, fabricators, painters, and QA teams—are a story of global specialization colliding with local, tightly integrated ecosystems that move parts from concept to car in weeks rather than months.

The apex of this ecosystem is found in a highly concentrated cluster in China, with Guangdong Province standing out as a hub where injection molding and fiberglass fabrication sit in close proximity to paint shops and tooling experts. This proximity is not accidental; it is a strategic arrangement that minimizes handoffs, reduces wait times, and accelerates prototyping to production. When a supplier can shift from a single prototype to a batch of hundreds of units in a matter of weeks, it changes the commercial calculus for distributors and professional buyers who rely on consistent supply. The Evo X bumper, in its OEM-style form or in aftermarket variants, benefits from this clustering because fitment accuracy hinges on tight tolerances across a complex geometry. High-fidelity bumpers must match the 2008–2015 spec with enough precision to align with mounting hardware, impact absorbers, and the air-paths energized by the vehicle’s front end.

At the heart of the production equation are materials that balance weight, durability, and cost. ABS plastic remains a workhorse for mainstream, cost-conscious variants that seek durable, impact-resistant components with predictable aging. For those chasing lighter weight and higher stiffness, fiberglass and carbon fiber are common choices, offered in varying weave densities and resin systems to tailor rigidity and surface finish. Polypropylene variants may be used for certain structural elements or interior-facing sections where UV resistance and chemical stability matter. The production line itself is a choreography: mold design specializes in capturing the exact curvature and texture of the Evo X’s face, while surface finishing labs apply primer, paint, and clear coats that must endure the harsh realities of road grime, heat soak, and warranty cycles. In this interconnected workflow, the most important metric is not the initial price point but the supplier’s ability to deliver an assembly that fits OEM tolerances and performs under real-world conditions.

The concept of production agility is embedded in the way these supply chains are organized. A shop can begin with a one-off prototype, validating fit and finish through rapid iteration, then scale to hundreds of units per month as demand signals justify capacity. This level of flexibility is essential for aftermarket channels where market demand can vary with seasonality, new model years, or shifting driver preferences for aggressive styling paired with functional upgrades like improved cooling or aero balance. The ability to pivot between materials—whether opting for more economical PP blends or premium carbon-fiber skins—enables buyers to calibrate price versus performance for a given application. The result is a dynamic equilibrium where lead times improve and reliability increases, not just because of aggressive manufacturing capacity, but because of a holistic approach to quality assurance.

Quality control threads through every stage of the value chain. ISO-certified processes, rigorous sampling, and traceability protocols help ensure that every bumper not only looks right but also performs as intended in terms of fit, finish, and structural integrity. For distributors, this translates into a lower risk of misfit and a higher confidence in post-sales support. In practice, this means a strict evaluation framework that weighs more than upfront cost. Technical capability, process capability indices, and the presence of robust after-sales support networks become decisive factors. As markets for aftermarket parts expand, buyers increasingly demand data-driven decision-making that weighs supplier reliability, batch consistency, and the ability to provide timely replacement parts for fleets or shop networks. In this context, the integrated Guangdong ecosystem excels because it coordinates the entire chain—from mold design and surface finishing to packaging and logistics—under a shared governance of quality and timing. If a supplier can align a new design with existing tooling, it compounds the efficiency gains that drive reductions in lead times by as much as thirty percent when compared with offshore alternatives.

The supply chain advantages extend beyond proximity and speed. Localized ecosystems enable tighter collaboration across functionally diverse specialists, which is crucial for a product that must marry aerodynamic objective with visual appeal. The front bumper’s shape and texture must be replicable across batches, and the painting steps must endure the same environmental exposure as the body panels it complements. This level of coordination reduces miscommunication and rework, and it consistently translates into more predictable inventory cycles for procurement managers and automotive parts distributors. In markets where aftermarket performance parts are rising in prominence, the importance of selecting strategic suppliers cannot be overstated. Buyers are becoming more discerning about the depth of a supplier’s technical toolbox: the precision of mold tooling, the fidelity of surface finishes, the stability of supply for carbon fiber components, and the capacity to provide samples that validate OEM-like fit before mass production begins.

Sourcing insights underscore how digital marketplaces have reshaped the way buyers connect with manufacturers. Platforms that aggregate verified suppliers offer OEM-fit precision body kits designed for specific Evo X model years, such as the 2008–2017 range, and provide a conduit for direct, data-rich conversations between buyers and fabricators. For the professional buyer, the advantage is clear: detailed specifications, material choices, and process transparency are surfaced up front, reducing the risk of late-stage design changes or nonconforming parts. The convergence of digital procurement with hands-on engineering is a defining feature of the contemporary Evo X bumper supply chain and a signal of the broader transformation underway in the automotive aftermarket.

Within this ecosystem, a single, representative supplier profile can illustrate how the pieces fit together. A profile of a manufacturer that emphasizes genuine Evo X front bumper production highlights their ability to deliver OEM-fit precision with a choice of materials, from durable ABS to lightweight carbon fiber, while maintaining tight tolerances across mounting points and air ducts. The ecosystem benefits when buyers integrate suppliers whose capabilities include rapid prototyping, robust QA processes, and scalable output. A practical takeaway for procurement teams is to look beyond unit price and to evaluate a supplier’s end-to-end capability: mold design maturity, surface finishing consistency, packaging integrity, and after-sales support that keeps the product performing through multiple seasons of use. This holistic approach aligns with the Evo X’s broader identity—a performance fixture that must endure both high-speed exposure and the rigors of daily driving.

For readers who seek a direct glimpse of the market’s breadth, one can explore the Evo X bumper landscape through a dedicated supplier profile that emphasizes genuine, OEM-fit options. Mitsubishi Evolution Evo X Front Bumper – Genuine (https://mitsubishiautopartsshop.com/mitsubishi-evolution-evo-x-front-bumper-genuine/). The page captures the essence of a sector where authenticity, compatibility, and finish are the currency of trust, and where buyers frequently triangulate between cost, lead time, and post-purchase support when selecting a partner.

As the aftermarket continues to grow, the Evo X bumper demonstrates how a single component can be a linchpin for a wider ecosystem that blends design intent with manufacturing pragmatism. The story is not merely about the part itself but about the orchestration required to bring it from drawing board to showroom and, ultimately, onto the street. The Evolution X’s distinctive front end thus serves as a case study in how modern automotive supply chains are organized: tightly clustered, highly technical, and increasingly data-driven, with a relentless focus on fit, finish, and speed. External resource: Alibaba Evo X Bumper – High Quality Rear Front Bumper Kit (https://www.alibaba.com/product-detail/Evo-X-Bumper-High-Quality-Rear-Front_1600549925885.html)

null

null

Final thoughts

The front bumper of the Mitsubishi Lancer Evolution X serves as more than just a protective piece; it reinforces the vehicle’s identity as a high-performance sports car. Each design element is meticulously crafted to optimize aerodynamics and cooling, which are crucial for high-speed performance. With a plethora of aftermarket options available, business owners are empowered to enhance their offerings and satisfy customer demand for customized performance enhancements. Moreover, understanding the manufacturing and supply chain dynamics allows businesses to make informed decisions, ensuring quality and compatibility. A strategic focus on the front bumper’s role will undoubtedly contribute to business growth in the competitive automotive market, solidifying the Evo X’s legacy.