The Mitsubishi Lancer Evolution X presents a unique opportunity for automotive enthusiasts and business owners alike to explore enhancements that combine aesthetics and functionality. The Evolution X front lip serves as a prime example of such an upgrade, delivering both visual appeal and aerodynamic benefits. In this analysis, we will delve into the mechanics of aerodynamics courtesy of the front lip, explore the materials and manufacturing processes that influence quality and performance, examine how these components contribute to overall vehicle performance, and finally, outline current market trends and consumer preferences surrounding front lips for the Evo X. Together, these insights will provide a comprehensive understanding for business owners looking to tap into this niche market intelligently.

Shaping Speed: How the Evo X Front Lip Rewrites Airflow and Handling

Shaping Speed: How the Evo X Front Lip Rewrites Airflow and Handling

The front lip on an Evolution X is far more than a cosmetic flourish. It is a deliberate aerodynamic tool that alters how air meets, moves under, and departs the car. When designed and fitted properly, it reduces lift, calms turbulence, and brings the front axle into a steadier, more planted state at speed. Those benefits change the way the car steers, grips, and responds; they are felt as crisper turn-in, more predictable mid-corner balance, and improved composure on long high-speed sections.

At its core, the front lip manipulates pressure differentials. The body of the Evo X forces air to split at the front fascia. Some of that flow is guided over the hood and roof, while the rest travels beneath the vehicle. A well-shaped lip controls the quantity and velocity of air entering the underbody. By directing a greater portion of flow around the sides and over the top, the lip reduces the high-pressure cushion beneath the front axle. That drop in underbody pressure translates into reduced lift and more effective front-end downforce, without the extreme penalty of a full-width splitter or heavy bodywork.

Beyond simple pressure control, the front lip eases the transition of air around the bumper and toward the wheel arches. Sharp corners, exposed tire surfaces, and abrupt edges create turbulent wakes that sap stability. A continuous lip smooths that initial contact, lowering flow separation and minimizing the size and energy of shed vortices. The result is a more attached airflow regime that keeps the car directional and predictable. In real-world driving, this translates into reduced steering corrections at speed and better feedback through the front end.

Small appendages integrated into many lips, commonly called canards, are not ornamental. These elements generate energetic vortices along the bumper flanks. Those vortices travel rearward, energizing the boundary layer along the lower side of the car. By keeping the flow attached longer, canards improve cornering stability and sharpen turn-in response. The effect is particularly useful when running wider tires and aggressive camber settings; the vortex helps maintain consistent pressure distribution across the tire contact patch during yaw. On a circuit, that translates into more confidence braking into corners and less looseness when the load transfers forward.

Material choice matters. Lightweight, stiff materials provide a clearer aerodynamic advantage because they preserve the designed shape under load. Carbon fiber, for example, offers high stiffness-to-weight ratio. That keeps leading edges sharp and profiles precise. When a lip flexes or deforms at speed, its ability to control airflow diminishes. Flexing can also change the camber of the whole front end and produce unpredictable handling. Conversely, polymer blends and urethane deliver resilience; they absorb impacts and return to shape, reducing repair needs for street-driven cars. The trade-off is often stiffness versus durability—rigid laminates are more aero-precise but can crack on impact, while flexible materials survive low-speed encounters but may sacrifice some aerodynamic fidelity.

Weight reduction is a secondary but meaningful benefit. Removing mass from the nose improves the car’s transient response. Reduced inertia allows the steering to settle faster and the chassis to change direction more readily. For cars that race or are track-prepared, every saved kilogram at the extremities improves lap times. However, the primary gains remain aerodynamic: improved downforce distribution and cleaner flow under the car.

Fitment precision is another critical variable. A direct-fit lip that matches the bumper contours seals the junction between bumper and add-on. Gaps or misalignment create local separation points that seed turbulence. Correct fasteners, support rods, and precise edge contours matter. Some designs include integrated reinforcement ribs or molded mounting pockets to maintain alignment and to reduce rattles and stress on the bumper. Proper installation practices—measuring ride height, ensuring level mounting, and verifying clearance at full suspension droop—preserve function and longevity.

Ride height and ground clearance play decisive roles. The closer the lip sits to the road, the stronger the low-pressure zone it can create beneath the front. But there is a practical limit. Too low and the lip becomes a liability on public roads, collecting scrapes and potentially creating a negative impact on daily usability. On track cars, very low splitters and lips work against a flat undertray and diffuser system. On street-driven cars, a compromise that balances aero gains with usable clearance is usually preferable.

The front lip does not operate in isolation. It forms part of an aerodynamic ecosystem that includes the hood, bumper openings, side skirts, undertray, and rear diffuser. When paired with complementary components, the lip helps manage the inlet and outlet flows that the underbody needs to generate stable pressure profiles. For example, a lip that closes off the lower bumper effectively can help the undertray maintain a slightly lower pressure than the ambient. That requires the rear diffuser and side skirts to be doing their jobs too, channeling and sealing air toward the back of the car. Owners seeking maximum gains should consider the entire suite of aero components rather than relying on one add-on alone. For more information on compatible bumper components and fitment, see this resource on CZ4A Lancer Evolution X front bumper.

Aerodynamic benefits can be quantified, but the real validation comes from matched testing conditions. Proper wind tunnel work or computational fluid dynamics (CFD) runs can reveal how much lift is reduced, where vortices form, and how drag is affected across different yaw angles and ride heights. On the road or track, consistent testing—measuring lap times, steering input rates, and stability at specific speed thresholds—provides the performance context. Many drivers report more decisive steering feel and reduced front-end wandering after fitting a well-designed lip. The best outcomes occur when aero changes are matched with suspension setup adjustments, such as damping and anti-roll balance, to harmonize the chassis with altered pressure loads.

Durability and maintenance are practical concerns for any upgrade. UV-resistant finishes and protective clear coats extend the life of exposed surfaces. Flexible materials tolerate curb strikes and road debris better, reducing the need for replacement. Still, regular inspections for cracks, loose fasteners, and finish wear are prudent. Small repairs performed early prevent progressive failure. For vehicles that see occasional track days, checking the mounting hardware after each event is a simple habit that prevents larger failures.

There are trade-offs to accept. Any front lip that reduces lift may add a small amount of drag at certain speeds or yaw angles. Designers aim to minimize drag penalties while maximizing downforce improvement. Street-driven cars benefit most when the balance favors reduced lift with minimal drag increase. Track cars, where cornering speed is paramount, often accept greater drag for added front-end grip. Legal and practical considerations matter too: extreme aero parts can conflict with local regulations, interfere with parking ramps, and complicate routine maintenance like oil changes. Owners should choose a design that fits their intended use.

A final, often overlooked advantage of a well-executed front lip is the psychological effect. A car that looks purposeful and feels planted invites a different driving approach. Drivers tend to be more confident braking later and setting up corners more aggressively. That confidence, when matched with real aerodynamic gains, yields better lap times and a more enjoyable driving experience.

The Evo X front lip remains a compelling upgrade because it offers a direct route to improved stability, sharper handling, and a cohesive visual identity. When selected with attention to material, fitment, and coordination with other aero elements, it becomes an integrated component of the car’s performance envelope. Whether the goal is daily-driven sharpness or track-focused balance, the lip’s job is to reshape airflow in service of control. For readers interested in technical validation and manufacturer-supplied testing data, consult the official product documentation here: https://www.duraflex.com/products/racer-x-front-lip-spoiler-air-dam-for-evolution-mitsubishi

Choosing the Right Material: How Evo X Front Lips Are Made and Why It Matters

Materials and manufacturing shape both performance and presence for the Evo X front lip. The material selected defines weight, durability, repairability, and the way the lip interacts with airflow. It also drives cost, finish options, and installation demands. For drivers balancing daily use with spirited driving, the decision between resilient polymer and lightweight composite is foundational. Below is an integrated look at the two dominant material paths, how each is manufactured, and the real-world trade-offs you should weigh when choosing or fitting a front lip for a Mitsubishi Lancer Evolution X.

Polyurethane and carbon fiber represent opposing priorities. Polyurethane emphasizes resilience and cost-effectiveness. Carbon fiber emphasizes weight savings and a race-inspired aesthetic. Both can be engineered into parts that look sharp and bolt up cleanly to stock bumper openings. However, the way they are made and finished profoundly changes their behavior on the road.

Polyurethane parts are typically produced via injection molding. Molten polymer is forced into a precision mold, cooled, and ejected as a single, near-finished piece. Injection molding allows tight tolerances and consistent repeatability across large production runs. It also enables complex geometries, integrated mounting bosses, and multiple screw points molded directly into the piece. Those details matter: they improve fitment and prevent stress concentrations that lead to cracks. Because polyurethane flexes under impact, it resists cracking and shattering. That makes these lips practical for daily drivers who scrape curbs, park in tight spaces, or encounter potholes.

The inherent flexibility of polyurethane gives it a forgiving failure mode. Small impacts compress or deform the lip instead of fracturing it. Deformations can sometimes be corrected with heat, or replaced cheaply compared to composite repairs. UV-stable coatings and gel coats enhance longevity. Modern formulations resist fading and embrittlement, preserving appearance over years. Manufacture via injection molding keeps unit cost down. That affordability is a major reason polymer lips dominate as OEM-style replacements and value aftermarket options.

Installation of polyurethane lips is straightforward. The molded mounting points align with factory bumper holes. Included hardware often consists of screws, rivets, and optional support rods to prevent sagging. The support rods are thin metal struts that transfer lift forces to the bumper and prevent flutter at speed. Properly installed, a polyurethane lip provides a neat, durable enhancement without dramatic weight penalty or risk of brittle failure.

Carbon fiber follows a different production path. It is a woven fiber composite cured into a matrix, typically epoxy. Two main manufacturing techniques appear across the market: wet lay-up with vacuum bagging and prepreg/autoclave curing. Wet lay-up uses dry or pre-wetted fiber cloth saturated with resin, then sealed under vacuum to compact layers and remove excess resin. Prepreg uses fiber already impregnated with resin. Prepreg parts are cured at elevated temperature and pressure inside an autoclave. Autoclave curing yields higher fiber-to-resin ratios and therefore superior strength-to-weight performance.

The result of composite manufacturing is a part that is markedly lighter and stiffer than polymer or fiberglass alternatives. For the Evo X, that means lower front-end mass and reduced moment of inertia at the extremity of the bumper. The weight savings can be meaningful for drivers chasing quicker turn-in and sharper response. Carbon fiber also accepts high-gloss clearcoats exquisitely, showcasing woven patterns that communicate performance intent. That aesthetic is often as important as the mechanical gains.

However, composites demand careful handling. Carbon fiber parts are stiffer and less forgiving of point impacts. Edge strikes and curb nicks can initiate cracks that propagate if left unrepaired. Repairing a carbon fiber lip requires composite techniques: sanding to the damaged zone, rebuilding fiber layers with epoxy and cure, then finishing with primer and clearcoat. These repairs are effective, but they cost more than replacing a polyurethane lip. In collisions causing crush-level damage, composites may fail catastrophically rather than flex, increasing the risk of hidden structural damage to adjacent bumper or mounting points.

Beyond raw material differences, surface finish and protective coatings matter. Both material types benefit from UV inhibitors and clearcoats. For carbon fiber, a UV-stable clearcoat prevents resin yellowing and preserves gloss. For polyurethane, pigmented finishes and UV-stable gel coats reduce fading and chalking. High-quality finishes improve longevity and make subsequent touch-up easier. They also affect how the lip integrates visually with other exterior upgrades, like a carbon bonnet or side skirts.

Fitment and compatibility are practical concerns. The Evo X uses multiple bumper variants across its model run. A direct-fit lip must match those contours precisely. Precision molds and jigs help manufacturers achieve consistent alignment. Whether polymer or carbon, verify the lip is designed for specific Evo X years and bumper types. Many aftermarket vendors include mounting hardware and instructions. Support brackets, double-sided tape strips, and additional rivets are common. Proper torque of fasteners and pre-fitting before final fastening reduce stress at attachment points and prevent misalignment.

Aerodynamic performance is where material choices interact with function. A front lip’s purpose is to manage airflow under the vehicle, reduce front-end lift, and generate a low-pressure region for improved stability. Material stiffness influences how reliably the lip maintains its designed shape at speed. A flexible polymer lip may deform under high aerodynamic load, reducing its intended effect. Conversely, a stiff carbon fiber lip holds shape and produces predictable downforce and airflow patterns. That said, engineering details like mounting points, support rods, and canard integration often determine real-world aerodynamic gains more than material alone.

Manufacturers sometimes integrate canards or vortex-generating elements into the lip. These small fins sculpt airflow and clean the boundary layer running along the bumper sides. On a stiff, lightweight carbon lip, canards remain aligned and effective at high speeds. On flexible materials, they can bend or chatter unless supported. Thus, if your use case includes track days or sustained high-speed driving, a stiffer construction will keep aero features working as designed.

Thermal and environmental resilience also vary. Carbon fiber resists heat well and does not warp from engine bay heat. Polyurethane tolerates temperature swings but can soften if exposed to extreme heat repeatedly. Chemical exposure from fuel or solvents affects both if left unchecked. Regular washing, careful drying, and periodic inspection prolong life. For parts exposed to road salt or coastal environments, ensure corrosion-resistant bracketry and stainless hardware are used.

Cost and ownership economics are straightforward to compare. Injection-molded polyurethane lips cost less to produce. They are cheaper to buy and cheaper to replace. Carbon fiber parts cost significantly more due to labor-intensive lay-up, autoclave processing, and finishing. However, they can add resale and aesthetic value. For dedicated builds and show cars, the visual payoff and performance edge justify the premium.

Choosing the right material depends on your goals. For a daily-driven Evo X with occasional spirited runs, polyurethane gives durability, easy repairs, and a lower long-term cost. For enthusiasts seeking weight reduction and track-ready response, carbon fiber delivers tangible benefits. Many owners mix approaches: carbon for hood and roof panels, resilient polymer for bumpers and lips where impact risk is higher. That balance preserves both performance gains and practicality.

When buying, inspect construction details. Look for consistent fiber patterns in carbon parts and smooth, pinhole-free clearcoats. For polyurethane, check molded screw bosses, included internal supports, and the presence of mounting rods. Ask for compatibility with your specific bumper variant. Seek parts with documented installation instructions and complete hardware kits. Professional installation is recommended for carbon parts to avoid damage and ensure correct alignment.

Finally, consider long-term maintenance and the availability of replacement parts. Polyurethane is easier to source and replace. Carbon fiber parts, while durable, are more specialized to repair or replace. If you plan frequent urban driving with exposure to curbs and debris, a resilient polymer lip reduces worry. If you race or show the car, carbon fiber aligns with those priorities.

For a visual reference on composite choices and application, see the shop catalog featuring a carbon fiber bonnet for the Evo X, which illustrates finish and weave patterns common to high-end parts. For an in-depth guide to material composition and effective use across the vehicle, consult the comprehensive body kit materials guide available online: https://www.oscarbennett.com/evolution-x-body-kit-materials-guide

Balancing aesthetics, aerodynamics, and longevity comes down to honest assessment of how you use your Evo X. The right front lip is the one that matches those realities. Materials and manufacturing tell you what a lip will do, and how it will behave over time. Use that knowledge to choose a lip that enhances both appearance and performance without exposing you to surprises on the road.

Gripping the Air: Performance, Precision, and Identity with the Evolution X Front Lip

The Evolution X front lip serves as a focal point for enthusiasts who seek more than a mere cosmetic upgrade. It is a purpose-built component that rewrites how the vehicle negotiates air and how the driver perceives the car at spatial extremes—high-speed straights and rapid corner entries alike. The front lip sits at the frontier where aerodynamics meets aesthetics, a boundary where every millimeter of extension toward the ground becomes a variable that can alter grip, steering feel, and even steering precision in transitions. In this sense, the lip is not simply a piece of molded plastic or a weave of carbon; it is a carefully calibrated instrument that channels air in ways the stock setup could only approximate. When chosen and installed with care, it helps the car bite into the pavement with more authority and invites the driver to lean more assertively into the next bend. The upgrade speaks to a philosophy of driving that treats the road as a liquid medium and the car as a responsive instrument, one whose surface and underbody interact to shape what happens at the precise boundary where front wheels meet the surface. The lip’s function thus lies at the intersection of science and instinct, where engineering data meets the driver’s tactile sense of balance and tempo through a corner.

From a practical standpoint, the lip’s primary contribution is aerodynamic finesse. High-speed stability depends on how the front end negotiates the air that pushes back from the grille and bumper, and a well-designed lip helps manage that interaction by reducing lift and introducing downforce where it matters most. The change is not colossal in a vacuum, but it compounds with speed, weight distribution, and tire grip to yield a more confident front axle response. This is especially true when the lip is paired with a thoughtful air-management strategy that includes side canards or aero skirts. The result is a clean, organized flow that encourages the car to hold a straight line more readily under acceleration and to turn in with more immediacy. The front lip helps to shape the pressure field around the bumper, guiding the air away from the underside and toward the sides where vortices can form and stabilize the boundary layer. The cumulative effect appears as a measurable enhancement in the sense of control during quick directional changes, rather than as a dramatic, single-moment improvement.

The role of vortices in this aerodynamic narrative cannot be overstated. Many Evolution X front lips are designed to generate small, controlled swirls along the vehicle’s flanks as air wraps around the bumper. These vortices act like tiny, purposeful mixers that minimize the chaotic wake created by the sharp edges of the bumper. By smoothing this wake, the car experiences less disturbed air along the tires, which translates to steadier turn-in and a more predictable response when the driver reduces steering input or applies moderate throttle through a corner. The logic is subtle but powerful: a cleaner side flow means the suspension and tires can work with more consistent air pressure distribution, and given the car’s balance characteristics, that consistency feeds into better tipping and load transfer behavior during transitions. In practice, drivers often report a sense of enhanced front-end bite and a more linear steering feel as the corner speed climbs, especially when the lip is integrated into a broader aero strategy that respects the car’s geometry and center of gravity.

The material choice for a front lip carries its own implications for performance. Carbon fiber and premium composites are favored for their superior strength-to-weight ratio, stiffness, and heat resistance. A lighter lip reduces the unsprung and sprung mass that the suspension has to manage, a detail that can translate into snappier response under braking and crisper turn-in. In addition, carbon fiber’s inherent rigidity helps preserve the intended aerodynamic shape even when the bumper experiences minor impacts or mounting stresses. But materials are a trade-off game. While carbon fiber delivers a race-inspired look and performance edge, it commands a higher price and sometimes requires more meticulous installation to avoid misalignment or finish damage. Alternatives like high-grade ABS or urethane offer resilience and cost efficiency but may demand careful attention to geometry to preserve the intended airflow angles. Regardless of material, the lip’s mass remains deliberately minimized to avoid eroding any gains in acceleration or braking performance. The goal is to keep the added component light enough to contribute positively to the car’s response while robust enough to survive the realities of daily driving and occasional track sessions.

Protection is another practical dimension of the Evolution X front lip. The lower portion of a car’s front bumper is constantly exposed to road debris, speed bumps, and the occasional off-line contact with curbs. A well-constructed lip acts as a sacrificial shield that takes the initial impact and drips away the energy away from the more delicate bumper cover. This protective function is not merely about saving aesthetics; it preserves the structural integrity of the bumper and reduces the likelihood of expensive repairs after routine encounters with rough pavement. In that sense, the lip contributes to the longevity of the front end and, by extension, to the vehicle’s resale value by maintaining a cleaner, more streamlined underbody profile that resists accumulation of road grime and minor scrapes. It is a pragmatic addition that bridges performance ambition with everyday practicality, a combination often prized by owners who want their upgrades to be both track-ready and road-ready.

From an aesthetic perspective, the Evolution X front lip communicates a deliberate, race-inspired identity. The line between function and form blurs here, with the lip offering a visual cue of intent: a commitment to handling precision, to lower drag, and to a front end that appears prepared for the open road or the closed circuit. The appearance of a front lip often harmonizes with the rest of the body kit, the canards, and the undertray to create a cohesive silhouette that sits lower, broader, and more purposeful. For many owners, this visual shift is as compelling as the performance gains because it signals an attitude about how the car is meant to be driven. It is not just about speed; it is about confidence, discipline, and a sense of belonging to a community that values dynamic balance as well as visual impact. The way light catches the carbon weave or the subtle sheen of a UV-protected finish also contributes to the lip’s allure, making it a focal point in show settings where the vehicle’s stance and detailing are under scrutiny.

The lip’s integration with a broader body-kit strategy deserves special attention. When the lip is part of a carefully planned front-to-rear aero system, its influence extends beyond the bumper to the overall drag and downforce distribution of the car. A cohesive kit can contribute to a more stable, predictable aero profile at high speeds. This is particularly relevant for driving dynamics at track-like conditions, where small aerodynamic gains can accumulate into meaningful improvements in cornering stability and queueing of airflow along the car’s sides. The key idea here is alignment: the lip’s geometry must harmonize with the underbody’s vented channels, the side skirts, and any diffuser components to create a balanced pressure gradient. In practice, this means ensuring the lip does not disrupt intake airflow or create ground clearance issues that would negate its gains. Proper fitment and a clean mounting interface are essential, and professional installation is often worth the investment to preserve both the performance and the visual harmony of the package.

The practical path to realizing these benefits begins with honest expectations about fitment, durability, and serviceability. Model-year compatibility matters because the bumper geometry, mounting points, and grille architecture can shift across a generation. A front lip designed for a specific range of years will slide into place with fewer gaps, fewer fastener complications, and a more predictable alignment. For owners who value a direct-fit experience, the premium options that include hardware and detailed installation instructions can make the difference between a straightforward upgrade and a frustrating, time-consuming project. Even when the lip is a near-direct replacement, a careful review of mounting points, edge gaps, and screw patterns helps prevent misalignment that would otherwise create air leaks or inconsistent performance. In many cases, installation is a two-person job, requiring a careful balance of weight and alignment to preserve the intended geometry. The payoff is a front-end with a crisp stance, a predictable leading edge during rapid steering inputs, and a sense of coherence between the vehicle’s surfaces that mirrors the driver’s expectations during aggressive driving.

Owners who pursue this upgrade often begin with the tactile feel of the car after installation. They report a more confident sense of front-end grip through corners, especially during late-apex turn-in where air pressure and weight transfer collide with the tire’s traction envelope. The change in steering feel—whether it’s more immediate turn-in or a steadier response under trail-braking—tends to be subtle but cumulative. The driver begins to anticipate a more linear relationship between steering input and vehicle motion, which reduces the cognitive load during high-speed transitions. This can translate into faster lap times or, for daily drivers, a more composed and controllable vehicle at highway speeds or on winding back roads. The lip, in essence, becomes a practical ambassador of a broader performance philosophy: tune the chassis for stability first, then refine direction and balance to extract the most from the tires and suspension geometry.

For readers curious about the broader context of where this kind of upgrade sits within automotive tuning, a comprehensive body-kit overview can provide valuable background on how aero elements interact with chassis dynamics and fuel-efficiency considerations. A detailed external resource offers a broader synthesis of kit features, specifications, and industrial applications that illuminate why certain combinations work better in particular usage scenarios. If you want to explore that wider landscape, you can consult the following external reference: MotorTrend body kit overview.

In the end, the Evolution X front lip is best understood as a finely tuned piece of a larger performance narrative. It is not merely about adding a fin or a film of carbon fiber; it is about shaping an invisible but measurable flow of air that supports traction, stability, and confidence. It asks the driver to engage with the car’s aerodynamics as a living system, one that rewards precise fitment, thoughtful integration with a full aero strategy, and a disciplined approach to maintenance. For enthusiasts, this upgrade offers a tangible sense of movement—an awareness of the air’s influence on balance—that aligns with a broader desire to push the car toward its potential without sacrificing everyday usability. That dual promise—enhanced handling at speed and a sharper, more focused aesthetic—defines why the Evolution X front lip remains a central upgrade in a generation whose reputation rests on both performance and presence. The front lip is a critical piece of the puzzle that, when chosen with care and installed with precision, helps the car meet the road with renewed composure and a more defined sense of purpose. Evo X halfcut embodies the practical, integrated approach that makes this kind of aero upgrade feel coherent, credible, and enduring.

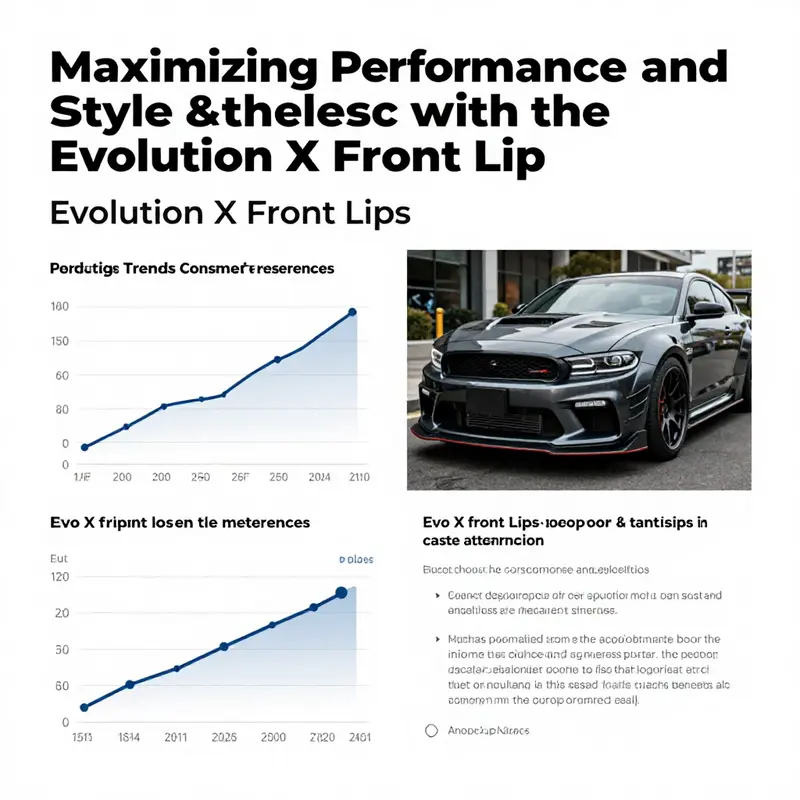

Why Buyers Choose the Evo X Front Lip: Trends, Tastes, and Practical Performance

Evolving Taste: the Front Lip as a Statement and a Tool

The market for Evolution X front lips has shifted from extremes to refinement. Enthusiasts increasingly favor parts that feel like a natural next step for the car. Buyers want upgrades that respect the Evo X silhouette. They look for pieces that add purpose and polish without undermining the car’s original design language. This preference shapes what manufacturers make, and what sellers highlight when they list parts.

Material choices reflect this shift. Polyurethane stands out for buyers seeking a clean fit and impact resistance at a reasonable price. Fiberglass remains a practical option for those who want a sturdy, lightweight upgrade while keeping costs modest. Carbon fiber commands attention from performance-focused customers and show car builders. Its visual cachet and strength-to-weight ratio are hard to match, even if the cost and repair complexity are higher.

Design language matters as much as material. The current aesthetic trend leans toward OEM+ styling. That means designers create lips that appear factory-inspired and refined. They avoid exaggerated lip lines that look bolted-on. Instead, they smooth transitions between bumper and lip, follow the angles of stock aero, and keep canards and splitters subtle. This restrained approach appeals to owners who want a more matured look. At the same time, it provides real aerodynamic gains.

Performance expectations are practical and measurable. Buyers want reduced front lift and cleaner airflow at highway and track speeds. A well-shaped lip can lower the nose slightly, improving front-end grip during high-speed cornering and reducing understeer. Small integrated canards or vortex generators are also popular. They tidy the airflow along the flanks, improving turn-in and stability. These are not flamboyant add-ons. They are subtle refinements that work in concert with the car’s existing aero philosophy.

Color and finish choices reflect larger cultural influences. Matte black has become a dominant finish in recent years. It reads as modern and aggressive without shouting for attention. The finish pairs well with factory paint and aftermarket trim. Matte surfaces also accentuate shadow and form, which is important on a car with defined lines like the Evo X. Other finishes remain popular too, but matte black’s rise mirrors broader trends in fashion and design.

Buyers are leaning toward authenticity. They want parts that sit correctly and look intentional. A front lip that seems improvised or loosely fitted can damage perceived value. That is why fitment precision, dedicated hardware, and clear instructions influence purchasing choices. Customers often choose parts from sellers who demonstrate repeatable quality and who provide full installation kits. This preference for authenticity drives demand for parts that integrate seamlessly with stock bumpers and mounting points.

The Evo X market shows distinct buyer segments. There are tuners who focus on weight savings and aerodynamic advantage. They favor carbon fiber options despite the cost. Track-driven owners emphasize function and may select reinforced designs with longer profiles. Then there are daily drivers. They want durability and impact tolerance, so polyurethane or urethane blends win out. Finally, the show-car segment values visual impact. They often pair carbon lips with other high-visibility mods but still follow the OEM+ movement to keep the overall build tasteful.

Price sensitivity varies across these segments. Budget buyers prioritize cost-effective upgrades that improve looks without expensive installation. They accept fiberglass or molded plastics for affordability. Mid-range buyers prefer the best compromise between cost and longevity. They often choose polyurethane. High-end buyers are willing to pay more for carbon fiber and bespoke finishes. For them, weight savings and exclusivity justify the investment.

Longevity and repairability factor into decisions. Some owners live in urban settings where curbs and speed bumps are everyday obstacles. Those buyers select materials that tolerate low-speed impacts and can be repaired easily. Fiberglass repairs are straightforward for experienced shops. Polyurethane absorbs shocks and snaps back better than rigid composites. Carbon fiber requires different techniques when damaged and often costs more to restore. Buyers factor these realities into their purchases.

Installation complexity also guides choices. Many lips are direct-fit and bolt onto existing points, while others demand drilling or trimming. Consumers increasingly favor parts that minimize modification. Simple bolt-on lips reduce installation hours and lower the chance of fitment errors. They also preserve resale value. More aggressive or custom pieces may need professional installation, which raises the total cost, and that affects buyer decisions.

Market channels influence perceived trust. Buyers shop across many online marketplaces and specialty retailers. Listings that offer detailed fitment notes, clear photos, and hardware lists perform better. Posts that include installation guidance and real-world photos from other owners build confidence. In many cases, a part’s perceived quality is as much about the seller’s transparency as the part itself.

A parallel trend is the demand for integrated packages. Buyers respond positively to lips that fit a wider aero system. They prefer lips designed to mate with side skirts, rear diffusers, and splitters. This integration creates a coherent visual narrative for the car. It also improves overall aerodynamic balance. Manufacturers who design cohesive kits rather than standalone pieces often capture more interest from committed builders.

Regional tastes can adjust market demand. In some markets, extreme aero remains popular and buyers pursue wide-body conversions and track-ready splitters. Elsewhere, minimalism rules and the goal is to keep the car drivable every day. Cultural touchpoints, including fashion direction and automotive media, shape these preferences. A visual trend in one region can quickly influence global tastes through social platforms and shows.

Authenticity and provenance carry weight among dedicated buyers. Parts that claim accurate reproduction of original lines or that match factory fasteners are more desirable. This preference increases the market for genuine-style bumpers and lips that maintain OEM mounting points. Sellers who can show compatibility with established bumper models, and who provide clear model-year fitment, make it easier for buyers to commit to purchases. For example, resources offering genuine front bumper fitment information are helpful to decision-making.

Environmental and practical considerations also influence buyers. Lightweight materials that improve acceleration and handling appeal to those who track their cars. But longevity and recyclability increasingly matter to some owners. UV-resistant finishes, corrosion-resistant hardware, and materials that stand up to road salts attract buyers who keep their cars for many years. This practical outlook complements the aesthetic desire and shapes long-term aftermarket strategies.

Finally, the dialogue between sellers and consumers has grown more sophisticated. Enthusiasts ask about pounds saved, expected lift reduction, and testing conditions. They compare clear performance metrics. They also value visual harmony and quality of fit. Manufacturers that publish measured gains and clear fitting guidance gain traction.

The Evo X front lip market today is nuanced and mature. It rewards subtlety, fit, and functional design. Buyers choose parts that reinforce the car’s character rather than overwrite it. Material selection, finish, and integration with other aero components determine the final choice. Whether for daily driving, show presentation, or track use, the modern buyer looks for balance between aesthetic restraint and measurable performance.

For owners exploring replacement or upgrade options, consulting trusted fitment guides can simplify choices. A helpful resource summarizes style and selection considerations for Evo X front lips, and it provides a framework for matching design, material, and intended use. See the Evo X fitment information for genuine front bumper compatibility here: CZ4A Lancer Evolution X front bumper (genuine).

For additional context on design trends and selection strategies, the guide at CarInterior provides a detailed overview of choosing the right front lip style for the Evo X. https://www.carinterior.com/evo-x-front-lip-guide

Final thoughts

In conclusion, the Evolution X front lip exemplifies how a relatively simple upgrade can yield significant benefits in both performance and aesthetics. By enhancing aerodynamics, utilizing advanced materials, and catering to current consumer trends, business owners are positioned to successfully tap into the aftermarket demand for Evolution X modifications. Offering these parts can not only elevate the driving experience of customers but also boost the profitability of businesses targeting car enthusiasts. Embracing this trend paves the way for long-term success in a competitive market.