In the competitive landscape of automotive personalization, the JDM EVO 8 rear bumper stands out as a pivotal upgrade for enthusiasts. This specialized aftermarket part not only replicates the sleek styling of Japanese domestic models but also enhances the performance and functionality of the Mitsubishi EVO 8. As businesses in the automotive sector seek to meet the demands of discerning customers, understanding the design, materials, installation, performance benefits, and market trends surrounding JDM EVO 8 rear bumpers becomes vital. This exploration will provide valuable insights for business owners looking to tap into this lucrative market.

Rear-End Precision: How the JDM Evo 8 Rear Bumper Defines Aero, Aesthetics, and Authenticity

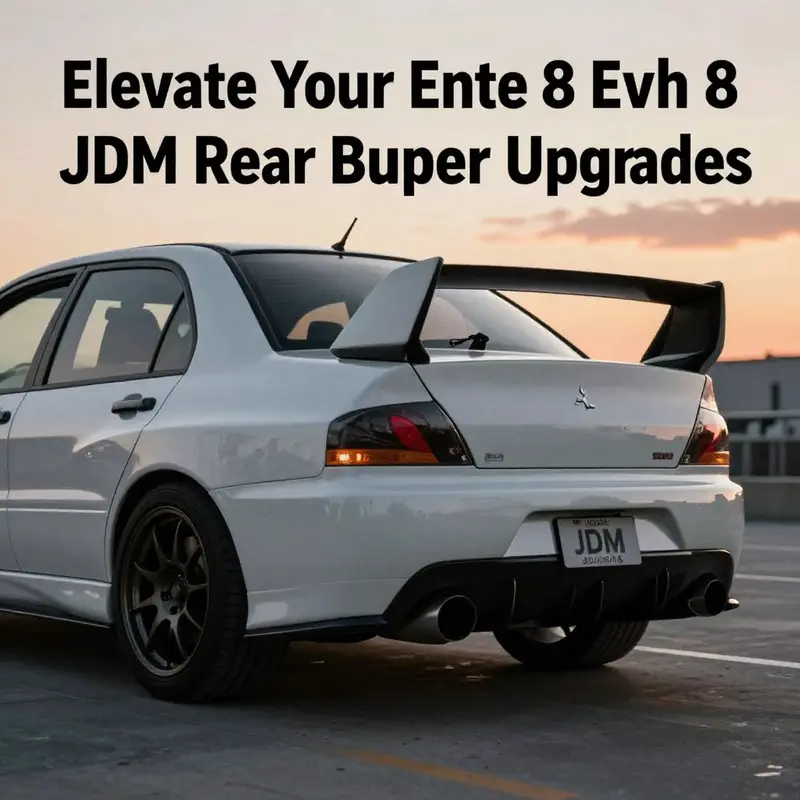

The rear end of the Lancer Evolution VIII carries more than a protective shell. It is a deliberate statement about performance, balance, and the care that engineers and designers apply to every centimeter of a car meant to sprint from street to track. The JDM rear bumper, in this sense, functions as both a visual anchor and a functional component. It embodies the Japanese market’s emphasis on understated efficiency, a philosophy that translates into a lower silhouette, tighter lines, and an integrated approach to aerodynamics. The result is a rear skin that does more than close the trunk opening; it helps define the car’s stance, its airflow behavior, and its overall impression of purpose. In the broader ecosystem of Evo 8 styling, this bumper stands out for how it preserves the car’s fundamental character while sharpening the edge that enthusiasts chase when they push their machines toward high-speed stability and precise handling. It is a reminder that in performance culture, the rear end is not merely the finish line of the body but a crucial conduit of physics and perception alike.

From the outset, the JDM approach to the Evo 8 rear is defined by contrast with more common US market designs. The bumper sits lower, a deliberate choice that reduces drag and creates a sleeker profile when the vehicle is viewed from behind or when the car is on the move. This lower profile is not about sacrificing protection or practicality; it is about refining the car’s postural language. The eye naturally follows the flush transitions where rear panels meet the bumper, and those transitions matter because they influence how the air streams around the rear end. A cleaner, more cohesive silhouette translates into reduced vortex formation and a more controlled wake. That control is the essence of high-speed stability, and it is the principle that drives the JDM rear bumper’s design language. Even at a casual glance, the bumper communicates performance intent—without shouting—from the street to the race track.

Beyond the silhouette, the bumper’s design integrates a diffuser system that is as much about airflow as it is about aesthetics. The lower portion of the unit often incorporates a carbon fiber or FRP diffuser beneath the bumper, a functional element that adds visual weight and deepens the car’s track-ready persona. This diffuser is not merely decorative; it channels air away from the undercarriage, mitigating lift as speed rises and guiding the flow toward areas where it can do the most good for downforce and stability. The effect is subtle in everyday driving, yet it becomes measurable on a test track or a spirited canyon run. When air is deliberately managed under the car, it reduces suction and helps preserve the Evo 8’s predictable balance. The diffuser’s surface finish—whether a polished carbon weave or a glossy FRP look—conveys the same message: performance is visible in the details as much as it is felt in the drive.

The aesthetic language of the JDM bumper is equally deliberate. It embraces a functional aesthetic that pairs clean geometry with a sense of purpose. The finish often features a 3K twill carbon weave, a detail that signals craftsmanship and performance intent. The high-gloss finish on the carbon weave catches light to reveal a depth that static photographs can scarcely capture. This level of finish communicates more than style; it signals a commitment to materials and methods that align with the Evo’s performance character. Even the choice of substrate—urethane, for instance, as a practical balance of rigidity and flexibility—reflects a pragmatic approach to aftermarket parts. Polyurethane offers a precise fit and a resilience that helps the bumper withstand daily use and occasional impact while preserving the crisp lines that define the rear’s visual footprint.

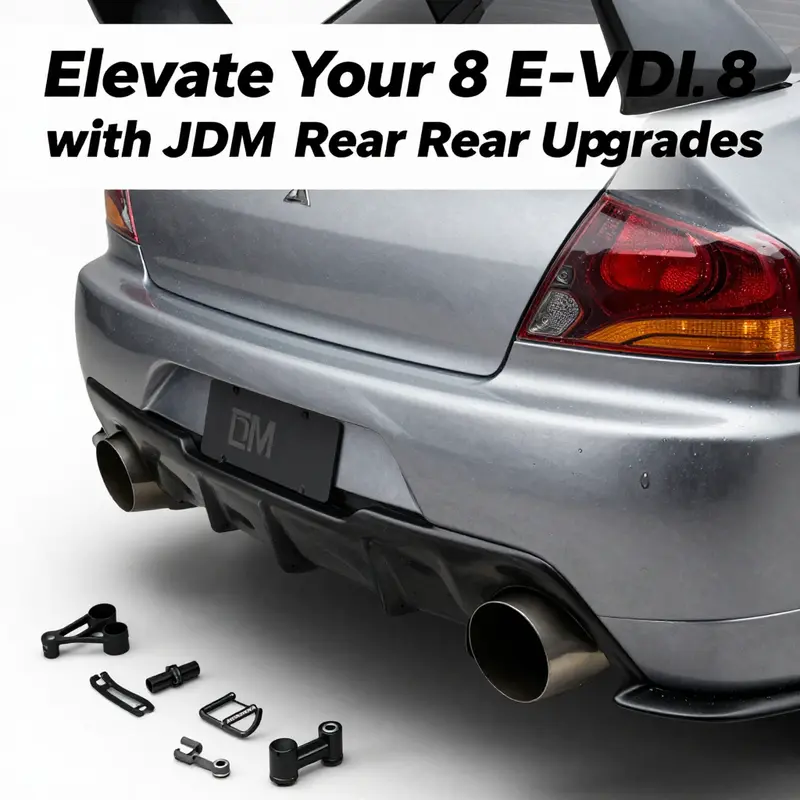

Material integration is where form meets function in a meaningful way. The bumper is designed to integrate with mounting points and body lines that are part of the vehicle’s original architecture. The goal is seamless fitment, with gaps tight enough to look factory while permitting easy installation. This is where the bumper becomes a functional upgrade rather than a cosmetic one. The hardware, screws, and clips that come with a complete unit are chosen to mirror OEM specifications and mounting philosophy, reducing the risk of misalignment or rattles after installation. In practice, the process is straightforward: remove the existing cover, align the new piece with the factory connectors, and secure it with the included hardware. The result is a rear assembly that feels native to the car, as if the factory team had always designed it that way.

Authenticity carries its own weight in the conversation about the JDM Evo 8 rear bumper. Enthusiasts often pursue a look that remains faithful to the factory’s intentions, even as they push toward capacity for speed and competition readiness. An authentic upgrade path emphasizes continuity with the car’s lines and the story of its origin. The JDM approach embodies this through its restrained, purposeful styling—eschewing superfluous adornments in favor of a coherent visual language that honors the Evo’s track spirit. A crucial part of this authenticity is the option to pair the bumper with a carbon diffuser finished in a deep, premium weave. The carbon detail is not merely cosmetic; it adds a tangible sense of weight and performance potential, a reminder that every surface and contour has a functional rationale.

For those who want an upgrade that mirrors factory intent, there is an OEM-style option that aligns with the original factory design while offering the benefits of modern aftermarket engineering. This path preserves the Evo 8’s signature look and feel, maintaining precise fitment and alignment with the body’s lines. The emphasis is on a seamless integration that respects the car’s design heritage while delivering the improved aesthetics and aerodynamic considerations that the aftermarket environment promises. When approached with care, this kind of authentic upgrade reinforces the Evo’s identity as a performance-focused compact sedan with a purpose-built rear end that communicates capability, confidence, and a keen eye for detail. If you’re pursuing this route, the emphasis should be on fitment, finish, and the way the bumper’s lines harmonize with the taillights, the rear deck, and the car’s overall stance. The result is a rear end that feels neither borrowed nor forced, but fully integrated and ready for the next drive, lawn-perfect, track-ready, and road-approved all at once.

As the narrative of the Evo 8 continues to unfold in garages, magazines, and online forums, the rear bumper remains a focal point for discussions about authenticity and performance. The JDM version is more than a component; it’s a philosophy translated into a practical piece of engineering. It honors the car’s heritage while acknowledging modern expectations for aerodynamics, fit, and finish. The lower profile, the diffuser, and the premium carbon finish all contribute to a cohesive story about how a small change in the rear end can influence the entire perception of a vehicle. In that sense, the JDM Evo 8 rear bumper offers more than protection for the tail; it offers a channel through which the Evo’s track-bred character can speak clearly, with restraint and intent.

For readers who want to explore a precise, factory-aligned option, the OEM JDM Evo 8 rear bumper is described and showcased through detailed listings that emphasize fitment and authenticity. This path invites the owner to maintain the car’s heritage while embracing the improvements that come with updated materials and engineering. The result is a rear end that looks and behaves as if it were designed in the same studio as the rest of the Evo’s celebrated arch and chassis. It is a reminder that the rear bumper, though often overlooked in casual conversations about performance, is a key piece of the Evos identity, a subtle, powerful tool that helps the car perform as intended and present itself with the quiet authority that defines JDM engineering at its best. If you are curious to see how the OEM-style option is positioned within the Evo ecosystem, you can explore more through this resource: OEM JDM Evo 8 rear bumper. The blend of authentic geometry, careful material choice, and a focus on airflow makes the rear bumper a meaningful component in the Evo 8’s ongoing story of performance and purity.

External resource: https://www.aliexpress.com/item/1005005287969799.html

Fiberglass Foundations and Carbon Accents: How JDM EVO 8 Rear Bumpers Are Built

Material choices shape appearance, fit, and function for a JDM-style EVO 8 rear bumper. The JDM rear bumper for the Mitsubishi Lancer Evolution VIII and IX usually starts with a Fiber Reinforced Plastic (FRP) foundation. FRP, commonly called fiberglass, combines glass fibers and resin. This creates a stiff, lightweight shell that captures the original equipment manufacturer (OEM) shapes. Manufacturers prefer FRP for these bumpers because it reproduces complex body lines reliably and keeps production costs reasonable while delivering a precise fit.

FRP begins life in a mold that mirrors the OEM panel. Layers of chopped or woven glass fiber are laid into the mold and saturated with polyester or vinylester resin. A smooth gelcoat layer often comes first to ensure a glossy surface and protect the fibers. Once cured, the assembly yields a rigid panel true to the car’s contours and mounting points. That precision is why FRP panels align well with bumper brackets, trunk edges, and adjacent panels on 2003–2007 EVO models. The result is a replacement that looks like it belongs on the car rather than an add-on.

Although FRP forms the structural base, the visual and aerodynamic cues often come from additional materials. Many JDM-style bumpers incorporate 3K twill carbon fiber weaves, usually applied as a visible diffuser or accent. In most cases, a carbon fiber piece is bonded over the FRP base or supplied as a separate insert. The glossy carbon finish contrast gives the rear a high-end, purposeful look. Beyond aesthetics, a properly designed carbon diffuser affects air movement. It smooths wake turbulence and offers minor aerodynamic benefits at speed. That said, these parts rarely alter high-speed balance drastically. They are primarily visual upgrades with modest functional payoff when matched to the rest of a tuned car.

Manufacturing techniques vary by supplier. Basic FRP molds yield quick, cost-effective parts. Higher-end or limited-run bumpers use vacuum bagging, hand layup of woven fabrics, or even resin infusion to reduce voids and improve fiber-to-resin ratios. For carbon pieces, manufacturers often mold a woven carbon skin, then bond it to the FRP substrate. This hybrid approach trades off the expense of full carbon construction with the aesthetic and stiffness benefits of a carbon finish. The combination keeps the part affordable while retaining strength for normal driving and minor impacts.

The material balance also affects repairability and durability. FRP offers good longevity but is more brittle than polyurethane. Under a hard impact, FRP panels are likelier to crack or fracture rather than flex. The silver lining is that fiberglass repairs are straightforward. Scuffs, cracks, and holes can be filled with new resin and fiber, sanded smooth, and repainted. Carbon fiber veneers, when bonded to FRP, can complicate repairs slightly but remain serviceable. Small chips in a carbon finish usually require touch-up resin and clearcoat. UV exposure can yellow or craze polyester resins, so a quality clearcoat and proper painting are essential for long-term visual resilience.

Finish options for JDM bumpers range from raw gelcoat to fully painted, primed units. New parts often arrive primed and ready for paint. This saves time but still usually requires sanding and proper adhesion steps before final color application. A gelcoat finish can be polished and left as-is for a rapid install, though many owners opt for a factory-matched paint job for the best visual integration. When a carbon diffuser is involved, a clearcoat is critical. The clear preserves the weave’s depth and prevents environmental degradation.

Fitment remains a major selling point of quality JDM bumpers. Because FRP molds are made to OEM profiles, the bumper matches the EVO’s body lines and mounting points closely. That reduces trimming or modification during installation. Still, buyers should confirm compatibility with their specific year and model. Some JDM bumpers suit both EVO VIII and IX with minor adjustments. Others are exclusive to a single model. If the car has sensors, tow hooks, or unique exhaust tips, those areas should be checked against the bumper’s cutouts.

Weight and structural considerations matter too. FRP with carbon accents tends to be lighter than stamped steel alternatives and similar in weight to other aftermarket shells. The bumper assembly is not a major crash structure, but it does help manage minor impacts and shields underlying components. For racing or track-focused builds, some purists prefer swapping to lightweight full-carbon units. Those are dramatically more expensive and complex to repair. The FRP-plus-carbon approach offers a practical compromise for street-driven performance cars.

Installation is usually straightforward for someone with moderate mechanical skill. Mounting points often match OEM hardware, making bolt-on installs possible without specialized tools. However, paint, alignment, and hardware gaps sometimes require professional attention for a flawless finish. Many kits ship with the necessary screws and clips to simplify installation. For anyone unsure about fitment or finish, professional installation ensures correct alignment and paint blending across adjacent panels.

Choosing a JDM rear bumper involves balancing several factors. FRP foundations provide shape and reasonable durability. Carbon accents add visual flair and some aerodynamic refinement. Finish quality, mold accuracy, and supplier reputation determine long-term satisfaction more than the choice between FRP and carbon alone. Confirm compatibility with the 2003–2007 EVO VIII and IX platforms, and inspect sample photos for fit and finish before purchasing. For those seeking an OEM-style replacement with authentic JDM lines, consider a verified OEM-fit option like the 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM for reference.

Finally, maintenance is simple. Wash gently, avoid harsh chemicals, and keep the clearcoat in good condition. Address chips promptly to prevent water intrusion into the fibers. Small carrier or parking bumps are unlikely to ruin an FRP bumper. Proper care preserves both the craftsmanship and the aggressive JDM aesthetic that makes the EVO 8 rear end stand out.

Materials determine how a bumper looks, how it performs, and how it ages. FRP delivers form and fit, and carbon accents add the finishing touch.

Fitting the JDM EVO 8 Rear Bumper: Practical Installation Strategies and Common Fitment Pitfalls

Installation Essentials and Fitment Strategies

Installing a JDM-style rear bumper on a Lancer Evolution VIII demands attention to fit, structure, and function. The replacement bumper is usually made from flexible urethane and engineered to align with the car’s OEM mounting points. Even so, small differences between markets, prior repairs, or additional bodywork can complicate a straightforward swap. Treat the process like a system upgrade rather than a cosmetic swap. Plan, inspect, and test each step.

Begin with a careful pre-install inspection of the vehicle’s rear structure. Confirm the factory reinforcement bar is intact and straight. This bar absorbs impact and secures the bumper’s load paths. If it is bent, cracked, or missing, installation should pause until that component is repaired or replaced. A cosmetically perfect bumper mounted to a compromised reinforcement bar delivers neither protection nor a reliable fit. Similarly, examine mounting tabs, trunk alignment, and adjacent panels for dents, rot, or aftermarket alterations. Fixing these issues first reduces the need for trial-and-error trimming later.

When you unbox the urethane bumper, lay out the supplied hardware. Most kits include screws, clips, and foam pads sized for OEM points. Confirm the included pieces match the vehicle’s attachment style. Many bumpers come as a complete cover ready to bolt on, but they still rely on correct hardware and proper clip engagement. Take time to test-fit the bumper before painting. Mocking up the bumper exposes alignment issues while components remain unpainted and adjustable. It also protects a finished paint job from accidental scratches.

Alignment is more than visual. A bumper that follows body lines helps maintain intended airflow around the rear of the car. Small gaps or mismatched edges can create odd aerodynamic effects at speed. Use consistent panel gaps as your guide, adjusting bolts gradually and symmetrically. Lowered cars and those with side skirts or widebody kits usually require extra attention. Aftermarket skirts can push the bumper outward or change mounting angles. In these cases, measure clearances and consider using short spacers at strategic mounting points to preserve both the look and functional spacing.

Modifications are common, but plan them carefully. Cutting for larger exhausts, adding diffuser sections, or integrating custom reflectors all require precise, conservative trimming. Mark cut lines with removable guides and cut incrementally. Test-fit cutouts frequently. For exhaust tips, ensure heat tolerance and clearance for suspension travel. If parking sensors are present, make accurate holes or relocations to maintain sensor performance. Incorrect sensor placement can cause false alarms or failure to detect obstacles.

Ground clearance and bumper geometry must be considered together. Many owners lower their Evo, which decreases clearance at the rear valance. Check typical driveways, ramps, and speed bumps before finalizing mounting height. If the bumper rides too low, it risks scraping and rapid wear. Keep an eye on the diffuser profile. Aggressive diffusers look correct on JDM designs, but ground clearance losses can negate the aesthetic and introduce damage risk. Where necessary, test different mounting heights until the design and clearance harmonize.

Integration of reflectors, license plate mounts, and bulb housings needs thoughtful placement. Some JDM bumpers include molded cutouts. If yours does not, create these openings using templates. Maintain proper size for reflectors to comply with local regulations. For license plate mounting, ensure the bracket is robust and flexible enough to absorb minor impacts without stressing mounting points. Wiring for reverse lights or sensors should be routed to avoid heat sources and moving parts. Use protective conduit and secure ties to keep runs neat and strain-free.

Fitment issues often stem from subtle deformations in the bumper or vehicle. Heat-forming urethane in a controlled manner can relieve tension and improve alignment. Use low heat and a consistent motion. Avoid overheating, which can damage coatings or change structural properties. If heat-forming is out of your skill set, a professional installer can perform the tweak safely. Speaking of professionals, consider professional installation when other systems are tied into the bumper. If parking sensors, camera modules, or complex wiring harnesses are involved, a trained technician reduces risk and ensures components work as intended.

Paint matching is deceptively challenging. Panel gloss, texture, and color shift vary between panels. A bumper painted separately may look slightly different than surrounding panels unless matched by a skilled shop. Request that the shop spray surrounding panels if necessary to achieve a seamless finish. Ask for a visual dry-cure before reinstallation to identify any color mismatches under natural light. Small differences are easier to fix before the bumper is bolted on.

After installation, perform a checklist-driven functional verification. Confirm that trunk lid closes evenly. Check tail light alignment and operation. Test the reverse lights and parking sensors across parking scenarios. Drive the car on a variety of surfaces and speeds to listen for vibrations or odd rattles. Inspect fasteners after an initial short drive, then again after 100 miles. Urethane flexibility can cause settling, which may require minor fastener retorques.

Legal compliance matters. Some countries and regions require specific reflector types, minimum ground clearance, or valid cutouts for lighting. Failing to meet rules can result in failed inspections or fines. If you intend to use the car on public roads, verify that your bumper modifications meet local regulations before painting or final assembly.

Finally, document the installation. Take photos of mounting points, cutouts, and wiring routes. Save part numbers and any alterations. This record helps with future maintenance and supports resale transparency. If you installed a JDM-style bumper that closely imitates Japanese-market design, note any additional components used to achieve that look, such as supplemental diffusers or trim pieces. Clear records protect you and future owners.

If you want to explore a ready-made option that matches Evo VIII and IX rear profiles, consider viewing a detailed listing for a compatible JDM rear bumper product: JDM rear bumper for Mitsubishi EVO VIII/IX (white).

For more on bumper design standards and performance expectations, consult the industry analysis at the external resource below for guidance on reinforcement, material properties, and testing protocols:

https://www.toyotapartsjapan.com/industry-bumper-analysis

Breathing New Balance: The Performance Case for a JDM Evo 8 Rear Bumper

At the intersection of form and function, a rear bumper on a high-performance sedan is more than a cosmetic touch; it is an active participant in aerodynamics, cooling, and chassis discipline. A JDM Evo 8 rear bumper is not merely an aesthetic swap but a track-informed upgrade that aligns with a broader performance strategy. The result is a balanced package where aero, rigidity, and exhaust routing work in concert rather than at cross purposes. When the chassis is already tuned for precision, the bumper helps preserve that intent by shaping airflow, maintaining geometry, and supporting heat management under load.

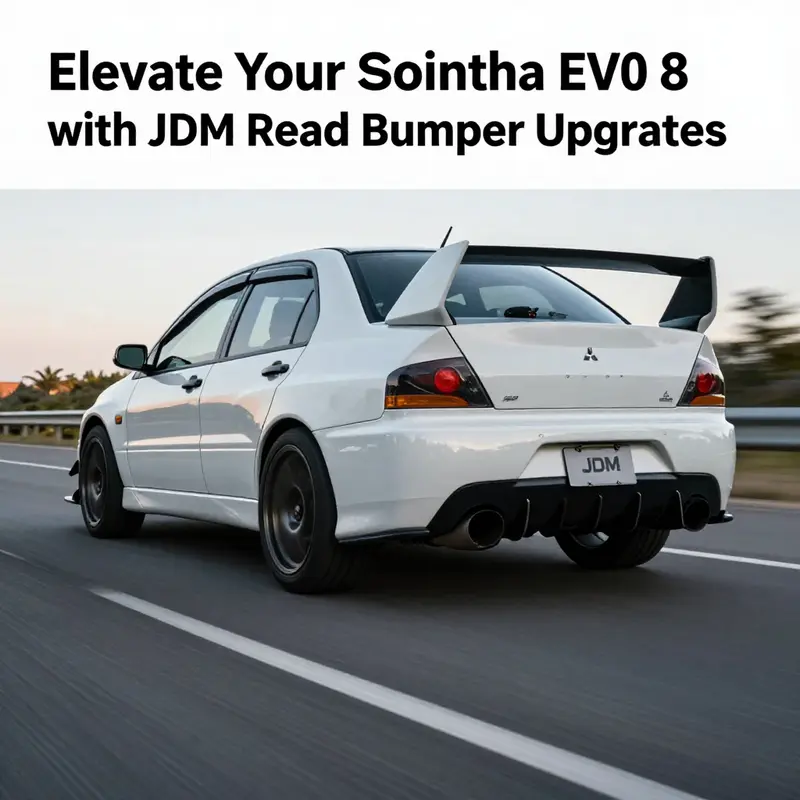

Aerodynamics: the Evo 8 rear bumper is often sculpted to manage the wake, reduce turbulent eddies, and direct air toward diffuser channels. Integrated steps and vents can guide underbody flow, helping the car settle into fast corners with minimal rear-end lift. The improvement is not abstract: it translates into steadier corner entry, more consistent mid-corner speed, and a more predictable exit as the tires load and unload on the curve. For drivers who track their cars, that stability is the difference between a confident apex and a twitchy moment at the exit.

Materials and construction: OEM-inspired JDM designs emphasize rigidity and long-term alignment. A robust shell, reinforced internal supports, and carefully selected plastics resist deformation during high-g cornering and repeated heat cycles. The goal is not to add mass for mass’s sake, but to lock in geometry so the aero cues remain effective over many sessions on the racetrack and many miles on the street. This durability supports a consistent diffuser interface, unchanged exhaust clearances, and reliable fitment that the rest of the performance suite can depend on.

Exhaust routing and heat management: rear bumper cutouts that accommodate dual exhausts can improve heat dispersion and spacing from sensitive components. Proper geometry helps minimize heat soak in the diffuser area and underbody panels, contributing to calmer engine response during sustained high-rpm use. While exhaust tuning is a system-level concern, a well-integrated bumper design ensures the pipe path and thermal channels stay clear of interference, preserving both sound quality and performance potential.

Fitment and installation: a direct-fit JDM rear bumper designed for Evo 8 should align with factory mounting points and gaps, making installation smoother and maintaining the intended look and stance. When the bumper respects body lines and diffuser geometry, the result is a clean transition from bumper to undertray and exhaust tips. For enthusiasts, that translates into repeatable geometry after removal and reinstallation and predictable behavior during track days.

Heritage and intent: the JDM rear bumper carries a motorsport lineage that communicates a clear purpose—precision and track readiness. On the street, it signals a driver who values balanced aero and chassis discipline as part of the overall vehicle character, not merely a visual upgrade. This philosophy helps the car feel more planted at speed and more confident through transitions, reinforcing the alignment between the bodywork and the suspension, tires, and intake/exhaust strategies.

In practical terms, a complete performance path considers bumper choice alongside a diffuser, a tuned exhaust path, and compatible underbody aero. A cohesive setup keeps airflow attached, preserves stable pitch through corners, and supports consistent corner speeds. The payoff is a more predictable car that communicates intent through every line and channel of the rear end.

Riding the Market Wave: Pricing, Perception, and the JDM Evo 8 Rear Bumper Renaissance

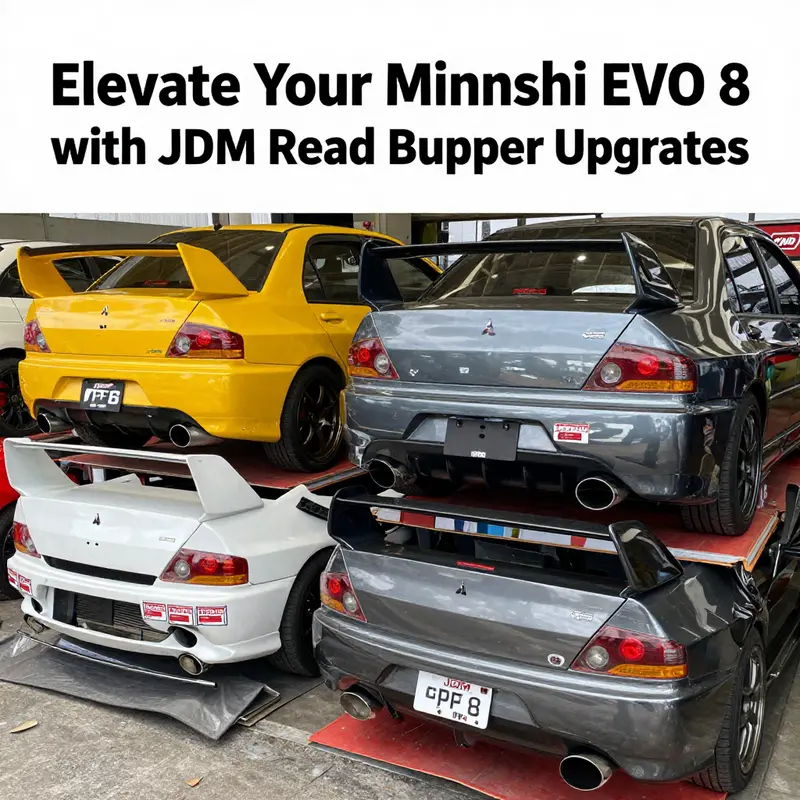

The rear end of a Mitsubishi Lancer Evolution VIII carries more than a hint of Japanese tuning heritage. For many enthusiasts, the JDM rear bumper is not merely a cosmetic update but a restoration of the car’s original silhouette and aerodynamic intent. As owners chase authenticity, the market for JDM EVO 8 rear bumper parts has entered a dynamic phase. By early 2026, a notable uptick in demand signaled a broader shift: more drivers are choosing to preserve or upgrade the styling cues that define the car’s identity, even as regulations quietly push performance toward efficiency and reliability. The result is a diversified marketplace where OEM-grade parts and high-quality replicas coexist, each appealing to different priorities—fit, finish, weight, and the enduring appeal of a line that many feel best represents the Evo’s era.

Material science sits at the heart of this evolving landscape. The rear bumper covers designed for the Evo VIII and IX are typically manufactured from polyurethane or glass-fiber-reinforced plastic (FRP). Polyurethane offers a durable, slightly more forgiving structure that can absorb minor impacts while maintaining precise dimensions, a practical feature for daily driving and spirited track days alike. FRP, on the other hand, often appeals to purists who prize stiffness and a weight-conscious profile that aligns with OEM aesthetics. In both cases, the goal is to replicate the original Japanese-market form—an aggressive stance with integrated design elements such as diffusers, larger air intakes, and a profile that emphasizes a balanced, purpose-built look. For those seeking a true JDM appearance, many of these rear bumper kits include a high-gloss carbon diffuser or a carbon-fiber texture that catches light and attention in a way that mirrors race-inspired engineering. The combination of a clean exterior line and a functional diffuser suggests a design philosophy where form and function are inseparable, a principle that resonates with Evo owners who treat their cars as both collectible and capable machines.

Pricing data from early 2026 paints a clear picture of who is buying and why. The market for new OEM-spec rear bumpers and high-quality aftermarket reproductions grew by roughly 22 percent year over year. That uptick is driven partly by increased awareness of emission standards globally, which nudges drivers toward preserving the vehicle’s original character rather than replacing it with unrelated modern styling cues. In practical terms, buyers are choosing parts that align with the car’s original geometry and airflow paths, ensuring that the dynamics of the rear end—trailing wake, diffuser efficiency, and overall balance—remain intact as powertrains and exhaust notes evolve. Within this broader trend, the Evo 8/9-specific rear bumper kit that features a carbon diffuser has become especially popular. The visual impact is immediate, with the 3K satin carbon texture offering a refined sheen that communicates both performance intent and a commitment to authentic styling.

From a price perspective, the landscape is surprisingly accessible for most committed enthusiasts. On mainstream e-commerce platforms, the price range for a complete rear bumper assembly with diffuser generally falls between approximately $263.46 and $375.30. This spread reflects a spectrum of build quality, from well-executed OEM-replica units to more budget-conscious options that still promise a precise fit. A typical listing with a carbon-fiber texture on the diffuser may land on the lower end at around $263.46, while a more premium, fully finished kit with enhanced gloss and tighter tolerances could approach the $375.30 mark. It’s common for vendors to offer promotions such as modest new-customer discounts, for example around $10 off, and to pair free shipping or easy return policies to sweeten the deal. These incentives are more than cosmetic; they reduce the perceived risk of investing in a part that will directly affect the car’s look and performance.

The pricing narrative, however, is not simply a matter of sticker price. Buyers weigh several practical considerations that influence value. First is compatibility: the Evo VIII and IX rear bumper is engineered to align with the car’s mounting points, body lines, and the rear hatch interplay. A bumper that promises a precise fit but arrives with misaligned mounting holes, or a diffuser that sits high or low, undermines the perceived value and increases installation time. Second is material integrity. While polyurethane can offer resilience and resilience-to-weight benefits, cheaper imitations may compromise impact resistance and long-term rigidity. Third is complete hardware and hardware compatibility. A full kit often includes screws, clips, and sometimes brackets, reducing the likelihood of scavenging parts from other sources. When these elements are present and well-documented, the kit becomes a straightforward, installable upgrade rather than a project requiring improvisation.

A practical note for buyers who are testing the market: while some third-party suppliers may present aggressive prices, those savings can be a double-edged sword. A lower upfront cost might mask hidden expenses such as shipping, longer wait times for international fulfillment, or diminished fitment when local inspection reveals tiny misalignments. In contrast, OEM-grade or certified-replica rear bumpers tend to offer tighter tolerances and more predictable installation experiences. For Evo 8/9 enthusiasts who see their car as a living project, the choice often comes down to whether the perceived savings in price translate into tangible gains in reliability and ease of installation. The balance between price and peace of mind becomes a deciding factor, especially for those who intend to run the car hard at events, or who want to keep the exterior looking as pristine as possible in daily driving conditions.

For readers curious about the concrete options in the catalog, there is a concise reference point within the Evo 8/9 community: the OEM-style rear bumper listings. These entries provide a snapshot of fitment, finish, and compatibility with the Evo’s body lines. For a direct look at one such listing, you can explore the dedicated page here: 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem. The page aggregates details about mounting points, diffuser options, and the way the unit mirrors the genuine JDM contour. It’s not just about the surface look; it’s about how the bumper integrates with the vehicle’s cooling ducts, rear valance, and bumper-to-quarter-panel seams. A comprehensive product presentation on such a listing helps buyers calibrate expectations, compare the embedded diffuser’s profile with the stock design, and assess whether the overall silhouette aligns with the car’s year-specific identity.

The narrative of pricing also intersects with supply dynamics and regional distribution. In a market that stretches across continents, the price bands reflect not only the material and finish but also logistics, duties, and import costs. The Evo community tends to converge around a shared understanding of what constitutes “authentic” shape and how that authenticity translates into value on the street or on the track. In regions with robust aftermarket ecosystems, the availability of multiple reputable suppliers means buyers can negotiate not just price, but delivery speed and post-purchase support. In less saturated markets, a premium may be charged for parts that meet exact OEM tolerances, simply because supply is more constrained. In both cases, buyers frequently rely on seller assurances about fitment and compatibility—assurances that are all the more persuasive when paired with a warranty or a clearly stated return policy. The presence of inclusive installation hardware in the kit adds a practical layer of value, ensuring that the upgrade proceeds without the need for a separate shopping trip to source clips or fasteners.

The broader takeaway from the 2026 market snapshot is that price is not the sole determinant of value. Rather, buyers are weighing fitment reliability, material performance, and the authenticity of the aesthetic against the risks of counterfeit or subpar components. The Evo 8 rear bumper, with its integrated diffuser and signature JDM lines, remains a kind of tangible badge—one that signals both adherence to a legacy design and a willingness to invest in a precise, well-executed upgrade. This is especially true for owners who view their vehicle as a dynamic platform rather than a static display. For them, the bumper is part of a holistic approach to air management, which includes how the diffuser interacts with the underbody, how airflow is guided around the rear fenders, and how the entire package harmonizes with a tuned exhaust or a revised intercooler setup. The pricing range supports this ethos by offering choices that align with different maintenance philosophies, time commitments, and budgets, while the market’s upward trend suggests that the JDM Evo 8 rear bumper will continue to carry cultural and technical weight among enthusiasts.

External reference: https://www.aliexpress.com/item/1005005734744112.html

Final thoughts

The JDM EVO 8 rear bumper serves as more than just an aesthetic upgrade; it is a strategic enhancement for those in the automotive market. By understanding its design, construction, installation, and performance benefits, business owners can capitalize on the growing interest in these aftermarket parts. With evolving market trends and clear pricing strategies, staying informed can foster a successful approach in catering to customers seeking to enhance their Mitsubishi EVO 8. This knowledge not only informs better purchasing decisions but also optimizes offerings in this niche segment.