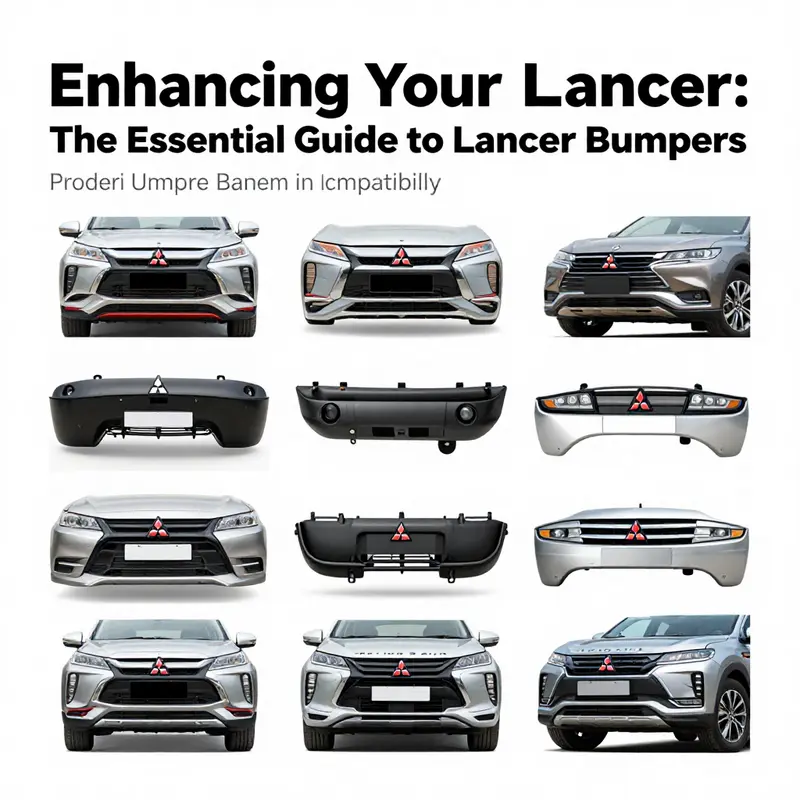

The Lancer bumper serves as a vital component in both protection and aesthetic enhancement for Mitsubishi Lancer vehicles. It plays a crucial role in safeguarding the front-end of your car, ensuring durability while showcasing a driver’s unique style. This comprehensive guide delves into the various types of Lancer bumpers available, their materials and performance, suitable application scenarios, essential usage rights, and an analysis of current market trends. By understanding each of these aspects, business owners can make informed decisions regarding product offerings and customer needs.

null

null

Material Matters: The Lancer Front Bumper as a Lever of Performance, Protection, and Purpose

The front bumper of a Mitsubishi Lancer is more than a piece of plastic cobbled to the frame. It is the first line of defense against the road, the first impression of its stance, and a subtle engineer of how the car moves through air, heat, and impact. When you look past the surface, you encounter a material conversation that determines weight, rigidity, energy management in a collision, and even how the car breathes at speed. That is where the science of bumper materials—ABS plastics, fiberglass, and polyurethane—meets the art of design. Each material carries a different promise about how the bumper behaves under everyday use, under racing demands, and under the long arc of time when a car owner contemplates upgrades or restorations. It is a conversation that begins with a practical concern—will the bumper survive a parking lot scrape?—and ends in a broader, more consequential place: how a front end can influence fuel economy, handling, and the vitality of engine cooling as the car pursues speed with poise.

Among the materials most commonly encountered in Lancer bumpers, ABS plastic is the baseline. It represents a blend of durability and affordability that makes it a familiar choice for daily drivers. ABS is resilient against minor impacts, guards against chipping under regular use, and accepts paint and repair work with relative ease. The practical value of ABS lies in predictability: it offers a consistent balance between cost and performance, a comfort for owners who want a bumper that withstands city potholes and routine parking lot dings without demanding premium maintenance. Yet ABS has its limits. It is heavier than some alternatives, and under high heat or prolonged heat exposure it can warp or deform more readily than polyurethane. For this reason, many manufacturers favor ABS as the base material in mass-market bumpers, especially for vehicles intended to remain reliable and approachable for a broad audience.

Fiberglass, by contrast, leans toward lighter weight and focused stiffness. It is a classic choice for enthusiasts who want a performance-oriented look without paying the high price of premium composites. The advantages of fiberglass extend beyond weight savings: its rigidity can sharpen the response of the bumper under aerodynamic loads, and it often allows for more aggressive shaping that enhances downforce and air management. For track days or show-focused builds, fiberglass can deliver a compelling balance of weight reduction and bold styling. The limitations, however, are real. Fiberglass tends to be less forgiving in manufacturing tolerances, and its design flexibility is not as forgiving as polyurethane when it comes to complex curves or intricate integration with headlights and fenders. For owners pursuing a race-inspired look, fiberglass is a compelling option, but it calls for careful fitment and a readiness to maintain and repair rather than a hands-off, long-term solution.

Polyurethane sits at a different end of the spectrum. It is the material most prized by builders who emphasize resilience, long-term durability, and a confident resistance to damage that might otherwise crack or fracture under impact. Polyurethane bumpers tend to be stiffer than ABS while still absorbing energy effectively, which translates into better protection for the radiator, engine bay components, and the lighting assembly during everyday mishaps or low-speed collisions. The rigidity of polyurethane does not compromise its ability to flex just enough to avoid brittle failures, making it a preferred choice for people who want a strong, high-performance front end that still maintains practical street usability. The higher initial cost is offset by longer service life and a lower likelihood of frequent repairs after minor encounters. In performance-focused builds—where air intake efficiency, heat management, and sensor alignment matter—polyurethane often proves its worth by delivering consistent fitment and robust structural integrity.

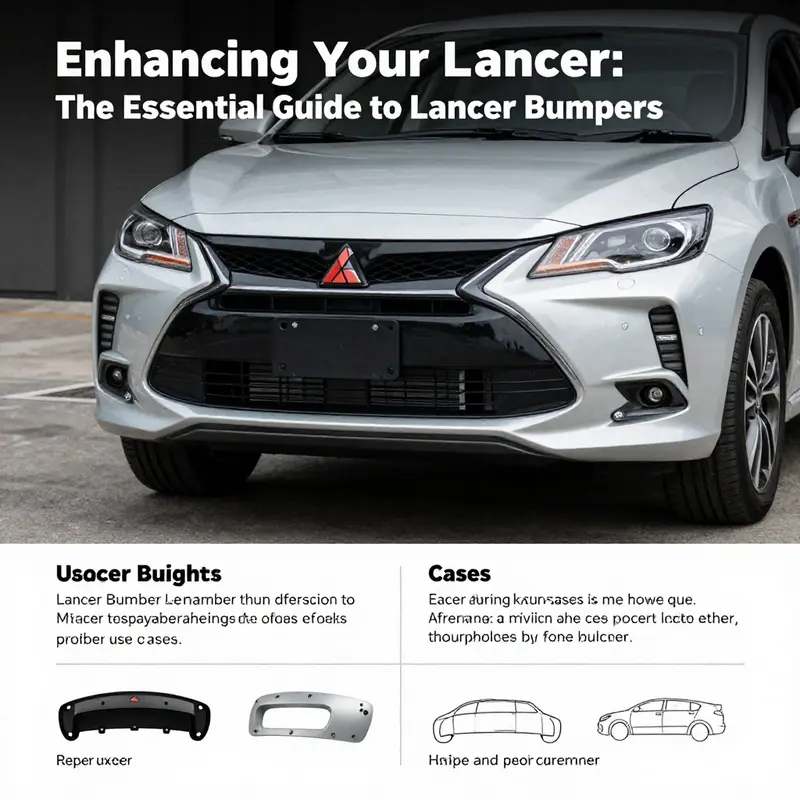

The study of these materials reveals a simple but powerful principle: the bumper is a system, not a shell. Its job is not only to look aggressive or refined; it must also work with the car’s aerodynamics, sensors (where present), and the way the chassis carries weight at the front corners. The shape of the bumper, the size of its vents, and the quality of its mounting points all influence how air flows around the front wheel wells and into the intercooler or radiator. Aerodynamic optimization can cut drag and improve stability at high speeds, especially when the bumper integrates carefully designed ducts and vents that direct airflow toward cooling channels. In a Lancer, where the aesthetic may favor a bold, race-inspired face, the material choice becomes a practical decision about durability and performance as much as a stylistic one. This is why the industry frequently frames bumper selection as a compromise between weight, rigidity, and cost, with the buyer’s priorities mapping directly onto the material’s intrinsic strengths.

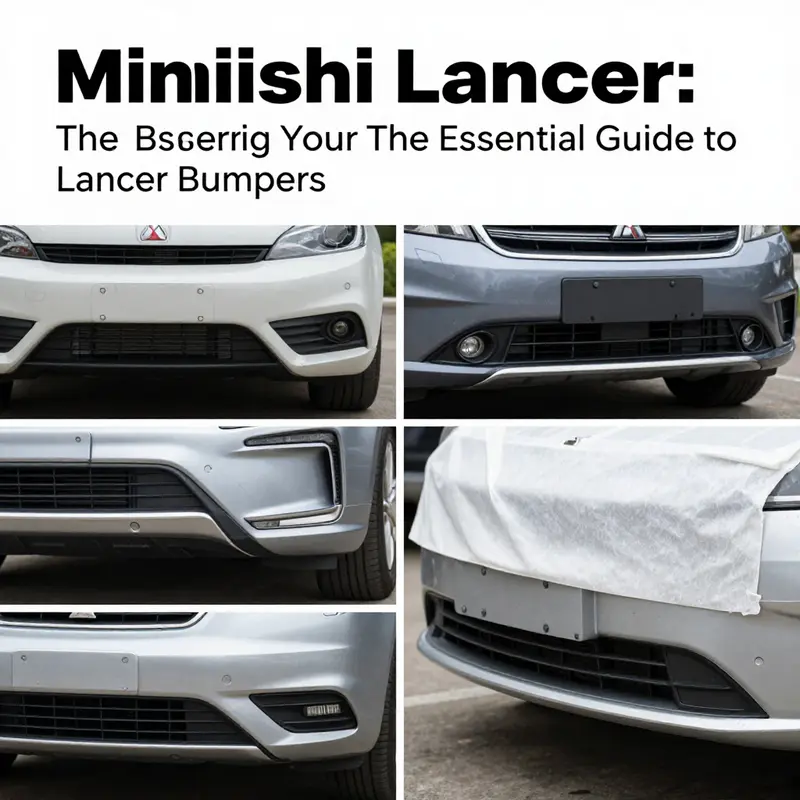

Beyond material properties, compatibility and installation approach shape the real-world performance story. Some bumpers are designed as universal-fit pieces, meant to accommodate a wide range of Lancer variants with minimal modification. Others are tailored for specific years or trims, offering a bolt-on experience that targets exact mounting points, grille alignment, and headlight interfaces. For a daily driver that wants easy maintenance and straightforward upgrades, a universal-fit design can provide a practical path to a refreshed appearance without extensive bodywork. For a enthusiast seeking a tight, factory-like fit that preserves precise alignment and sensor geometry, a year-specific, bolt-on bumper can minimize fidgeting and misalignment. The choice between these routes affects not only installation time but also the long-term durability of the fit. A well-matched bumper supports consistent panel gaps, reliable headlight sealing, and predictable lighting performance—critical factors when handling the road at night or in challenging weather.

The appeal of a modern Lancer bumper often lies in its ability to deliver a look that communicates intent while keeping the car’s function intact. For owners chasing a retro vibe, a bumper that echoes a classic silhouette—such as a 1992-era face—offers a nostalgic nod to the brand’s heritage. But retro styling can complicate fit with contemporary lighting geometry or cooling requirements. The best approach is to balance homage with practical integration: the bumper’s shape, its mounting strategy, and its material choice should cooperate with the car’s existing architecture, not force the owner to compromise performance for aesthetics. In this sense, material selection becomes a pragmatic contributor to both the vehicle’s appearance and its daily capability. The bumper’s ability to absorb a minor impact, to maintain a clean line with the fenders, and to remain resilient under sun, heat, and road salt—all of these hinge on the material’s inherent behavior and the engineering standards used in its production.

From a safety and standards perspective, the assumption that a bumper must merely look the part has shifted toward a more rigorous expectation. Automotive suppliers increasingly emphasize OEM-grade engineering standards and testing that simulate harsh driving environments. The objective is not to produce a piece that merely passes a cosmetic check but to ensure the bumper behaves predictably under a range of conditions, protecting critical components such as the radiator, condenser, and headlights while managing low-speed collision energy. The material’s performance under repeated loading, the integrity of its mounting hardware, and the durability of its surface finish under UV exposure all matter. In a field focused on both performance and everyday reliability, the best bumper choice aligns with the car’s overall design intent, the driver’s use case, and a conservative assessment of risk. That is why many builders and buyers prioritize materials that demonstrate consistent energy absorption properties and long-term resilience, rather than chasing the most aggressive look at the expense of durability.

Material selection is inseparable from how one sources and evaluates options. While it may be tempting to chase the latest, flashiest design, the chapter’s throughline remains clear: choose a material that suits your driving life. For some, the budget-friendly, easy-to-work-with ABS pathway provides dependable results for daily commutes and weekend adventures. For others, the lightweight elegance of fiberglass promises performance-led aesthetics, complemented by disciplined maintenance. For a third group, polyurethane’s blend of rigidity and robustness ensures that the bumper stands up to high-speed runs, weather, and the test of time. In all cases, a careful fitment plan matters as much as the material itself. A well-chosen bumper, matched to the vehicle’s architecture and to the owner’s expectations, becomes a reliable partner in both sport and daily travel. And because the front end represents such a visible and functional interface, it deserves the thoughtful consideration that only a true material story can justify.

For readers who want to explore a practical, material-focused reference on how these options live in a real product context, consider a dedicated overview of PP-based bumper materials within the Lancer ecosystem. This resource highlights how a PP rear bumper material behaves, which translates conceptually to the front in terms of rigidity, impact resistance, and long-term durability. It is a useful anchor for understanding why synthetic polymers are a staple in performance-oriented bumpers and how their characteristics inform both design and everyday usability. Lancer Evo X Inspira rear bumper PP material

In the end, the bumper’s material choice anchors a broader philosophy: the Lancer’s front end should protect, perform, and present itself with a coherent aesthetic. The most successful setups are those that marry the right trade-offs to the owner’s goals, whether that means a quiet daily companion or a track-ready machine that still handles a potholed street with composure. The conversation about ABS, fiberglass, and polyurethane is not merely technical; it is a dialogue about how a car’s first point of contact with the world reflects a driver’s intent, budget, and care for the machine. As designs continue to evolve, the core idea remains stable: the bumper is not just a shield, but a calibrated interface where material science and automotive artistry meet.

External resource for further reading: https://www.alibaba.com/product-detail/Madly-GAF-Front-Bumper-for-Mitsubishi_1600734982462.html

The Lancer Front Bumper as a Versatile Interface: From Daily Comfort to Track-Ready Performance

The front bumper of a Mitsubishi Lancer serves as more than a shield; it is an interface between environment and machine, a first point of contact that shapes air, cooling, and the car’s stance. In daily driving it can be tuned for efficiency and quiet confidence, while on a track it becomes a platform for added cooling, improved air management, and controlled aerodynamics.

Materials and fitment matter. Polypropylene bumpers keep weight down and trim, but more demanding climates or usage may favor polyurethane or reinforced composites for stiffness and durability. Universal designs offer broad compatibility and simple installation, while year-specific options preserve factory geometry, illumination, sensor placement, and crash structure integration. The choice affects not just fit but how the bumper interacts with the radiator, intercooler, fog lamps, and the rest of the front-end ecosystem.

Aerodynamics go beyond mere appearance. A well-engineered bumper reduces drag, channels air to cooling paths, and minimizes turbulent wake. Proper ventilation and ducting ensure cold air reaches critical components, preserving power and braking performance during long sessions or hot days. Excess rigidity or an aggressive lip can raise drag or hamper cold-air delivery, while too little grip can invite lift at the front end.

For daily driving, the bumper emphasizes balanced styling, integrated lighting where allowed, and a silhouette that preserves the Lancer’s approachable character. Fog-light integration is common, improving nighttime visibility without compromising OEM-like fit.

When the goal is performance, track-oriented bumpers add dedicated cooling paths, integrated air intakes, and aerodynamic features such as front lips or diffusers that increase downforce and stability. These elements help maintain power delivery under repeated high-speed runs and reduce the risk of overheating, delivering a more confident front-end feel.

In harsh climates or dusty environments, durability comes into play. Polyurethane options often tolerate heat and sun better, resist cracking, and return to shape after minor impacts. They also take paint and wrap well, making it easier to refresh the car’s appearance over time.

Beyond the hardware, the bumper sits within a broader modification culture. Enthusiasts often pair front bumpers with larger grilles, diffusers, and spoilers to craft a coordinated aero package that reduces drag and lift while preserving a cohesive look. The aesthetic choices—color, texture, and finish—signal speed and precision without resorting to loud graphics.

Usage rights and licensing shape how bumpers and imagery are presented. Marketing materials and product imagery must follow guidelines for where and how they can be used online and offline, balancing aspirational storytelling with protections against misuse. This framing helps buyers understand the product while respecting the car’s identity.

For a concrete reference to a front-end option that embodies track-focused styling and precise fit, consider the Evo X front bumper variant that maintains factory alignment while improving air management. You can view it here: Evo X front bumper option.

As owners contemplate their next steps, the decision often centers on how aggressively they want to push the front end’s capabilities and how much maintenance they are prepared to perform. A universal bumper offers convenience and a clean slate for customization, while a carefully engineered, year-specific option promises an almost seamless integration with the vehicle’s styling cues and engineering standards. In any case, the bumper remains a focal point in the Lancer’s front-end identity, a space where performance, durability, and personal taste converge for daily drivers and weekend warriors alike.

External reference: For a concise primer on automotive aerodynamics, see https://en.wikipedia.org/wiki/Automobile_aerodynamics.

Guardrails for the Lancer Bumper: Navigating Usage Rights, Compliance, and Smart Sourcing

在改装前保险杠的实践中,车主不仅要关注外观与性能,更要穿透表面的法规与授权。真正决定改装成败的,往往是对使用权、授权与来源透明度的理解。把关注点从“我能不能改”转向“我该如何合规地改”,既能保障驾驶安全,也能在未来的保修、保险理赔和转售时减少纠纷。本章将以叙述性的方式展开,帮助读者在追求个性与性能的同时,建立一套稳健的合规思维,避免踩到法律与授权的雷区。行车安全与合法性并行,才是长期价值的根基。

首先把话题落在法律合规性上。几乎所有地区对车身改装有明确的规定。最基本的一条是不得让改装部件遮挡车牌、干扰灯光或影响识别系统。某些区域还要求官方认证或合格检验,尤其是涉及前部结构与抗碰撞性能的变动。试图在不了解当地法规的情况下盲目改装,往往会遭遇整改、罚款乃至强制复原的后果。因此,在真正动手前,向当地交通管理部门咨询并取得书面指引,是明智的第一步。这样的步骤并非繁琐,而是对自身安全与法律责任的负责。

在产品来源与授权方面,逻辑同样清晰。优先选择正规渠道的原厂件或经过严格认证的高质量后市场件,而不是凭直觉或低价驱动的购买。所谓原厂件与认证后市场件的区别,应以是否具备精准匹配、可靠材料与明确保修条款为衡量标准。购买前,需对型号、接口、安装方式与保修范围进行核对,确保零件与车身结构能协同工作,避免因错配带来的额外成本与安全隐患。

关于地区供应链与采购流程的信息,对于评估供应商的技术能力与生产可靠性也很有帮助。资料显示,针对特定年代的翼神前保险杠,某些区域的制造与配套体系较为成熟,这为购买方提供了一个判断供应商实力的参考框架。采购时,建议进行严格的供应商尽职调查,关注其工艺流程、质量控制、售后服务与退换政策。通过这样的尽调,可以在事前降低风险,避免因低质部件导致的安全问题或后续纠纷。

材料与适配性方面,车型在不同年代、不同版本之间的设计与接口差异往往很大。为避免错配,必须确认产品是否为针对您车型和年份专门设计的部件,或者是否为在法规允许范围内的通用替代件。常见材料包括ABS、聚碳酸酯、聚氨酯等,各自的刚性、耐热性与耐用性不同,成本与重量的权衡也不同。若追求极具冲击力的外观和更大进气口,某些设计会带来更强的赛道感;而日常通勤则更强调耐用性、容易维护和一定的美观平衡。

在使用场景层面,前保险杠不仅是外观的一部分,更是前部结构中承担一定保护功能的关键件。在低速碰撞中,它能分散能量,保护发动机舱、灯具和散热系统等关键部件。然而,现实中的优先级并非一成不变。城市通勤与周末赛道日之间,所需的保护强度、散热效率与空气动力学性能的权衡会有所不同。因此,选择时应结合实际用途做出更明智的取舍。对于追求经典复刻或复古风格的车主,符合历史气质的外观也可能成为独特的个人表达。

在使用权限与授权方面,内容不仅涉及产品的正当购买,更与数字与印刷媒介中的使用权紧密相关。线上用途通常包括微博、微信公众号、网站设计、电子商贸图片与网络简报等,这些场景通常被允许。然而,当涉及将图片用于产品外包装、装饰画、手机壳、贺卡等转售品时,往往需要额外授权。线下用途如户外广告、宣传册、海报、杂志封面等,也需要遵循相同的授权边界。换句话说,素材的使用范围越广,授权的复杂程度越高,谈判、署名与记录也就越重要。

这种授权管理并非冷冰冰的制度,而是涉及长期伙伴关系的建立。对改装者而言,除了确认零件来源的合法性和匹配度,还需要从头到尾保留完整的记录,以便未来的质保、保险或潜在法务审查。建议保存购买证明、安装手册、检测报告以及任何合格证书,以确保进出保修链条、索赔流程和后续服务的透明与可追溯性。若读者需要快速了解某一具体选项在可用性上的证据,可以参考如以下链接所指向的真实目录页面:mitsubishi-cz4a-lancer-evolution-x-front-bumper-genuine。这一链接体现了车型与年款精确匹配的重要性,也是评估供应商能力、确保质量与兼容性的重要依据。

从操作角度看,任何改装都应避免盲目性。错误的部件、错误的安装步骤,都会对安全产生直接影响。建议由具备资质的技师执行安装,确保螺栓紧固、定位正确,并妥善处理与前灯、进气口、格栅等部件之间的干涉关系。完成安装后,应进行路试,确认灯光对准、夜间照明与可见性符合标准。这些细节往往在年检、保险理赔乃至二手交易时体现出来,错过再补救往往代价更大。

在总结性层面,以上内容共同指向一个清晰的原则:合法合规地使用与安装前保险杠,是建立在正确选择、合规来源与精准匹配之上的。合规并不等于放弃美学或性能。通过透明的授权流程、稳定的供应链以及对法规的持续关注,车主可以在不放弃个性与性能的前提下,长期维持车辆外观与结构的稳定。对于那些寻求明确表达与强烈性能感的爱好者,理解授权边界、地方法规与可信赖渠道,将是避免未来纠纷、降低总成本的基石。

外部参考与进一步阅读:一份权威的选型指南提供了跨品牌、跨风格的对比分析,帮助车主在不同情境下权衡取舍。请参考外部资源以深化理解: How to Choose a Bumper for Lancer Evo X – Full Guide.

Rally Aesthetics and Aerodynamics: Navigating the 2026 Lancer Bumper Market

The front bumper of a Mitsubishi Lancer is more than a protective shell. In 2026 it has become a signal of intent, a place where racing heritage intersects with everyday driving. Enthusiasts seek the bold, aggressive lines that harken back to the Evolution era, while builders demand real performance gains. The market meets these ambitions with a spectrum of options that marry lightweight materials, thoughtful aerodynamics, and straightforward installation. This convergence reflects a clear philosophy: a bumper is not a mere accessory but a strategic component that shapes airflow, cooling, and perceived speed on the street as surely as on the track. In this ecosystem, a single nose can communicate ownership of the road, make a track-day feel closer to home, and set a car apart in a crowded lineup.

A practical look at the current landscape reveals two broad paths. The first is the universal, non-specific option designed to fit multiple Lancer trims with simple mounting. These designs emphasize ease of fit and quick turnarounds, appealing to owners who want a striking look without a headache of modification. The second path favors year-specific designs, especially for models produced between 2009 and 2017, including special variants that draw on performance styling cues. These bumpers are typically molded from durable polypropylene and are built to bolt on with minimal fuss, ensuring a clean, factory-like alignment that respects the car’s original geometry. The trade-off, of course, is that some non-Evo trims may require a bit more attention to alignment and occasional trimming, but the payoff is a precise look that honors the car’s lineage.

Material choices play a decisive role in the feel and resilience of modern bumpers. Where the base plastics offer good impact resistance and color stability, higher-end offerings increasingly lean on reinforced composites. Some mid- to high-tier options incorporate glass-fiber reinforcement, which reduces weight while boosting rigidity. This matters on the street where minor bumps are common and on the track where every gram counts toward handling. Even with lighter construction, these bumpers are designed to absorb low-speed impact energy, protecting the radiator, headlights, and surrounding structure from cosmetic and functional damage. At the same time, developers optimize airflow paths with precision: big central air dams, carefully shaped side intakes, and subtle undercuts that guide air to coolers and brakes without creating a noisy, drag-inducing front end.

The aerodynamic intent behind these designs is no gimmick. A well-integrated front bumper lowers lift at high speed, helps manage boundary layers around the wheels, and supports more stable handling in corners. The lower extensions and side skirts many bumpers sport work in concert with the chassis to reduce front-end lift and improve downforce just enough to feel connected to the road. For hot climates or spirited driving days, such features become practical considerations, offering a perceptible difference in how the car behaves when the throttle is pushed and the road narrows ahead.

From the standpoint of appearance, the 2026 Lancer bumper market leans toward a blended identity. Enthusiasts want a look that telegraphs performance, yet remains functional and reliable for daily use. This dual demand has elevated designs that resemble the rally-inspired aesthetics of the Lancer GT and the Ralliart without sacrificing everyday practicality. The GT-influenced options tend to strike a balance between aggressive grilles and moderated air intakes, delivering a modern, sport-informed silhouette that still suits daily commutes. In contrast, the Ralliart-inspired elements push more aggressively, with bolder lower grilles and sharper lines that announce intent without compromising road manners. For many owners, it is this spectrum—the calm, refined modernity of the GT alongside the assertive stance of the Ralliart—that best matches their priorities: eye-catching style, dependable fit, and measurable performance gains.

A noteworthy trend in 2026 is the rise of mid-tier replica bumpers. These products aim to capture the essence of high-end, performance-oriented designs at a more accessible price. While premium brands carry prestige and perhaps marginal gains in material behavior, many buyers find replicas offer the right balance of fidelity, weight, and cost. The key for buyers is to assess fitment across trims. OEM Evo bumpers often require trim or mounting modifications to fit non-Evo models, so replicas that mimic the Evo X look but remain compatible with broader trim lines have strong appeal. This pragmatic approach lets owners achieve a dramatic visual upgrade without compromising reliability or install simplicity.

In parallel, the market continues to emphasize functional features that extend beyond pure aesthetics. Modern designs increasingly embed integrated fog-light housings, sculpted side intakes, and aerodynamic lips that align with the car’s cooling strategy. These features aren’t merely decorative. They contribute to engine bay temperature control, radiator efficiency, and brake cooling when the vehicle is driven hard. Materials like polycarbonate and reinforced polymers are favored for their impact resistance and lower thermal expansion, which matter when the nose is exposed to sunlight and high heat during street-to-track transitions. The result is a bumper system that looks purposeful at a standstill and behaves predictably when the pace picks up.

Within this evolving landscape, the trim ecosystem continues to influence what buyers expect. Lancer GT and Ralliart trims, once defined by crisp performance cues, shape how bumpers are styled and mounted. The GT’s contemporary silhouette invites a restrained, modern look with modest air intake openings, while the Ralliart’s more aggressive edge calls for bolder detailing and a lower overall stance. These influences ripple through the aftermarket, guiding designers toward options that can satisfy a mixed audience: owners who drive every day and those who occasionally chase a heartbeat-down-the-straight feeling on a track day.

The practical realities of installation and durability are never far from the conversation. Direct-bolt designs—especially those built around a year-specific shape—offer straightforward mounting with factory-provided points. For universal fit bumpers, adapters may be required, which adds a layer of complexity but also expands the pool of compatible models. Either path expects a careful fit to avoid gaps that could allow water intrusion or wind noise at speed. Durability concerns are balanced by the bumper’s role as the first line of defense; even a design favored for its look must withstand everyday road hazards. The industry increasingly recognizes this, emphasizing not only style but also the capacity to tolerate minor contact and environmental stress without compromising alignment or finish.

Beyond the technical, the market’s marketing reality matters. Visuals are essential in a category where appearance sells. Online catalogs, social media, and e-commerce listings rely on imagery that communicates both form and function. At the same time, the licensing rules around imagery and promotional materials are real. For marketers and builders, the line between promotional use and resale-oriented packaging is sharp. Images used to decorate websites or social posts can be shared widely, but distributing imagery on product packaging or as standalone artwork often requires explicit authorization. This boundary shapes how shops promote bumpers and how enthusiasts share their own build stories.

As a natural extension of these dynamics, owners seeking a balanced approach can look to a specific option that has drawn attention among GT and Ralliart enthusiasts. The front bumper design associated with the CZ4A Evolution X family exemplifies a look that many fans classify as the sweet spot between aggression and daily usability. It embraces a large central air dam, integrated lighting housing, and flared side intakes that echo the rally lineage while remaining adaptable to a broad range of trims. For those curious about this path, there is a representative example you can explore: cz4a-lancer-evolution-evo-10-front-bumper-red-color. This option demonstrates how a single nose can carry a strong emotional charge without demanding a full-scale chassis modification. You can learn more about this specific design at the linked page.

The conversation about bumpers naturally leads to practical guidance for buyers. Before making a choice, consider your driving context. If you spend a lot of time on local roads and want a dramatic look, a Kota-like Evo-inspired shape with robust protection and lower front extensions may deliver both style and confidence. If you regularly push toward the limit on open roads or track days, prioritize aerodynamics and cooling performance, ensuring the bumper complements the car’s overall weight distribution and brake setup. Fitment checks, paint matching, and warranty coverage become essential steps in this process. In addition, buyers should balance cost with expected use. While mid-tier replicas offer compelling value, the longevity and real-world performance can hinge on the quality of the mold, the resin system, and the precision of the mounting hardware.

As these bumpers become more common, the conversation shifts from “how it looks” to “how it behaves under load.” Dealers and builders increasingly share data about heat soak, cornering stability, and shield effectiveness in minor impacts. This empirical approach helps owners plan maintenance and understand the limits of a bumper upgrade. It also feeds into the broader narrative of customization as a disciplined practice: you upgrade not just for style, but to improve the car’s behavior on roads and tracks you actually drive.

For readers who want to deepen their understanding of how different bumper designs map to Lancer Evo X-inspired goals, an external resource provides a practical, technical baseline. This guide compares various bumper options for Evo X models, detailing fitment, airflow considerations, and real-world performance implications. It is a helpful companion to the decisions described above and can anchor your evaluation as you compare options across materials, finishes, and price points. How to Choose a Bumper for Lancer Evo X – Full Guide

In closing, the 2026 Lancer bumper market reflects a blend of rally heritage, modern engineering, and consumer pragmatism. Buyers are positioned to weigh the visual drama of Evo-inspired lines against the realities of fit, durability, and daily usability. The result is a vibrant, diverse market where a well-chosen bumper can transform a car’s stance, airflow, and confidence without demanding prohibitive compromises. For those following this evolving space, every new launch becomes a data point in a living story about how a classic performance symbol remains relevant in a world that increasingly values efficiency, street capability, and personal expression.

Final thoughts

The Lancer bumper is not just a protective feature; it is an essential element of vehicle identity and customization. Understanding the diverse product types, materials, application scenarios, and market dynamics empowers business owners to effectively cater to customer needs and preferences. By leveraging this knowledge, owners can enhance their product offerings and stay competitive in a rapidly evolving automotive market.