The Lancer Evo Wing is a hallmark of performance engineering, symbolizing a blend of aesthetics and functionality. As businesses revolve around optimizing vehicle performance and attracting enthusiasts, understanding the impact of iconic designs like the Lancer Evo Wing becomes crucial. This article will delve into the aerodynamic principles behind the wing, track its historical evolution in high-performance vehicles, and explore how it influences car performance and racing culture.

How the Lancer Evo Wing Works: Aerodynamics, Design and Real-World Trade-Offs

The rear wing on a Lancer Evo is more than an iconic silhouette. It is a tuned aerodynamic device. It manages airflow, creates downforce, and shapes how the car behaves at speed. For drivers, the wing translates aerodynamic theory into tangible grip and confidence. For builders, it is a focal point where form, function, and compromise meet.

At its core the wing’s purpose is simple. When air flows over the car, the wing alters pressure above and below its surfaces. That pressure difference pushes the rear axle toward the road. More vertical load on the tires means higher lateral and longitudinal grip. The effect is subtle at low speeds and pronounced at high speeds. That variation explains why a wing can feel invisible in town traffic yet critical on fast corners.

Design begins with shape. A wing is an airfoil adapted for an automotive rear deck. Its chord, span, camber, and profile determine lift and drag behavior. A wide, high-aspect wing produces considerable downforce with relatively less drag. A thicker profile can delay stall and resist flow separation. Endplates help contain spanwise flow and make the wing behave more predictably. Small features, like a gurney flap or louvers, refine the pressure distribution and tune stall characteristics. Every millimeter of curvature and every gap between wing elements changes the airflow field.

Most wings on this platform fall into two broad families: single-element and multi-element. Single-element wings are simpler, lighter, and offer clean packaging for road use. Multi-element wings stack surfaces to increase downforce without proportionally increasing frontal drag. They also give engineers more degrees of freedom to tune the curve of lift versus angle of attack. On a race car, that tunability is essential. On the street, packaging, noise, and cosmetic proportions matter just as much.

Materials affect both performance and practicality. Carbon fiber provides high stiffness and low weight. A carbon wing resists twisting loads and keeps an aerodynamic shape under high stress. That stability translates into consistent downforce and predictable balance. Carbon also allows designers to push thin profiles and intricate geometries. The downside is cost and susceptibility to impact damage. A rock strike or an accidental trunk slam can crack a composite skin, and repairs are specialized.

ABS plastic and fiberglass offer resilience and lower cost. They can absorb minor impacts without catastrophic failure. Thermoplastic parts are easier to mold into complex shapes and can hide impact history better than raw carbon. Their stiffness is lower, though, so larger cross-sections or internal reinforcement may be required to avoid deformation under load. Metal wings exist too, but they are heavier and require corrosion-proofing.

Materials choice connects directly to mounting strategy. A wing produces vertical loads and bending moments that transfer into the trunk lid and rear structure. A small spoiler pressurized at 100 kph will impose modest forces. A high-mounted, multi-element wing at 250 kph will transmit a lot more. Proper installation spreads these forces across reinforced points. Factory wings often use substructure brackets, larger-diameter bolts, and load-distributing plates under the trunk to avoid local tearing.

When owners swap aftermarket wings, they frequently need to reinforce the decklid. Reinforcement can be as simple as an under-tray plate bonded to the trunk skin. In more involved cases, fabricators add welded brackets to the body shell or bolt into reinforced inner rails. A clean install also considers water ingress. Each penetration must be sealed, and drainage paths preserved. Failing to seal mounts invites corrosion and rattles.

Aerodynamic balance is the next critical concept. A wing does not exist in isolation. It trades forces with the front end and the underbody. Adding rear downforce without corresponding front downforce shifts the torque balance toward understeer. Conversely, a strong front aero setup with a mild rear wing can induce oversteer at speed. Achieving neutral handling means tuning the relative magnitudes of front and rear aerodynamic loads across the relevant speed range.

This interplay explains why cohesive aero packages matter. A rear wing works best when the underbody and diffuser manage downstream flow. A diffuser accelerates air under the car and lowers pressure beneath the rear axle. The wing then works against a cleaner, lower-pressure wake, increasing overall efficiency. You can find components designed to work together, including a carbon rear diffuser for Lancer and Evo-10 that complements a raised wing. That diffuser helps anchor the wing’s benefits to real tire contact improvements.

Adjustability is a powerful practical tool. Many wings allow angle changes on the support stanchions. A higher angle of attack increases downforce but raises drag and may reduce top speed. A lower angle favors straight-line velocity and fuel economy. On the track, teams alter the angle between sessions to suit circuit demands. The ability to fine-tune also helps match aero balance when tires, springs, or anti-roll bars change.

Two-stage wings and variable geometry systems add another layer. Historically, some rally-derived designs employed multi-plane wings or pivoting elements. These provide a baseline downforce and a secondary stage for higher loads. Adjustable flaps, while rare on street cars, can unlock additional performance when combined with controlled cooling or ride-height systems.

Ride height and suspension stiffness influence the wing’s effectiveness. A wing’s downforce acts on sprung mass, not directly on the tires. If the suspension compresses under load, the ride height changes, altering the wing’s angle to the oncoming air and the underbody flow. Stiffer springs and proper anti-dive geometry stabilize ride height and preserve aerodynamic intent. Similarly, cornering load transfer interacts with aerodynamic load transfer. A balanced suspension lets the wing offer usable, predictable gains.

Measuring aero effects requires care. Wind tunnel testing and computational fluid dynamics provide controlled insights. On-car testing in an open environment can use yawed flow rigs or telemetry comparing lap times with and without the wing. Track testing remains the ultimate arbiter. A wing that looks effective in a CFD model might create troublesome vortices or buffet a rear glass area when mounted on a production body. Practical evaluation captures vehicle interactions that pure theory can miss.

There are real-world trade-offs to consider. More downforce reduces straight-line speed and increases fuel consumption. It can also add structural stress to mounting points and the trunk floor. A large wing raises the car’s silhouette and can reduce rear visibility. It may also create low-frequency buffeting that affects cabin comfort. For daily-driven cars, these compromises can outweigh any marginal grip benefits encountered on public roads.

Legal and regulatory issues matter too. Some jurisdictions limit protruding aero devices. Others require that externally mounted items meet pedestrian safety guidelines. High wings can also complicate parking in garages and affect roof clearance at speed humps. Insurance policies may change when aftermarket aero parts are fitted. Owners must review local rules and insurance requirements before committing.

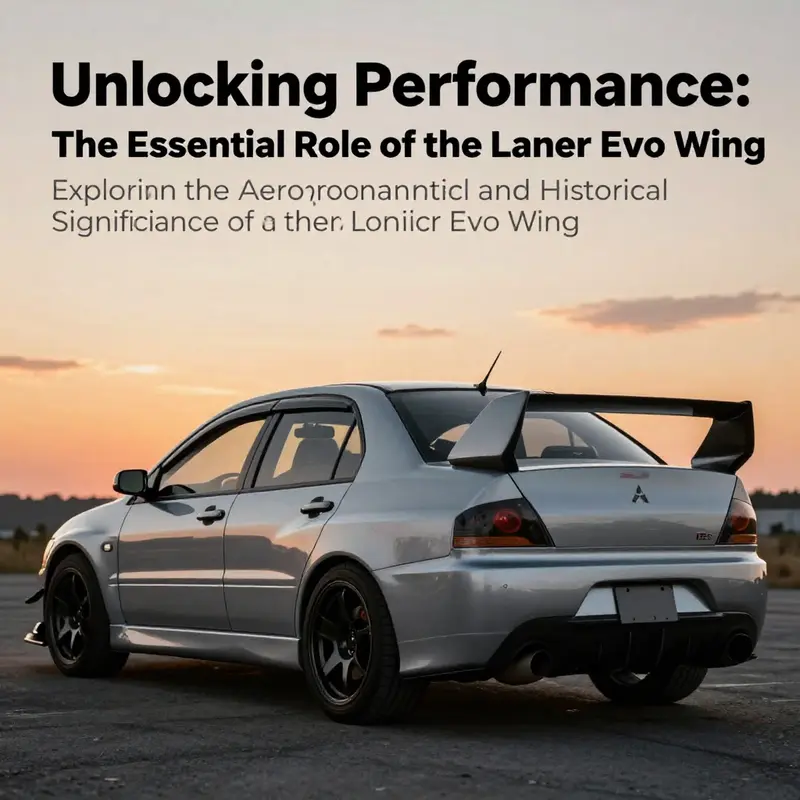

The wing’s visual language deserves attention. It signals performance intent and motorsport lineage. For many owners, the wing is as much about identity as it is about lap times. Designers balance aggression with refinement, ensuring the wing reads as a purposeful aerodynamic tool rather than an aftermarket accessory. Subtle choices, like matching the wing finish to interior trim or integrating brake lights into the trailing edge, can elevate perceived quality.

A cohesive approach treats the wing as part of a broader aerodynamic ecosystem. Side skirts reduce underbody leakage, front splitters increase front downforce, and rear diffusers convert underbody pressure recovery into usable lift reduction. Together, these elements alter load distribution and handling. Installing one component in isolation often yields marginal gains. Packages, whether factory or aftermarket, aim to optimize these trade-offs across speed ranges.

Maintenance and durability are practical concerns. Composite wings can delaminate under cyclic load if not properly cured. Thermoplastic wings can fade under UV exposure and may develop micro-cracks from stress. Fastener points should be inspected periodically. Torque should be checked after the first track outing. A small looseness can quickly translate into larger structural problems. Protecting painted and exposed surfaces with wax or film reduces stone-chip damage and helps preservation.

Installation choices reflect budgets and goals. A bolt-on kit that reuses factory mounts offers ease of fit and preserves warranty lines. A full custom install with welded reinforcements prioritizes longevity and high-speed stability. Some owners choose quick-release systems for modularity in competitive environments. Each approach carries pros and cons in time, cost, and long-term effect on the vehicle.

Performance gains are often situational. On tight, low-speed circuits, mechanical grip dominates. A large wing has limited effect. On high-speed tracks or long sweeping corners, aerodynamic downforce becomes crucial. Drivers should set expectations accordingly. Improving the aero balance can unlock faster, more consistent lap times, but aero alone will not replace the benefits of improved tires, suspension, or a powertrain upgrade.

When testing a wing, adopt a methodical protocol. Begin with baseline data logging for lap time and sector performance. Make only one aero change at a time. Record tire temperatures, ride height, and steering effort. Use consistent fuel levels and suspension settings. Small changes in wing angle often produce measurable differences in lap time. The key is interpreting those differences within the broader vehicle system.

Cultural considerations matter in the tuning community. The wing is a visible link to rally history. It evokes images of gravel stages and high-speed sprints. That symbolism drives choices beyond raw performance. Some owners prioritize authentic proportions and factory-style mounting hardware. Others chase exaggerated aesthetic statements. Both approaches coexist, and both shape the community’s evolving standards.

Finally, consider retrofit and resale. A well-chosen wing installed thoughtfully can enhance a vehicle’s appeal. A poorly executed or ill-suited wing can deter buyers and lower value. Keeping original mounting hardware and maintaining a reversible installation helps preserve options. If resale is a goal, emphasize quality of components and documented installation work.

A rear wing is a focused tool. It alters airflow, increases rear axle load, and affects handling in quantifiable ways. Its effectiveness depends on design, materials, mounting, and the rest of the vehicle’s aero and suspension setup. For drivers seeking measurable performance gains on high-speed tracks, a properly integrated wing is a crucial component. For street-driven cars, the balance shifts toward compromise between function, durability, and day-to-day practicality.

Understanding that balance unlocks better choices. The wing becomes a tunable instrument rather than a cosmetic flourish. With careful selection, correct installation, and informed testing, the wing can improve stability, enhance grip, and give the car a purposeful presence on the road or track.

Further technical reference can be found in manufacturer aero documentation and engineering overviews. A concise technical write-up on this platform’s aero wing provides additional data and diagrams for those wishing to dive deeper.

External reference: https://www.mitsubishi-motors.com/tech/evolution-x-aero-wing

Internal resource: carbon rear diffuser for Lancer and Evo-10 (https://mitsubishiautopartsshop.com/carbon-rear-diffuser-v-style-mitsubishi-lancer-and-evo-10/)

Winged Precision: Tracing the Lancer Evolution’s Rear Wing Through Rally Heritage and Road Performance

A wing is more than a visual flourish on a performance car; it is a carefully tuned piece of aerodynamic engineering that translates speed into stability, grip, and a driver’s sense of control. In the lineage of a storied family of four-door, four-wheeled challengers, the rear wing emerges not merely as a feature to be admired but as a functional statement about how a car communicates with air, tires, and the road. As with many iconic performance projects, the wing’s role evolved alongside the car’s overall aerodynamic strategy, moving from a necessity born of high-speed rally demands to a sophisticated, integrated element of a complete performance package. The arc of this evolution mirrors a broader automotive culture that treats downforce not as an indulgence but as a fundamental tool for turning power into predictable behavior at speed. Within this narrative, the wing becomes a sensory reminder of the car’s purpose: to link the kinetic energy of a quick lap with the composure needed to conquer a twisty road or a rally stage at the limit.

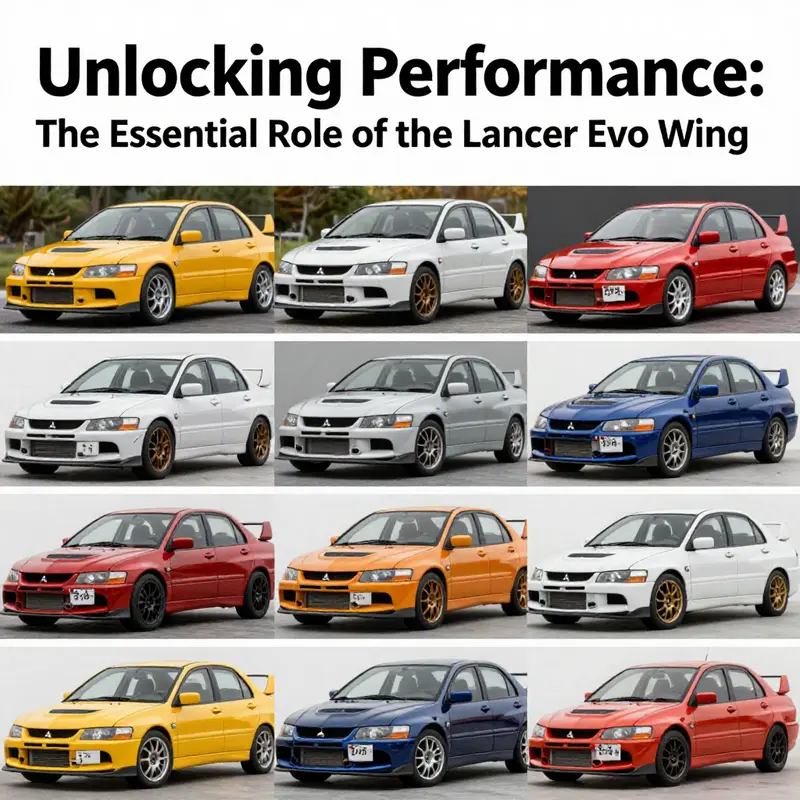

From the outset, the philosophy surrounding the wing was clear: generate meaningful downforce without compromising the car’s balance or its ability to breathe. Early iterations of the performance sedan’s aero philosophy emphasized raw downforce, often realized through a wide, conspicuously large rear element that extended across the width of the tail. This design was not a cosmetic afterthought. It served a clear aerodynamic function, creating a high-pressure zone above the trailing edge that aided the diffuser and the underbody airflow in steering the car’s tail through corners at high speed. The integration of the rear wing with the bumper, the rear fascia, and the side skirts created a unified aero concept. It was the product of a time when homologation demands for rally competition guided engineering, and every component, from the spoiler to the tail, carried measurable, testable intent. The visual heft of a wide rear wing signaled restraint under acceleration and courage under braking; it announced, in a single, sweeping gesture, that the car’s dynamics were being tuned for a world beyond the street.

As generations progressed, the wing’s architecture grew more intricate and more purposeful. The transition from a purely wide, fixed rear element to a more integrated, aerodynamically refined system reflected a deeper understanding of how air behaves around a fast-moving silhouette. Designers began to treat the rear cowl and the spoiler as parts of an interconnected family of aero devices rather than as separate pieces slapped onto the tail. The wing’s size remained a defining feature, but its function evolved: it no longer existed just to press the rear axle down at a single speed; it began to manage airflow over a broader spectrum of speeds and yaw moments. For the onlooker, the wing’s silhouette became a signature—the car’s stance announcing that its aerodynamics are balanced, cohesive, and tuned to a particular kind of tempo that only high-speed corners and long straights can reveal.

Within the broader aero package, the rear wing interacts with other elements in nuanced ways. A shovel-like front splitter, a sculpted underbody, and a pronounced diffuser generate a symphony of airflow that the wing can influence from the rear. The rear element’s lift-reducing task is not isolated; it complements the front’s attempt to keep the nose planted and the center of gravity under control. This mutual dependence creates a stability that is more than the sum of its parts. The wing’s role extends beyond downforce into managing flow separation around the vehicle’s trailing edge, which in turn reduces drag penalties at high speeds and improves high-speed stability. That is the subtle evolution at work: downforce now comes with drag-aware efficiency, a dual objective that makes the wing a keystone of the car’s overall performance architecture.

The culture surrounding the car also reshaped the wing’s meaning. In the hallways of rally history and in the garages that served as laboratories for performance tuning, the wing transformed from a function-first device into a symbol of the car’s ethos. It signaled a commitment to speed, but not reckless speed; it signaled an insistence on control at the limit. The wing’s visibility—its tall, sweeping profile—made a visual statement that performance could be accessible, even iconic. Enthusiasts could recognize a certain philosophy in the stance of the rear end, a philosophy that spoke to years of engineering focus and to a collective desire to push the edge of what a sedan could do at speed. The wing became not only an aerodynamic tool but a badge of belonging for a community that valued precision, discipline, and the beauty of a well-balanced machine in motion.

In the arc of design, a later phase introduced more integrated aero features. Rather than a stand-alone element perched above the trunk, wings began to speak the same aerodynamic language as the car’s other key surfaces. The rear wing grew larger, but its relationship with the rest of the body became more considered. The aerodynamic rear cowl, airfoil shaping, and endplate geometry were tuned to reduce lift while also shaping the wake behind the car so that the trailing edge would interact with the diffuser in a way that encouraged a clean, attached flow. This is where the wing’s function begins to feel like sculpture: the mass of air, the speed of air, and the car’s own momentum all converge to unleash a controlled, predictable response. The wing is no longer just a postscript to the chassis; it is a central element of what makes the car feel alive at 100 miles per hour and more.

The evolution toward an even more radical rear wing footprint occurred as road cars drew inspiration from the discipline of rally technology. The line between race car and road car blurred as engineers borrowed strategies that had proven themselves on the stage and applied them to production models. A large, multi-element rear wing emerged as a defining look, paired with a redesigned front fascia and a more aggressive diffuser. The result was a visual language that spoke to a broader audience of enthusiasts—the person who sees speed first in the tail’s silhouette and knows that air is doing the work of grip so the tires can deliver traction where it matters most. This combination of function and form created an enduring icon. It resonated with those who value the marriage of engineering rigor and stylistic audacity, a balance that makes the wing both a practical instrument and a cultural emblem.

As the story of the wing moved forward, it didn’t exist in isolation. It became part of a broader belief about how a performance sedan should behave in the real world. On a winding pass, the wing helps manage lift and drag so the car’s chassis remains composed as the speed builds. On a long, open straight, it contributes to the stability that keeps the car planted and predictable when the throttle is pressed toward the limit. On a rain-slick road, its influence extends into how the car responds to subtle steering inputs and shifting weight. The wing, in other words, is a translator: it translates the driver’s intentions into manageable forces through the air. And because it translates those forces so directly, it carries a certain trust—an unspoken bond between machine and driver that is reinforced, generation by generation, by the ongoing pursuit of balance and performance.

This narrative of integration is where the wing most clearly reveals its character: it is not a single gadget but a system component whose value emerges through careful coordination with the rest of the aero package. The car’s designers learned to see the rear wing not as a solitary lever to pull but as a partner in a coordinated strategy. In practice, that means the wing’s size and angle work in concert with the front splitter’s bite, with body channels that guide air toward the diffuser, and with the cabin’s cooling outlets that must operate without being starved by recirculating air. It is a delicate choreography where each element must respect the others’ boundaries while pushing toward a shared goal: a car that feels planted and responsive as it moves swiftly from corner to corner.

If you walk through a modern garage or scroll through a gallery of rally-inspired road cars, you will notice how the wing’s profile often hints at the path the entire aero approach has taken. The silhouette is not accidental; it’s the culmination of decades of testing, of wind tunnel work, and of on-road and on-stage evaluation. Enthusiasts often point to the wing as the most visible element of a design language that values precision over excess. The rear wing’s presence, its height and span, its endplates, and the way it sits in relation to the trunk line—all of these cues tell a story about the car’s aspiration: speed with control, raw power tempered by discipline, and a willingness to push how air can be harnessed to help a driver stay in command.

Throughout this journey, the wing also embodies a broader cultural memory. It evokes the era when rally engineering insisted on near-perfect downforce to conquer gravel, tarmac, and mixed surfaces. It recalls late-night tuning sessions, the hum of wind tunnel tests, and the collective excitement that accompanies a new aero upgrade announced in a showroom or a magazine spread. The wing becomes a touchstone that connects the performance world’s technical rigor with a community’s shared experiences—the late-night discussions about angle of attack, downforce versus drag trade-offs, and the kind of driving partner a tire can become when air helps to keep the chassis honest. It is no accident that the wing has become a recognizable shorthand for performance tuning: an emblem of a philosophy that values that rare blend of science and sensation, where data and emotion meet at the same crawl of air just behind the car.

In the practical realm of hobbyist and professional tuning, the rear wing remains a focal point of how to coax maximum performance from a given platform. The integration of the wing with the chassis, the suspension geometry, and the tire development program creates a feedback loop. Engineers rely on wind tunnel data and track testing to tune each parameter so that adjustments at the rear do not destabilize the front—or vice versa. The result is a chassis that communicates clearly to the driver: here is your limit, here is where the car’s grip begins to fade, and here is how the wing helps you ride that edge with calm assertiveness. For a community that cares deeply about precision, this dialogue between air and chassis is a living craft. The wing becomes a focal point where engineering science and driving art converge, a symbol of the craft and the patience that defines long-term performance improvement.

To underscore the practical side of this evolution, one can see how modern aero philosophy leans toward holistic integration rather than simple appendage installations. The wing’s job is best understood as part of an aero ecosystem that includes the bodywork, the undertray, the diffuser, and even the tires. When these elements are harmonized, the car can achieve remarkable handling fidelity. The wing contributes to a broader performance mosaic that turns high-speed straightline power into confident cornering. It helps the chassis feel composed even when the scale and speed of the driver’s inputs would otherwise unsettle the balance. In that sense, the wing’s history is also a history of engineering discipline—the willingness to test, to refine, and to push the envelope while honoring the car’s overall dynamic integrity.

For readers who want to connect this historical thread with tangible examples of how the wing’s legacy lives on in contemporary designs, consider a side reference to how aero components extend beyond the tail and into the sides of the car. A modern package often pairs the rear wing with carefully sculpted side elements that manage corner flow and reduce interference with the underbody’s pathways. In some implementations, you can even encounter the related aerodynamic details that accompany the wing—such as side-skirt or underbody features—that work in concert with rear devices to optimize pressure distribution across the whole vehicle. This integrated approach is a direct descendant of the wing’s original mission: to convert high-speed air movement into stable, predictable grip at the rear, while preserving an efficient path for the air to exit the car cleanly.

The takeaway is not just a lineage of shapes but a philosophy of performance that has endured for decades. The rear wing, in its many generations, tells a story of how engineers translated the demands of rally competition into a road-going capability. It reveals how a team could shift focus from purely mechanical grip to a more nuanced understanding of airflow, and how the car’s visual identity became a signal of that deeper technical conversation. The wing’s evolution—from a wide, fixed, rally-first mass to an integrated, multi-element, road-optimized feature—maps a broader trend in how performance cars are designed: with an eye toward balance, synergy, and the driver’s experience at speed.

In this way, the legacy of the wing speaks to a conversation about the very nature of performance. It is not merely about making the tail look dramatic or lending the car a more aggressive stance. It is about sculpting air in a way that aids a driver’s decisions, preserves traction, and converts dynamic energy into controllable momentum. The wing stands as a visible reminder of the collaboration between wind, wheels, and will—the way in which an engineering concept becomes a cultural touchstone and, ultimately, a vehicle for personal connection to speed. It is this fusion of science, spectacle, and shared passion that gives the Lancer Evolution’s rear wing its enduring meaning: a symbol of precision-driven performance that remains legible, even at a glance, as air and asphalt meet in a moment of pure driving intention.

For readers who want to explore related aero imagery and road-focused interpretations of this heritage, you can see how elements like side components complement the rear wing’s function in modern tuning packages. One example that illustrates the contemporary approach to aero harmony is the side-skirt design associated with late-generation chassis, where the lower body panels guide the air toward the rear diffuser while helping to reduce parasitic drag along the sides. This helps the rear wing do its work with a more favorable flow field and contributes to the overall balance that makes the car feel alive in the hands of a skilled driver. The concept is simple in its essence: air has memory. It remembers where it came from, how it moves around the body, and where it exits. If every surface collaborates, the tail can deliver downforce in a predictable, manageable way, while the front remains tractable and communicative to the driver’s inputs. That is the practical fruit of decades of aerodynamic experimentation, and it is what continues to inspire enthusiasts who chase the thrill of speed with a disciplined respect for balance.

In this sense, the rear wing’s timeline is not a serial list of models and numbers. It is a narrative about how a performance car learns to speak air, how a design language grows more sophisticated yet stays true to its rally-born roots, and how a community of drivers and engineers keeps the conversation alive with every new iteration. The wing’s legacy endures because it reminds us that speed, when pursued with care, becomes a language—a shared vocabulary of downforce, stability, and driver confidence. It is this language that turns a fast sedan into a trusted partner on a winding road and into a legend on the ears of enthusiasts who recognize the silhouette and know the story behind it.

To ground this exploration in a concrete sense of the modern ecosystem around these vehicles, consider how aero components today often exist in families. The rear wing, the side elements, and the underbody devices work together as a system designed to optimize balance across a broad spectrum of speeds and driving conditions. This system-level thinking is a natural outgrowth of rally experience and road engineering alike. It is a reminder that the wing’s history is not isolated in the annals of a single model year or a single race season, but rather in the ongoing commitment to improved handling, more precise steering, and the sustained joy of driving a machine that feels connected to the air it moves through. In that sense, the wing is less a gadget and more a continuous exploration of what air can do when guided by human intention and technical craft.

As the narrative moves forward, the wing’s role remains a defining thread that ties together performance engineering, motorsport heritage, and the everyday thrill of driving a highly capable sedan. The geometry of the wing, the way it interacts with the surrounding aerodynamics, and the culture that surrounds its place in the car’s design all speak to a broader truth: the most enduring symbols of performance are those that stay true to their function while evolving in response to new challenges and new ways of thinking about speed. The rear wing of this lineage stands as a testament to that philosophy—a visible reminder that the pursuit of grip at speed is as much about how air is managed behind the car as it is about how power reaches the road ahead. And in that balance, enthusiasts find the continuity between the thrill of a rally stage and the refined confidence of a road-going performance sedan.

Internal reference note: for those interested in a practical example of aero-inspired design elements that extend from the rear toward the sides, a related component commonly explored in modern tuning packages is the side-skirt treatment seen on several late-generation chassis. This feature, while modest in scale compared with the rear wing, contributes to the overall airflow management and helps ensure that the air’s journey from front to rear remains orderly. The continuity across aero components—front to rear, top to sides—embodies the same ethos that made the wing a lasting symbol of performance. lancer-evo-x-side-skirt

External Resource: for a contemporary perspective on the Lancer Evolution X’s first-drive impressions and the broader aero narrative surrounding modern iterations, see this external analysis: https://www.motorauthority.com/news/1146338-mitsubishi-lancer-evolution-x-first-drive

The Lancer Evo Wing: A Downforce Icon That Bridges Rally Heritage and Modern Track Tech

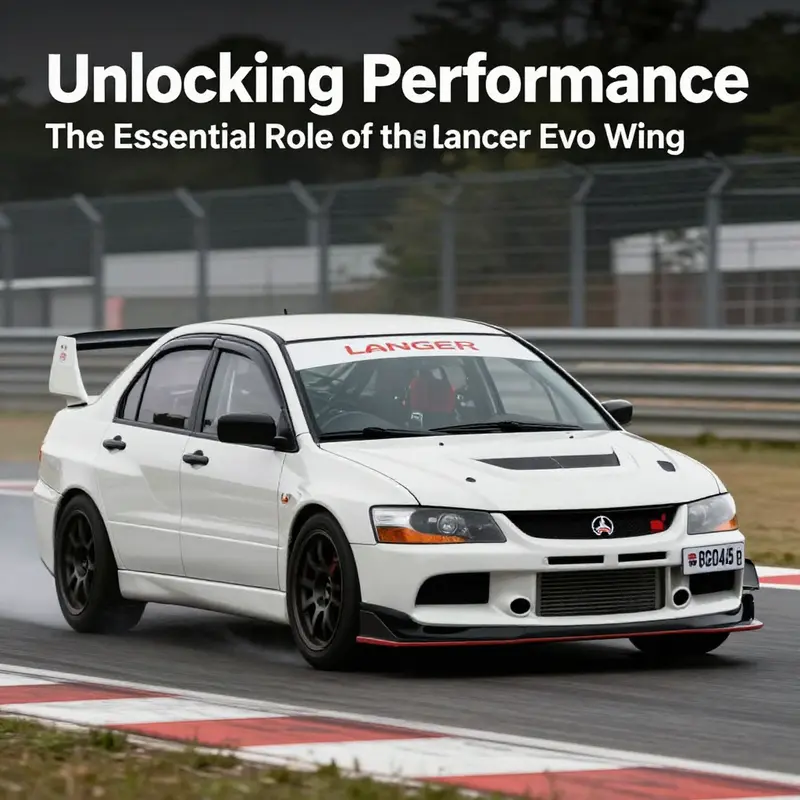

In the world of high-performance sedans, the rear wing on a Lancer Evolution is more than a visual cue of speed. It is a carefully engineered device that translates race-bred aerodynamics into tangible handling advantages. Across generations, from earlier rally-bred iterations to the modern renderings that hint at a continued pursuit of peak performance, the wing stands as a focal point where design meets physics. It is a component that signals intent: a car designed to stay glued to the tarmac at the apex of a corner, to shed lift at the moment high-speed stability becomes crucial, and to balance the car’s overall aero profile with the demands of daily driving. When you study how a wing works in concert with suspension geometry, tire compounds, and chassis stiffness, you begin to understand why engineers in this lineage have treated the rear aero element as more than a flourish; it is a primary instrument for achieving and maintaining control at the limits of grip.

The principle is straightforward in theory, but its execution is intricate in practice. A large rear wing functions by generating downforce that presses the rear tires into the road. At high speeds, this downforce counteracts lift, helping the rear axle maintain tire contact and resist rear-end instability. The effect is most pronounced when the car enters a fast corner or when heavy braking transmits a surge of aerodynamic load to the rear. A well-tuned wing not only increases cornering grip but also stabilizes yaw behavior by shaping the flow under the rear of the car. The bird’s-eye view of a rally-inspired sedan reveals a wing that is proportionate to the body’s mass, its angle of attack carefully chosen to optimize downforce without introducing prohibitive drag that would sap top speed. This balance is the essence of an aero package that looks aggressive yet behaves intelligently on a road that demands both speed and precision.

Historically, the Lancer Evolution’s relationship with rear-wing design has mirrored its racing ascent. In the rally era, engineers learned that the car’s performance was as much about how the aerodynamics kept the rear planted as it was about engine output or suspension tuning. The wing became a signal of the car’s intent to compete at the edge of traction, and in those early iterations the ambition was visible in a large, unmistakable silhouette that could be recognized from the service area to the stage start. As the model matured, this understanding matured with it. The wing evolved from an iconic visual cue into an aero element that required careful integration with the chassis and with the bodywork, especially where the rear deck interacted with the tailgate and the underbody. The result is a design language that speaks to the car’s roots while addressing the needs of modern performance, where wind tunnels, computational fluid dynamics, and real-world track testing converge.

In the evolution of the Lancer Evo, the wing’s role extended beyond adding downforce. It became a symbol of the car’s racing DNA, a constant reminder that the sedan could bridge the gap between a street machine and a competition chassis. The earliest high-downforce configurations were developed in an era when the rally scene demanded reliable, repeatable performance across rough stages and abrupt transitions. The wing’s height, width, and end-plate geometry were optimized to maintain rear traction through long, high-speed straights and into sweeping corners where the angle of the road could suddenly shift the aerodynamic balance. Later generations refined these details, offering adjustable angles or multi-element configurations that allowed drivers or engineers to tailor the aero feel to track conditions or driving style. The name itself has become a shorthand for a philosophy: the car is fast because it is engineered to stay planted, not merely because it can punch out of corners with a loud exhaust note or a luminous shift pattern.

What makes the rear wing so compelling is its interconnectedness with the rest of the aero system. A wing does not operate in isolation; its effects are amplified or muted by the car’s front-end aerodynamics, its wheel arch shaping, and the undertray’s ability to manage vortices and ground effect. In a well-balanced EVO aero package, the wing’s downforce is complemented by a sculpted front splitter, carefully vented fenders, and a diffuser setup designed to reduce turbulent wake. When such an ensemble works in harmony, the car experiences improved high-speed stability, more predictable turn-in, and brakedown that allows the tires to hold a consistent contact patch. The driver perceives this as a chassis that communicates cleanly through the steering wheel, translating driver inputs into confident, linear responses at the limit of adhesion.

The narrative of the wing’s significance is not only about performance; it is also about lineage and identity. Rallying taught engineers that the road is a dynamic, unpredictable surface, and the wing was their answer to that uncertainty. The wing’s presence on classic EVO models—where the rear aero device became a signature element—signaled the car’s purpose as a track-focused sedan that could function as a close-to-the-edge road companion. Each generation carried forward that sense of purpose, even as the car’s daily practicality and emissions regulations reshaped some of the packaging decisions. When modern renderings show a substantial rear wing perched over the tailgate, they are not simply drawing on nostalgia. They are signaling a deliberate aero strategy: that speed on the street is most effective when it is paired with control, when downforce earns its keep by preserving tire grip through corners and during abrupt deceleration.

From a performance perspective, the wing’s effect on handling is inseparable from how the car distributes weight and manages load transfer. During aggressive cornering, the rear wing helps resist lift as the outer front wheel unloads and the vehicle’s pitch shifts under the braking and cornering forces. The result is a more predictable yaw response and a more cooperative chassis attitude as the driver modulates steering, throttle, and braking. This does not come without a cost. The wing inevitably introduces drag, which can reduce top speed if not matched with an efficient front-end and underbody design to manage wake. The best implementations seek to minimize these drawbacks by aligning the wing’s lift with the car’s overall aerodynamic footprint. A well-balanced package uses the wing to extract maximum stability where it matters most—during high-speed straightaways and high-load corner exit—without surrendering drama at lower speeds where daily driving comfort and fuel economy are at stake.

In the context of the Lancer Evolution’s racing heritage, the wing is a visible thread that ties the road car to the competition car. It is a reminder that the Evo’s DNA is not solely about acceleration but about controlled, repeatable performance across a variety of conditions. This heritage is most evident in the car’s WRC years, where aerodynamic strategies were refined through countless rally stages, each presenting unique challenges in terms of surface texture, elevation changes, and weather. The wing’s geometry was honed to deliver consistent downforce across those conditions, a factor that helped the car maintain speed through fast sections and stay planted on loose gravel or damp asphalt alike. The enduring image of the big rear wing, the way it slices through the air above the tail, is more than a nostalgia cue. It is a continuous reminder that the Evo’s engineering focuses on the car’s relationship with the road, with the wind, and with the tires that carry the force of gravity into traction.

Modern owners and enthusiasts who pursue performance-oriented driving often consider upgrading or preserving the wing as part of a broader aero strategy. OEM integrations, or high-quality replicas, can preserve the wing’s structural integrity while optimizing its interaction with the rest of the car’s aero elements. The higher the quality of the wing and its mounting, the more predictable the downforce behavior across the speed range. In practice, this means pairing the wing with a calibrated suspension kit, a tuned dampers setup, and a front aero package that complements the rear’s lift profile. The aim is not to chase a single peak in downforce but to deliver a stable aero balance throughout the car’s operating window. A well-executed upgrade should enhance the driver’s ability to place the car exactly where they want it on the road or the track, with the rear end staying composed under braking and mid-corner transitions. The intelligent choice is to approach the wing not as an isolated upgrade but as a component that demands a holistic view of the vehicle’s dynamics and the driver’s objectives.

The broader lesson for the reader is clear: the Lancer Evolution wing is a material expression of a philosophy. It embodies the idea that performance is earned through a carefully considered blend of downforce, drag, balance, and psychological readiness. It is the physical manifestation of a racing lineage imprinted onto a road-going sedan. When spectators observe renderings or actual cars with a pronounced rear wing, they are witnessing a lineage that has tempered raw speed with disciplined control. The wing, in this sense, is not simply a feature of the car; it is the seal of a performance story that began on a rally stage and continues in modern engineering practice, where aerodynamics remains a central criterion in the car’s overall capability.

For readers who want a sharper sense of how these concepts translate into real-world reference points, consider the way a complete aero package is designed. The rear wing coordinates with underbody surfaces, side deflectors, and front-end lip elements to create a coherent airflow pattern. This pattern minimizes energy loss in the wake produced by the wheels and bodywork and channels high-pressure air toward areas where it can do the most good—supporting the car’s grip in the direction of travel and helping the driver to maintain control during dynamic maneuvers. The result is a tangible, measurable improvement in track performance: faster corner exit speeds, more consistent lap times, and a chassis that responds to steering input with a fidelity that a driver can trust. In the hands of an experienced pilot, that trust translates into smoother, more aggressive lines through corners, a higher level of confidence when the car is asked to push beyond conventional limits, and a driving experience that feels as much like a controlled flight as a road car can be.

The chapter closes with a note on the ongoing relevance of the wing in contemporary interpretations of the Evo’s identity. As renderings and concept previews hint at a contemporary interpretation of the model’s aero story, the wing remains a central element in the narrative. It’s a reminder that the Evo heritage is not merely a collection of performance numbers but a continuous dialogue between track-tested engineering and road-going practicality. Modern aero work respects the past while seeking incremental gains in downforce efficiency and drag reduction, acknowledging that every gram of weight, every degree of wing angle, and every choice in mounting geometry can influence the vehicle’s behavior in the moment when speed, balance, and driver intent intersect on the racetrack or on a late-night highway run. In that sense, the Lancer Evolution wing is not simply a feature—it’s a badge of a performance tradition that continues to evolve, refine, and inspire.

Traditional sources of historical context support this narrative by highlighting the wing’s central role in the Evolution’s racing story. The official history of the brand’s performance lineage notes how aerodynamic features like the rear wing contributed to the car’s capabilities in rally competition and high-speed driving scenarios, shaping a design language that combines aggressive stance with disciplined engineering. The wing’s continued presence in modern visuals and renderings underscores a commitment to the core values that defined the Evo era: precision, balance, and a relentless pursuit of speed under control. This is not merely about moving air; it is about translating that air movement into tangible performance advantages that drivers can feel and rely upon when it matters most.

For readers interested in a deeper exploration of how these aerodynamic features were developed and refined through competition, the historical perspective from the brand’s official channel provides a valuable touchstone. It frames the wing not as a standalone component but as an element embedded within a broader engineering discipline that values reliability, repeatability, and the art of turning data and experience into real-world speed. As you examine current interpretations of the Evo design language, you can appreciate how the wing has maintained its symbolic and functional significance, continuing to signal a lineage that began on rally stages and matured into a sophisticated, track-ready platform for both enthusiasts and professional drivers.

External resource for further reading: For a deeper historical perspective on the Lancer Evolution and its aerodynamic features, including the rear wing’s impact on racing performance, refer to the official Mitsubishi Motors history page. https://www.mitsubishi-motors.com/en/evolution/history/

Internal link reference for related aero components: evo-8-9-varis-front-bumper-with-carbon-lip-2

Relevant source: Official Mitsubishi Motors website detailing the history and technical evolution of the Lancer Evolution, including aerodynamic features like the rear wing and their impact on racing performance.

Final thoughts

In summary, the Lancer Evo Wing exemplifies the intersection of design, performance, and racing heritage. Understanding its aerodynamic role not only enhances appreciation for such engineering feats but also informs business decisions in performance-driven markets. As companies strive to innovate, reflecting on symbols of high performance like the Lancer Evo Wing can inspire new approaches to product offerings.