The rear bumper of the Mitsubishi Lancer Evo X and Proton Inspira is more than just a vital component for aesthetics; it significantly influences vehicle performance and safety. Among various materials available, PP (polypropylene) stands out due to its unique benefits that make it a prime choice for aftermarket replacements. This article delves into the advantages of PP materials, the current market supplies, their applications in bumper design and performance, an economic analysis of using PP, and the environmental implications associated with these materials. Each chapter provides valuable insights for business owners seeking reliable information to enhance their product offerings in automotive accessories and aftermarket parts.

轻量、安全、可持续的护盾:聚丙烯材料在 Lancer Evo X Inspira 后保险杠中的应用与价值

后保险杠在高性能车型的日常使用中承担着重要的安全与功能性任务。

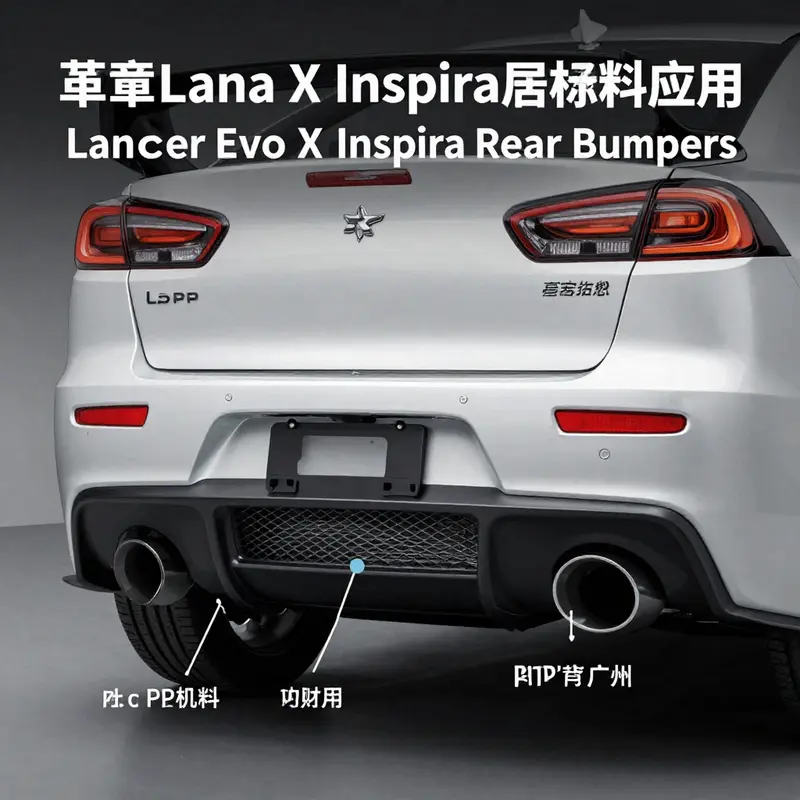

聚丙烯(PP)作为后保险杠的常见基材,提供了良好的冲击分散能力、较低的重量以及出色的成型自由度。对于 Evo X Inspira 这类车型,PP 的应用在安全性、燃油经济性与维护成本之间实现了平衡。

第一维度是能量管理与外观修复性:PP 在低速冲击下能有效分散撞击力,且具备一定自我回弹性,帮助小碰擦后的外观恢复,降低日常维护成本。它也有助于满足行人保护与安全法规对后部结构的要求。

第二维度是重量与燃油经济性:相比金属,PP 往往减重约 30%~50%,从而提升加速响应、转向灵活性与制动效率,并改善整车油耗与排放表现。

第三维度是耐候性与成本可控性:PP 不易生锈或点蚀,具备良好的耐腐蚀性,在日常路况和潮湿环境中表现稳定。注塑成型也使大规模生产及更换成本更具竞争力。

第四维度是涂装与售后协同:PP 表面通常需要专门的底漆和涂装工艺以实现颜色与光泽的一致性,选择合适的供应商与施工流程对于后期外观保持至关重要。

总体而言,PP 材料在 Evo X Inspira 的后保险杠应用中提供了综合性的性价比。若对极致强度有特别需求,可以考虑在专业改装框架内进行材料组合的定制,但这通常伴随成本与加工时间的增加。

The Rear Bumper Dilemma: Material Realities and Market Signals in the Lancer Line

The rear end of a performance-focused hatchback is more than a cosmetic panel. It is a statement about how a car communicates with the road, how a community of owners and modifiers interprets value, and how a sprawling network of suppliers translates a single part into countless variations. In the landscape surrounding the Lancer family and its derivatives, the question of rear bumper material becomes a touchstone for understanding availability, compatibility, and the subtle dynamics that govern aftermarket parts. On markets in Southeast Asia, particularly Malaysia, there is audible chatter about a certain PP-based rear bumper listing tied to a model lineage that blends a rally heritage with compact practicality. The chatter is not merely about color or finish; it is about whether a polypropylene solution can deliver the balance of weight, impact resistance, and paintability that enthusiasts expect when they lift the hood or open the trunk. The reality, however, is more nuanced than a single material label. The materials in play can range from polypropylene to fiberglass composites, and those choices often reflect the supplier’s manufacturing capabilities, the target price point, and the intended use case—whether the piece is meant to be a showpiece, a daily driver, or a track-ready upgrade.

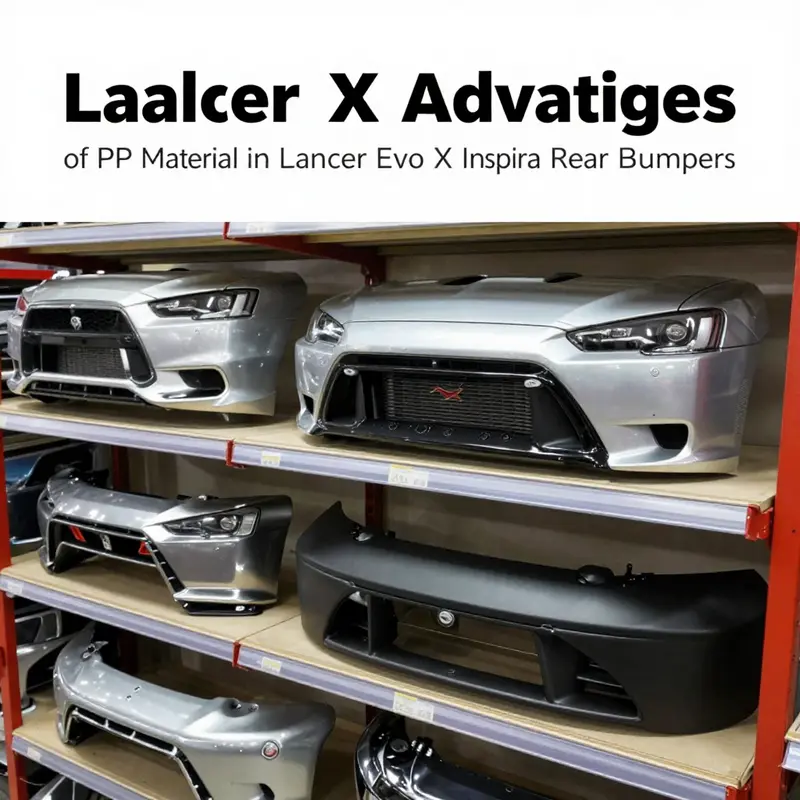

The initial material question, in many listings and conversations, tends to surface as a binary: PP or something else. But the global supply chain that underpins even small online storefronts shows that the landscape is not binary at all. In practice, a rear bumper marketed for the same model family can be made from PP in one batch, and from a fiber-reinforced composite in another. The difference matters. PP is favored for its light weight, low cost, and chemical resistance, which helps with salt spray in coastal climates and makes it easier to mold into complex shapes. Yet PP can behave differently under UV exposure, and its surface may respond to heat and impact in ways that owners learn to manage through protective coatings and careful installation. A fiber-reinforced version may offer stiffness and rigidity that feel premium, but at a higher price and with different mounting tolerances. The market, therefore, rewards clarity on material details, not because one material is universally superior, but because fit, finish, and longevity depend on the material’s inherent properties and the way those properties are harnessed by the maker.

In this context, a question frequently asked by shoppers concerns the relationship between two ostensibly related vehicles: a high-performance hatchback variant and a more utilitarian sedan derived from the same architectural lineage. The two are often conflated in online listings, especially when the term Inspira appears in the same breath as Evo X. In truth, Evo X and Inspira occupy separate corners of a broader family tree. Evo X represents a lineage born in performance debugging, a car tuned for cornering speed and grip. Inspira, by contrast, sits in a more mixed position within the regional market, sharing platform bones with its Lancer relatives but pursuing different branding and market expectations. This distinction matters when evaluating rear bumpers because the mounting points, bumper contours, and load-bearing aspects can diverge. What fits one version of the family may not align with another, even when the outward silhouette appears similar or the part is marketed as a universal solution. This is not merely pedantry. It translates into practical concerns about how a bumper aligns with the trunk line, how the fasteners locate, and how the edge treatments meet the fenders without gaps that become eyesores or, more importantly, safety concerns during low-speed impacts.

The marketplace in Southeast Asia often reveals a mosaic of sourcing stories. On regional shopping platforms, a portion of the listings explicitly state that the product is in stock and ready for shipment, and a noteworthy number identify the material as PP, with the language sometimes translated awkwardly from supplier notes. Such listings offer a practical pathway for owners who want a direct replacement rather than a full cosmetic rebuild. Yet the fine print can be telling: different SKUs may refer to different base materials, different grades of polymer, and different post-processing steps such as priming, painting, or clear-coating requirements. A PP bumper listed as “ready to ship” might still demand additional preparation before it can meet a paint shop’s standards or a body shop’s quality expectations. For the consumer, this underscores the importance of not taking a material label at face value. It is essential to read the item description closely, confirm the exact model compatibility, and understand whether the bumper is a raw, unpainted unit or a fully finished piece.

This is where the practical process of verification becomes part of the buying ritual. A buyer can recognize patterns: listings that emphasize stock availability, those that point to regional fitment notes, and others that curate the material story as a selling point. In some instances, the same model family will have multiple SKU options within the same storefront, each with its own material narrative. The risk of misalignment—buying a bumper that does not mount correctly or that requires significant modification—appears whenever a consumer relies on a single attribute, such as color or price, without cross-checking the technical details. The responsible approach blends a careful read of the product page with a quick cross-check against manufacturer-fit guides or community consensus on fitment. The result is a smoother path from order to installation and a reduced likelihood of discovering, after the crate arrives, that the bumper’s inner geometry clashes with brackets, impact absorbers, or energy-absorbing components behind it.

From a design perspective, the bumper’s surface aesthetics and structural behavior are two sides of the same coin. A PP-based panel can be sculpted to reflect precise contours, and its finish can be refined to a near-OEM appearance when properly primed and painted. But PP’s performance in everyday use hinges on more than a glossy exterior. The material’s resilience to environmental stress—heat, humidity, road salts, and minor impacts—depends on additives, processing methods, and the quality of the molding. A high-quality PP bumper that is intended to be painted typically requires an adhesion-promoting primer and a compatible topcoat to prevent delamination or micro-cracking over time. In contrast, a composite or fiber-reinforced bumper may demand different surface preparation steps, such as abrading the fiber resin interface and selecting a paint system that can bond with the composite matrix. For enthusiasts who plan to swap in a bumper that is not original equipment, the reality is that fitment is seldom dictated solely by model numbers. It is also about how the part was engineered, the tolerance stack in the mounting points, and whether the bumper’s load paths line up with the vehicle’s energy-absorption strategy. The last factor matters for safety, even if the change is cosmetic at first glance.

The practical implications extend to the ownership experience. Even when a PP-based bumper seems to check all the right boxes for weight, price, and availability, the finish and its longevity can depend on who is delivering the part and how it was stored prior to sale. Shipping conditions matter. Temperature swings in transit can affect plastics, especially when the cargo sits in an unheated warehouse or a sunlit curbside during a long layover. A buyer who receives a bumper that shows the wrong texture, an inconsistent color, or minor warping is likely to worry about the post-sale service and the return policy more than the initial bargain. This is another reason why buyers benefit from seeking listings that clearly label not only material but also the scope of preparation—whether the bumper is a bare molding or a ready-to-paint, UV-protected surface. The more transparent the listing, the more confident the customer can be in budgeting time for installation and in planning for a professional paint job where needed.

In this landscape, a small but telling point of reference is a direct product listing that explicitly connects material claims to the specific rear bumper geometry in question. For those who want an explicit, material-verified example, a dedicatedPP-material rear bumper listing provides a useful case study. While it is not a guarantee of universal compatibility, it offers a tangible path to confirm whether a particular PP bumper aligns with the chosen model’s attachment points and edge contours. relevant PP-material bumper listing can serve as a concrete anchor for readers who want to see how such a claim is presented in a real-world marketplace. Of course, the broader lesson remains: always cross-check fitment notes and photos, and be prepared to verify with a seller or a mechanic before committing to a purchase.

Looking outward, the broader discourse on rear bumper options for the Lancer family is not limited to Malaysia or a single online platform. It resonates with buyers across regions who want performance-grade aesthetics without compromising on daily usability. The market responses suggest a continued appetite for lighter, affordable, and readily paintable bumper options, but they also reflect a careful consumer mindset. Owners acknowledge that the rear bumper is a part of the vehicle’s identity as much as its engine, chassis, and tires. The decision to choose PP over other materials, or to select a particular finish and mounting approach, is ultimately a negotiation between cost, compatibility, and confidence in longevity. In this sense, the rear bumper becomes a microcosm of automotive customization: a space where design intent, material science, supplier practices, and personal taste converge to shape a car’s look and feel over time.

External resource: https://mitsubishiautopartsshop.com/2008-2015-mitsubishi-lancer-evo-x-rear-bumpers/

PP材料在Lancer Evo X/Inspira后保险杠中的设计与性能协同:轻量、安全与可持续的综合考量

如需进一步阅读关于PP材料在汽车行业中的应用与趋势,可以参考行业专业资源对高性能聚丙烯在汽车中的应用分析。该类资源对材料改性、填料选择以及与薄壁化设计配合的技术要点提供了系统性的解读,能帮助读者从材料科学的角度理解为何PP成为当下后保险杠的主流选择。外部参考来源: https://www.ptonline.com/articles/high-performance-polypropylene-in-automotive

在前述讨论中,我们也通过内部链接的方式,指向具体的产品信息页以帮助读者理解当前市场上对PP材料的实际应用与可获取性。你可以通过以下内部链接进一步了解该车型族在后保险杠材料方面的实际案例与供应信息: 后保险杠PP材料详情。

Lancer Evo X Inspira rear bumper PP material: a pragmatic look at economy, performance, and longevity

In the world of high-performance compact sedans, the rear bumper is more than a cosmetic edge or a simple shield against road spray. It is a purposeful component that ties together safety, weight, cost, and aerodynamic efficiency. When engineers and enthusiasts talk about choosing materials for a rear bumper, particularly for a model that blends rally-inspired performance with street-legal practicality, polypropylene (PP) often emerges as a compelling choice. The conversation around PP for a rear bumper on a car like the Evo X Inspira is not merely about raw material preference. It is about how a surface that interacts with impacts, pedestrians, weather, and airflow can deliver a balanced equation: safety and resilience at a modest cost, with minimal weight penalties that support dynamic performance. To understand why PP has earned a stable position in this role, one must trace its material characteristics, how those translate into lifecycle economics, and how real-world design considerations shape the final product you encounter on the road, on a shop shelf, or in a workshop bay. The essence of PP as a bumper material lies in its dual capacity to be both affordable and resilient. The raw cost of PP resin is lower than many metals and some advanced composites, and it remains economically favorable even as manufacturing scales up. For a bumper, which is produced through high-volume injection molding, this translates into a predictable, repeatable process with tight tolerances and quick cycle times. This efficiency, in turn, reduces per-unit manufacturing costs, a factor that becomes meaningful as the car ages and the bumper frequently faces scuffs, scrapes, and bumper-cover-level accidents. The economic argument is not simply about the sticker price of a new bumper; it also encompasses the maintenance calendar that a modern car owner must navigate. PP bumpers are easier to repair or rejuvenate than metal counterparts in many common scenarios. Minor cosmetic damage can be addressed with heat-assisted reshaping, gentler surface smoothing, or targeted repainting, which helps preserve the vehicle’s overall value without the need for expensive structural work. In a lifecycle sense, the upfront material and manufacturing cost of a PP bumper is typically dwarfed by the long-run savings from reduced corrosion risk, lower maintenance overhead, and simpler replacement logistics. The Evox-inspired chassis that characterizes the Evo X Inspira—replete with performance-oriented suspension tuning and a relatively rigid body shell—benefits from the PP bumper’s light weight. Every gram saved on the outer shell is a gram less that the engine must move, a small but meaningful contributor to acceleration, braking, and fuel efficiency. In the realm of high-performance cars, fractional improvements can accumulate into tangible on-road gains. A PP bumper’s lightness complements the car’s design goals by reducing inertial load, which helps maintain steering precision during dynamic maneuvers and minimizes unsprung weight. Yet PP is not merely a lightweight part; it is also a material capable of absorbing energy in a controlled manner. Modern PP formulations used in bumper applications are engineered to be tough and ductile, offering good impact resistance at low and moderate speeds. This property is central to the bumper’s job: to deform and absorb collision energy so that more of the impact is spent protecting the passenger compartment and vital structural elements. In this sense, PP serves as a sacrificial layer that works in concert with the bumper’s multi-layer architecture. A typical bumper assembly integrates an exterior PP skin, a foam or energy-absorbing core, and an internal reinforcer that may include steel or aluminum components. The outer skin must maintain shape and stiffness to guide energy absorption, while the inner structure provides the load path that transfers forces away from the cabin. This tri-layer concept is not a luxury; it is a practical design response to real-world crash data, pedestrian protection norms, and regulatory expectations. Standards crafted to reduce leg injuries in pedestrian collisions influence how bumper stiffness is controlled. Modern guidelines encourage a measured rigidity so that the energy is directed into the bumper rather than into vulnerable limbs. In practice, this means an exterior surface that can flex and distribute forces, with a backing that supports the energy-absorbing elements without inviting brittle fracture. For the Evo X Inspira and similar performance models, this balance is critical: it preserves the car’s performance character while adhering to safety norms that protect not only occupants but pedestrians as well. Aerodynamics and airflow are not afterthoughts in bumper design. The rear bumper plays a substantial role in shaping wake patterns and drag characteristics, which in turn influence fuel economy and high-speed stability. A well-designed PP bumper can feature subtle contours and air-guiding lips that reduce turbulence behind the vehicle, contributing to a cleaner flow field. While the aerodynamic payoff of a bumper is incremental compared with larger body surfaces or underbody shaping, every improvement matters when a car is pushed toward its performance envelope. The practical reality for buyers and builders is that PP bumpers come in various flavors. Some listings emphasize the PP composition and indicate them as ready-to-fit, direct replacements. Others may blend materials or offer versions that incorporate fiber-reinforced elements for added stiffness, particularly in high-load areas. The crucial takeaway for anyone evaluating options is to scrutinize the product description carefully, confirming the exact material composition and any structural reinforcements. This is where the marketplace visibility becomes essential: a PP bumper advertised for a performance sedan might still vary in terms of thickness, reinforcement location, or integration with existing crash structures. If you are exploring PP versions for a model like this, you can view a representative listing here: lancer-evo-x-inspira-rear-bumper-pp-material. The link serves as a practical anchor for understanding what to expect in terms of build quality, fitment, and finish. Beyond the raw material itself, the material supplier and the manufacturing process become important signals of value. PP is forgiving in molding, allowing for a wide tolerance window and consistent results across large production runs. But the margin for error exists if the mold design is imperfect or if the polymer grade chosen does not align with the intended operating environment. For owners who live in climates with wide temperature swings, UV exposure, or road salt, choosing a PP bumper that has been properly stabilized against UV degradation and chemical exposure is essential. This is not merely about longevity; it is also about preserving the bumper’s appearance and functional performance across seasons and miles. A practical way to assess this is to examine disclosures about stabilizers, color retention technologies, and the presence of post-processing steps like priming and coating. These factors influence not just aesthetic longevity but how well the bumper resists micro-cracking, chalking, and flexural fatigue after repeated impacts or minor scrapes. When contemplating repairs or replacements, the ease with which a PP bumper can be manipulated without dedicated equipment matters. Small dents might respond to localized heating and shaping, while deeper damage could still warrant replacement of the entire panel. The advantage here is not merely cost; it is operational flexibility. A bumper that can be serviced with basic tools and widely available materials reduces downtime and ensures a vehicle that remains road-ready after routine incidents. It is worth noting that PP is part of a broader spectrum of bumper materials used across the industry, including reinforced composites and, in some cases, fiber-loaded variants. Each material choice carries its own trade-offs in stiffness, impact resistance, and repairability. In the case of a performance-oriented, street-legal model, PP’s combination of low cost, light weight, and resilient energy absorption aligns well with the car’s engineering priorities. It supports the brand’s ethos of delivering a responsive, engaging driving experience without imposing prohibitive maintenance costs. That alignment matters more than the allure of exotic materials because it translates into real-world ownership experience: less downtime, predictable maintenance, and the confidence that the bumper will do its job when the car is pressed hard on a winding road or on a track-inspired highway stretch. For enthusiasts who focus on upgrading or tuning, PP bumpers present a flexible platform for customization. They can be painted to match body color, refinished after curb scrapes, or paired with performance-oriented accessories without heavy modification to the vehicle’s underlying safety systems. In practice, responsible customization involves verifying compatibility with the existing mounting points, ensuring that the bumper’s energy-absorbing zones align with the vehicle’s crash structure, and confirming that any aftermarket accessory integrates without compromising the car’s regulatory compliance or safety performance. The bottom line is that a PP-based rear bumper for a high-performance, street-oriented model balances the essential triad of safety, performance, and cost. It offers reliable energy absorption and resilience without imposing unsustainable weight or expense. The material’s molding versatility supports consistent production, which helps keep pricing predictable and parts availability stable for owners who want to maintain a car with a reputation for spirited driving. As the market continues to evolve, the conversation around PP bumpers will likely incorporate tweaks to resin formulations, improved UV stabilization, and more robust reinforcements in critical load paths. Yet the core value proposition remains: a PP bumper is a practical, intelligent choice for a performance-focused vehicle that seeks to combine dynamic driving enjoyment with sensible ownership costs. External resource: https://www.sae.org/publications/technical-papers/content/2025-01-1234

Green Armor on the Lancer Evo X Inspira: A Deep Dive into the Environmental Footprint of PP Rear Bumpers

The rear bumper of a modern performance compact, especially in a model lineage like the Lancer Evo X Inspira, is more than a cosmetic apron hiding the vulnerable rear fascia. It is a carefully engineered interface that balances aerodynamics, impact energy management, and, increasingly, the environmental footprint of a car’s lifecycle. In recent years, the dominant choice for this vital shell has been polypropylene, or PP, a material that blends cost efficiency, impact resistance, and recyclability in a way that many alternatives struggle to match. The conversation about PP in this context is not merely a matter of material science; it is a lens through which we can gauge how enthusiast-oriented vehicles adapt to tightening environmental standards without sacrificing performance or maintenance practicality. When we look at the Lancer Evo X Inspira rear bumper through this lens, we begin to see how a seemingly small component can embody the broader shift toward sustainable engineering in high-performance platforms. The online marketplace landscape, including regional platforms where such parts are sold as aftermarket or OEM-equivalent products, reflects this shift. Listings that specify PP as the bumper material reveal a market preference for a solution that promises not only compatibility with the car’s geometry and mounting points but also a workflow for repair and end-of-life recycling that aligns with contemporary environmental goals. For readers curious about a PP-based rear bumper for this model, see Lancer Evo X Inspira rear bumper (PP material). In this chapter, we explore why PP has earned its place, what that means for eco-conscious drivers, and how the material performs across the bumper’s entire life cycle.

PP, as a thermoplastic polymer, offers a suite of properties that propel it to the forefront of automotive bumper applications. Its recyclability is a central virtue. In practice, PP parts can be ground, melted, and remolded into new products, which translates into a closed-loop potential for the bumper itself and its related interior or exterior components. Industry estimates from plastics associations emphasize that automotive PP recycling rates have risen, driven by improvements in sorting technologies and the increasing adoption of recycled PP in non-critical sections of vehicles. This progress matters for the Evo X Inspira’s rear bumper because it typically sits low in the car’s energy absorption hierarchy. When a bumper endures minor collisions or cosmetic scrapes, the modular design—where the outer shell, energy-absorbing foam, and mounting frame can be separated—means that a single component may be replaced rather than the entire bumper assembly. That modularity reduces waste and can keep a higher fraction of the original materials out of landfills, a practical payoff that aligns with broader environmental directives.

The environmental appeal of PP extends beyond end-of-life considerations. The production footprint of polypropylene is generally lighter on energy than many metals used for bumper substrates. While high-strength steels and aluminum panels have their roles in structural components, PP’s lighter mass translates into a lower energy input per unit of vehicle mass during manufacturing. And because the bumper is a relatively large exterior part, even small reductions in its weight can translate into measurable fuel economy improvements over a vehicle’s lifetime. In the context of a performance-oriented model like the Evo X Inspira, where enthusiasts often rack up kilometers quickly, every kilogram saved in the bumper can contribute to a modest but meaningful reduction in fuel consumption and, by extension, lifecycle emissions. The net effect is that PP, when used in bumper shells and related exterior panels, can contribute to a lighter, more efficient vehicle without compromising safety or aesthetics.

A further environmental advantage of PP lies in its surface resilience and compatibility with durable finishes. Official eco-friendly coatings, including water-based or low-VOC paints, can be applied to PP bumpers without sacrificing adhesion or color consistency. Where some metal parts require multi-step priming to prevent corrosion, PP paint processes can be engineered to achieve durable, long-lasting finishes with fewer hazardous solvents. This intersection of material chemistry and coating technology reduces the potential release of volatile organic compounds during manufacturing and over the bumper’s service life. In the Evo X Inspira’s rear-end design, where the bumper must visually integrate with a sculpted tail and, potentially, integrated exhaust accents, the ability to hold a consistent finish while maintaining environmental performance is valuable. The synergy between PP’s surface compatibility and modern low-VOC coatings helps ensure that the visual appeal of the bumper remains intact across years of operation.

Yet no material choice is without its environmental caveats. A salient concern associated with PP is microplastic release through wear and abrasion. As a bumper endures road debris, stone chips, and weathering, tiny plastic particles can dislodge and disperse into the environment via wind, runoff, or atmospheric deposition. This risk is not unique to PP; it accompanies most durable polymeric exterior parts. The industry response includes enhancements to top-coats that resist micro-scratches and the addition of wear modifiers that slow surface degradation. In the long run, better aging performance means fewer particles entering sensitive ecosystems, which is a meaningful environmental gain given the scale of global automotive use. Additionally, the balance between performance and recyclability continues to shape the material’s evolution. Engineers are investigating how filler strategies, such as short glass fibers or mineral fillers, can bolster stiffness and impact resistance without derailing recyclability or inflating energy use in production.

Another facet of the PP equation concerns the regional and global supply chain. In markets where car parts are bought online—such as regional e-commerce platforms—the exact material specification must be verified on the product page. The reality is that some listings may describe a PP bumper while others rely on different polymers or reinforced composites. That reality underscores the importance of careful due diligence: buyers should confirm the material description, confirm whether the bumper is a direct-match replacement or a close-finish alternative, and inspect the return policy in case the material differs from expectations. The Evo X Inspira’s rear bumper, when sourced from online vendors, sits at a crossroads between performance ideology and practical sustainability. The PP option supports a life-cycle approach that favors recycling and reduced energy for manufacturing, but the success of that approach depends on transparent product specifications and consistent post-purchase handling.

The environmental narrative for PP bumpers also intersects with policy frameworks that govern vehicle material stewardship. Regulations that encourage or require higher recycling rates for end-of-life vehicles push manufacturers toward modular designs and recyclable polymers. While these policies vary by region, they collectively incentivize solutions that reduce landfill waste and lower the carbon footprint of the automotive supply chain. Per the European Union and several national programs, vehicle designers are urged to consider material recoverability alongside impact performance. The Evo X Inspira’s rear bumper, with its repair-friendly structure and potential for recycled-content plastics, serves as an instructive case study in how performance cars can align with such policy directions without compromising driving dynamics. In practice, this means a bumper that is not merely a consumer item but a component that embodies a philosophy of circular design—one that favors disassembly, material separation, and repurposing rather than obsolescence.

From a consumer perspective, there is also a practical dimension to this environmental calculus. Enthusiasts who pursue performance upgrades naturally weigh weight, rigidity, and aerodynamics against cost and maintenance. PP bumpers provide a compelling combination: reasonable stiffness for the aerodynamic needs of a high-performance compact, resilience to minor impacts from daily driving, and a repair ecosystem that eschews more invasive replacements in favor of targeted panel swaps. The Evo X Inspira rear bumper, in its PP incarnation, becomes a tangible example of how sustainable engineering can coexist with a culture of speed and customization. For those who want to validate the material on a specific listing, the internal link above points to a page that offers direct insight into the PP specification for this model’s bumper, helping readers bridge theory with on-the-ground shopping realities.

The conversation about sustainable materials is not solely about what is most environmentally friendly in a vacuum. It is about what works best within a vehicle’s overall design, manufacturing, use, and end-of-life system. PP’s environmental narrative for the Lancer Evo X Inspira rear bumper is strongest when viewed as part of a broader design philosophy: choose materials that support lightweight performance, enable efficient repair, and fit into a recycling ecosystem that reduces waste. When those criteria are met, the bumper becomes more than a protective shell; it becomes a responsible choice that aligns high-performance aspiration with a sensible environmental trajectory. This alignment matters to engineers who must balance crash energy management with recyclability, to suppliers who must communicate material specifics clearly to buyers, and to drivers who increasingly want to know the environmental imprint of every component they replace.

In sum, the rear bumper of the Lancer Evo X Inspira, when manufactured from PP, embodies a pragmatic and forward-looking approach to sustainability in performance cars. The material’s recyclability, lower production energy, and potential for weight reduction collectively contribute to a smaller lifecycle footprint relative to heavier, less recyclable alternatives. While challenges like microplastic release and uneven regional recycling infrastructure persist, ongoing materials research, improved coating technologies, and supportive policy frameworks are steadily narrowing the gap between performance and responsibility. For enthusiasts and engineers alike, PP bumpers offer a compelling path forward—one that preserves air-curved aesthetics, supports dynamic handling, and honors the growing demand for smarter, cleaner automotive design. External resources on the broader landscape of automotive plastics and recycling can be found here: https://www.pcauto.com.cn/tech/insurance/5921231.html

Final thoughts

The use of polypropylene (PP) for the rear bumpers of the Mitsubishi Lancer Evo X and Proton Inspira emerges as a strategic choice for both performance and sustainability. Its advantages in durability, cost efficiency, and environmental friendliness align with the evolving demands of automotive consumers. For businesses, investing in PP materials can enhance product differentiation and customer satisfaction while supporting eco-conscious practices. As the automotive market continues to innovate, understanding and leveraging the properties of PP will be crucial for staying competitive and responsible.