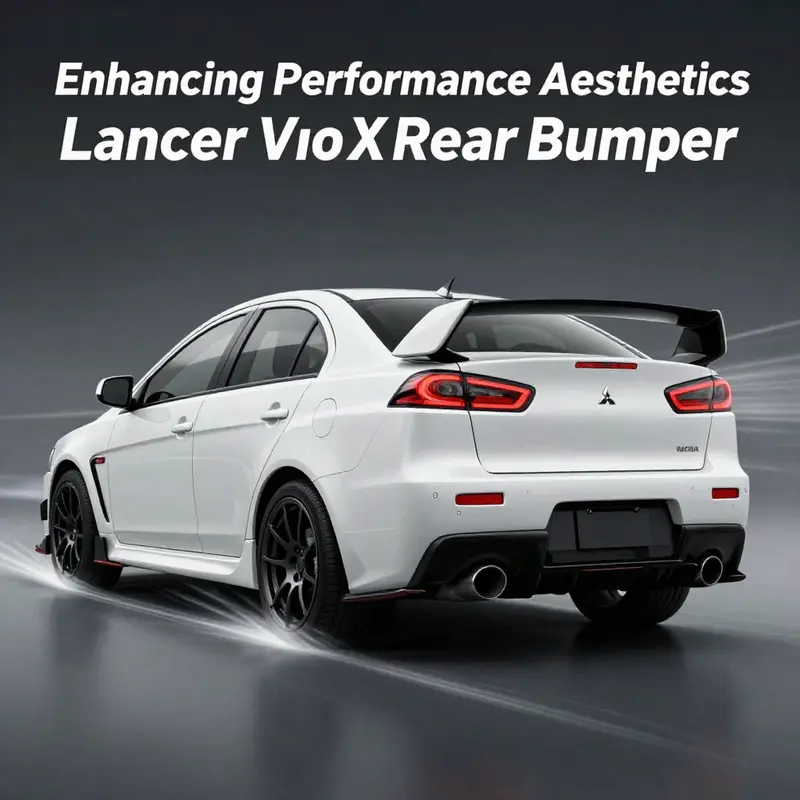

The rear bumper of the Mitsubishi Lancer Evolution X is more than just a protective element; it is a vital component that enhances both the vehicle’s aesthetics and aerodynamic performance. As business owners in the automotive aftermarket parts industry, understanding the intricacies of the Lancer Evo X rear bumper can help you effectively cater to your clientele, comprising both everyday drivers and performance enthusiasts. This article will discuss the materials used in these bumpers, the aerodynamic benefits they provide, installation considerations, styling options, and their applications in performance driving. By delving into each chapter, you will gain insights that are crucial for positioning your products effectively in the market and meeting your customers’ needs.

Forged for Impact and Aerodynamics: Material Secrets of the Evo X Rear Bumper

Material Anatomy of the Evo X Rear Bumper

The Mitsubishi Lancer Evolution X rear bumper is more than a cosmetic flourish. It represents a carefully engineered fusion of materials designed to absorb impact, shape airflow, and resist the rigors of street and track driving. Whether tackling daily commutes or spirited track sessions, understanding the underlying material composition reveals why this bumper delivers strength, flexibility, and style without unnecessary weight.

Most factory rear bumpers on 2008–2015 Evo X models are crafted from injection-molded ABS plastic. This thermoplastic is renowned in the automotive industry for its balance of toughness and lightness. Engineers begin with high-grade ABS resin pellets, melted and precisely injected into custom tooling. The result is a seamless outer shell that can be painted in any OEM color and finish, while maintaining consistent rigidity across complex curves.

Beneath the visible shell, manufacturers integrate internal foam absorbers. These energy-absorbing inserts compress under low-speed impacts, dispersing force away from critical components such as the trunk lid, taillight assemblies, and rear suspension mountings. By combining a tough exterior skin with a crushable core, the bumper maintains its shape during cosmetic scrapes but still cushions slightly harder bumps, reducing repair costs and keeping the Evo X structurally intact in parking-lot collisions.

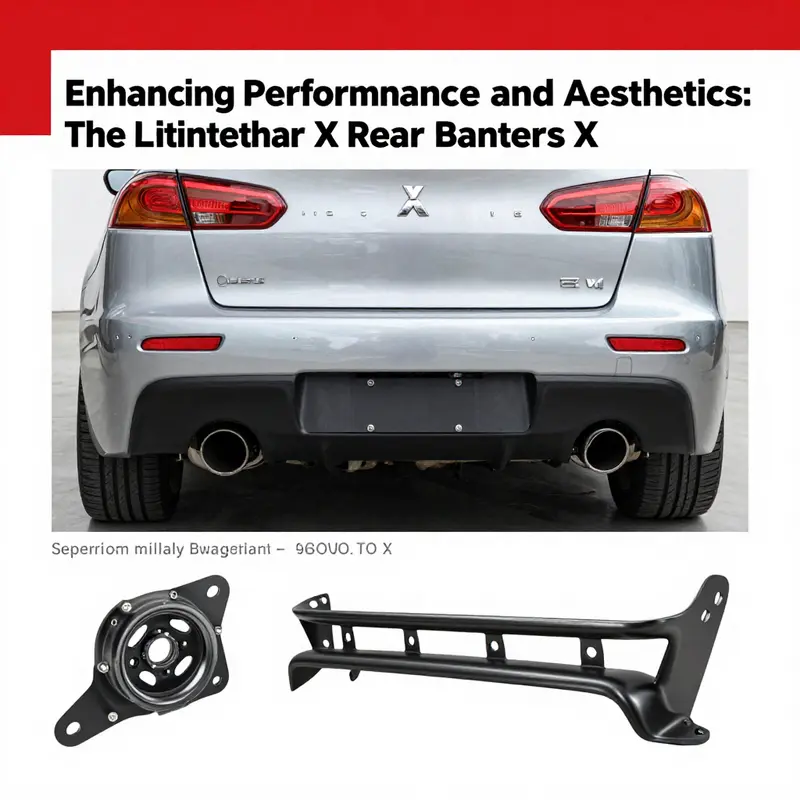

Steel reinforcement beams often form the third layer. Strategically positioned along the bumper’s backbone, these stamped steel bars enhance mounting stability and help the bumper remain securely attached during abrupt deceleration or misaligned impacts. They maintain the proper gap between bumper and chassis rails, ensuring that energy transfer follows designed crush zones rather than damaging brittle plastic panels.

Beyond impact protection, the injection-molded ABS design allows integrated aerodynamic features. Subtle channels and vent shapes can be molded directly into the bumper, guiding airflow across the rear diffuser area and smoothing wake turbulence at high speed. Even small design tweaks—like inset fins or underbody passageways—can improve rear downforce by redirecting air smoothly under the car, boosting stability on mountain roads and racetracks alike.

Aftermarket manufacturers see opportunity in reshaping airflow and reducing weight further. Many popular Evo X V3 Style rear bumpers use hand-laid fiberglass. This composite trades some impact resilience for a slight weight reduction, often shaving several pounds over ABS units. Fiberglass panels can adopt more aggressive diffuser angles or larger exhaust outlet surrounds, giving the Evo X a racing-inspired presence with deeper cutouts and sharper lines.

These aftermarket bumpers require careful fitting. Fiberglass chatter and minor warping can occur if mounting holes aren’t perfectly aligned. Unlike OEM ABS, fiberglass rarely flexes under load, so even moderate impacts risk permanent cracks. Enthusiasts who choose a fibreglass option typically accept that occasional repairs or reinforcement patches will be necessary, especially when pushed hard on rough road surfaces.

Selecting an aftermarket piece also means checking for sensor compatibility. Factory Evo X bumpers support reverse cameras and parking sensors with pre-cut mounting points. Many fiberglass replacements skip these features to simplify molds, so owners must retrofit brackets or drill new holes for sensors. Those wanting a seamless installation often source conversion kits or work with a body shop to integrate OEM hardware into the custom bumper.

Polyurethane is another alternative seen in performance circles. Polyurethane bumpers maintain flexibility under impact, resisting cracks that might plague fiberglass. They can be molded with complex shapes, yet rebound nearly to their original form after a minor collision. The trade-off is a modest weight increase compared to ABS, and some grades may yellow over time if exposed to harsh UV rays without proper coatings.

For those chasing the ultimate in lightness, carbon fiber rear bumpers emerge as track-only options. High-modulus carbon weaves are laid into pre-formed molds, then cured under heat and pressure. These parts can weigh half as much as ABS, but they lack the built-in crush characteristics of multi-layer systems. A carbon fiber bumper can shatter under moderate impact, leaving owners with expensive replacements and no sponge or steel reinforcement to soften the blow.

When deciding between ABS, fiberglass, polyurethane, or carbon fiber, consider your priorities: daily reliability demands durable ABS with repair-friendly paint finish. Track performance leans toward stiffer fiberglass or lightweight carbon fiber, understanding that brittle failure becomes more likely when pushed to extremes. Polyurethane sits comfortably in the middle, offering a blend of flexibility and detail fidelity.

One of the most practical considerations is compatibility with existing mounting hardware. License plate brackets, washer nozzle hose ties, and factory hood prop rod mounts may not line up on aftermarket shells. Some Evo X bumpers lack a built-in license plate bracket, requiring a relocation bracket kit. Others force you to re-route washer fluid hoses or find alternative tie points. Taking time to inspect the bumper’s mounting flange pattern against your chassis rails can prevent surprise modifications during installation.

Maintenance and repair also vary by material. Scratches in ABS are often sandable and repainted without complex prep. Fiberglass cracks demand epoxy or resin patches. Polyurethane tears can be welded or re-shaped with specialized adhesives. Carbon fiber panel repairs rely on re-lamination—an involved process best left to composites specialists.

Beyond the main material choice, infusion-style manufacturing can inject stiffeners or composite fibers into ABS to boost strength without adding weight. High-impact ABS blends may include reinforcing agents, giving better rock-chip resistance on rally-style Evo X builds. These advanced resins blur the line between pure plastic and a lightweight composite.

A final note on environmental factors: ABS and polyurethane both respond well to standard automotive primers and topcoats, maintaining UV resistance when properly finished. Fiberglass needs a sealed gel coat to resist moisture ingress and prevent blistering. Carbon fiber must be sealed under clearcoat to shield epoxy from UV degradation.

For Evo X owners seeking an OEM-like fit with plenty of aftermarket style options, browsing a catalog of Evo X rear bumpers can reveal numerous ABS, polyurethane, and fiberglass designs. Careful comparison of material pros and cons ensures your choice aligns with your driving demands.

For a complete guide on selecting the ideal bumper material and tips on proper installation, see this external resource: How to Choose a Bumper for Lancer Evo X – Full Guide.

Air, Downforce, and the Evo X: The Rear Bumper as a Quiet Architect of Speed

The rear bumper on a Lancer Evolution X is more than a styling cue or a simple protective shell. It is a carefully integrated piece of the vehicle’s aerodynamic system, designed to work in concert with the car’s overall silhouette and its undercarriage to manage the flow of air at speed. When you consider the Evo X as a complete package, the rear bumper’s shape, openings, and connections to the rest of the aero components become a focused lesson in how form supports function. The result is a balance between visual aggression and functional efficiency, a combination that matters most when the car is driven hard on road courses or pushed along a highway at speed. In this sense, the rear bumper serves as a relatively small component with a disproportionate impact on stability, grip, and the precision that the chassis communicates to the driver at the limit.

From the outset, the bumper’s role is to sculpt the wake created by the car’s rear quarters. The Evo X is designed to channel air smoothly from the sides toward the rear diffuser and along the underbody panels. This coordinated air management reduces the size and strength of the turbulent vortices that form behind the wheels and body. By guiding air in a controlled manner, the bumper helps keep the rear flow cohesive, which in turn reduces drag and helps the car stay planted at higher speeds. The downstream effect is an increase in downforce at the rear axle without a corresponding rise in overall lift or unwanted drag penalties. The bumper, diffuser, and underbody components operate as a system, each part reinforcing the others to sculpt a stable, linear response when the throttle is pressed and the steering wheel is asked to place the car precisely where the driver intends.

A closer look at the bumper’s integrated features reveals how aerodynamic intent translates into measurable performance. Many bumpers for this platform incorporate ducts or vents that subtly guide air away from the chassis where it would otherwise spur unwanted heat buildup or wake formation. Small air channels can direct a portion of that rear-bound air toward the sides or upward along the body where it can be shed more cleanly without creating harmful back-pressure at the trailing edge. Even when the openings are modest, their strategic placement matters. They act as pressure relief points that prevent the rear from becoming a suction zone or a vortex factory, a problem that can manifest as lift-induced instability under aggressive driving scenarios. In practice, this translates to a more predictable yaw behavior and a more confident line when negotiating a high-speed sweep or a fast corner exit.

Another explicit design cue is the presence of integrated exhaust outlets and the way the bumper accommodates the exhaust angle and diameter. When exhaust outlets are designed to sit flush with the bumper’s contour, the exhaust plume exits cleanly, reducing the chance that hot exhaust flow disrupts the surrounding air as it mixes with the vehicle’s wake. The alignment of these outlets also helps manage the sound and the boundary layer around the rear fascia, which, while aesthetically pleasing, also contributes to the overall efficiency of air removal from the car’s rear quarters. In conjunction with the diffuser’s central blade and any side diffusers, these elements keep the rear wake tight and steadily directed downstream rather than curling upward or outward in a way that would promote drag and lift.

The performance mindset behind the Evo X rear bumper extends beyond the stock configuration. Aftermarket alternatives exist that take aerodynamic refinement further, often backed by computational fluid dynamics testing and wind-tunnel validation. These advanced designs aim to coax more downforce with less drag, a two-for-one improvement that is especially valuable on track days when every aerodynamic gain compounds with driver skill to shave seconds from lap times. The trade-off, of course, is that aggressive aero work must still meet safety standards and maintain structural integrity. A bumper that promises greater downforce must not compromise impact resistance or the ability to transfer loads safely to the chassis in the event of a collision. In the end, the best aerodynamic bumpers for this platform provide a cohesive air-management story: they improve how air behaves around the car without forcing the system to work harder than necessary to achieve that behavior.

To appreciate why rear-end aerodynamics matter so much on the Evo X, it helps to imagine the car moving at high speed with and without an aerodynamically tuned bumper. At lower speeds, the bumper’s influence is subtle, a whisper of efficiency that translates into a quiet, confident feel. As speed increases and the car begins to push against the air more aggressively, the bumper’s job becomes more crucial. It helps maintain rear stability, improves the likelihood that the tires stay planted, and reduces the tendency for lift to soften the rear suspension’s dynamic response. In a car with balanced weight distribution and a responsive chassis, the bumper’s contributions become a part of the driver’s ability to place the car in a turn, hold a line, and commit to a throttle application with reduced fear of rear-end instability. This is where the rear bumper earns its reputation not as a mere cosmetic shell but as a working component of the Evo X’s performance envelope.

Material choice also intersects with aerodynamics and durability. The vast majority of OEM and aftermarket bumpers for this platform rely on an impact-resistant thermoplastic—commonly ABS—for its combination of resilience, affordability, and ease of repair and repainting. ABS offers enough rigidity to hold the bumper’s form under normal driving conditions and moderate impacts while remaining lighter than many metal-based alternatives. It’s not the stiffest material available, and it can be more susceptible to deformation in extreme impacts or very cold temperatures, but for most street and track-day use, ABS bumpers deliver a durable, economical solution that can be repaired without the need for specialized tools or processes. The weight savings over metal bumpers help the overall vehicle dynamics indirectly by preserving suspension travel and reducing the unsprung mass that a car carries at the rear. While it won’t match the rigidity of polyurethane or the lightness of carbon fiber in absolute terms, ABS remains a practical and widely accessible option that aligns with the Evo X’s balance of performance and daily usability.

When considering an upgrade or replacement, drivers encounter a spectrum of choices that reflect different priorities. Some bumper designs emphasize a more aggressive stance and a more aggressive aero silhouette, while others seek to preserve or refine the stock flow. In all cases, the underlying principle remains the same: any rear bumper that purports to enhance performance must be consistent with the car’s intended aero map. It should cooperate with the diffuser and underbody panels, align with the wheelbase geometry, and avoid creating new vortices or pressure pockets that would work against the car’s stability. This is not merely a matter of appearance; it is a test of how well the bumper integrates into a holistic aero strategy that your Evo X uses to deliver confidence under pressure.

For enthusiasts who want to understand the technical rationale behind choosing a bumper for the Evo X, there are dedicated resources that dive into how to evaluate different designs, the balance between drag and downforce, and the importance of maintaining overall structural integrity. A contemporary guide outlines how to assess the voiture’s aero needs, how to interpret CFD results, and how to translate that information into a practical selection for road use or track work. A useful starting point for anyone seeking a deeper, more structured approach is a comprehensive overview that connects airflow management with practical installation considerations. This guide also reminds readers that a bumper is part of a broader ecosystem that includes diffusers, vents, and underbody panels, all of which contribute to the car’s aerodynamics in concert rather than in isolation.

Internal links can help readers quickly locate relevant bumpers that suit the Evo X’s design language and mounting points. For instance, a resource focused on the 2008–2015 Evo X rear bumpers provides a concise snapshot of compatibility, mounting nuances, and how these parts relate to the vehicle’s existing structure. Such a reference can serve as a practical map for owners contemplating a bumper swap or a refinement project. 2008-2015 Mitsubishi Lancer Evolution Evo X rear bumpers offers a straightforward overview of fitment and integration considerations that users commonly encounter during installation. The goal is not to fixate on a single option but to understand how various designs align with the Evo X’s aerodynamic philosophy and the driver’s performance objectives.

From a broader perspective, the rear bumper’s aerodynamic role sits within an ecosystem of performance-oriented design choices. It interacts with a rear diffuser that helps manage the exit flow and with the underbody panels that smooth the air that travels beneath the car. The bumper’s shape can subtly influence the speed at which wake dissipates, which in turn affects tunnel effects around the axle and the rear tires. When well executed, this synergy yields a more linear steering feel and a more predictable response to throttle inputs as one exits a bend. In track conditions, such coherence between bumper, diffuser, and underbody is not optional; it is a critical factor in sustaining grip and minimizing fluctuations in stability that can interrupt a driver’s rhythm. The Evo X, by design, invites that coherent aero narrative, and the rear bumper is a central character in that story.

For readers seeking actionable guidance that blends theory with practical steps, a respected full guide on bumper selection emphasizes evaluating the bumper as part of a system. It recommends examining how air moves around the rear, assessing potential impacts on cooling, and verifying mounting points to ensure compatibility with existing chassis hardware. It also underscores the importance of safety considerations, such as maintaining structural integrity in the event of a rear impact, which is part and parcel of choosing any performance-oriented bumper. In other words, the rear bumper is not merely a matter of looks or a single performance tweak. It is a connected decision about how your Evo X breathes, sticks, and travels through space at speed.

As the Evo X platform continues to attract drivers who value both form and function, the rear bumper remains a focal point for those who want to tune airflow without losing street practicality. The lesson is clear: even small aerodynamic refinements at the rear can translate into meaningful gains in stability and cornering confidence when pushed to the limit. The bumper, with its integrated ducts and thoughtful geometry, embodies a philosophy of engineering where aesthetics and performance coexist. It demonstrates how the Evo X’s design language translates into real-world behavior, turning a bold rear silhouette into a purposeful machine that communicates its intent to the road with every straightaway and every corner melt.

External resource for deeper technical depth on choosing a bumper for the Evo X, including CFD considerations and safety constraints, can be found here: How to Choose a Bumper for Lancer Evo X – Full Guide.

Rear Bumper Realities: Fitting, Fabrication, and Aerodynamic Edge on the Lancer Evo X

The rear end of a Mitsubishi Lancer Evolution X is where performance becomes personality. The bumper is more than a cosmetic shell; it is a carefully engineered element that shapes airflow, manages underbody pressure, and cues the eye to a stance that speaks of speed even when the car is at rest. For enthusiasts, choosing and fitting a rear bumper is a decision that blends aesthetics with engineering, especially when the goal is to extract meaningful gains in handling and stability at high speeds. The Evo X crowd often leans toward bumpers designed to fit the model’s distinctive geometry, offering routes to a more aggressive silhouette while preserving or enhancing aerodynamics. This is not merely about slapping on a new look; it is about ensuring the rear end works in harmony with the rest of the car’s aero profile, the weight balance, and the mechanical interfaces that keep the vehicle safe and drivable on road and track alike. When the bumper is designed for the Evo X’s unique chassis, it can elevate the car’s visual impact without compromising the function that makes the Evo X a standout in performance driving.

At the core of any rear bumper choice is the fitment type. Aftermarket options must be engineered for the Evo X’s exact dimensions and mounting geometry. A bumper that does not align with the factory mounting points, body lines, and bumper beam can throw off the important aero cues that keep airflow on a predictable path. Misalignment can produce unintended gaps, disrupt the intended airflow channels, and even introduce unwanted vibration that travels up the chassis at speed. The reality is simple: precision fitment saves time, reduces the risk of bodily harm to the car’s structure, and preserves the intended performance characteristics. For Evo X owners, this means seeking a bumper that explicitly claims compatibility with the Evo X’s range of years and trims, typically 2007 through 2016, so that the rear fascia integrates with the car as the engineers designed it to.

Material durability is another pillar of the rear bumper conversation. ABS plastic has become a default choice for many aftermarket bumpers because it blends impact resistance with affordability and paint adhesion ease. It is forgiving in daily driving and resilient enough for occasional parking lot bumps, yet it remains robust enough to withstand the scuffs and scrapes that accompany street use. Yet, ABS is not the end of the road for performance enthusiasts. Some builders offer fiberglass or composite options for those seeking a lighter weight or a different shaping tolerance, though fiberglass tends to crack more easily under extreme stress or temperature swings. Carbon fiber variants exist as well, promising the best in stiffness-to-weight ratio, but they push the price point higher and often require more meticulous installation and finishing work. The choice of material circles back to the use case: daily-driven Evo Xs benefit from resilience and repairability, while track-focused builds may justify the extra cost and care associated with carbon fiber or reinforced composites.

Compatibility with existing components sits high on the priority list. A bumper is not a standalone shell; it must play nicely with the car’s taillights, license plate mounts, and any sensors that might be present—parking assist, reverse cameras, or proximity sensors. Some aftermarket kits demand changes to wiring harnesses or bracketry, which can complicate installation and potentially affect warranty coverage if not performed correctly. It is essential to confirm that the bumper integrates with OEM taillights and mounts, and to verify any minor modifications that may be required for license plate relocation or washer nozzle hoses. The Evo X’s rear corner architecture is tuned to manage venting and diffuser alignment; aftermarket pieces that disrupt these channels can degrade handling or create unwanted noise and turbulence. The practical implication is that you should approach compatibility as a systems question, not a single part swap.

Installation method and alignment demand equal attention. A bolt-on bumper is the simplest route, but many Evo X rear bumpers rely on an adhesive-bonding process or a combination of fasteners and bonding to achieve the strongest seam and the best aero results. Improper installation risks gaps that disrupt airflow, reduces diffuser effectiveness, and can even lead to detachment at high speeds if the bumper is not properly secured. A clean alignment with the body lines—particularly at the wheel arches, the rear hatch edge, and the base of the bumper—helps maintain a coherent silhouette and predictable airflow paths. Given the Evo X’s tendency to display a race-inspired stance when accessorized, the alignment must be undertaken with care, using proper clamps, supports, and, ideally, a technician who understands Evo X bodywork. The presence of added features like integrated diffusers or exhaust outlets further shifts the installation dynamics, amplifying the need for precise mounting and sealing throughout the rear fascia.

The practical installation narrative for a rear bumper includes a handful of nuanced steps. Before any hardware is tightened, a careful test fit is essential. This allows you to map out where shims or minor trimming might be necessary and to confirm that all mounting points align with factory anchors. When securing the bumper, technicians often check the continuity of the aero seams with the body panels and ensure the vertical and horizontal gaps honor the natural lines of the car. If a diffuser or an integrated exhaust outlet is part of the kit, the alignment must also consider the exit path and the surrounding bodywork to avoid interference with the exhaust flow or with the bumper’s edges catching on road debris. The use of appropriate hardware, including bolts, nuts, and thread locker as needed, reduces the risk of loosening under high load while maintaining a clean, uniform appearance.

Beyond the mechanics of fitment, the Evo X bumper’s impact on aerodynamics deserves careful consideration. The redesigned shape of many rear bumpers in this category seeks to optimize how air travels around the rear wheels, exits the underbody, and helps generate structured rear downforce at speed. The diffuser elements, if included, guide air beneath the car in a way that reduces suction and helps stabilize the rear end on straightaways and during cornering. A well-executed rear bumper also harmonizes with the undertray and side skirts, creating a coherent aero narrative that supports the car’s overall balance. It is not merely about adding stiffness or reducing drag; it is about shaping a controlled wake behind the Evo X so that turbulence does not feed back into the rear suspension or the diffuser’s performance. For the purist, this means selecting a bumper that respects the Evo X’s existing aero philosophy, rather than simply slapping on a silhouette that looks aggressive but performs unpredictably.

The rear bumper’s role in daily driving versus track use is another axis of consideration. ABS-based bumpers offer durability for everyday commutes and occasional track days, while more specialized builds might explore reinforced materials or even composite options to shave weight and extract marginal speed gains. The cost differential reflects the investment in performance: carbon-fiber or high-strength composites demand higher price tags and more dedicated installation, but they can yield meaningful gains in weight reduction and rigidity. When weighing these options, it is wise to consider the frequency of track days, the reliability of the vehicle on public roads, and how the bumper’s design interacts with cooling, braking, and suspension calibration. A bumper that looks the part but neglects these functional details risks diminishing the Evo X’s proven balance.

Color and finish complete the picture. A bumper must be painted and finished to match the vehicle’s color and gloss, and it should be prepared for rock chips and road debris. The painting process benefits from the bumper’s material properties; ABS takes paint well and handles color matching predictably, while fiberglass or carbon-fiber-laced options may require additional prep steps to achieve an even tone and sheen. Because rear fascia color can be a focal point in a car’s stance, many owners budget additional time for a meticulous finish that highlights the bumper’s lines and textures rather than masking them with heavy coatings. The end result should be a seamless integration with the rest of the Evo X’s exterior, a look that communicates confidence and performance without appearing heavy-handed or mismatched.

In the end, the decision to fit a rear bumper on an Evo X is a blend of fitment accuracy, material choice, and installation care. For readers seeking a resource that consolidates compatibility details and product assessments, a comprehensive guide to choosing a bumper for the Lancer Evo X can be a valuable companion. It helps align the practical steps of selection with the realities of vehicle dynamics and road use, ensuring the choice supports both the car’s performance envelope and its visual identity. Internal links to product-specific pages can provide direct, model-relevant options while reinforcing the practical considerations discussed here. For Evo X owners exploring rear bumper options, a curated destination that concentrates Evo X bumper availability and compatibility can serve as a practical starting point: 2008-2015 Mitsubishi Lancer Evo X rear bumpers.

As you consider the broader ecosystem around the Evo X’s rear fascia, it is valuable to acknowledge the balance between performance-driven goals and everyday usability. The rear bumper must not only survive incidental contact but also contribute to a predictable and stable driving experience. The integration with the vehicle’s electrical and mechanical systems matters as much as the bumper’s face. If you plan to add sensors or a camera system, confirm wiring harness compatibility early in the process and prepare for potential harness routing or connector changes. A well-planned installation reduces the chance of warranty concerns and ensures that the car remains a reliable everyday driver even as its rear end embraces a more aggressive, race-inspired presence. While the Evo X invites enthusiasts to push the boundaries of style and speed, the underlying message remains simple: respect the engineering, honor the fitment, and you’ll enjoy a rear that not only looks the part but performs with confidence at the edge of grip.

External resources can provide additional context for the broader bumper ecosystem. For readers seeking a broader overview of bumper selection and fitting considerations, a detailed guide on Evo X bumper choices offers foundational guidance and practical tips grounded in real-world application. External bumper guide

The Shape of Speed: Styling and Performance Through the Lancer Evo X Rear Bumper

The rear bumper of the Mitsubishi Lancer Evolution X is more than a closing line at the back of the car. It is a deliberate statement that blends personality with performance, turning the tail end into a functional canvas where aesthetics and aerodynamics meet. In the Evo X, the bumper becomes a primary instrument for shaping airflow, guiding wake behind the car, and supporting the stance that many enthusiasts chase. When a driver talks about the Evo X’s aggressiveness, the rear silhouette often carries as much weight as the front. A well-chosen bumper is a bridge between style and function, a piece that makes the car look faster even when it is standing still, while actively contributing to high-speed stability and downforce when the road becomes a straight, open ribbon.

The journey into styling begins with recognizing that the Evo X rear bumper is not a single, static shell. It is part of a larger aerodynamic dialogue that starts at the rear lip and diffuser and moves upward toward the taillights and body lines. The most compelling aftermarket options in this space are designed to be lightweight yet capable of delivering real performance gains. Instead of focusing on a single “look,” they offer a family of shapes that emphasize a low, squared-off rear profile, recessed channels, and diffuser-like elements that manage the exit flow. This shift in design philosophy makes the rear bumper a practical upgrade for both daily driving and circuit testing. The goal is not merely to appear race-ready but to refine the car’s balance. A bumper that aggressively channels air can reduce turbulence that would otherwise disturb the wake behind the car at speed, promoting a calmer rear-end behavior and improving corner stability as speeds climb. For those seeking a concrete reference to the kinds of bumpers available for the Evo X, see the catalog of rear bumpers for this generation: 2008–2015 Mitsubishi Lancer Evo X rear bumpers.

Material choice anchors the decision. ABS plastic is the most common baseline because it offers a solid mix of impact resistance, cost, and paintability. It is a practical choice for daily-driven cars or weekend enthusiasts who want a visible upgrade without a steep price tag. ABS provides enough rigidity for everyday use and can absorb small impacts without cracking, which is essential in the parking-lot drama many drivers navigate. On the other end of the spectrum, fiberglass presents a lighter option with a sense of stiffness that responds well to aggressive shaping. It can be molded into more intricate diffuser details and air outlet configurations, which can enhance both appearance and airflow management. Carbon fiber completes the spectrum with exceptional rigidity and minimal weight, a level of performance material that appeals to track-focused builds where every gram counts. The choice among these materials depends on the driver’s priorities: daily usability, mid-range cost, or peak performance in a controlled environment. Each material has trade-offs in durability, cost, and the ease with which it can be repaired or repainted, and informed owners weigh these against the look they want to achieve.

The functional side of the rear bumper is where customization stops being cosmetic and starts influencing dynamics. Integrated diffusers—a common feature across well-considered kits—are not just stylistic; they guide the returning air in a way that minimizes drag and can help sustain rear-end traction at higher speeds. Functional air outlets are positioned to relieve pressure from within the bumper cavity and to support more efficient cooling of nearby components, while also aiding in reducing turbulent wake. The right combination of diffuser geometry and outlet placement can make the Evo X feel more planted at the edge of its speed envelope, giving the driver a more confident sense of control when changing lanes or exiting a high-speed corner.

Beyond airflow, the rear bumper’s lines contribute to the visual language that the Evo X communicates. A design that follows the car’s sculpted rear fenders and integrates smoothly with the tail light strip can amplify the built-for-speed impression without creating a disjointed silhouette. This coherence is essential because the Evo X’s identity is tied to its tension between athletic stance and crisp, clean lines. A bumper that looks like part of the original design rather than an add-on exudes a sense of purpose, making the car appear more cohesive at a glance. For many owners, the attractiveness of a new bumper is inseparable from the ability to paint or finish it to match the body color or to create a contrasting, aggressive look that still respects the car’s original geometry.

The aesthetic conversation is not limited to the bumper shell. Many kits anticipate the complete body kit ecosystem and provide mounting points or compatible shapes that align with wider bodywork. The aim is to maintain a balanced visual rhythm while enabling the inclusion of features such as built-in reflectors, reverse cameras, or parking sensors. These additions reflect a practical approach to modern driving, where a bumper is not just a visual statement but a functional platform for digital aids and safety features. The installation choreography often involves more than simply detaching the stock unit. It can require rethinking license plate brackets, relocating washer nozzle hoses, or adapting the hood prop rod to accommodate the new geometry. These nuances matter because an ill-fitting bumper can generate rattles, unwanted gaps, or fitment issues that undermine both aesthetics and performance. The result is a finished product that looks as if it grew from the car itself, rather than being bolted on as an afterthought.

The integration of design and function extends to how a bumper accommodates other customization elements. For some builders, the bumper becomes a base for canards, additional fog lighting, or auxiliary aerodynamic devices. While integrating new features, careful attention must be paid to the car’s overall weight distribution and frame alignment. The balance between front and rear grip, the distribution of downforce, and the car’s overall aerodynamics all influence how the rear end behaves under braking and at corner exit. A thoughtfully conceived bumper does not presume to solve every performance problem, but it helps in shaping a more predictable and confident chassis response. The best outcomes come from a plan that respects the Evo X’s underlying airframe while embracing the freedom of personalization that its enthusiasts prize.

In practice, the choice of a rear bumper is a negotiation between form, function, and budget. Those who want an immediate visual upgrade at a lower cost may gravitate toward simpler covers and paint-matched finishes. Those targeting a more aggressive track-friendly stance will explore bumpers with integrated diffusers and roomy air channels, knowing that the added weight can be a manageable trade-off for improved flow and stability. The more advanced builds factor in the bumper’s compatibility with the vehicle’s sensor suite and camera system, ensuring that rearview visibility and parking aids remain fully functional. The result is not a single perfect answer but a ladder of options, each with its own emphasis on aesthetics, aerodynamics, and daily usability. For readers curious about the practical entry point for Evo X rear bumpers, the internal reference to the Evo X rear bumper catalog offers a helpful overview of what is possible and how different configurations respond to real-world driving.

Connecting the rear bumper to the car’s complete identity also invites a broader look at how styling evolves with technology and road habits. The modern Evo X owner often seeks a cohesive upgrade path: a bumper that aligns with the proven lines of the car, supports broader aero goals, and respects the vehicle’s existing hardware. The synergy between bumper design and the car’s intended use matters as much as the look itself. In turns, this means the right bumper can become a practical collaborator—assisting with air management during cooldown laps on a track or simply aiding in a more serene highway cruise by smoothing the wake behind the car. It is this dual capacity—visual impact paired with measurable aerodynamic benefits—that makes the rear bumper a focal point in any styling and performance conversation.

For readers who want to explore the shopping landscape while keeping a focus on design integrity, it helps to start with a reference that frames both the aesthetic and engineering possibilities. A catalog of rear bumpers for the Evo X offers a pragmatic window into how different shapes, materials, and integration strategies translate into performance and style. This kind of resource can guide a buyer through the trade-offs between lighter, stiffer materials and the cost or repair considerations that come with them. It also helps frame expectations about fitment and compatibility with the vehicle’s current hardware, including license plates and rear cameras. The right choice balances the eye with the road, the scale with the chassis, and the wallet with the willingness to learn and adapt during installation.

In a broader sense, the rear bumper becomes a symbol of how a modern performance car communicates its identity through details. The Evo X speaks with a posture that is simultaneously aggressive and precise, a blend that is reflected in the lines of its rear end. The bumper is a key instrument in that conversation, a piece that can amplify the car’s stance, improve airflow, and echo the careful engineering that underpins the chassis. Whether the upgrade takes the form of a simple paint-to-match shell or a more elaborate diffuser-driven piece, the objective remains the same: to preserve the Evo X’s core character while elevating its presence on the road and on the track.

External resources offer additional context for those who want to understand how materials and construction influence performance. For an overview of kit construction and materials, one external reference discusses how aftermarket combinations of plastic and resin composites are used to achieve strength with favorable weight. This broader perspective helps explain why certain rear bumpers are valued for their durability during daily use and for their capacity to withstand on-track loads without compromising safety. See this external resource for more depth: https://www.alibaba.com/product-detail/Mingyang-EVO9-Body-Kit-PP-Plastic-New_1600728796747.html.

Ultimately, the Evo X rear bumper is more than a cosmetic upgrade. It is a thoughtfully engineered interface between the driver’s desire for style and the car’s necessity for stability and efficiency at speed. When approached with a clear understanding of materials, aerodynamics, and fitment realities, the bumper becomes a purposeful enhancement that respects the car’s original design while opening a window to personal expression. For those who value a one-piece visual and performance upgrade, the rear bumper offers a robust avenue to shape the Evo X’s tail, making the entire package feel faster, more assured, and unmistakably the product of careful tuning and owner-specific intent.

Rearward Strategy: Aerodynamics, Stance, and the Evo X Rear Bumper’s Performance Potential

The rear end of a performance-oriented Lancer Evolution X is more than a visual statement; it is a carefully tuned frontier where airflow, stability, and weight distribution converge. The rear bumper acts as the last mile of a holistic aerodynamic package, shaping the vehicle’s wake, guiding underbody air, and anchoring the visual aggression that enthusiasts chase. When engineered with an eye for efficiency as well as aesthetics, this panel becomes a practical leverage point for downforce and drag reduction at highway and track speeds. The Evo X rear profile, with its wider stance and pronounced shoulder line, benefits from a bumper design that smooths the transition from the body’s contour to the air entering the rear diffuser and exhaust area. In other words, the bumper is not merely a shell; it is a functional component that influences how the car breathes and behaves when the air pressure around the car is highest and least forgiving. A well-executed design reduces parasitic drag while increasing the organized downforce that stabilizes high-speed cornering and straight-line tracking, two realities that matter whether a driver is chasing laps or a club-level drift session. The balance is delicate. Too aggressive a shape without structural integrity can invite chatter at the seams or compromise cooling, while too tame a form might look good in a parking lot but offer little tangible gain on the track. The art lies in harmonizing these goals within the constraints of the Evo X’s all-wheel-drive architecture and turbocharged performance envelope. Aerodynamic efficiency, in this sense, becomes a system-wide goal rather than a single part’s triumph. The rear bumper’s form interacts with the undercarriage, the diffuser’s rake, and even the exhaust outlets to influence flow separation and pressure recovery behind the rear wheels. When the diffuser integrates smoothly with the bumper’s geometry, the car experiences a cleaner, more attached rear wake. This has downstream effects: less lift, more ground-effect-like response, and improved stability through high-speed sweeps and mid-c corner transitions. The conversation surrounding rear-end aerodynamics is not only about raw numbers; it is about predictable behavior. A track-tested bumper design can help the driver anticipate how the car will bite into a corner or resist gusts at speed, translating into more confident throttle application and faster exit speeds. At the same time, the visual mass of a redesigned rear fascia signals intent. The aggressive stance that accompanies a performance-oriented bumper is not just about aesthetics; it is a visual cue that the vehicle’s aerodynamics have shifted toward a more purposeful, race-inspired geometry. In this sense, the Evo X rear bumper serves as a bridge between engineering and expression, pairing measurable performance benefits with a bold, coherent look that communicates a driver’s intent without saying a word. The material choice, too, plays a decisive role in realizing these goals. ABS, a common choice for mass-market aftermarket parts, offers a pragmatic blend of cost, impact resistance, and ease of repair. It provides enough rigidity for everyday use while absorbing minor impacts and skirmishes with curbs that might occur during street-driven sessions or weekend tracks. Yet, for enthusiasts seeking the lightest possible response, carbon fiber or high-modulus composites present a compelling alternative. The trade-offs are clear: carbon fiber delivers lower weight and stiffer panels but commands a higher price and more careful handling during installation and maintenance. A true performance bumper—whether composed of ABS or a composite—often includes integrated diffusers and airflow channels that manage the air entering from the sides and beneath the car. This is where the rear bumper earns its keep. A diffuser that aligns with the bumper’s silhouette helps to redirect air away from turbulent regions behind the rear tires and toward the trailing edge of the vehicle. The objective is to decrease lift and cultivate a cleaner, more organized wake. When executed well, the diffuser works in concert with the Evo X’s AWD drivetrain and turbocharged engine, ensuring that cooling and airflow around the radiators and intercooler remain uncompromised. The result is a more composed vehicle at speed, with the chassis responding with a flat, planted feel that inspires confidence. The performance-oriented rear bumper often integrates larger exhaust outlets or a more open shape to accommodate upgraded exhaust systems and to refine the exhaust plume’s interaction with the rear flow. These geometry choices are not solely about control; they also influence the visual silhouette and the auditory impression of the car—the kind of deliberate design that signals capability as much as it signals attitude. Beyond the aerodynamic logic, the bumper’s role extends into structural and compatibility considerations. A reinforced construction is common in performance-oriented bumpers, offering improved protection against impacts typical of track environments or rough road conditions. This robustness helps preserve the alignment of the rear fascia and its integrated components, such as the diffuser, while resisting flex under load. The compatibility with performance systems extends to mounting points, fasteners, and fitment tolerances that must not interfere with the Evo X’s architecture or cooling pathways. It is essential that upgraded rear fascias accommodate the AWD layout and turbocharged cooling strategy, ensuring that the redesigned contours do not constrain airflow to critical heat exchangers. In the broader scope of performance, many enthusiasts adopt a comprehensive kit approach. A complete aero-focused package—rear bumper with diffuser, accompanying hood, side skirts, and a front lip—offers the most coherent path to tuned airflow. This holistic route helps optimize pressure distribution over the entire vehicle, reducing drag while enhancing downforce where needed. It also allows for a more even weight distribution around the vehicle’s perimeter, which can translate into crisper turn-in and steadier balance under braking and deceleration. The result is a chassis that feels more responsive and communicative during aggressive maneuvers, a quality that track drivers and drifting enthusiasts particularly value. While the benefits are tangible, the practical realities of ownership cannot be ignored. Installation considerations for the Evo X rear bumper include alignment with body lines, hood mechanics, and, on some designs, the relocation of certain hoses or fittings. The literature surrounding these parts notes that some bumper revisions may not provide a ready-made license plate bracket or may require relocation of factory hose paths and the removal or modification of the stock hood prop rod. These realities remind us that performance styling must be matched with a sensible approach to fitment and maintenance. The practical side of this work—careful measurement, proper mounting hardware, and, when needed, professional installation—protects both the vehicle’s structural integrity and its aesthetic cohesion. In the end, the worth of a rear bumper upgrade can be measured in more than speed or look. It is about the way a car communicates its purpose at speed, and how a driver translates that signal into confidence behind the wheel. The Evo X’s rear bumper, when chosen and installed with intention, becomes a reliable ally at the edge of grip, a component that helps the car breathe properly, stay planted through transitions, and present a stance that mirrors the precision of its mechanical heart. For readers who want to explore the broader ecosystem of Evo X rear fascia options, a dedicated page details a range of rear bumper configurations and compatibility notes that align with the goals discussed here. Rear bumper options for Evo X. This resource provides additional context for fitment, aesthetics, and how different shapes interact with underbody airflow and diffuser design. On a longer view, the integration of rear-end components with a complete performance package yields the most consistent and measurable gains. When a driver considers a full aero kit, the relationship between weight, downforce, and balance becomes a guiding principle rather than a collection of individual parts. A holistic approach—one that respects the Evo X’s architecture while embracing aero gains—offers the most meaningful path to optimized performance that can be realized on both track and street. As with any performance modification, the goal is not to chase the loudest look or the lightest parts alone, but to craft a coherent system where each element complements the others. The rear bumper is a pivotal piece of that system, and when chosen with care, it helps transform a street machine into a purpose-built tool for high-speed stability, precise handling, and a compelling, race-inspired presence. For readers seeking a broader technical context on body-kit features, the external resource below provides a comprehensive overview of Evo X body-kit applications, including performance implications and assembly considerations: https://www.carperformancehub.com/mitsubishi-evo-x-body-kit-overview/.

Final thoughts

Understanding the Mitsubishi Lancer Evo X rear bumper is essential for automotive business owners looking to cater to a diverse customer base. Its smart design, crafted from durable ABS plastic, not only enhances the vehicle’s aesthetic appeal but also plays a crucial role in aerodynamics, installation ease, customization opportunities, and overall performance enhancements. By familiarizing yourself with these features, you can offer valuable insights to your customers, ensuring they make informed decisions that align with their performance and styling needs. Stay ahead in the competitive aftermarket landscape by prioritizing knowledge about key vehicle components like the Lancer Evo X rear bumper.