Mitsubishi Lancer headlights illustrate a pivotal blend of functionality, safety, and aesthetic appeal in the automotive industry. As vehicle owners look to enhance their cars, understanding the array of headlight options becomes vital. This guide delves into the essential aspects of Lancer headlights, including halogen, HID, and LED technologies. Each chapter will explore these technologies, their configurations in Lancer models, and their impact on driving performance while addressing durability and market trends that influence upgrade choices. By the end, business owners will gain a comprehensive insight into the importance of selecting the right headlight system for their vehicles, driving safety, and aesthetic enhancement.

穿透夜幕的镜面之光:揭开Lancer大灯的反射、光强与升级潜力

在讨论燃烧夜色的灯光时,常见的误解是把“Lancer大灯”当成一种独立的灯具类型。其实,Lancer不是一种灯具,它是三菱汽车家族中的一个车型系列。因此,所谈及的“Lancer大灯”指的是搭载在这一系列车型上的前照灯系统。这些前照灯的光学表现和光强水平,随年份、车型配置和选用的照明技术而显著不同。要真正理解它们的反射特性和照明效果,必须从最基础的卤素灯开始,逐步走到投射式设计、以及后来的LED与带透镜的HID系统。通过这样的演变,我们能看到夜间行驶的视野如何从单纯的亮度提升,逐步走向更精准的光型控制与更低的眩光负担。光学原理并非单纯的亮度对比,它是光线如何被产生、导向、聚焦以及在道路上分布的综合表达。这也解释了为何同样是“卤素灯”,在不同车型版本中会呈现完全不同的照明效果。对于夜间驾驶者而言,这种差异往往决定了是否需要升级,以及升级的方向究竟应以何种原则来权衡。正是在这条轨迹上,卤素、氙气(HID)和LED的各自特性被逐步揭示,成为理解Lancer大灯的关键线索。

从光学角度看,卤素灯的核心组件是一个带钨丝的玻璃泡。光线从灯丝射出后,首先被前端的抛物面反射镜汇聚与导向。这种反射镜的形状和表面设计决定了最初的光型分布:早期的卤素大灯多采用简单的抛物面结构,光线容易发散,照明距离和远距照明的聚焦能力有限。随着技术发展,一些前灯设计在卤素基础上引入投射式结构,增加了一个透镜系统。透镜的作用不是制造新的光,而是对已有的光线进行精准聚焦,将光束切成清晰的轮廓,形成“切线”般的光型,从而减少对向车道的眩光并提升远距离照明的有效性。这种设计在Lancer的高配版本中更为常见,而低配或入门级车型往往仍使用无透镜的卤素大灯总成。此时,即使灯泡本身的光输出没有显著下降,光的利用效率和照明分布也会因为缺乏透镜的聚焦而显著不足。

在实际应用层面,三菱Lancer家族的灯具配置呈现出清晰的层级差异。高配版本或在某些年份的车型,可能引入更高亮度的光源组合与更精细的光学调校。相比之下,大多数基础款车型仍然装备无透镜的卤素大灯,光束在反射镜的控制下扩散,远距离照明受限,夜间高速行驶的视野往往不如人意。面对这种现实,许多车主会选择对原车大灯进行升级——要么保留卤素体系但换上带透镜的卤素灯要么选用LED大灯作为替代。这样的升级不仅在外观上提升辨识度,更在光强分布和照明均匀性上带来显著改善。需要强调的是,升级并非纯粹追求更高数值的灯泡亮度,而是在获得更合理的光型控制、减少眩光干扰的前提下提升夜间驾控的舒适度和安全性。

区域市场的供给与选择也会影响升级的现实性。以某些区域的后市场生态而言,形成了相对完整的光学模块、透镜组件与灯罩等供应链,车主可以在较短的时间内获得较高品质的照明组件。与此同时,供应商资质、合规性与物流安排也成为关键因素。若要确保改装的安全性与合法性,选购时需要关注认证标准与合规性标签,避免因光源和光型配置不当而造成新的眩光风险或法规问题。对于打算进行大灯升级的车主而言,理解透镜或LED系统相对卤素的光学优势,是作出明智选择的前提。

对于大灯外壳材料,聚碳酸酯(Polycarbonate)是市场上的主流选择。它具备优良的抗冲击性和耐候性,能够承受恶劣天气与日常驾驶中的冲击,且便于实现复杂的造型。这对于追求更现代外观和更精确光学分布的后市场组件尤为重要。对照这一点,卤素灯组件在外形与安装方面的兼容性,常常比HID或LED系统更易于适配原厂灯具结构。这也是很多基础款车型仍选用卤素总成的重要原因之一。

在决定升级路径时,预算、驾驶习惯、车辆年款乃至改装政策都应纳入考量。若追求更稳定的夜间照明和更低的维护成本,带透镜的卤素大灯或高品质LED投射灯也许是既经济又高效的中间选项。若对色温、显色性和夜间视觉舒适度有更高要求,LED或更高端的HID方案可能更能满足需求,但同时需要关注点火、安定器、散热与安装工艺等因素,以避免早期故障与光斑问题。

在考量升级的同时,也应注意法规和合规性,因为不同市场对前照灯的光型、照度、眩光控制及认证标准有不同的要求。确保新灯具具备必要的认证标识,并符合当地安装规定,是保障安全与合法性的关键步骤。这意味着选择合适的光学设计与光源类型,不仅仅是追求更高的亮度,而是在提升照明质量的同时,控制对向车辆驾驶员的干扰。

若在升级路径上需要更多实操的参考,可以查看某些具体的升级案例,在那里你能看到带透镜的卤素灯和LED系统在同一前灯总成中的实际表现。具体链接如下: headlights-for-lancer-evo-x-2007-2017-audi-design-version-2。在浏览这些案例时,留意光束分布的变化、对照远近光的切换效果,以及透镜、反射镜和灯罩如何共同作用来塑造最终的照明轮廓。

从宏观上看,卤素灯的光强本身存在一定的天花板,通常近光在约1000至1450流明的法规区间内浮动,远光则可能达到1500至1750流明的上限。然而,光强并非唯一决定因素。反射与聚光的效率、光束形状的清晰度、以及在雨雪雾日条件下的穿透性,往往比简单的亮度数字更能反映实际夜间驾驶的安全性。在这个意义上,Lancer大灯系统的升级潜力,往往来自对光学结构的深入理解——尤其是透镜设计、反射镜曲面的精细调整,以及灯罩材料对光的扩散与抑制效果。

此外,全球制造业格局也在影响后市场的可获得性。以珠三角、长三角等地形成的高度集成照明制造集群为例,高品质后市场大灯组件的供应相对充裕,车主在选购时可以更容易获得整体灯具总成、灯罩和透镜模块等一体化方案。这种集成化供应,有助于提升改装的一致性与光学匹配的稳定性,但同样需要审慎评估供应商资质、合规性与物流方案,以确保改装的长期可靠性。

对材料与工艺的理解,帮助我们在选择时有更清晰的判断。聚碳酸酯灯罩在耐冲击方面的优势,使其在高速行驶与路面不平时更不易破损;同时,优质透镜对光束的聚焦能力决定了灯光分布的边界清晰度。若要实现更高的光强与更均匀的照明分布,LED与透镜的组合在夜间驾驶中的表现往往要优于单纯的卤素系统,但这也对散热设计和整灯的光学协调提出了更高要求。综上所述,Lancer大灯的升级策略应以提升实际照明效果为核心,而非单纯追逐灯泡的亮度数值。

通过上述分析,我们可以把握一个清晰的逻辑:卤素灯在基础照明中具有成本效益与易维护的优点,但其光型控制往往受限,尤其在非透镜设计的版本中更为明显。带透镜的卤素或LED系统,提供更好的光型控制和远近照明的一致性,是提升夜间驾控体验的更有力途径。选择升级路径时,理解光学原理与实际应用场景之间的关系,是做出明智决定的关键。最终,合规、安全、经济与性能之间的折中,决定了哪种配置最契合你对夜间照明的需求。外部资源与专业案例可以帮助你在理解光学原理的基础上,做出更具可操作性的选择。

外部参考资源: https://en.wikipedia.org/wiki/Headlamp

氙气大灯在头灯体系中的演进:高亮度背后的配置与合规之道

氙气大灯在头灯体系的历史中扮演着一个重要的角色。它并非单纯的光源升级,而是对夜间视觉体验、能耗管理以及光学工程设计的一次综合考量。通过在高压下点燃氙气,氙气大灯能够产生广泛且均匀的光束,照明强度远超传统卤素灯,色温接近自然光的范围通常位于4300K至6000K之间。这种“自然光”色调带来的不仅是明亮的夜间视野,更是一种驾乘者在长时间驾驶中的视觉舒适感。对于需要穿透雾气或雨雪天气的场景,氙气光束的穿透力和投射距离往往更具优势,驾驶者能在更短的时间内判断前方路况,减少疲劳积累。与之相伴的,是对整车照明系统的全局考量。氙气大灯的光输出往往达到3000流明以上,某些情况下甚至能触及4500流明,这使得光线覆盖范围更广、投射距离更远。为了实现这一高强度输出,系统通常需要配备专用的点火器和稳定器,配合透镜模块以确保光线在道路上的分布更加均匀、无盲区。相对卤素灯,氙气大灯的功耗通常在35W左右,较卤素灯的55W以上有显著降低。这样的能效提高不仅减轻了电气系统的负担,也对冷启动时的热管理提出了更高要求。寿命方面,氙气灯的维护成本在长期使用中通常更具竞争力,因为其核心发光机理没有易损的钨丝结构,使用寿命常被标注在3000小时以上,远超传统灯泡的寿命区间。色温的稳定性与光色的一致性,也成为评估氙气系统优劣的关键指标之一。稳定的色温不仅影响夜间驾驶的直观感受,还会影响目标物体在视野中的对比度,从而提升辨识力与反应时间。光分布的均匀性和投射角度的控制,是氙气大灯系统设计中的核心。正确的透镜设计、反射腔的几何形状以及灯罩的材质共同决定了灯光在前方道路上的覆盖面与边缘清晰度。透镜的聚光效果、镜头的光学涂层,以及灯罩对热膨胀的耐受性,都会影响到夜间的辨别度与对向车辆的眩光控制。关于氙气大灯的技术优点,公开资料常将亮度、能效、寿命和光色作为四大支柱。颜色偏暖的光源在雾天中的对比度有时略显不足,但4300K至6000K区间的冷白光则更接近自然光,能够减少视觉疲劳,提高连续驾驶时的警觉性。与此同时,氙气系统的光线分布通常更为均匀,照明区域在道路左边和右边的过渡也更柔和,这对于高速公路或郊外道路的长距离观察尤为重要。相应地,驾驶者在夜间的反应时间往往有所缩短,尤其在高速行驶时,前方标线、路面缺陷和对向车辆的灯光变化都能被更早地捕捉到。对于那些追求高水平夜间视野与外观气场的车主,氙气大灯常被视为高配或性能版本的标志性配置。它不仅提升了照明性能,还在视觉冲击力上带来明显的升级感,成为车灯组整体设计中的一个重要层次。尽管如此,氙气大灯也并非没有局限。启动需要一定的预热时间,通常在2到5秒之间才能达到全光输出,这在瞬时点亮需求较高的场景中会显得略有迟滞。此外,要实现稳定的点亮,必须搭配稳定器(高压包)与专门的透镜系统,以避免灯光散射造成的眩光。这类系统的安装与调校也比卤素版本更为复杂,涉及电气接线、灯具定位以及光束的几何对准等关键环节,因此在改装或升级时,专业安装是几乎不可避免的。成本方面,氙气灯的整套改装通常高于卤素系统,包含灯泡、安定器与透镜等组件的总价区间会有较大浮动,且不同地区的劳务费、合规要求也会显著影响最终花费。正因如此,许多车主在考虑升级时,会权衡短期的投入与长期的收益,评估是否值得为夜间行驶带来如此显著的光学提升。关于配置层面的实际应用,某些高端版本在多年的车型矩阵中往往将氙气大灯作为标准配置或高阶选项,强调在夜间行驶中的安全性与行驶乐趣。这些版本通常也配合了其他高端灯光元件,例如透镜式光学系统与定制的光分布设计,从而在灯具整体的一致性与美学表达上达到较高水平。反之,入门或中端版本在成本控制考量下,仍以卤素灯为常态。市场与区域之间的差异也会体现出不同的灯光策略:在某些区域,法规对照明系统的要求与监管更严格,厂商需要确保灯具的合规性与安全性,甚至对改装提出明确的界限。无论是原厂配置还是售后升级,合规性都成为一个不可忽视的前提。随着LED技术的快速兴起,后续车型逐步将头灯系统转向LED为主的配置,氙气灯在新设计中的比重有所下降,但在一部分高性能版本中仍然以兼容性与特定光学特征的组合存在。LED的高效、低耗、寿命与更灵活的光学分布,使其成为许多市场的主流选择。对于改装者而言,LED与HID各自的优劣并非简单对比,而是需要结合车辆年款、原有灯具结构、透镜模块和法规要求来综合考量。就市场生态而言,头灯外壳材料多以聚碳酸酯为主,它具备出色的抗冲击性和耐候性,且容易塑形以实现复杂的灯具轮廓。高质量的外壳设计不仅能承受日常驾驶中的震动与风化,还能承受温差带来的胀缩效应,从而维持光学系统的对准与密封性。改装时若涉及外壳、透镜或灯罩的更换,选择材料的耐久性与防护性能尤为关键,因为二次加工后的密封性不佳往往会带来水汽侵入、光学性能下降甚至灯腔腐蚀的问题。整体而言,氙气大灯在夜间照明领域代表了一种高亮度、高能效与相对成熟的光学工程的结合体。它的优势在于显著提升的视野与驾驶舒适度,以及更强的光学辨识度,但同时也带来启动延迟、安装与合规性方面的挑战。对于车主而言,做出选择时需要把预算、驾驶习惯、车型年代与所在地区的法规共同纳入考量。对那些寻求性能与品质并举的人来说,氙气大灯往往是一个值得深入探讨的选项,尤其是在需要大光束覆盖与稳健长距离照明的情境中。若你对某一特定的头灯方案感兴趣,市场中确实存在若干专门针对特定车系设计、将氙气灯与高透镜技术相结合的升级组合。此类方案的灯组结构通常更注重光束的分布特性与整车灯组的视觉统一性,适合追求高水平夜间照明与外观质感的车主。你可以查看此页面进一步了解具体的灯组结构与装配要点:lancer-evo-x-10-headlights。此外,若需要更全面的法规与技术背景,可以参考品牌方的官方信息,以确认在所在地区的合规性与维护要点。外部资源也同样重要,了解制造商在头灯设计与法规遵从方面的官方资料,有助于做出更稳妥的改装决策。外部资源链接: https://www.mitsubishi-motors.com/vehicles/lancer

LED Headlight Evolution in the Lancer: From Halogen Warmth to Precision LED Illumination

The Mitsubishi Lancer’s front lighting has tracked a quiet but steady evolution that mirrors the broader shift in automotive lighting technology. Early Lancer models relied on halogen lamps, simple reflectors, and modest optics. Those configurations offered affordable maintenance and straightforward replacement, and they did a reliable job of cutting through drizzle or fog with a warm, familiar glow. Yet as years progressed and the road conditions beyond city streets grew more demanding, the headlight system began to tell a more sophisticated story. The shift toward LED technology, with its slender, high-efficiency light sources and nuanced beam control, redefined not only how the car meets the road after dark but how its face communicates intent and character to onlookers. In this sense, the Lancer’s headlight narrative is less a sequence of plug-and-play upgrades than a design dialogue between form, function, and user experience that continues to unfold as new technologies mature.

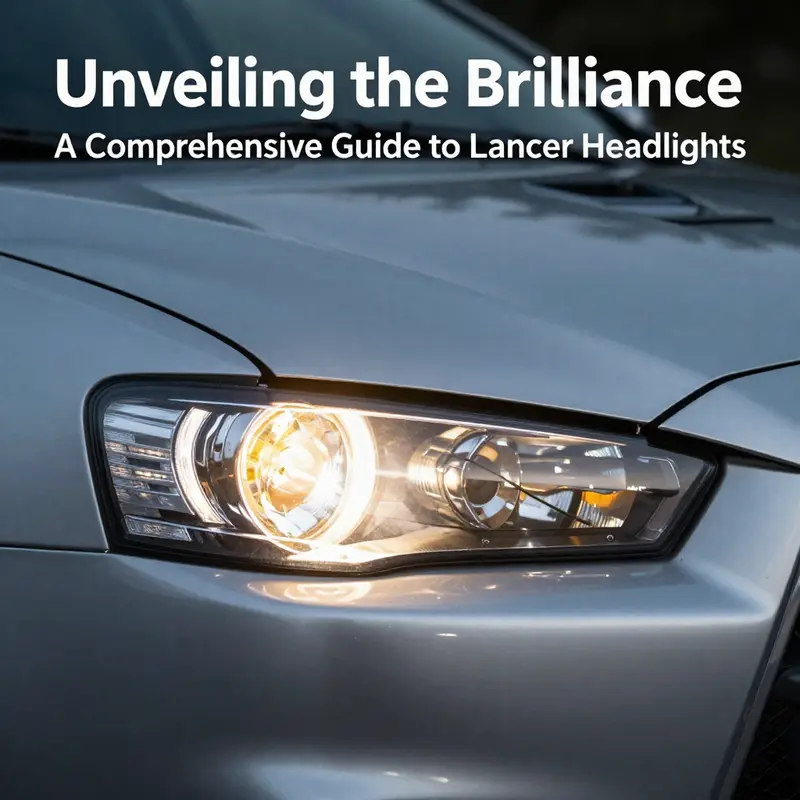

The most noticeable design cue of LED headlights in the Lancer lineage is the portrayal of light as a design element, not merely a functional component. The long, narrow LED arrays that began to appear on several models extended the visual width of the car’s front end, sharpening the silhouette and lending an almost predatory stance at a standstill. The eye is drawn along the length of the headlamp cluster, which, with careful sculpting of the surrounding fascia and a precise interplay of surface planes, communicates a modern, technologically oriented identity. In certain mid-cycle evolutions—particularly the late-2000s era—manufacturers experimented with halo or “angel eye” accents that circled the primary LED projectors. These halo rings didn’t merely glow; they framed the central light action with a distinctive ringed aura, subtly elevating the perceived complexity of the headlight system while reinforcing a sense of forward-looking engineering.

From a functional standpoint, LED headlights deliver a suite of advantages that align with the Lancer’s performance-oriented ambitions. First, energy efficiency sets LED lighting apart. The LED modules pull less current for the same or greater output, contributing to lower overall electrical load. This is not just a matter of fuel economy in the narrow sense, but a broader reduction in parasitic power draw that can free up energy for other systems and, over the life of the vehicle, may contribute to fewer electrical symptoms under high-demand driving conditions. Second, the longevity of LED components translates into fewer replacements and lower maintenance costs over the vehicle’s lifetime. The lifespan of a well-designed LED headlight is typically longer than traditional halogen setups, which means fewer opportunities for misalignment drift or degraded light output that could affect nighttime visibility.

The third and perhaps most tangible advantage is the speed of response. LED lamps reach full brightness almost instantaneously, a trait that becomes meaningful in emergency braking scenarios or quick lane-change maneuvers where milliseconds can influence safety. While this advantage is often most celebrated in advanced driving-assistance package descriptions, it is very real in day-to-day driving where a split-second difference in illumination may aid perception and reaction time for both the driver and nearby road users. Alongside this, modern LED systems benefit from advanced optical engineering that enables more precise light distribution. Beam shaping, projection, and cooling strategies work together to create a consistent, far-reaching field of illumination without the glare that sometimes accompanies high-intensity discharge systems when miscalibrated or poorly aliased to the vehicle’s geometry.

In practical terms, the LED-equipped Lancer has not only improved night-time visibility but also changed the character of the front end’s lighting signature. The LED clusters are often paired with low-drag housings and lens optics that optimize light spread while keeping a clean, compact silhouette. The result is a combination of practical performance and aesthetic refinement that can be appreciated in both urban and rural contexts. The introduction of LEDs also aligns with broader trends in vehicle lighting, where intelligent features begin to accompany higher light output. Daytime running lights, automatic headlamp operation, and adaptive or matrix-like lighting patterns become more common as OEMs and aftermarket suppliers push for smarter, more connected lighting ecosystems. In the Lancer’s case, this trend has often translated into a more integrated approach to lighting—a front end that reads as a unified lighting language rather than a collection of independent elements.

Regional dynamics have also shaped how LED headlights have entered and evolved within Lancer models. In some markets, especially those with mature automotive clusters or robust aftermarket ecosystems, the availability of LED and LED-with-lens headlight assemblies has accelerated. The high-density supply networks in certain manufacturing hubs enable a broader range of options, from complete headlight assemblies to modular lens and reflector components. These clusters also bring the risk of inconsistent quality, which is why calibration, compliance, and compatibility remain critical considerations for buyers and installers alike. When upgrading or replacing headlight components, it is essential to consider not only the light output but the alignment with the vehicle’s mounting points, wiring harness compatibility, and the electrical system’s ability to support the added features such as automatic or adaptive lighting functions.

In the context of the Lancer’s evolution, LEDs have also become a visual shorthand for performance and precision. A driver glancing at the front of a Lancer with LED daytime running lights and a well-defined LED low- and high-beam pattern immediately perceives a vehicle that embodies modern engineering values. The optics themselves contribute to a perception of speed and capability, even when the car is stationary. This is especially true for the high-performance variants, where the headlight assembly is part of a broader visual language that expresses the car’s purpose: to engage the road with confidence and clarity, day or night.

From a specification standpoint, LEDs often come with a suite of features that reflect evolving expectations for safety and convenience. Some models incorporate automatic headlight leveling to adapt to vehicle pitch and load, ensuring the beam remains properly aimed as passengers shift or as the car travels over uneven pavement. Others integrate daytime running lights that meet regulatory standards while enhancing daytime visibility and brand identity. While some aftermarket upgrades emphasize the aesthetic refinement of the LED modules, others highlight practical enhancements such as improved beam cutoff, reduced glare for oncoming drivers, and enhanced compatibility with modern electronic control units. In all cases, the move toward LED is less about chasing the brightest possible light than about delivering a balanced, controlled, and reliable lighting experience that works with the car’s dynamics and driver expectations.

For readers seeking a concrete example of contemporary headlight assemblies tailored for the Lancer’s design language, consider an option that demonstrates the practical blend of Audi-inspired architecture and Lancer identity. Headlights for Lancer EVO X (Audi design version 2) embodies a design approach that merges refined optics with a modern silhouette. It is a useful reference point for understanding how leading-edge headlight geometry can harmonize with the Lancer’s lines while delivering the reliability and efficiency that LED technology enables. Headlights for Lancer EVO X (Audi design version 2).

As the technology continues to mature, more iterations of automatic and adaptive lighting are likely to become standard, particularly in higher trim levels or in markets with stringent safety regulations. The choreography between sensor data, beam shaping, and LED emission patterns promises a future where headlights adapt in real time to weather, traffic density, and road geometry. In this sense, the Lancer’s headlight system is not merely a lighting instrument but a dynamic interface between the vehicle and the road—a visible indicator of the vehicle’s ability to respond to changing conditions with precision and poise. The design language will continue to evolve, but LEDs will likely remain at the heart of that evolution, guiding the way toward brighter, smarter, and more efficient illumination.

Within the broader lifecycle of the Lancer, the shift to LED represents more than a swap of light sources. It marks a transition in how the car communicates with the driver and with other road users. The front end, once dominated by a warm but relatively modest glow, now tells a story of precision engineering, energy-conscious performance, and a forward-looking aesthetic that aligns with the era’s emphasis on intelligent systems. The durability and efficiency of LED technology fit naturally with the Lancer’s emphasis on practical, real-world driving—whether navigating rain-slick urban streets or lighting the remote backroads that test a vehicle’s true character. In that sense, LED headlights are not just a convenience; they are a statement about the road ahead and the kind of driving experience a Lancer owner seeks to achieve.

External reference: Autocar’s evaluation of the Lancer Evo X’s lighting and performance provides a detailed perspective on how optics, beam pattern, and overall lighting behavior translate to real-world driving conditions. It offers a broader context for understanding why the move to LED and related technologies matters beyond mere aesthetics. See the external resource for a deeper analysis: Autocar review: Mitsubishi Lancer EVO X.

Materials, Durability, and Through-LED: Lancer Headlight Architecture in the LED Era

Materials engineering and durability define the Lancer’s LED headlight philosophy. Moving into the LED era, the emphasis is not only on brighter beams but on enduring performance, stability, and environmental resistance. The headlight assembly becomes a compact ecosystem where optics, electronics, and exterior materials converge to deliver reliable light over the vehicle’s lifetime.\n\nAt the core is modified polycarbonate, chosen for lightness, toughness, and optical clarity. In premium headlight systems this polymer is engineered to minimize haze, reduce micro-cracking under thermal cycling, and maintain transmittance well above 90%. The through-LED configuration makes beam fidelity critical, so the material’s aging behavior and surface stability matter as much as raw brightness.\n\nUV stabilization is a central strategy for long-term clarity. Exterior surfaces and interior optical paths may employ UV-absorbing layers, stabilizers, UV-stable coatings, and nanoscale additives such as titanium dioxide to filter damaging wavelengths before they reach the polymer matrix. While spec specifics are not public, the design trend points toward layered defense against photo-oxidation and yellowing.\n\nThe through-LED (贯穿式) concept adds optical sophistication and demands a multi-layer structure. The outer surface uses high-molecular-weight PC with low impurities to resist environmental attack. An anti-UV cured optical film reinforces the UV barrier while preserving surface smoothness for image formation. Inside, an additional protective layer—sometimes a tempered or reinforced glass-like layer— distributes impact and protects the LED array behind it. This architecture helps preserve beam quality by reducing micro-scratches and micro-deformations that scatter light.\n\nLens, diffusers, and the multi-element optics shape the LED output for a clean cutoff, uniform roadway illumination, and controlled glare. The through-LED approach enables a continuous ribbon-like light appearance while maintaining precise optical performance across temperature ranges.\n\nDurability is not only about materials but how they are processed and protected. High-end PC housings with UV stabilization show far lower yellowing under accelerated aging than non-stabilized alternatives. When surfaces stay clear, beam color and intensity remain within design tolerances, preserving nighttime visibility and color rendering over time.\n\nMaintenance remains practical and simple but meaningful. Regular cleaning removes abrasive contaminants, and periodic reapplication of protective coatings keeps the anti-yellowing barrier intact. The guidance emphasizes pH-neutral cleaners and avoiding harsh scrubbing to prevent surface damage; these steps sustain transmission, beam homogeneity, and color stability over years of use.\n\nMarket context matters as well. In key regions with a robust supply ecosystem, genuine OEM and high-quality aftermarket assemblies are available, while buyers should verify supplier qualifications and safety certifications to avoid counterfeits or nonconforming parts. Regulatory considerations—such as regional lighting standards—continue to frame the development and use of LED headlight components. The best upgrades come from sources that document material specs, UV protection strategies, and verified beam performance.\n\nFor readers curious about practical engineering details, project pages and technical PDFs can provide deeper insight into how optical systems are arranged and how housing geometry supports consistent illumination. External references from industry studies help illuminate the path forward, underscoring the importance of material selection, aging resistance, and system integration in creating headlights that endure while performing at peak efficiency.\n\nExternal reference: https://tu-dresden.de

From Halogen to Hyper-Illuminated: Market Trends and Modding Paths for Lancer Evolution X Headlights

The Mitsubishi Lancer Evolution X headlight system sits at the crossroads of performance, style, and what is possible with modern automotive lighting. Enthusiasts do not simply replace worn parts; they reimagine the way the car speaks at night. Across model years, the Evo X has shown openness to brighter, more efficient technologies while balancing beam pattern, glare control, and street legality. This evolution mirrors a broader shift where headlights become technical showcases and identity markers rather than mere visibility devices.

Market trends reveal a desire for brightness beyond the traditional halogen baseline, with owners seeking longer reach and more precise light distribution to match the car’s handling. The focus extends beyond lumens to color temperature, cutoff sharpness, and reduced scatter. Early halogen setups leaned warm and amber; modern options skew cooler, resembling daylight and reducing eye fatigue on long night drives. Regions with challenging night routes particularly reward the extra light and clarity.

LED and high performance HID systems have emerged as the dominant paths for performance oriented builds. LEDs offer energy efficiency, instant response, and easier integration, while HID options remain attractive for their distinct glow, albeit with ballast and wiring considerations. The choice often comes down to fitment, reliability, and how the upgrade integrates with the Evo X electrical system.

Across the market, intelligent features are gaining traction. Adaptive lighting, automatic dimming, and cornering light functionality can improve visibility around blind corners without washing out the drive. For the Evo X, these features balance performance with the car’s broad stance and track ready character.

Regional supply chains have matured, delivering ready to install assemblies that fit the Evo X chassis and meet quality standards. Buyers increasingly look for vendor credentials, product testing, and after sales support, ensuring long term reliability and consistent color temperature. This maturity helps avoid compatibility pitfalls and reduces the risk of misalignment or electrical incompatibility.

From a materials perspective, polycarbonate housings and glare minimizing lenses remain standard, with robust reflectors or projector optics that preserve sharp cutoffs. A well designed upgrade preserves optical alignment over thousands of miles and maintains a coherent look with the vehicle’s lines, contributing to the car’s aggressive yet refined street presence.

Practical modding journeys are personal and layered. Some owners seek direct performance gains with high brightness LED or HID kits matched to Evo X mounting points and a cooling strategy for longevity. Others aim for a complete lighting language, including daytime running lights, upgraded fogs, and coordinated turn signals that create a unified front end.

The upgrade process is not only about brightness. Fitment, heat dissipation, and electrical compatibility are essential. Proper heat sinking, careful aiming, and professional alignment checks help prevent glare and regulatory concerns. A cohesive upgrade is one that drops into stock mounting points with minimal modification while integrating with the car’s electronics.

For readers seeking a practical path, exploring Evo X specific headlight options and catalogs can be a helpful starting point; see the Evo X headlights catalog for compatible assemblies designed to preserve geometry and wiring. Looking ahead, LED technology is likely to become even more accessible, combining brightness with safety, reliability, and a design language that complements the Evo X’s character.

Final thoughts

Mitsubishi Lancer headlights represent more than just a functional component; they embody the technological advancements in automotive lighting systems that enhance safety, visibility, and vehicle aesthetics. With options ranging from traditional halogen to modern LED and HID systems, business owners must consider which lighting technology best aligns with their needs and preferences in terms of performance and durability. As trends shift towards aftermarket enhancements, understanding these concepts will equip car owners to make informed purchasing decisions that ultimately improve driving experiences. By investing in the right headlight technology, businesses can ensure customer satisfaction and success in the automotive market.