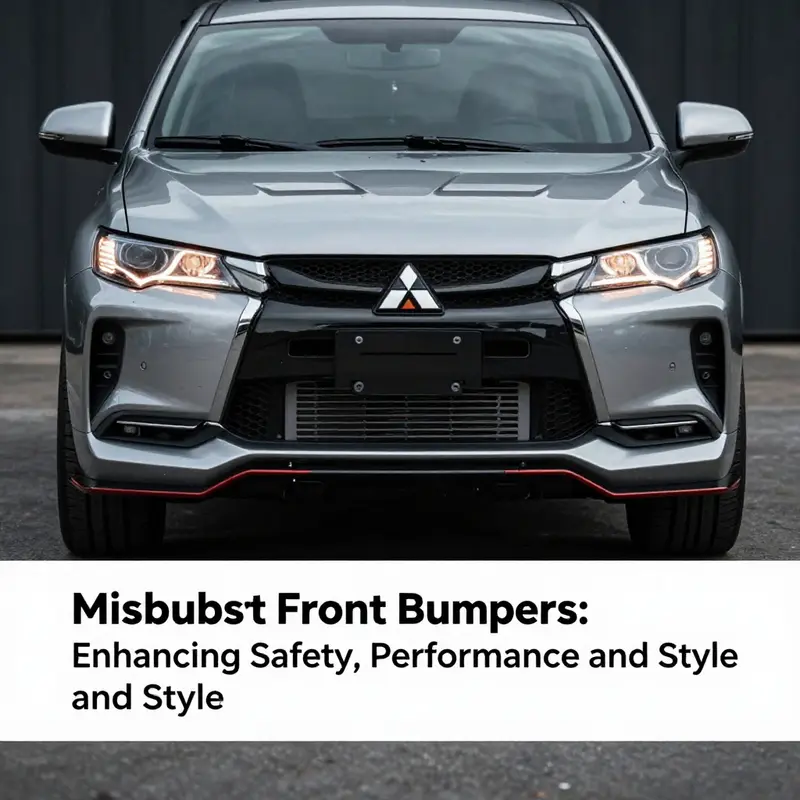

Understanding the integral role of front bumpers is essential for business owners operating Mitsubishi vehicles. These components not only serve as the first line of defense in collisions but also play a significant part in enhancing vehicle performance and aesthetics. In this comprehensive exploration, we will delve into the different types of Mitsubishi front bumpers available, the importance of OEM bumpers in ensuring vehicle safety, and how performance and aesthetic customizations can benefit various business applications. Each chapter provides crucial insights, helping you make informed decisions that impact vehicle efficiency and appearance.

Guardians at the Grille: How Mitsubishi Front Bumpers Blend Safety, Style, and Off-Road Readiness

The front bumper is more than a shield for the nose of a vehicle; it is an engineered interface between protection, performance, and perception. In the Mitsubishi lineup, bumpers perform three essential roles: energy management during low speed impacts, contribution to aerodynamics and cooling, and a canvas for sensor integration and branding. This chapter treats the bumper as a system rather than a collection of parts, tracing how different bumper philosophies reflect priorities from maintaining factory geometry to enabling rugged functionality in demanding environments. The narrative shows how fit, function, and form ripple through daily use, maintenance, and long term ownership, while recognizing the broader ecosystem that supports modern driving, including driver assist systems and evolving safety standards.

Energy management is central to bumper design. Modern bumpers distribute impact forces away from more fragile components, reinforce crumple zones, and work with foam inserts and reinforcements to preserve the integrity of critical systems. When a vehicle relies on advanced driver assistance, the bumper footprint must accommodate sensor housings, radar units, and cameras positioned with precision to maintain reliability. This precision also helps with pedestrian protection targets and compatibility with forward lighting and safety systems. OEM bumpers are often the most straightforward path to insurance-aligned repairs and predictable crash performance.

Material choices reveal the bumper’s character. Everyday use favors lightweight polymer composites such as ABS for corrosion resistance, stiffness, and cost efficiency, enabling sculpted shapes that optimize airflow. For vehicles meant to tackle rough terrain or heavy use, steel or steel-reinforced hybrids provide added durability and modularity. Off road and heavy duty bumpers commonly include winch mounts and recovery points, designed to absorb shocks while supporting accessory compatibility. In fleet contexts, polymers balance reliability with serviceability, while steel reinforcements deliver the rigidity needed for repeated impacts in challenging environments.

Styling and performance optimization form a third axis. Performance oriented bumpers trade some weight and ground clearance for improved aerodynamics and cooling. They may channel air to intercoolers, integrate functional canards, or offer venting that manages high speed flow. Consumers seeking sportier aesthetics get a sharper silhouette and a more aggressive stance, but essential protection remains intact through robust chassis mounting and energy absorption characteristics. The bumper becomes a visible statement of intent, whether toward speed, rugged endurance, or a blend of both.

Maintenance, fitment, and daily life follow from these design choices. OEM bumpers typically preserve the vehicle’s original geometry, keeping headlamps, grilles, sensors, and camera housings aligned for reliable ADAS operation. Misalignment can degrade sensor performance, potentially reducing braking assistance and parking aids. Because OEM units are engineered to the manufacturer’s tolerances, repairs using genuine parts tend to preserve crashworthiness and sensor calibration. In urban fleets, this predictability supports warranties, insurance terms, and long term depreciation.

Installation journeys differ by class. OEM bumpers usually require precise mounting to fit designated points and to accommodate integrated sensors and lighting. Aftermarket performance or off road bumpers emphasize modularity with standardized mounting points and removable bracing, expanding customization at the cost of potentially more complex installation. Professionals often handle installations involving winches, light bars, or heavy recovery gear to ensure that the front end remains secure and aligned under demanding use.

Beyond the mechanics, integration with the vehicle’s safety architecture matters. The bumper is a node in a safety network that feeds data to parking systems, collision mitigation, and forward looking sensors. Changes in geometry or material thickness can affect sensor calibration, so OEM replacements are frequently preferred when sensor alignment is critical. The aftermarket has evolved to offer sensor compatible options and mounting points that respect this reality, balancing customization with safety compliance.

The Mitsubishi spectrum reflects owner intent. Daily urban drivers may value authentic fit and sensor integrity for predictable behavior and service history. Fleet operators require uptime and predictable maintenance, often favoring OEM replacements to maintain factory specifications. Adventurers and overlanders may choose rugged bumpers with recovery gear and mounting capacity for lighting, accepting the need for professional installation. Industrial users may seek specialized bumpers tuned for durability and practical functionality in loading, towing, and fleet safety integration.

To illustrate the logic across categories, OEM bumpers offer reliable crash performance and sensor reliability; aftermarket solutions emphasize durability and capability with modularity; industrial variants prioritize long term endurance and serviceability. Across all classes, finish quality, corrosion resistance, and ease of maintenance remain constant concerns.

In closing, the front bumper embodies a philosophy of protection, performance, and practicality that must align with how the vehicle is used. As driver assistance technologies advance, bumpers will continue to evolve to accommodate sensors without compromising energy absorption or airflow. For readers seeking practical, model-agnostic context, the next chapter will explore installation best practices, common pitfalls, and the decision matrix for choosing between OEM, performance, and industrial bumper solutions. A model-inclusive reference, including compatibility and sensor integration considerations, will be explored in the forthcoming sections.

Guardians of the Front: The Vital Role of OEM Mitsubishi Front Bumpers in Vehicle Safety

A front bumper is more than a visible shield at the leading edge of a car; it is a purpose-built safety component that represents a critical junction between protection, performance, and everyday reliability. When we talk about OEM Mitsubishi front bumpers, we are referring to parts that are designed to fit a vehicle’s body with exacting precision, preserving not only the visual harmony of the car but also the safety philosophy that underpins modern automotive engineering. This precision matters because a bumper is a structural element that participates in energy management during a collision. It houses and channels impact forces away from vital components, helps control deformation paths, and, crucially, determines how the rest of the vehicle behaves under stress. In the language of crash physics, every curve, every hollow, and every mount point in an OEM bumper is a calculated decision intended to absorb and redirect energy in a predictable way. That predictability translates into real-world safety, from the moment a driver glances at the road to the instant a collision is averted or mitigated by the vehicle’s own systems. Beyond the moment of contact, OEM bumpers are integral to the ongoing performance of driver-assistance technologies that increasingly define modern motoring. Advanced radar and camera systems, which support automatic emergency braking, adaptive cruise control, lane-keeping assist, and other ADAS features, rely on a stable, known geometry around the front of the car. If a bumper warps or its mounting shifts, sensor alignment can drift, compromising the precision of perception and the confidence of the entire system. OEM bumpers are engineered not only to maintain a clean external silhouette but also to preserve the internal relationships among sensors, housings, and the critical electronics that interpret the world outside the vehicle. In practical terms, this means that choosing the factory-backed option is less a matter of prestige and more a matter of consistency. The alignment of radar emitters, the line of sight for cameras, and even the expected behavior of proximity sensors are calibrated to factory specifications. When a bumper is replaced with an aftermarket part that lacks the same tolerances, the result can be subtle and cumulative: slight misalignments that degrade system responses, recalibration requirements, or, in worst cases, a compromised safety net when the car relies on sensor inputs to react to a sudden hazard. The OEM path, then, is a promise of an intact safety ecosystem that does not gamble with the timing and accuracy of sensing or the predictability of responses. The design philosophy behind OEM bumpers extends to their energy-absorbing structures, which may include foam inserts or crushable cores positioned to begin their work at precisely defined forces. These elements help distribute crash energy away from the engine, radiator, and cooling systems, protecting the powertrain and preserve the integrity of the safety cell that surrounds the occupants. They also support the bumper’s ability to mitigate damage to fascia supports and mounting brackets, which reduces the likelihood of cascading failures in the event of a collision. In the Mitsubishi context, these features are not add-ons but foundational aspects of the car’s safety architecture. They work in harmony with the rest of the vehicle’s crumple zones, which are designed to absorb energy progressively as a collision unfolds. This harmony matters because a bumper is not a single component but part of an integrated safety system that includes the hood, fenders, headlights, and under-hood structures. When all of them function as a coordinated whole, the vehicle behaves more predictably, allowing occupants to experience lower injury risk and first responders to gain a clearer understanding of the crash scene. The integration goes further still when you consider the contemporary emphasis on aerodynamics and cooling. OEM bumpers are sculpted to minimize drag while directing airflow toward radiators and intercoolers, ensuring that engine temperatures stay within safe limits even during strenuous conditions. This design balance between energy absorption and airflow management supports not only performance but also longevity, because overheating can degrade both safety systems and mechanical wear patterns over time. The result is a front end that does not simply look the same as it did from the factory but behaves the same way under performance and restraint. The logical companion to these physical and aerodynamic considerations is the practical reality of repairs and maintenance. Trusting the OEM path means choosing parts that are tested to perform in line with the vehicle’s original safety standards, which is why insurance guidelines and repair guidelines often emphasize authenticity. This is not merely about keeping a vehicle looking pristine; it is about preserving the intended performance envelope and safety outcomes. For people who drive daily in busy urban environments, or for fleets that must uphold a consistent safety standard across a wide range of driving conditions, OEM bumpers provide a dependable baseline. It is the baseline that ensures sensor calibration remains valid, that crash energy is managed in a consistent way, and that the vehicle retains its designed crashworthiness rating. In the realm of practical decision-making, a crucial but often overlooked factor is how a bumper relates to the rest of the front-end assembly. The bumper does not operate in isolation; it connects, through mounting points and reinforcement bars, to the vehicle’s frame and to energy-absorbing substructures. When a bumper is replaced with a genuine OEM unit, these connections restore the intended load paths that engineers designed to mitigate intrusion and preserve occupant protection. In contrast, non-OEM replacements may fit but fail to restore those critical load paths to the same degree, creating potential gaps in the safety envelope that can affect how other safety systems perform under stress. This is especially relevant for vehicles that rely on automatic braking and other sensor-driven responses to dynamic hazards. If the bumper shifts even subtly relative to the bumper reinforcement, then the timing of sensor responses can be altered, sometimes requiring additional calibration steps that are not needed when OEM parts are used. The safety case for OEM front bumpers thus rests on a convergence of fit, function, and integration. Finite element studies and crash-test data would typically show how OEM bumpers, with their integrated impact-absorbing structures, absorb and distribute forces more predictably than aftermarket alternatives. Those predictable outcomes translate into real-world advantages: drivers experience a reassuring stiffness in the response of the vehicle to an impact, engines and cooling systems stay protected within the designed envelope, and the car’s electronics communicate with sensors in the manner the manufacturer intended. The narrative for everyday use is equally compelling. Consider how a bumper contributes to curb appeal while maintaining practicality. In the balance between aesthetics and performance, the OEM bumper preserves original lines, gaps, and angles that contribute to the car’s cohesive look and its aerodynamics. A mismatch in any of these aspects can create a visual disconnect and, more importantly, disrupt airflow patterns designed to optimize stability at speed and fuel efficiency on long highway stretches. For drivers who value reliability and a consistent driving experience, the OEM path is a way to protect the vehicle’s investment while avoiding the patchwork symptoms that can accompany non-OEM repairs. It is also worth recognizing the broader ecosystem around these components. Specialized protection elements such as brush guards and reinforcement bars extend the role of the bumper beyond standard protection. A brush guard, for example, is a tubular frame that guards grilles and headlights from off-road hazards, while reinforcement bars sit behind the bumper to bolster rigidity. In off-road scenarios, where the vehicle may encounter rocks, brush, or unexpected impacts, these accessories work with the bumper to maintain the integrity of the front end and to preserve sensor alignment in challenging environments. The interplay between protection and practicality becomes even more important when we consider model-specific realities. Different Mitsubishi models—whether a compact SUV, a rugged utility vehicle, or a family-oriented crossover—present unique front-end geometries, cooling needs, and sensor layouts. OEM bumpers are tailored to these variations, ensuring that a daily commuter’s Outlander does not simply wear a generic cover but receives a bumper that respects the vehicle’s intended thermal management, frontal crash design, and sensor geometry. As a practical example within the broader narrative, it is informative to examine how an OEM approach translates into real choices for owners who are preparing their vehicles for different duties. For instance, in the context of an SUV designed for urban daily driving with occasional highway use, the emphasis on sensor integrity, pedestrian impact considerations, and low-speed crash performance remains paramount. Yet for commercial applications where dependable protection against minor bumps and debris is essential, the bumper’s energy-absorbing characteristics and resilience under repeated small impacts become crucial. The OEM philosophy, with its emphasis on precise fit and safety-first engineering, underpins both scenarios. It also informs the way repairs are discussed with insurers and service centers, clarifying why certain parts are selected and how they preserve the vehicle’s safety performance. In the practical world of maintenance and ownership, this translates into clear, actionable guidance: when replacing a front bumper, opt for parts that maintain the original geometry of the assembly, preserve sensor alignment, and respect the design intent of the vehicle’s crash structures. Car owners who understand this nuance are less likely to encounter post-repair issues, such as miscalibrated cameras or altered aerodynamic behavior, which can otherwise arise from mismatched aftermarket components. The narrative of OEM bumpers, therefore, moves beyond the bumper itself and into the broader confidence that comes from knowing the car’s safety and performance systems remain harmonized after a repair. It is a confidence earned not through marketing rhetoric but through engineering discipline, testing, and the disciplined maintenance culture that keeps vehicles performing as their designers envisioned. For readers who want to explore concrete examples of the front-end architecture in Mitsubishi models, a practical route is to examine how the Outlander and similar lineups approach bumper design. While each model has its specifics, the underlying principle remains consistent: the bumper is a carefully integrated piece that communicates with the car’s brain through sensors, with the chassis through mounts, and with the road through aerodynamics and cooling. The value of this integrated approach becomes especially clear when minor damage is repaired after a low-speed collision. Replacing only the cosmetic cover, while leaving the crash structures intact, can restore appearance but may fail to restore the original energy absorption profile or the sensor calibration that keeps ADAS functioning as designed. In the broader landscape of vehicle safety and technology, OEM Mitsubishi front bumpers stand as a tangible example of how thoughtful engineering can quietly support high-stakes outcomes. The emphasis on precise fit, reliable energy management, sensor harmony, and aerodynamic integrity demonstrates that safety is not a single feature but a system-level outcome. For those who value a seamless, confidence-inspiring ownership experience, the OEM path offers a consistent baseline that supports safety technology, driving dynamics, and long-term durability. As the vehicle ages, that consistency matters even more, reducing the risk that an aftermarket part will drift away from the original design intent and complicate future maintenance or inspections. In assessing the broader implications of bumper design, it is useful to reflect on how the industry as a whole views front-end components. The move toward higher levels of automation and smarter safety systems places a premium on components that not only withstand the physical demands of a collision but also preserve the fidelity of data that feeds safety features. OEM bumpers, with their known tolerances, provide a reliable platform for such data integrity. This reliability becomes a practical advantage when vehicles are used in diverse driving environments, from crowded city streets to remote backroads, where road debris and minor collisions are common. It is this blend of safety, reliability, and performance that makes OEM Mitsubishi front bumpers a cornerstone of modern vehicle design. When owners consider upgrades for aesthetics or protection beyond the factory baseline, they should weigh the trade-offs carefully. While off-road and performance-focused bumpers may offer enhanced protection or aggressive looks, they typically introduce changes in weight, airflow, and sensor geometry that require careful evaluation and professional installation. The objective remains clear: preserve the integrity of safety systems while aligning with the vehicle’s intended use. In this light, the front bumper becomes more than a shield; it is a statement about how a driver values safety, consistency, and engineering rigor. For readers who want to explore a concrete example of a bumper’s application and fitment in a specific model, consider the Outlander front bumper as a reference point for how OEM standards translate into real-world compatibility and service considerations. Outbound to a detailed product page, this example helps illustrate the practical steps involved in selecting a bumper that preserves sensor alignment, crash protection, and aerodynamic performance while meeting insurance and manufacturer guidelines. The guideposts laid out here reflect a broader conviction: that genuine OEM components offer a dependable path to maintaining the vehicle’s safety performance over time, especially as cars become more capable and more reliant on automated safety systems. As the industry continues to evolve, the core principles behind OEM bumpers—precision, integration, and validated safety outcomes—will remain essential. These principles remind us that safety is not an afterthought but a continuous design objective that accompanies every mile driven. In this sense, the bumper is not simply a shield against minor bumps; it is a guarantor of the reliability of the car’s sensing suite, a steward of its aerodynamic character, and a guardian of its mechanical and structural health. External resources for deeper exploration of these concepts reinforce the idea that the best path to safety is a holistic approach that respects the engineering choices made at the factory. For readers seeking a broader exterior reference, the AutoParts World guide on Mitsubishi front bumpers provides a comprehensive overview of the considerations involved in selecting and maintaining these critical components. It offers technical context that complements the narrative here, helping readers understand why OEM bumpers matter so much in a car’s safety story. External resource: https://www.autoparts-world.com/mitsubishi-front-bumper-guide

Performance-Driven Style: How Mitsubishi Front Bumpers Shape Safety, Cooling, and Personal Expression

Bumpers are often overlooked as mere shields in most everyday conversations about cars, yet in Mitsubishi lineups they stand at a critical intersection of safety, performance, and personal expression. A front bumper, properly conceived, does much more than simply cover the most forward part of the chassis. It manages airflow, protects vital cooling systems, anchors sensors that power modern driver-assistance features, and provides a canvas for a vehicle’s personality. The chapter ahead follows a single thread: that performance and aesthetics are not competing goals but complementary forces when it comes to Mitsubishi front bumpers. The best designs emerge from this combination, where engineering discipline meets artistic intent, yielding parts that are safer in collisions, cooler under pressure, and more engaging to look at when the car is at rest or in motion. In practice, the most transformative bumpers are those that bridge the gap between the lab and the street, the track, or the trail, depending on the owner’s appetite for driving experiences. The narrative begins with performance, moves through the engineering that makes high-speed confidence possible, and then settles into the visual language that owners use to communicate how they drive, what they value, and where their journeys take them. Even readers who are not chasing track records will recognize the value of bumpers that tune cooling, dimensional stability, and pedestrian protection while offering a design that is clearly aligned with the vehicle’s overall silhouette.

From a performance perspective, Mitsubishi bumpers are not passive shells but active components within a car’s thermal and aerodynamic strategy. Modern aftermarket and OEM variants alike rely on smarter materials and smarter shapes. The choice of material has become a central decision point. High-strength fiberglass and carbon fiber composites have moved from the periphery of customization into core efficiency for some models. These materials offer a compelling blend of strength and lightness, which translates into lower sprung weight and improved suspension response. When a bumper contributes even a few extra kilograms less than the original, the chassis can react more quickly to steering inputs, while still absorbing the energy of an impact. The story is not simply about shedding weight; it is about preserving the structural integrity that protects the radiator and other cooling components at the exact speeds and temperatures where performance matters most. If you picture a track-ready scenario, the ability to maintain steady, unobstructed airflow through large, strategically placed channels becomes a decisive factor in engine breathing. This, in turn, supports sustained power delivery and reduces the risk of heat soak that can erode performance over long sessions. In practical terms, a bumper engineered with cooling in mind may feature broad, uninterrupted air intakes and channels that wick heat away from critical components. While the language of speculation often surrounds such features, the engineering logic remains grounded: better cooling means more consistent performance and longer life under stress.

The research landscape acknowledges a spectrum of bumper designs that target different driving environments. For track-focused enthusiasts, a bumper with integrated channels and larger openings can contribute to a measurable reduction in drag and a more favorable pressure distribution around the front end. In a real-world setting, this translates to enhanced high-speed stability and reduced front-end lift, especially when combined with a properly matched grille and underwhat’s exposed to the wind. Even for street-driven cars, the same principles apply, albeit in a more nuanced form. The aim is to maintain the original aerodynamic character of the vehicle while providing just enough extra opening to improve engine cooling and intercooler efficiency. The balance is delicate: too much opening could compromise cooling efficiency in the wrong way or invite debris into the engine bay, while too little could create heat buildup that curtails performance. The design challenge, then, is to harmonize airflow with a front-end geometry that respects radiator protection, sensor alignment, and pedestrian safety concerns. This balancing act is a core reason why many drivers opt for bumpers that are either OEM-spec or are engineered with a careful eye toward protective rigidity behind the fascia. In either case, performance gains emerge not from dramatic, single-feature improvements but from a holistic concept—an integrated approach where the bumper, the grille, the radiators, and the air ducts act in concert to support reliability and speed.

Behind the visible face of the bumper lies a structural reality that is equally important. The energy-absorption characteristics of any bumper are shaped by reinforcement elements and the choice of core materials. High-strength steel or aluminum reinforcements placed behind a resilient outer shell are designed to deform in a controlled manner, absorbing a portion of impact energy and preventing it from cascading into the engine bay or radiator. This approach is especially relevant to off-road and heavy-duty configurations, where the bumper must withstand not only the occasional low-speed collision but the harsher realities of trail obstacles and ground contact. A well-engineered bumper does more than protect; it preserves the ability to start or continue a journey after a perturbation, reducing the risk of expensive downstream damage. Pedestrian protection, too, relies on controlled deformation within these reinforcement zones. The energy absorption profile is tuned to reduce injury risk while maintaining the bumper’s protective role. In a broader sense, this focus on structural integrity helps explain why some enthusiasts are drawn to bumpers that emphasize reinforcement behind the fascia. The presence of a robust, crash-ready structure can contribute to a sense of security and confidence, a subjective but meaningful factor when drivers push their cars toward the limits.

Aesthetics, however, is not the indulgent afterthought that some picture-book designs imply. Customizable design is the heart of a modern visual language, and bumpers serve as the interface between a car’s silhouette and the driver’s personal preferences. The modularity of contemporary bumper systems allows for a high degree of customization without compromising fundamental safety or fit. A bumper can be designed to accommodate aftermarket body kits or to remain compatible with stock panels, depending on the owner’s goals. The possibility to adjust grille mesh density is a subtle yet potent tool for shaping the vehicle’s expression. A denser mesh can convey aggression and speed, while a lighter mesh can suggest a refined, sophisticated stance. The finish thickness, too, becomes a dimension for expression. A thicker, more pronounced finish can emphasize a muscular front end, whereas a thin, smooth surface can reflect a more understated, aerodynamic look. For those who want track-inspired aesthetics without sacrificing daily usability, the modular approach is a practical compromise that preserves the car’s core integrity while enabling a dramatic visual statement.

The visual language extends beyond the bumper’s contour to the overall voxel of the front fascia. A bumper that reads as part of a single, coherent design with accent lines and air intakes can emphasize a vehicle’s motion even when it is stationary. This is not merely cosmetic; it can affect impressions of speed, efficiency, and performance temperament. When a vehicle sits still, the bumper’s lines, the way the air channels carve through the front, and the gloss of the finished surface all communicate an intent: this is a car built with purpose, capable of speed in its DNA. The aesthetics, in this sense, are not superficial; they are a consequence of engineering choices aimed at achieving both form and function in a single, coherent package. A good bumper becomes part of a vehicle’s storytelling—the way its lines echo the car’s performance history, the way its air intakes suggest a thermal strategy, and the way its finish reflects light and color choices that echo the owner’s taste. The result is not merely a new look but a more complete machine, one that can deliver confidence on a winding road and a distinctive impression in a parking lot.

In terms of integration with driver-assistance systems, bumpers must be designed with sensors in mind. Modern safety arrays rely on cameras, radar, and sometimes lidar that live in the area around the bumper or rely on connectors and housings near the grille. A bumper that fails to align with sensors can degrade performance or require costly recalibration after installation. Therefore, while a bumper offers performance and aesthetics, it must also provide precise sensor mounting points and unobstructed air pathways to avoid detrimental interference. The modern Mitsubishi front-end has to harmonize structural geometry, the protective fascia, and the sensor array in a way that keeps the car’s safety suite functioning as intended. The result is a design language that respects sensory geometry while still delivering the aggressive look that many owners crave. For those who are considering a custom path, it is essential to discuss sensor placement and calibration with a qualified professional to ensure that any aftermarket component preserves the integrity of the car’s safety systems over time. A well-executed configuration respects both the machine’s safety architecture and its aesthetic ambitions, delivering a bumper that is not simply seen but felt in the car’s performance envelope.

Of course, the practical realities of installation and maintenance shape every choice.OEM bumpers are engineered to exact factory specifications, ensuring a precise fit and straightforward installation that preserves factory crash protection and alignment with sensors. These options remain attractive for daily drivers and for insurance-compliant repairs where authenticity and reliability are paramount. Off-road and heavy-duty bumpers lean into the advantage of durability; they are crafted from steel or aluminum alloys and commonly include integrated winch mounts and recovery points. They deliver improved ground clearance and robust protection when negotiating rocky trails, but they come with added weight and cost and often require professional installation. Then there are performance- and style-focused bumpers that prioritize aerodynamics and an aggressive appearance, often incorporating air intakes, canards, and bold styling cues. They can improve high-speed stability and cooling but may decrease ground clearance slightly and might demand specialized installation skills.

Designed for more extreme conditions, specialized protection components like brush guards and reinforcement bars complement full bumpers by reinforcing the vulnerable front-end areas, guarding grilles and headlights against impacts that could otherwise cause costly damage. These accessories offer a layered approach to front-end protection, enabling owners to tailor their builds to a balance of rugged capability and everyday practicality. The choice among OEM, off-road, or performance-focused configurations is not a mere matter of taste; it is a calculation of how a vehicle is used, where it goes, and what the owner wants from a driving experience. A daily commuter seeks reliability and quiet operation, while a weekend enthusiast may chase a front-end that looks ready for a sprint and a trail. A commercial operator may require additional protection and easier service access. In every case, the bumper is a foundational element in a vehicle’s safety, performance, and personality.

To illustrate the practical implications of these choices without getting lost in catalog details, consider how a front-end design translates into real-world outcomes. A bumper engineered for improved cooling channels helps the engine maintain stable temperatures under sustained load, whether on a hot freeway climb or in a rolling rally event. A bumper with reinforced backstops reduces the likelihood that a minor collision will escalate into mechanical failure. A modular bumper can accommodate an aftermarket kit while maintaining a reasonable fit with factory lines, preserving both aerodynamics and aesthetics. And a design that respects sensor geometry ensures compatibility with adaptive cruise control, lane-keeping, and other technologies that many drivers now consider non-negotiable. It is the integration of these elements—airflow management, robust energy absorption, modular adaptability, and sensor alignment—that yields bumpers with lasting value. The goal is not to chase novelty but to create a front-end system that works in harmony with the entire vehicle, from the radiator to the radar, from the paint to the parking sensor grid.

Within this broader framework, owners and builders often turn to one practical resource that helps translate theory into a usable plan: a well-curated product page or catalog that clearly outlines fitment, materials, and performance expectations. For readers who want to see how these principles translate into a concrete build path, a representative example can be accessed through this internal reference page front bumper for Mitsubishi Outlander 19. The page provides a concise illustration of how modularity, reinforcement, and finish work together to deliver a bumper that not only looks bold but also behaves responsibly under real-world conditions. It is a reminder that the most successful customization journeys begin with an honest assessment of how the car is used, who is behind the wheel, and what degree of risk or reward defines the owner’s driving story.

Finally, for those who want to widen their reading beyond shop descriptions and into broader industry trends, an external reference offers a complementary perspective on the evolution of front-end design in high-performance and off-road contexts. See this external resource for a broader look at how universal approaches to front bumpers are evolving in response to higher safety standards, weight considerations, and the demand for more aggressive styling: https://www.alibaba.com/product-detail/Mitsubishi-EVO-9-Front-Rear-Bumpers-Universal_1600587943477.html?spm=a2700.details.c0.1.1a1e4d69tQmBhG. This link anchors the chapter’s discussion in a larger market and demonstrates how some design philosophies fit into a broader ecosystem of parts and performance culture, even as individual builders customize to fit their own needs.

In sum, the modern Mitsubishi front bumper is more than a protective shell. It is a performer in its own right, a canvas for creativity, and a strategic component in the vehicle’s thermal management, safety architecture, and sensory integration. The best choices align with the owner’s aims—whether to chase track records, conquer rough terrain, or simply present a striking street presence—while staying true to the car’s core identity. The result is a front end that communicates intent through both its lines and its functions, a tangible manifestation of how performance and aesthetics can harmonize in one of the vehicle’s most visible and influential elements.

Final thoughts

In summary, Mitsubishi front bumpers are essential components that greatly influence the safety, performance, and aesthetic appeal of vehicles. For business owners, understanding the different types available—OEM, off-road, performance, and specialized components—allows you to choose an option that meets specific operational needs while ensuring compliance with safety standards. As you plan for customization, consider how these enhancements can support your brand image and improve vehicle functionality. Ultimately, investing in the right Mitsubishi front bumper not only protects your assets but can also elevate your brand’s presence on the road.