The 2016 Mitsubishi Lancer front bumper plays a crucial role in enhancing vehicle performance, safety, and aesthetic appeal. As a business owner in the automotive industry, understanding the types of bumpers available, their aerodynamic enhancements, economic impacts, and safety compliance is essential for informed decision-making. The dynamics of the aftermarket sector reveal significant opportunities for quality parts sourcing and sales strategies. This narrative unfolds in four chapters, each detailing vital aspects of the Mitsubishi Lancer front bumper that can impact your business’s success in the automotive parts market.

Material Matters and Structural Design: The Construction of the 2016 Mitsubishi Lancer Front Bumper

A front bumper is often overlooked as a simple cosmetic panel, yet in the 2016 Mitsubishi Lancer it operates as a carefully engineered interface between the road, the vehicle’s safety systems, and the driver’s daily expectations. The bumper is more than a shield; it is a structured element that governs energy management during low-speed impacts, helps preserve the integrity of the grille and headlights, and subtly influences the car’s aerodynamic profile. In the 2016-2017 Lancer lineup, the front bumper assembly is composed with a practical balance of stiffness, resilience, and form. It is designed to integrate with a front bumper cover fascia and grille assembly kit that is commonly configured as a seven-piece set. This modular approach is not arbitrary; it supports precise fitment, streamlined manufacturing, and efficient replacement when accident or wear dictates. The seven-piece configuration typically contributes to the overall appearance by accommodating the grille, trim accents, and related components while preserving consistent gaps and mounting points. The practical outcome is a front end that looks cohesive in showroom photos and remains serviceable in the shop bay after years of daily driving. For readers tracing the evolution of the Lancer’s front end, the arrangement aligns with the general concept of OE-level fitment and repairability that characterize many modern mass-market sedans, where the bumper system is treated as a system rather than a single rigid cover. A closer look at the materials and construction reveals why the bumper remains a critical touchpoint for safety, reliability, and aesthetics across the vehicle’s life cycle. This relationship between material choice and structural design is not incidental; it is the result of decades of polymer science and automotive engineering converging to yield parts that perform under diverse conditions, from hot summer commutes to cold, damp mornings and occasional off-road detours.

The foundational material for the stock front bumper is a durable plastic, most commonly a grade of Acrylonitrile Butadiene Styrene (ABS). ABS is favored in automotive exterior components for its combination of stiffness, impact resistance, and processability. It provides a resilient skin that resists cracking and deformation under normal temperature variations and modest impacts—conditions that typify everyday driving scenarios. ABS also offers a favorable balance between rigidity and slight give, an important characteristic when the bumper system engages with other structural members or load paths during low-rate impacts. This material choice supports OE-level fitment because it tolerates repeated mounting and dismounting without compromising the alignment of the bumper cover, the grille, or the surrounding fascia. In the context of the Lancer, the bumper’s design assumes the ABS skin is backed by an energy-absorbing layer and a rigid reinforcement member, creating a two-layered protection strategy. The reinforcement the bumper attaches to is typically connected to the vehicle’s frame or subframe through impact-absorbing structures that help dissipate energy and reduce the likelihood of damage to critical components behind the bumper. And from a manufacturing perspective, ABS lends itself to efficient, repeatable production through injection molding, ensuring uniform walls, consistent wall thickness, and predictable performance across thousands of units.

Among the practical implications of this material choice is the bumper’s behavior under a spectrum of environmental conditions. ABS handles normal temperature variation without significant warping or cracking, a quality that is essential for daily use in varying climates. The automotive-grade standards that govern OEM components demand resilience to UV exposure, moisture, and road salts, and ABS formulations used for bumpers are engineered to resist surface degradation while maintaining color stability. The chrome and black accents sometimes seen on the front-end assembly arise from additional cosmetic treatments or inserts that complement the main ABS shell. These cosmetic touches are not merely decorative; they must endure the same weathering cycles as the base material, or the finish will peel or fade, undermining the overall aesthetic and perceived quality of the vehicle.

From a design perspective, the seven-piece front bumper kit is more than a collection of parts. It represents a modular approach that streamlines assembly, replacement, and repair. Each piece plays a well-defined role in shaping the front end’s geometry, ensuring consistent tolerances around the grille, fog-light housings, lower valance, and side openings. The interplay between the bumper cover fascia and grille assembly influences airflow, which in turn affects cooling efficiency and minor drag characteristics. While the Lancer’s chassis remains relatively compact, the bumper’s geometry is carefully sculpted to minimize air resistance while preserving the necessary room for interior components behind the bumper line. The end result is a front end that blends form and function, delivering a confident look without compromising daily usability. In this context, an OEM-style bumper is designed not only to endure routine contact with minor obstacles but also to align with the vehicle’s overall silhouette and aerodynamic intentions.

For enthusiasts who crave performance-oriented upgrades, the landscape includes options built from reinforced plastics or composite materials such as fiberglass. These materials can bring meaningful gains in rigidity and weight reduction, which can translate into small but noticeable improvements in handling and acceleration response. They also enable more ambitious aerodynamic configurations, as composite bumpers can incorporate integrated diffusers or spoilers to manage airflow more aggressively than a conventional ABS shell. However, such upgrades must be chosen with care, because the combination of higher rigidity and altered mass distribution can affect crash behavior and pedestrian safety characteristics. In the broader sense, the evolution from standard ABS to reinforced or composite alternatives illuminates a general trend in the sport- and performance-oriented segment of the market: engineers and fabricators seek to push the envelope on aerodynamics and downforce while maintaining reliable energy management and OEM-grade fitment. The underlying principle remains the same: materials selected for the bumper must balance stiffness, impact resistance, weight, and durability so that the part supports both everyday reliability and occasional high-performance demands.

Safety and certification remain central to the story of any bumper design. Automotive-grade parts are expected to comply with various safety and durability standards, ensuring that the bumper holds up under routine use and in more demanding driving conditions. The material science behind ABS and the engineering of the bumper’s internal support structures work together to meet these requirements. The bumper cover is not an isolated shell; it is a component of a larger system that includes mounting brackets, energy-absorbing foams, and reinforcement bars. The integrity of this system depends on precise tolerances, robust bonding between materials, and durable finishes that resist environmental wear. OEM-grade parts achieve this through controlled manufacturing processes, rigorous quality control, and a supply chain designed to deliver consistency across multiple production runs and geographic regions. In practice, this means the bumper system is designed to integrate with other front-end components—such as the grille, headlights, and trim—without introducing misalignment or gaps that could affect aerodynamics or aesthetics. When viewed in this light, the bumper becomes a small but essential module in a larger ecosystem that keeps the vehicle performing, looking, and feeling right on the road.

The sourcing landscape for these components adds another layer to the discussion. The global supply chain for modern bumper systems reflects a mature ecosystem in which injection molding, fiberglass fabrication, painting, and tooling converge to produce high-fidelity parts at scale. For OEM replacements and quality-conscious buyers, the emphasis rests on achieving a seamless fit with the original vehicle geometry, ensuring that mounting points align and that the bumper’s surface finishes maintain their appearance under exposure to sun, rain, and road grit. The practical implication for owners is a straightforward path to replacement when required, with parts that preserve the vehicle’s intended appearance and performance. As the literature and industry notes indicate, the manufacturing centers that support these parts are often located in regions with established plastics and composite industries, where a full spectrum of capabilities—from molding to painting to final assembly—can be coordinated to deliver reliable, consistent components.

In terms of maintenance and longevity, ABS-based bumpers are typically resilient but not impervious. Routine care involves cleaning the surface to prevent abrasion of the finish and inspecting for any microcracks that could propagate under repeated impacts or temperature cycling. In the event of a collision or a heavy scrape, the modular nature of the seven-piece kit can facilitate targeted replacements rather than wholesale bumper replacement, reducing downtime and preserving factory alignment. For drivers, this translates into a practical approach to upkeep: treat the bumper as a shared surface that bears the brunt of road hazards while remaining a visually integral part of the vehicle’s front end. The combination of material choice, modular construction, and thoughtful design yields a bumper that supports the Lancer’s everyday reliability and its occasional, more spirited driving experiences without demanding excessive maintenance or frequent cosmetic repairs.

The broader implications for the field are clear. The 2016-2017 Lancer front bumper, rooted in ABS plastic, demonstrates how a seemingly modest component can embody the intersection of safety, style, durability, and efficiency. The material’s properties align with the car’s intended usage—daily driving with an eye toward repeatable replacement when needed—while leaving room for performance-oriented upgrades that do not compromise basic safety standards. In short, the bumper provides a practical, measurable platform for both ongoing everyday performance and the potential exploration of aerodynamics and weight-saving customizations. Those who study or work with front-end components can trace how material selection, geometry, and modular assembly converge to deliver a part that protects, guides, and visually anchors the vehicle’s face. The resulting chapter in the Lancer’s ongoing design story is one of balanced engineering—where cheap, cheerful plastics meet quality control, and where the road, rather than the showroom, ultimately tests the bumper’s mettle.

For readers who want to explore more about the specific overview of the 2016 Mitsubishi Lancer front and rear bumpers, this discussion aligns with the broader catalog of Lancer front-end configurations and their compatibility with various trim levels and body styles. See the overview here: 2016 Mitsubishi Lancer front and rear bumpers. This internal reference helps connect the material-focused analysis with practical replacement considerations and the evolving landscape of front-end parts available for this model.

From a practical perspective, the takeaway is straightforward: for the 2016 Lancer, the front bumper is a purpose-built, OEM-quality interface that balances rigidity, impact resistance, and ease of replacement. The ABS plastic skin provides a robust, cost-effective solution suitable for daily driving, while the seven-piece kit arrangement ensures precise fitment and straightforward service. In the hands of a professional shop or a careful owner, the bumper remains a durable, adaptable component that can accommodate modest upgrades without sacrificing core safety and reliability. The future of bumper design continues to push toward materials that reduce weight and improve aerodynamics, yet any advancement will still need to respect the fundamental principles observed in the Lancer’s front-end construction: predictable crash energy management, durable finishes, and a modular approach that makes maintenance practical rather than punitive. In that sense, the 2016 Lancer bumper offers a compact but instructive case study in how modern automotive design harmonizes material science, manufacturing practicality, and the daily realities of ownership.

External resource for further reading: External reference listing on bumper materials and construction

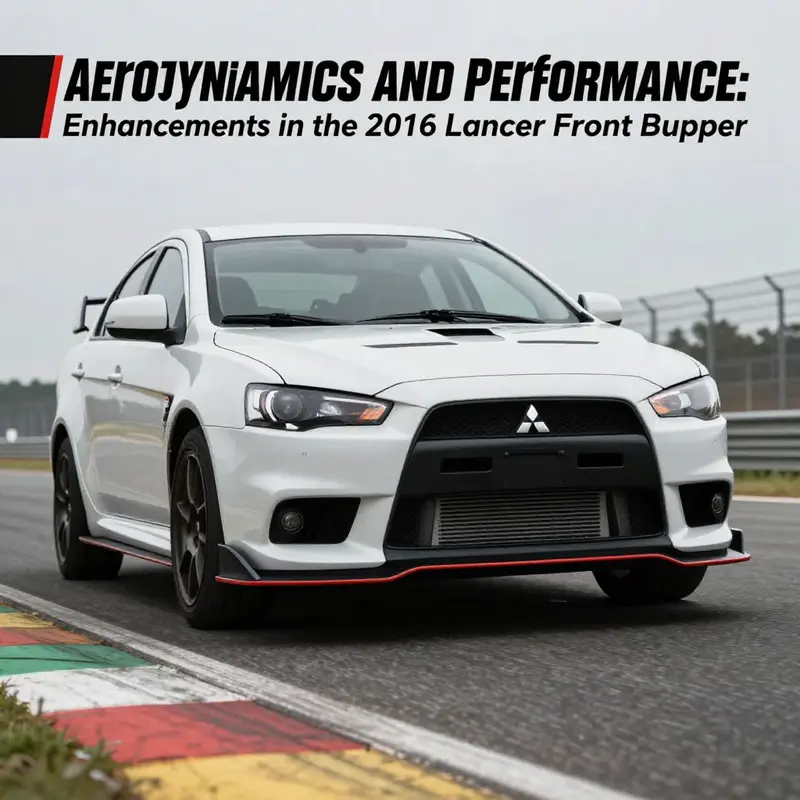

Racing-Ready Airflow: Aerodynamics and Performance of the 2016 Mitsubishi Lancer Front Bumper

The front bumper is more than a visual frame for a car’s face; it is the first interface between the vehicle and the air that surrounds it. In the case of the 2016 Mitsubishi Lancer, the bumper plays a pivotal role in shaping the way air travels around the front end, how turbulence forms near the grille and under the chassis, and how the car begins to respond to throttle and speed. A well-conceived front end channels air efficiently, reducing drag and smoothing the buffet of microscopic eddies that would otherwise sap fuel efficiency and stability. This is not mere theory; even small changes in the way air streams around the bumper affect the vehicle’s overall performance on highway miles and on the tighter, momentum-driven paths of track days. The bumper functions as a critical node in a broader aerodynamic system that includes the grille, the hood contour, the underbody panels, and any add-on elements that engineers, designers, and enthusiasts fit to the car. In the 2016 Lancer’s design language, the nose was shaped to guide air toward the sides of the radiator and into carefully contoured channels beneath the car. The aim was to minimize flow separation at the leading edge and to create a smooth transition from the free stream to the quieter, lower-pressure region under the bumper. The resulting airflow reduces pressure drag while preserving the structural and thermal integrity of the front end. Even at city speeds, where the car spends a lot of its time in a turbulent boundary layer, the bumper’s geometry helps keep the front fascia calm, which translates into steadier steering feel and more predictable response as road conditions change. The principle remains the same at highway speeds: a streamlined nose lowers the energy cost of pushing air over the surface, enabling a modest improvement in fuel efficiency and enabling the car to settle into a stable aerodynamic state more readily. For enthusiasts seeking to push the envelope further, the conversation often turns to how aftermarket enhancements interact with the base geometry. A common path is to add an air dam or splitter that extends outward from the lower lip of the bumper. The purpose is twofold: to generate a controlled amount of downforce and to trap the boundary layer in a way that keeps it attached to the surface longer, reducing local turbulence that would otherwise destabilize the front end at speed. When executed with care, these elements can yield a practical benefit without a heavy penalty in drag. Yet the balance must be managed. The pursuit of more downforce must be weighed against the potential for increased drag that could hamper top speed and fuel economy on longer highway segments. In essence, the goal is to tune the air against the bumper so that the payoff in stability and grip at speed is not offset by excessive aerodynamic resistance. Another pathway into performance lies in integrating forms that manage the air as it exits and flows beneath the car. A diffuser-like underside, even when modest, works with a well-designed splitter to encourage a smoother wake behind the bumper. The combined effect can lower pressure under the car, reducing lift and increasing front-end stability. For drivers who track their cars or push harder on winding roads, such configurations can translate into more confident turn-in, a more planted front axle, and a clearer sense of the car’s intent when steering input is applied. This is not about chasing extreme aero numbers; it is about achieving a coherent, repeatable front-end behavior across a range of speeds and driving conditions. It is the kind of design philosophy that makes the bumper an active contributor to handling, rather than a passive skin that merely covers the frame. The material story behind these front-end adaptations also matters. Modern aftermarket options for bumpers and related aero components are typically crafted from lightweight, rigid composites or reinforced plastics. The material choice helps keep weight down, preserving the chassis balance and fuel economy while offering the ability to mold more complex shapes that optimize flow. A fiberglass composite, for example, can deliver a strong, lightweight structure suitable for aggressive aerodynamics, while high-grade plastics can provide excellent impact resistance and dimensional stability. The trade-off is the usual engineering equation: stiffness, weight, and durability must align with the intended use, be it street driving, spirited canyon runs, or circuit days. When designers integrate these elements with OEM mounting points, attention to fit and finish becomes essential. The result is a front end that not only looks the part but behaves in a predictable, repeatable way under a wide spectrum of speeds and road conditions. In the broader ecosystem of performance parts, the bumper’s aerodynamic role is often complemented by integrated features that enhance both safety and aesthetics. Some builders opt for lightweight, purpose-built diffusers or vents that work with the bumper to manage airflow around the wheels and the sides of the car. Others incorporate lighting elements that improve visibility and signaling without compromising the aero profile. Even small additions can influence how the front of the car interacts with the air, and the cumulative effect across the entire fascia can be meaningful. Importantly, these enhancements are designed to be compatible with everyday driving as well as with more demanding scenarios like track days. The chassis benefits from consistency in aerodynamic behavior, which translates into more confident handling and better feedback through the steering wheel when entering and exiting corners at speed. From a procurement and production perspective, the story extends beyond the individual car to the larger supply chain and manufacturing landscape. The global ecosystem for 2016 Lancer-front-end components reflects a mature market in which engineers and buyers pursue precision and repeatability across production runs. The ability to scale from a single customized unit to a batch of parts hinges on integrated processes—such as injection molding for certain plastics, fiberglass fabrication for composites, precise painting, and tooling that supports consistent fitment. Across regions, manufacturers have established capabilities that allow rapid turnaround while maintaining automotive-grade standards. In practice, this means a bumper design that can be prototyped, tested for flow, and refined for durability without sacrificing the clarity of the front-end silhouette or the alignment of mounting points with the rest of the car’s architecture. The result is a coherent system where every piece works in harmony with the next, rather than a collection of add-ons that merely sit on the surface. The end user thus experiences a more cohesive vehicle character, with aerodynamic cues that reinforce the car’s stance and driving persona without sacrificing daily usability. For readers who want a concrete sense of how these ideas translate into real-world options, a deeper dive into technical details and design considerations can be found in product listings that discuss the 2016 Mitsubishi Lancer front bumper in a broader context. The discussion there emphasizes how airflow management, structural integrity, and certification standards come together to create a part that performs on both street and track. To explore the concept in a linked format, see the page linked here: 2016-mitsubishi-lancer-front-and-rear-bumpers. This reference helps illuminate how practical fitment, material choices, and production realities intersect with the aerodynamic goals described above, offering a bridge between theory and applied engineering. The broader takeaway is that the 2016 Lancer’s front bumper, when viewed through the lens of aerodynamics and performance, embodies a holistic approach to vehicle dynamics. It is not merely about reducing drag or increasing look-at-me appeal; it is about shaping the car’s response to air in service of safer, more controlled handling and a more engaging driving experience. The considerations extend from the wind tunnel-inspired ideals that govern the shape to the everyday realities of mounting, maintenance, and compatibility with other vehicle systems. Aerodynamics is thus a living discipline on the street, where even modest upgrades can reshape how a car feels when you push through a bend or merge onto a highway. And because the bumper lives at the intersection of form and function, its evolution continues to reflect advances in materials, manufacturing, and the evolving expectations of drivers who seek both performance and reliability from a car they use every day. The conversation remains open, and the path forward is about balancing efficiency, stability, and practicality in a way that feels seamless to the driver who sits behind the wheel. External resource: For a deeper technical look at the kind of specifications and design insights that inform these decisions, you can consult an external listing that outlines the related features and performance considerations: https://www.alibaba.com/product-detail/2016-Mitsubishi-Lancer-Front-Bumper-946_62587351724.html

How the Lancer 2016 Front Bumper Supply Chain Drives Regional Industry and Global Trade

The front bumper for the 2016 Lancer is more than a cosmetic panel; it is a focal point of an industrial network that channels investment, skills, and trade through a tightly integrated supply chain. This chapter traces how manufacturing clusters, materials markets, logistics nodes, and aftermarket demand combine to create measurable economic effects. It explains why production for this single part supports jobs, sustains suppliers, and shapes procurement strategies worldwide.

Clusters of specialized production give the front bumper its economic power. In regions where fabrication of exterior body parts concentrates, companies share suppliers, tooling expertise, and labor pools. Processes such as injection molding, fiberglass layup, composite curing, painting, and final assembly sit side by side. That co-location reduces transaction costs and lead times. It also enables firms to scale production quickly when orders rise. For the Lancer 2016 front bumper, manufacturers that operate these operations together can offer competitive pricing without sacrificing throughput or quality. The result is an export-oriented manufacturing base that channels revenue into local wages, business services, and capital investment.

Raw material markets form the backbone of this activity. Common substrates like ABS, polycarbonate, and various fiberglass resins maintain steady demand. Suppliers of pellets, reinforcement fibers, and coatings benefit from predictable consumption patterns driven by aftermarket cycles. When a new bumper program ramps up, upstream suppliers increase output and sometimes expand capacity. That ripple effect supports secondary employment across shipping, warehousing, and processing plants. It also insulates the local economy against downturns in single sectors, because these materials serve many automotive and consumer-product applications.

Ports and freight corridors magnify economic impact. Proximity to major seaports reduces shipping costs and shortens transit times to key markets. Efficient access to container terminals and bonded logistics zones allows firms to consolidate shipments and meet strict delivery windows. These advantages attract foreign buyers and distributors that need reliable supply chains. Freight efficiency also lowers inventory carrying costs for B2B buyers, enabling leaner procurement models. Over time, port-adjacent manufacturing tends to draw supporting infrastructure—freight forwarders, customs brokers, and inland trucking services—creating additional business opportunities.

Quality standards and certification are important economic drivers as well. Meeting international automotive-grade certifications expands market access to North America, Europe, and Japan. Compliance demands investments in testing equipment, process controls, and staff training. Those investments increase the value of local capacity. Manufacturers that achieve and maintain certifications can charge premium prices and secure larger, long-term contracts. Certification therefore channels resources into higher-skilled jobs and encourages technology transfer, as firms adopt better metrology, paint booths, and automated finishing lines.

Aftermarket demand shapes product varieties and volumes. Enthusiasts and performance-minded drivers create niches for lightweight or aerodynamic bumpers. These niches support specialized suppliers who develop composite solutions and aerodynamic add-ons. Although niche volumes are smaller, they carry higher margins and drive innovation. Small firms that design aerodynamic features often partner with larger manufacturers for production scale. This collaboration spawns design services, small engineering consultancies, and localized prototyping facilities, expanding the economic footprint beyond simple part manufacturing.

The supply chain’s economic benefits extend into tooling and capital goods. Molding tools, cutting jigs, and paint fixtures represent substantial upfront costs. Local toolmaking shops supply these assets and, in doing so, build durable capabilities. Over time these shops diversify into tooling for other vehicle models and industries. Their revenue from tooling contracts underwrites reinvestment in CNC machines, inspection gear, and training programs. This capital deepening raises regional productivity and supports higher-value exports.

Trade flows created by bumper production also influence currency and trade balances. Export revenues from body panels help stabilize regional trade positions. For economies with large manufacturing clusters, automotive component exports constitute a reliable foreign exchange source. That inflow supports other sectors through multiplier effects. Taxes and fees on export activity feed public budgets that can be reinvested in infrastructure, vocational training, and industrial parks. Those public investments in turn reinforce the competitive advantages of manufacturing clusters.

Employment effects occur at multiple skill levels. Assembly lines employ technicians and machine operators. Tool shops and paint facilities require skilled tradespeople. Design and quality assurance roles support engineers and metrologists. Training programs tailored to composite fabrication and injection molding help workers transition into higher-paying roles. The distribution of jobs reduces income inequality in host regions and increases consumer spending power. Local service industries—restaurants, housing, finance—benefit directly from this strengthened demand.

Logistics and inventory strategies shape procurement economics for buyers. Shorter lead times reduce stock requirements for distributors. Manufacturers close to ports can adopt just-in-time deliveries for larger clients. For procurement managers, sourcing from regional clusters lowers total landed costs even when unit prices are similar. That reliability creates long-term supplier-buyer relationships and reduces the need for costly contingency inventory. As a result, distributors and installers can offer faster turnaround to end customers.

Scale economies in production allow price competitiveness that supports global distribution. High-volume runs spread fixed tooling and setup costs across many units. When manufacturers can group orders across multiple bumper designs or adjacent models, they lower per-piece costs. These savings transfer into lower wholesale prices and higher margins for intermediaries. For buyers seeking OEM-grade replacements, this structure yields attractive unit economics without sacrificing fit and finish.

Risk and resilience are economic realities in a global supply ecosystem. Tariff changes, shipping disruptions, and raw material price swings can affect margins. Strategic diversification of suppliers and dual-sourcing arrangements helps firms manage volatility. Investment in local buffer stocks or alternative materials can soften shocks. Some manufacturers pursue nearshoring or regional assembly to reduce exposure to long-haul container delays. Those strategic shifts have secondary economic effects, including demand for local warehousing and logistics software, and increased hiring in procurement and supply planning.

Environmental and regulatory compliance adds complexity and value. Paint shops and composite facilities must manage emissions and waste. Compliance creates costs, but it also creates opportunities for specialized service providers in waste treatment, solvent recovery, and emissions monitoring. Firms that demonstrate strong environmental controls gain market access in jurisdictions with strict import regulations. Certification for environmental management can thus become a market differentiator, enhancing export potential.

Smaller firms and startups play a role in the ecosystem too. They bring design agility and new materials expertise. When they collaborate with larger manufacturers, they create innovation pathways. Those pathways produce intellectual property and service exports, including design licenses and prototyping work. Local economies benefit when these startups employ engineers and designers who purchase local services and contribute to a skilled talent pool.

For procurement managers and B2B buyers, the economic landscape translates into actionable choices. Evaluating suppliers on total cost, not unit price, captures logistics, lead time, and compliance costs. Prioritizing certified suppliers reduces rework and warranty claims. Building long-term contracts with production clusters can secure volume discounts and priority scheduling. Using suppliers close to major ports can further trim logistics costs, simplifying global distribution.

The supply chain supporting the 2016 Lancer front bumper exemplifies a mature aftermarket ecosystem. It leverages concentrated industrial capability, stable raw material demand, and efficient logistics to create a resilient export sector. This sector supports jobs across skill levels, drives investment in tooling and testing, and underpins local service industries. Firms that operate within or source from this network gain access to competitive pricing, quick turnaround, and certified quality, while regional economies earn stable export revenues and technological upgrading.

For a practical view of supplier capabilities, quality assurance practices, and logistics optimization within this ecosystem, see the supplier guide tailored for buyers in this segment: https://www.mitsubishilancerparts.com/supplier-guide-evo-x-bumper.

For parts, replacement options, and examples of aftermarket body panels compatible with the 2016 Lancer, explore the detailed listings for front and rear bumpers on the shop page: 2016 Mitsubishi Lancer front and rear bumpers.

Meeting Impact, Climate, and Sensor Demands: Compliance Essentials for 2016 Mitsubishi Lancer Front Bumpers

Materials, integration and tested performance: how compliance shapes the front bumper for the 2016 Mitsubishi Lancer

Selecting a front bumper for a 2016 Mitsubishi Lancer means balancing looks with safety, durability, and legal compliance. A bumper’s role goes far beyond styling. It absorbs low-speed impacts, helps manage crash forces, and supports pedestrian protection systems. It also houses fog lamps, sensors, and aerodynamic features. When a replacement differs from factory specifications, the car’s safety performance can change. For owners, fleet managers, and procurement teams, understanding how bumpers are tested and certified is essential for choosing parts that preserve both functionality and compliance.

At the core of compliance is engineering to original fitment and performance. Factory replacement bumpers are designed to match the vehicle’s mounting locations, stiffness, and energy-absorption characteristics. These parts are engineered to interface with restraint systems. When a bumper meets those design tolerances, it helps ensure predictable crash behavior. It also keeps the timing and functioning of supplemental restraint systems intact. For aftermarket options, the presence of certification and third-party test reports is the most reliable sign that a design achieves comparable safety performance.

Testing regimes for bumpers focus on impact absorption and pedestrian compatibility. In many jurisdictions, federal or regional standards set baseline requirements for how a bumper reacts in collisions. These standards assess energy absorption at defined speeds and impact points. Independent programs, such as regional vehicle assessment protocols, evaluate pedestrian protection and sensor interference. Credible aftermarket suppliers subject their parts to similar tests. They provide documentation covering impact loads, deformation characteristics, and how the bumper affects sensor lines. Requesting those reports is a practical step before purchase.

Material choice plays a direct role in compliance and long-term reliability. Thermoplastic polymers like polyurethane and polycarbonate are commonly used for front bumper skins. These materials offer controlled flexibility, good impact resistance, and UV stability. Composite options, including reinforced fiberglass, provide a different balance: they can be lighter and stiffer. That stiffness can help aerodynamic goals, but it may change how impact energy is distributed. When a component is stiffer, crushing behavior changes, which can alter forces transmitted to crash structures. Because of that, any material substitution must be validated by impact testing to confirm it does not degrade occupant or pedestrian safety.

Environmental durability is an often-overlooked compliance dimension. In hot, arid climates with high UV exposure and airborne dust, materials can embrittle, warp, or fade if not specified and tested for those conditions. High-quality materials undergo thermal cycling, UV exposure, and sand/abrasion testing to mimic real-world extremes. This testing documents expected lifespan and performance under heat and dust exposure. For buyers in harsh climates, technical data on thermal resistance and UV stability should be part of procurement decisions. A bumper that fails prematurely can compromise safety just as surely as one that fails in a collision.

Modern bumpers must also integrate seamlessly with vehicle electronics. Parking sensors, forward collision sensors, and ADAS cameras rely on predictable mounting positions and material transparency to perform correctly. A change in bumper geometry or material can distort acoustic signatures or alter radar reflections. That may reduce detection accuracy or delay system responses. Good replacement designs preserve sensor mounting brackets and maintain the same relative thickness and surface characteristics. Suppliers supplying certified parts will include test data showing ADAS compatibility and the absence of interference with sensors.

From a manufacturing standpoint, quality control and traceability matter. Leading supplier hubs offer integrated production capabilities. This includes injection molding, composite layup, painting, and tooling. Full integration supports consistent wall thickness, uniform resin distribution, and repeatable fitment. Consistency reduces variability in impact response and makes certification more reliable. For procurement teams, documented production processes and quality control records are useful indicators of maturity. Traceability of raw materials, resin grades, and batch testing for key properties should be requested for critical fleet purchases.

Certification and documentation are the practical proof that a bumper meets regulatory and safety expectations. Look for parts that reference compliance with regional vehicle safety standards. In the United States, Federal Motor Vehicle Safety Standards establish performance expectations for many vehicle components. In Europe, vehicle assessment programs examine pedestrian protection and overall crash performance. Reputable suppliers will share certificates, lab reports, and test data demonstrating performance against these frameworks. When such documentation is absent, treat the part as unverified and weigh the potential liability.

Fitment and installation are the final links in the compliance chain. Even a certified part can underperform if installed incorrectly. Mounting hardware, absorbers, and energy-management brackets must be fitted as designed. Some aftermarket kits change mounting interfaces; others reuse factory brackets. Insist on installation instructions, torque specifications, and alignment procedures. Where possible, use certified technicians who document the fitment process. For vehicle owners, retaining installation records supports warranty claims and helps with insurance coverage in the event of a claim.

For B2B buyers and procurement managers, sourcing strategy influences compliance outcomes. Sourcing from experienced suppliers with integrated production capabilities and track records of certification reduces risk. Manufacturing centers with mature ecosystems often provide faster iterations, tooling, and localized testing. When dealing with overseas production hubs, require independent verification. Contract clauses should mandate batch testing, material certificates, and inspection protocols. Clear acceptance criteria tied to test results protect buyers against nonconforming deliveries.

Insurance and legal implications are part of the compliance picture. Using non-certified parts in repairs can complicate insurance claims after a crash. Insurers may question whether substitute components contributed to damage or injury. Likewise, regulatory authorities may scrutinize vehicles with parts that alter crash conformity. Keeping an auditable chain of custody for replacements, and choosing parts with transparent compliance documentation, reduces legal risk.

Labeling and parts marking help with post-installation traceability. Legitimate manufacturers provide part numbers, batch codes, and material identifiers on each bumper. These markings support recall actions and warranty processes. If a part lacks marking or permanent identification, its provenance is unclear. For fleet operations, serial tracking of replacement parts improves maintenance planning and regulatory compliance.

Procurement decisions should include practical checks buyers can perform. Request technical datasheets specifying material grade, tensile strength, and impact resistance. Ask for environmental test reports showing UV and thermal performance. Confirm that sensor mounting locations match OEM positions. Insist on photographs or test certificates proving no interference with ADAS. Finally, obtain a written warranty that ties coverage to correct fitment and to the stated material performance.

When aesthetic changes are important, verify that styling modifications do not affect safety. Aerodynamic add-ons such as diffusers or lips can change airflow and affect cooling or downforce. Changes in downforce can alter vehicle dynamics at speed. Ensure that any aerodynamic enhancements have been validated in wind tunnel or computational studies that also check for unintended load changes at typical operating speeds.

In markets with extreme environmental challenges, prioritize materials and tests tailored to those climates. Suppliers often offer upgraded formulations with increased UV stabilizers and modified resin systems that better resist cracking. Where dust ingress is a concern, ensure that mounting tolerances and sealing features prevent abrasion against metallic structures. These details extend service life and preserve safety performance.

Choosing a front bumper that meets safety standards requires diligence. Request objective test data, insist on traceability and proper installation, and verify compatibility with sensors and restraint systems. For buyers seeking model-specific replacements, a focused resource on available parts and fitment can simplify validation. A good starting point for parts and service information is the site’s detailed listing for 2016 Mitsubishi Lancer front and rear bumpers, which includes fitment notes and contact details for verified suppliers: 2016 Mitsubishi Lancer front and rear bumpers.

For definitive guidance on federal safety requirements and certification pathways, consult the official regulatory resources that outline impact resistance and testing protocols: https://www.nhtsa.gov

Final thoughts

The 2016 Mitsubishi Lancer front bumper is more than just a cosmetic element of the vehicle. It embodies advancements in materials, aerodynamics, economic opportunities in manufacturing, and adherence to essential safety standards. By understanding these aspects, business owners can better navigate the aftermarket parts market, ensuring that they provide high-quality, performance-enhancing components that meet industry demands. A strong grasp of these factors not only fosters growth in sales but also builds a reputation for reliability and safety within the automotive sector.