The Mitsubishi Lancer EVO X engine, known as the 4B11T, is a remarkable engineering feat that embodies high performance and reliability. Designed for enthusiasts and business owners alike, this engine represents a commitment to innovative technology and impressive power outputs. As we delve into the various chapters, we will explore the engine’s specifications, the incredible possibilities for modifications, and its reputation for reliability within the automotive community, demonstrating why it remains a top choice for performance vehicles.

Heart of a Rally Legend: The 4B11T Engine that Fueled the Mitsubishi Lancer Evolution X

The Lancer Evolution X stands as a hinge between two eras of Mitsubishi’s performance story, and its engine, a compact 2.0-liter turbocharged inline-four, is the beating heart that translated engineering intent into road-and-rally capability. Rather than a mere powerplant, the engine here embodies a philosophy: combine aluminum finesse with precise breathing, turbocharged impetus with refined control, and a layout that sustains high-rev drama while still lending itself to reliability under punishing driving conditions. In this sense, the engine becomes not just a source of horsepower but a conductor of the car’s character—lean, exacting, and capable of delivering a surge of speed that feels as deliberate as it is exhilarating. The chassis, weight, and drivetrain then respond as a single system, a cohesive whole that rewards both measured, high-speed tempo on a track and the brutal, unpredictable tempo of a rally stage. To understand the EVO X’s engine is to understand the entire approach of the car: it is not about loud claims or dramatic acceleration alone, but about a balanced, repeatable, high-performance envelope that a skilled driver can explore, refine, and trust when the road narrows and the corners demand confidence.

The engine’s construction begins with a material choice that signals intent: a full aluminum architecture designed to shave weight without sacrificing rigidity or durability. In the lineage of Mitsubishi’s performance lineage, this represents a meaningful shift from earlier generations, where heavier castings weighed the response of the entire powertrain. The EVO X’s aluminum construction reduces mass by a notable amount compared to its closest predecessor, allowing the engine to respond more eagerly to throttle input and to work more efficiently with the car’s drivetrain as a whole. That lighter heart helps the front end bite into corners with less parasitic rotation and helps the suspension do its job with less opposing inertia. It is a quiet kind of performance engineering, the kind that does not reverberate as loud claims but resonates in the feel of the steering wheel and the chassis through every hard corner and acceleration out of it.

Moving beyond the outer shell, the engine is a dual overhead cam design that embraces advanced valve timing and lift control. Rather than a single, rigid timing profile, the design allows for continuous adjustment of valve opening on both the intake and exhaust sides. This gives the engine a broad, usable torque curve across a wide rev range while preserving high-end breathing that sustains peak power toward the upper limits of the tachometer. It translates into a very practical trait: when the turbo spools and the boost comes on, the engine can respond with enough airflow and precise combustion to deliver meaningful thrust without the kind of abrupt, uneven surge that can unsettle a car at the limit. In day-to-day driving this means smoother progress from low speeds and better fuel efficiency, but when pushed into sport or competitive use the engine reveals a disciplined, predictable surge that a skilled driver can time with the throttle and clutch to maximize corner exits and mid-capacity speed.

The turbocharged nature of the engine is central to its character. The forced induction breathes through a layout designed to extract performance while maintaining drivability. Turbocharging in this package is tuned to deliver a potent midrange and a usable top end, so that even when the peak horsepower sits in the mid-three-figure range, the engine’s real advantage lies in how readily it makes torque across a broad band. The torque figure, peaking in the vicinity of 3,500 rpm, provides a palpable shove that helps the car accelerate with a sense of momentum rather than a sudden, disruptive burst. This is crucial on winding roads or on a rally stage where the driver must manage grip, throttle, and steering input in quick succession. A well-balanced torque delivery allows the driver to apply power smoothly, maintaining momentum through corners and on the throttle’s exit to lay down traction rather than simply spinning it away in the midrange.

Within this framework, the engine’s fuel and ignition system are also calibrated to support a broad, reliable power envelope. It uses a multi-point fuel injection system designed to meet emissions standards while delivering precise fuel metering across the rpm spectrum. In practice, this means the engine can maintain a clean, stable flame front and minimize knock tendency while taking advantage of the turbo boost. The octane requirement—premium fuel with a high knock resistance—plays a key role here. The combination of high compression and turbocharging means the engine can safely run with strong ignition timing and robust boost pressure, but only if the fuel quality is sufficiently high. The result is a package that behaves predictably at high load, with a controllable temperature profile and a favorable air-fuel mixture, all of which keeps the engine from entering an aggressive, unhealthy detonation scenario under spirited driving.

The exhaust path of the engine is another facet of its performance-focused design. A reverse-flow exhaust configuration is characteristic of this family of engines, a layout intended to optimize exhaust scavenging and boost response. By shaping the exhaust flow in a way that promotes efficient energy transfer from the exhaust gas to the intake stroke, this design helps the turbocharger spool more quickly and sustain boost as rpm climbs. The effect is subtle yet meaningful: a quicker response in the lower part of the rev range, a more linear surge as the throttle is applied, and a flatter, more predictable curve as the engine approaches its peak performance. For the driver, that translates into a sense of immediacy—when you press the accelerator, the car replies with a clear and confident surge rather than a laggy or uneven ramp.

The engine’s performance numbers place it squarely in the realm of high-performance street and track offerings. Officially, the maximum output sits close to the mid- to high-300 horsepower range depending on version and tuning, with peak torque arriving in the mid-range to deliver strong, usable acceleration. While the standard version delivers a robust performance figure, Mitsubishi also offered a limited Final Edition that raised the horsepower ceiling further through exhaust refinements and calibration work. This edition, a nod to the model’s storied career, demonstrates how a relatively modest set of changes—focused on exhaust path and tuning—can unlock additional power while preserving all the driveability that makes the car appealing to enthusiasts. It is a reminder that the engine’s potential is not simply a matter of raw numbers but of how those numbers are realized in the context of the whole vehicle’s design.

The 4B11T’s mechanicals also accommodate two distinct drivetrain philosophies that expand the EVO X’s appeal. Traditionalists can opt for a five-speed manual transmission that rewards precise shifting and a direct connection to the engine’s character. Alternatively, there is a six-speed automated manual option that automates gear changes while preserving the performance-oriented feel that enthusiasts crave. This dual-paradigm approach was a deliberate choice: it allowed buyers to choose the driving experience that best matched their needs, whether that meant the tactility of a classic driver’s car or the convenience and predictability of an automated system in more demanding daily use. In both configurations, the engine’s core attributes—weight efficiency, breathing capacity, and precise control of the air-fuel mixture—work in concert with the chosen transmission to deliver a coherent and responsive performance profile.

The engine’s power and torque figures, while impressive in isolation, are most meaningful when understood as part of a broader engineering strategy. Weight savings, a carefully tuned breathing system, and a flexible exhaust path all contribute to a practical outcome: a powerplant that feels powerful where it matters and behaves predictably under a wide range of conditions. This isn’t about chasing peak numbers alone; it’s about a usable performance envelope that the driver can exploit without surprise. The result is a car that excels on winding roads and on performance-oriented circuits alike, where the driver’s ability to manage boost, torque, and throttle response translates directly into faster laps and more confident corner exits. If there is a throughline to the EVO X’s engine, it is that harmony—where lightness and breathing, controlled airflow, and robust torque come together to create a machine that rewards committed, disciplined driving as much as raw speed.

For those who crave deeper technical curiosity, the engine’s core has also inspired a healthy aftermarket curiosity. Enthusiasts often pursue enhancements that push power figures well beyond stock, provided they maintain the integrity of the engine’s balance and the cooling and fueling systems that keep it healthy under higher stress. In this context, the engine’s architecture proves to be a fertile platform: the aluminum block and head, the robust cooling layout, and the valvetrain’s adaptability all provide a canvas for tuning that can yield meaningful gains while still preserving reliability. It is precisely this blend of durability and upgrade potential that has cemented the EVO X’s reputation among fans who treat performance as a careful, ongoing dialogue with their machines. The engineering story here is not about an isolated engine that sits comfortably within a factory’s limits; it is about a platform that invites experimentation while demanding respect for its engineering boundaries.

To illustrate how the engineering community respects the block’s robustness, consider the aftermarket focus on strengthened components that reinforce the engine’s endurance under high-stress use. A notable example is the use of reinforced blocks and associated performance parts, designed to handle sustained high-brake-boost conditions and elevated cylinder pressures. While such enhancements push beyond factory specifications, they underscore a broader truth: this engine’s design tolerates, and even welcomes, deliberate, well-planned augmentation. The spirit here is not reckless escalation but thoughtful evolution—a pathway that allows a driver to keep the machine on its edge while remaining within a corridor of mechanical integrity. As with any high-performance platform, the key is a holistic approach: improving intake and exhaust flow, refining intercooling, ensuring robust lubrication, and calibrating the engine’s control logic to respond cleanly to the driver’s intent under load.

In this context, the engine’s place within the EVO X’s broader identity becomes clearer. It is not simply a power unit; it is the core that enables a dynamic driving experience. The chassis, suspension, and tires all respond to the engine’s output with a sense of proportion. The acceleration and braking balance radiate from the engine’s torque delivery, while steering feedback remains precise and communicative because the powertrain’s mass and inertia are carefully managed. The result is a car that feels agile and composed—capable of aggressive moves when commanded and reassuringly predictable when the road demands a steadier hand. This is a vehicle whose performance is not defined by a single, sensational moment, but by a continuum of moments that the engine helps to shape: the quick response from a light throttle, the confident surge when exiting a corner, and the sustained tempo that allows the driver to maintain speed through a sequence of bends.

Even the engineering culture surrounding the engine reflects its dual life as both a street hero and a rally contender. On the street, the engine delivers efficient power with a tuning margin that allows a careful driver to explore performance without sacrificing everyday reliability. On rally stages or track days, the same engine reveals its true potential, with a surge of torque and the ability to deliver decisive acceleration out of corners, all while maintaining a balance with the car’s weight distribution and traction control. The EVO X’s engine, therefore, embodies a philosophy that performance can be accessible yet uncompromising, responsive yet controlled, and powerful yet manageable in a way that a broad spectrum of drivers can appreciate. It is a rare combination, one that speaks to Mitsubishi’s long-running commitment to building machines that reward skill, discipline, and an understanding of the machine’s own limits.

As with any performance-centric engine, the true measure of its impact lies not only in factory figures but in the culture it helped foster. The EVO X became a hatchback that drivers could push toward the limit with confidence, knowing that the engine would respond predictably rather than surprise them with inconvenient detachment. Enthusiasts across the globe repurposed the platform: they swapped exhaust components, refined intercooling paths, and tuned engine control strategies to coax more power out of the same fundamental architecture. This culture of iteration—rooted in the engine’s robust design and supported by a community of engineers and tuners—illustrates how a well-balanced powertrain can live far beyond its initial certification. The engine is not merely a set of mechanical specifications; it is a catalyst for a shared passion—a catalyst that continues to spark conversations about how far a four-cylinder turbocharged unit can go when pushed by drivers who understand its character and respect its boundaries.

The chapter on this engine would be incomplete without acknowledging how the engine’s core design supports not only exceptional performance but also reliability under demanding use. The aluminum construction reduces mass, which helps heat management and reduces parasitic losses in a daily context. The variable timing and lift system provide a flexible approach to valve control that adapts to both efficiency and performance demands. The turbocharger’s contribution—boost response and high-end power—remains closely connected to the exhaust design and the fuel system’s precision. The multi-point injection scheme ensures that the engine’s combustion remains clean while supplying the necessary fuel across a spectrum of operation. The combination of these elements yields a powertrain that is approachable in regular driving but capable of delivering clarity and speed when the road or track demands it. The EVO X’s engine, in this sense, embodies a rare balance: it can be domesticated for everyday use and unleashed for high-performance pursuit, all within a coherent, carefully engineered package.

For readers seeking deeper technical context, there is additional information available from the manufacturer and related technical references that illuminate how these choices were made and how they performed in various versions of the car. In particular, the Final Edition’s improvements, which shaved a bit more horsepower through exhaust refinements, highlight how small, targeted changes can yield meaningful gains within the same fundamental architecture. The story of this engine is thus a narrative of thoughtful engineering—of material choices, airflow dynamics, and control strategies that together create a machine whose essence is more about the unity of its parts than any single flashy feature.

Internal link note: a tangible example of how the engine’s robustness has bridged stock capability and aftermarket ambition can be seen in component enhancements such as fortified engine blocks. For a concrete illustration of this upgrade approach, see the dedicated aftermarket billet-block option here: 4b11t-billet-block.

In sum, the engine that powers the EVO X is more than a sum of numbers. It is a design that embraces lightweight construction, a sophisticated valvetrain, and a turbocharged breathing system to deliver a compelling driving experience. It rewards the patient, skilled driver with a steady, immediate sense of power. It invites enthusiasts to push its potential through thoughtful modifications while maintaining a core of reliability that supports both everyday driving and the most demanding racing environments. The 4B11T-inspired ethos—efficiency born of precision, power born of balance, and durability born of conservative, engineering-first thinking—continues to inform how modern performance four-cylinders are imagined, built, and enjoyed. The EVO X remains a benchmark for enthusiasts who appreciate how a well-executed engine can shape the entire driving experience, keeping alive a heritage that blends rally DNA with road-going precision in a way that continues to resonate years after its production.

External resource: https://www.mitsubishi-motors.com

Under the Hood: The 4B11T Heartbeat of the Lancer EVO X

Engine architecture and real-world performance

The Lancer Evolution X’s character is rooted in its engine. At the core sits the 4B11T, an inline-four turbocharged engine that redesigned expectations for high-performance four-cylinders. Its architecture blends lightweight materials, modern valve control and forced induction to deliver a compact, potent powerplant. The block and head are aluminum for reduced mass and better heat management, helping lower the car’s center of gravity and improving handling balance. The cylinder head uses a 16-valve DOHC layout, married to Mitsubishi’s MIVEC variable valve timing. That combination gives the engine a wide, usable powerband while retaining sharp throttle response at both low and high rpm.

Factory ratings differ slightly by market and special editions, but the baseline numbers make the Evo X competitive with much larger engines. In U.S. GSR and RS trims the 4B11T produces roughly 291 horsepower at 6,500 rpm and about 300 lb-ft of torque at 3,500 rpm. European and Japanese figures sometimes list the Final Edition and other tuned variants closer to 303 brake horsepower (307 PS) at the same peak rpm. Measured torque figures convert to roughly the 366–407 Nm range common in contemporary spec sheets, with some factory and market variations nudging peak torque higher depending on calibration.

These figures tell part of the story. The 4B11T was engineered to support sustained performance. The turbocharger delivers strong midrange boost, making the engine feel immediate in normal driving and explosive when you push it. MIVEC optimizes valve timing and lift, smoothing the transition between low-end torque and top-end horsepower. The result is an engine that feels responsive from around 2,000 rpm and continues to pull strongly to its redline. Paired with a six-speed manual or the optional six-speed dual-clutch SST, power reaches all four wheels through a sophisticated all-wheel-drive system.

All-wheel-drive integration is central to how the engine’s output is exploited. The car’s S-AWC suite—Super All-Wheel Control—ties the engine to stability and yaw management. Active Center Differential, Active Yaw Control, and ABS work together to apportion torque, limit wheelspin and stabilize turn-in. The outcome is consistent, predictable traction that lets drivers use the engine’s torque without fighting the chassis. On a slippery surface, the system channels torque intelligently; on a track, it sharpens cornering precision. In short, the powertrain and chassis are calibrated as a unified package.

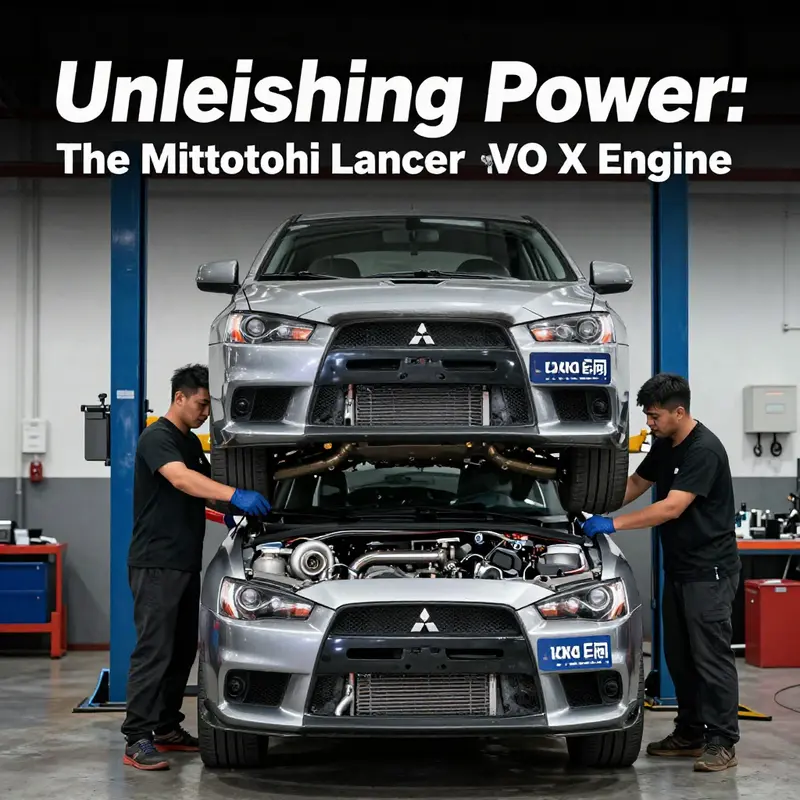

Beyond stock numbers, the 4B11T is notable for its modifiability. Enthusiasts prize the engine for a robust bottom end and an architecture that responds well to bolt-ons and tuning. Common upgrades include larger turbochargers, more efficient intercoolers, freer-flowing intake and exhaust systems, and custom engine mapping. These changes can push factory outputs into the 400-horsepower range with relative ease when supporting mods and fueling are correct. At progressively higher boost levels and with upgraded internals, examples exist that reach several hundred horsepower beyond that. Some builders even prepare strengthened blocks, forged pistons and rods, and billet components to handle four-digit power targets in extreme builds. For those considering heavy modifications, options and parts for reinforcing the 4B11T are readily available, including aftermarket billet blocks that address the limits of the stock casting and allow extreme power goals.

Thermal management and fueling are critical when extracting more performance. The small-displacement, high-boost nature of the engine makes efficient intercooling and robust fueling essential to safe power increases. The standard multi-point injection system supports performance while maintaining drivability and emissions compliance. Upgrading to larger injectors, high-flow fuel pumps, and precise ECU tuning are common steps when increasing boost. Equally important is airflow: improved intake plumbing and low-restriction exhausts reduce backpressure and help the turbo spool sooner. Many owners add larger front-mount intercoolers to lower intake temperatures under sustained loads, improving knock resistance and permiting more aggressive ignition and fueling maps.

Reliability is a major reason the 4B11T earned respect. The engine’s design balances performance and durability for both spirited street use and competition. When kept within reasonable power and thermal limits and maintained properly, the 4B11T can be very dependable. That said, pushing the engine beyond its design envelope without upgrading supporting systems shortens service life. Common failure points in heavily tuned setups include the stock turbo, which can be replaced by stronger units, and the internals when sustained high cylinder pressures exceed the stock forged component threshold. Proactive measures—like upgraded cooling, frequent oil changes with high-quality lubricants, and conservative tuning during break-in phases—extend longevity.

How the engine breathes matters. The 4B11T benefits from the DOHC head design and MIVEC tuning to achieve efficient volumetric filling at elevated rpm. Its turbocharger is selected to balance spool and top-end power, but aftermarket turbos often shift this balance to suit specific goals—quicker spool for street use or higher flow for peak horsepower on track builds. Cam and valve timing characteristics, tuned by MIVEC, allow the engine to make usable torque at low rpm while not sacrificing the top-end power that enthusiasts expect in a performance sedan. That adaptability is one reason tuners find it straightforward to tailor the engine to diverse driving styles.

The transmission choice influences perceived engine performance. The six-speed manual keeps the driver in full control of the rev range, letting the 4B11T’s midrange torque shine. The SST dual-clutch provides lightning-fast shifts under load and a different feel, useful in time-attack or circuit scenarios where shift consistency matters. Either gearbox requires attention when power climbs; clutches, flywheels and drivetrain components are often strengthened as part of a power-upgrade plan.

Fuel economy and emissions were part of the design brief as well. Compared to earlier large-displacement turbo engines in the series, the 4B11T sought better thermal efficiency and lower weight. The move to an aluminum block and heads reduced mass and improved heat rejection. MIVEC optimizes valve timing for both emissions and efficiency without dulling performance. In real-world driving, the engine can be frugal when driven gently, but spirited driving and higher boost will naturally reduce economy.

The 4B11T’s sound and character are part of its appeal. Its exhaust note is sharper and more modern than older, larger four-cylinder rally engines. Turbo spool and midrange rush provide an engaging auditory feedback that complements the car’s chassis dynamics. Many owners tweak exhaust systems to refine tone and reduce backpressure, both for sound and performance gains.

Practical considerations matter. Maintenance is straightforward for a performance engine: regular oil and filter changes, coolant service, and timely replacement of wear items keep the motor healthy. When modifying, plan for the entire supporting system: fueling, cooling, intake, exhaust, transmission and brakes. Upgrades should be balanced to ensure the car remains safe and enjoyable at the intended performance level. For those seeking block-level upgrades or extreme builds, billet block options and reinforced components exist to support ambitious power targets — a path shown by many enthusiasts and builders.

The 4B11T transformed the Evolution formula by blending modern engine technology with rally-bred drivetrain control. Its stock output and refinement provide a potent foundation for spirited driving. Its adaptability makes it an attractive candidate for tuning, while its aluminum construction and MIVEC system demonstrate a balance between performance and efficiency. For owners and builders, the engine is both a sophisticated factory piece and an open invitation to personalization. Those interested in structural upgrades for high-power builds can reference aftermarket billet solutions that reinforce the 4B11T casting for extreme applications: 4B11T billet block.

For official specifications and additional factory details, consult the vehicle’s published data from the manufacturer: https://www.mitsubishimotors.com/vehicles/lancer-evolution-x/specs/.

null

null

Built to Last: How the EVO X 4B11T Earned Its Reliability and Reputation

Built to Last: How the EVO X 4B11T Earned Its Reliability and Reputation

The Mitsubishi Lancer Evolution X’s heart is the 4B11T, a compact 2.0-liter turbocharged four-cylinder designed for a single purpose: deliver repeatable power under stress. That purpose shaped every engineering choice, and those choices explain why the engine is widely trusted by enthusiasts and racers alike. The story of reliability starts with materials and design, continues through cooling and fueling systems, and ends with sensible maintenance and realistic tuning. Understanding each link in that chain helps owners preserve the engine’s strengths while avoiding predictable pitfalls.

At its core, the 4B11T was built with durability in mind. Forged internals give it a mechanical advantage that many modern four-cylinders lack. The forged crankshaft, forged connecting rods, and forged pistons form a robust rotating assembly. These parts resist fatigue and distortion under high boost and prolonged track use. Forged components allow higher peak cylinder pressures without catastrophic failure, and they reduce the progression of wear that leads to engine failure. In plain terms: the 4B11T was given a stronger skeleton than most of its competitors, and that extra strength provides a wide safety margin for spirited driving and moderate tuning.

Thermal management is the next critical element. Turbocharged engines generate lots of heat, and the 4B11T counters that with a cleverly integrated cooling package. A water-cooled intercooler reduces intake temperatures more effectively than an air-to-air unit in some packaging constraints, keeping charge air densities high and detonation risk lower. The overall cooling system was engineered to handle extended hard driving. Radiator capacity, thermostat behavior, and coolant routing aim to prevent hot spots. In practice, this means the engine tolerates repeated runs and long spirited sessions more gracefully than many street motors that were never designed for racing stress.

Fueling and valve control technologies contribute to both performance and longevity. The engine’s direct injection works with MIVEC variable valve timing to optimize combustion across the rev range. Properly managed injection timing and variable cam timing reduce knock and improve fuel efficiency. When the engine breathes efficiently and combusts cleanly, internal stress is reduced. That lowers thermal and mechanical strain on critical surfaces, which translates directly to longer service life when maintenance is kept current.

Even with strong internals and good cooling, real-world reliability depends on parts quality and service practices. OEM parts are a major factor here. Using genuine gaskets, seals, timing components, and other trim parts preserves the engine’s intended fit and performance. OEM timing parts, for example, match original tolerances and material choices. When replacements are necessary, maintaining those tolerances reduces the chance of premature wear or secondary failures. Owners who prioritize OEM parts for routine work typically avoid small issues that snowball into big ones.

There are, however, known weak points and common service items. Early-model oil cooler line fittings have occasionally leaked, so inspecting those fittings during scheduled services pays off. Some owners report issues with the variable valve timing solenoid or intake manifold gaskets; these tend to be maintenance items rather than catastrophic failings. Addressing them early — replacing worn gaskets, cleaning or replacing VVT components — keeps the engine operating smoothly. Regular oil changes, attention to coolant condition, and timely inspection of hoses and clamps mitigate most predictable problems.

Tuning and modifications change the reliability equation. Part of the 4B11T’s mystique comes from its upgrade potential. With an upgraded turbo, better fueling, and a tuned ECU, a stock 4B11T can exceed advertised power levels by a wide margin. Many owners reach 400 horsepower reliably with supporting upgrades. But reliability depends on how the additional power is produced and managed. Increasing boost without upgrading fueling, intercooling, and engine management invites detonation, excessive cylinder pressure, and component fatigue. Heat management becomes more critical as power rises, so larger intercoolers, upstream cooling improvements, and more efficient oil systems are essential for sustained reliability.

For those chasing higher output, the path to dependable power is incremental and holistic. Strengthening the bottom end further, for example, can be done with aftermarket blocks or billet solutions where practical. These upgrades can allow extreme builds to function without the risk of block distortion or failure. For owners considering such upgrades, it is valuable to review available high-quality block options and the compatibility they offer with forged internals and high-capacity pumps. If you are exploring heavy-duty bottom-end upgrades, consider information on the 4B11T billet block as part of your planning and sourcing strategy: 4B11T billet block.

Beyond hardware, engine management strategy determines how cleanly the engine converts increased fueling and boost into usable power. Reliable tune philosophies insist on conservative ignition maps, closed-loop fueling where possible, and progressive ramping of boost targets. Wideband air/fuel monitoring, knock detection, and datalogging become non-negotiable when moving beyond mild bolt-ons. Those data streams let tuners and owners react to conditions before they become failures. In short, the electronics and data side of tuning protect the mechanical parts.

Maintenance intervals also shift with modification level. A mildly modified car might require more frequent oil changes and routine inspections, while a heavily modified car demands an aggressive service schedule. Oil quality is paramount; high-performance engines under stress must use oils rated for higher shear and thermal stability. Regularly inspecting cooling system hoses, intercooler piping, and turbo connections prevents simple leaks from turning into reliability crises. Attention to detail in routine tasks — torque settings, thread locking, replacement with OEM-grade parts — separates long-lived builds from those with recurring problems.

Motorsport history underscores the engine’s balanced design. The 4B11T platform has roots in rally and circuit environments, and its track record proves the baseline engineering choices were sound. Engines that thrive in competition environments often show their strengths in street use. The Evo X’s drivetrain and engine package deliver consistent power without the fragility seen in high-strung engines built solely for peak output. That blend of robustness and tunability is why many enthusiasts regard the 4B11T as a platform engine rather than a one-off performance piece.

Practical signs of a healthy 4B11T are straightforward. Stable oil pressure at idle and under load, consistent coolant temperatures, and steady boost response point to normal operation. Unusual noises, sudden drops in oil pressure, or persistent misfires require immediate attention. Addressing symptoms early prevents secondary damage. Preventive checks during seasonal maintenance should include inspecting oil cooler lines, VVT solenoids, and intake manifold seals. These are inexpensive checks with outsized benefits.

Ultimately, the EVO X engine’s reputation is earned where theory meets practice. Its forged internals and engineered cooling systems give it an advantage. OEM-quality parts and regular maintenance maintain that advantage. Responsible tuning, with careful attention to fueling, heat control, and engine management, allows significant power upgrades without sacrificing reliability. Owners who combine these elements keep the 4B11T running reliably for many years.

If you respect the engine’s limits, address known service items, and upgrade thoughtfully, the 4B11T rewards you with consistent performance. Its resilience under stress, combined with real-world racing heritage, is why the EVO X remains a favorite among drivers who demand both speed and durability.

For authoritative technical specifications and official guidance on maintenance practices, refer to the vehicle manufacturer’s technical documentation: https://www.mitsubishi-motors.com/en/

Final thoughts

The Mitsubishi Lancer EVO X’s 4B11T engine is not just a mechanical setup; it is a legacy of engineering excellence, delivering tremendous power and room for customization, all while maintaining a reputation for durability. For business owners in the automotive space or car enthusiasts alike, understanding this engine’s capabilities and potential can lead to informed decisions about performance vehicles, whether for personal enjoyment or business ventures. The EVO X remains a benchmark for balancing power and reliability, showcasing the best of Mitsubishi’s engineering prowess.