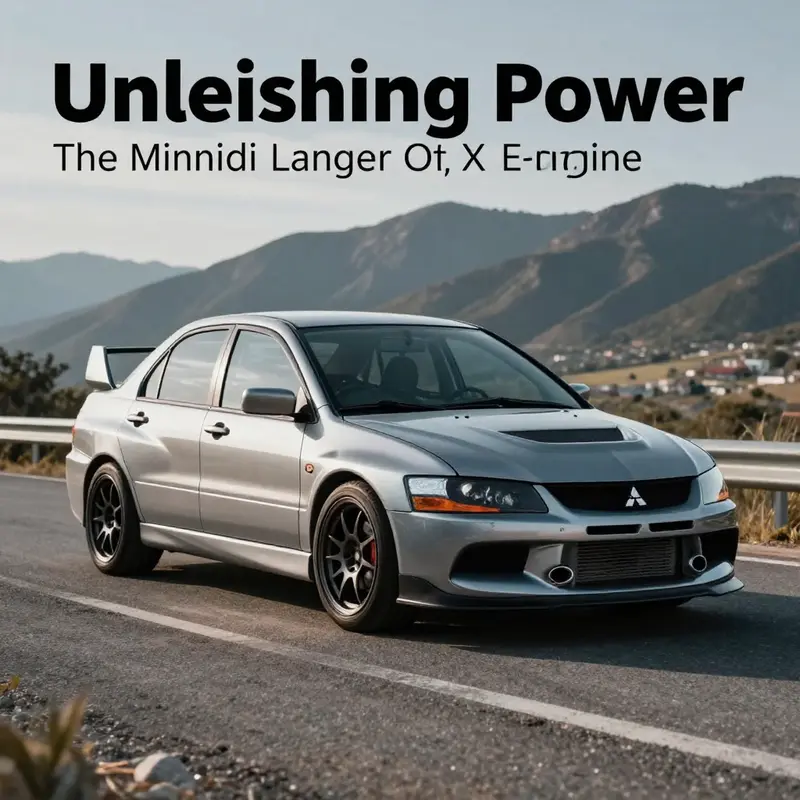

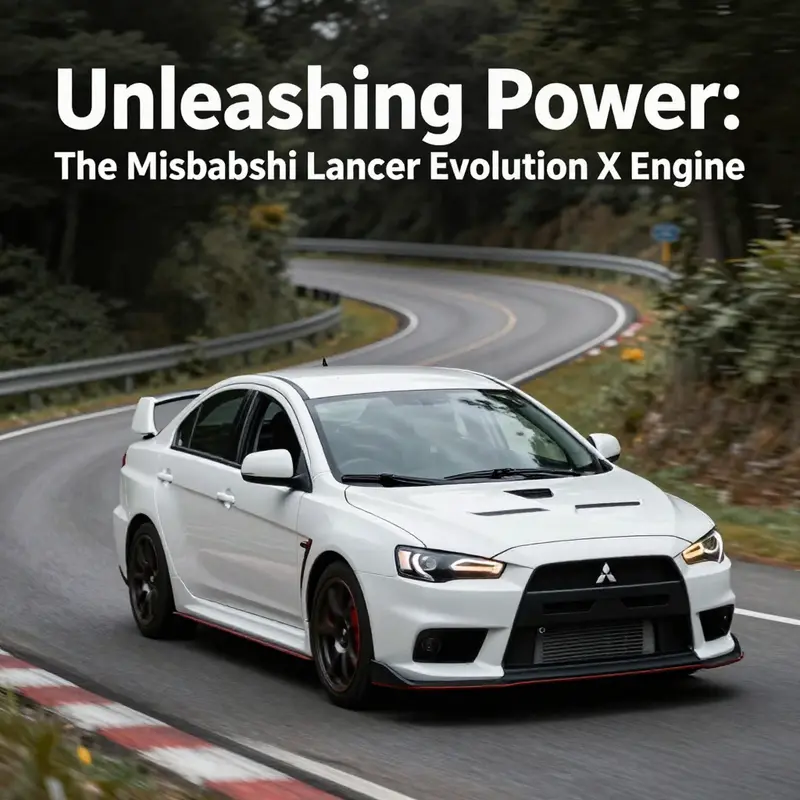

The Mitsubishi Lancer Evolution X, often celebrated as a pinnacle of performance and engineering, boasts a motor that is as thrilling as it is sophisticated. Central to its allure is the 4B11T engine, a 2.0-liter turbocharged powerhouse that has taken automotive performance to new heights. This article explores the engine specifications and performance metrics that make the Evo X a driving enthusiast’s dream. We’ll delve into the sophisticated technology innovations that enhance power and efficiency, the driving dynamics that provide exceptional control, and the enduring legacy of the Lancer Evolution X. Each chapter is designed to provide business owners with the insights needed to appreciate this engineering marvel and consider its relevance in the competitive automotive market today.

Heart of the Evo X: How the 4B11T Engine Defines the Lancer Evolution X’s Performance

The engine that gives the Lancer Evolution X its character is more than a collection of parts; it is a deliberately engineered package that balances everyday drivability with track-capable punch. At the center of that package sits a 2.0‑liter turbocharged inline‑four whose architecture, turbocharging strategy, and drivetrain integration define how the car accelerates, turns, and responds to driver input.

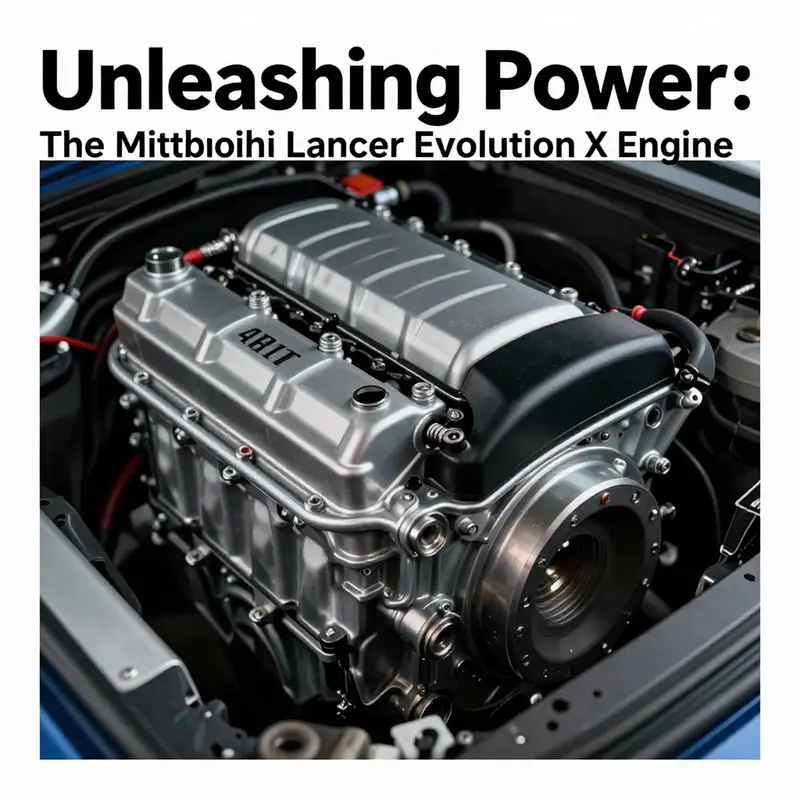

From a hardware perspective the powerplant is built around a compact, lightweight design that prioritizes thermal control and transient response. The block and head use aluminum construction to save weight and improve heat dissipation, while the combustion chamber, cam profiles, and valve timing systems are tuned to extract power efficiently from a relatively small displacement. A twin‑scroll turbocharger is fitted to tame lag and sharpen spool characteristics. By separating exhaust pulses, the twin‑scroll design reduces interference and boosts low‑to‑midrange torque without sacrificing top‑end power, so the engine feels naturally eager from low revs and remains potent at higher rpm.

Variable valve control plays an important role in that responsiveness. The variable timing system alters valve events to improve low‑rpm torque and high‑rpm breathing, which gives the engine a broad, usable torque curve. Complementing the turbocharger and variable valve timing is a robust charge cooling system: an efficient intercooler sits between the turbo and intake to lower intake air temperature and increase air density. Cooler, denser air improves knock resistance and allows higher boost or ignition advance, both of which translate directly into more power and safer operation under sustained load.

Published output numbers vary by market and model tuning, which reflects differences in measurement standards and final calibration. Factory figures commonly cited for the platform range from the high‑two‑hundreds to just over three‑hundred horsepower, with torque ratings shifted according to version and regional settings. Some official specifications list a maximum power in the low‑to‑mid 290s (horsepower) with a torque curve designed to carry strong thrust through the midrange. Later, limited or final editions received further tweaks to exhaust flow, ECU calibration, and intake systems, nudging peak numbers upward and freeing additional torque for spirited driving.

Equally important to peak figures is how that power is put to the pavement. The engine is not an isolated element: its output is managed by advanced all‑wheel control and torque management systems. These systems blend selective torque distribution, yaw control, and traction modulation to translate engine torque into usable acceleration and cornering stability. When the driver demands grip, the drivetrain can shift torque toward wheels with traction and mediate the engine’s output to keep the car balanced. The result is a sensation of controlled acceleration and a level of lateral confidence rare in street cars with similar power.

Transmission choices affect how the engine is experienced. Buyers could opt for a close‑ratio manual for direct, mechanical engagement and precise launch control by foot and hand. Alternatively, a paddle‑shift automatic offered quick, consistent shifts with torque management built into the gearbox logic, allowing fast up‑ and downshifts without unsettling the chassis. Regardless of the gearbox, the engine’s torque curve and the drivetrain software are calibrated to minimize interruptions in power delivery during gear changes, so momentum is rarely sacrificed.

Underpinning these dynamic behaviors is the engine management system. A modern ECU governs boost pressure, fuel delivery, and ignition timing, while protective maps monitor temperature and knock sensors. The ECU’s layered maps allow conservative operation when fluids are cold or boost is high, and more aggressive timing as operating conditions stabilize. That intelligence preserves reliability without diluting performance—a balance that matters whether the car is piloted on a canyon road or in a timed lap session.

Beyond the factory tune, this engine has earned a reputation for tuning potential. Enthusiasts often upgrade intake and exhaust paths, intercoolers, and turbo components to unlock additional horsepower. Software recalibration can yield significant gains by optimizing fuel and ignition maps to match hardware changes. For those looking to push the internals, reinforced blocks, upgraded pistons, and strengthened connecting rods are common reinforcement paths. Projects that replace the stock turbo with a larger, carefully matched unit can dramatically increase peak power, though they demand corresponding upgrades to cooling and fueling systems to maintain durability. For readers exploring heavy modifications, the topic of reinforced and billet components—such as aftermarket billet block options—comes up frequently and is worth further research: 4B11T billet block.

Thermal and mechanical limits define how far modifications can go before reliability becomes a concern. Boost pressure increases cylinder pressures and thermal loads, so upgrades must be considered as system changes rather than isolated swaps. Improved fuel delivery, cooling capacity, and engine management sophistication are necessary companions for higher boost targets. Drivers who keep these systems in balance tend to preserve the engine’s longevity while enjoying significantly increased performance.

Noise, vibration, and refinement were also considered in the engine’s design. Intake and exhaust tract geometry, mounting strategies, and damping materials contribute to a cabin experience that remains usable daily yet reveals its performance intent under load. The tone of the exhaust changes character under throttle, offering an audible cue to the engine’s state without overwhelming occupants in routine driving.

Serviceability and longevity were factored into the base engineering. Regular maintenance—timely oil and filter changes, cooling system checks, and belt inspections—extends the engine’s service life and preserves its performance. For a high‑output turbocharged engine, ensuring optimal oil cooling and clean air delivery is especially important. Enthusiast owners often add auxiliary gauges and monitoring tools to track oil temperature, boost, and air‑fuel ratio during spirited use; doing so helps detect issues early and prevents catastrophic failures.

Taken together, the engine is not merely a source of peak numbers; it is the defining element that shapes the Lancer Evolution X’s behavior. Its compact displacement, turbocharger design, variable valve timing, and calibrated interaction with advanced drivetrain systems produce a car that feels both tractable in everyday conditions and responsive when driven hard. Whether experienced through a mechanical manual linkage or a rapid paddle gearbox, the engine’s torque and power delivery remain tightly integrated with the chassis, brakes, and electronics—creating the coherent driving identity enthusiasts prize.

For full technical reference and official specifications, the manufacturer’s technical pages remain the primary source of details and model‑specific figures: https://www.mitsubishi-motors.com/.

Engine and Drive Dynamics: Measuring the Evolution X’s Motor Performance

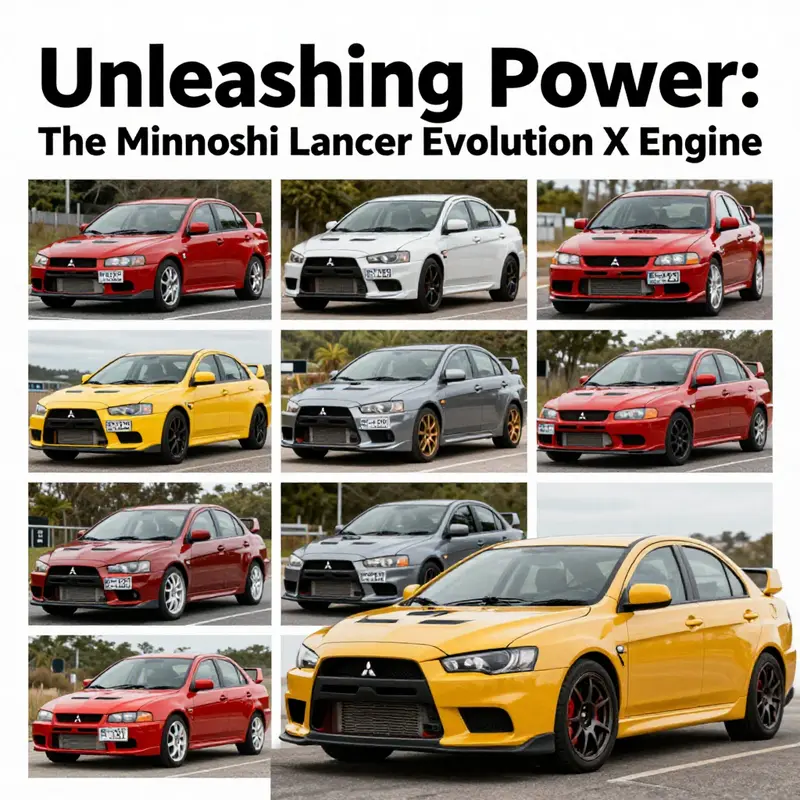

The Lancer Evolution X’s motor is where the model’s engineering intent is most visible. With the shift from the cast-iron 4G63T to the all-aluminum 4B11T, the platform moved toward a balance of efficiency, mass reduction, and modern control systems. That change reshaped performance metrics across power delivery, drivetrain interaction, and real-world pace. This chapter examines those metrics and explains how the 4B11T and the car’s integrated systems translate numbers into repeatable performance.

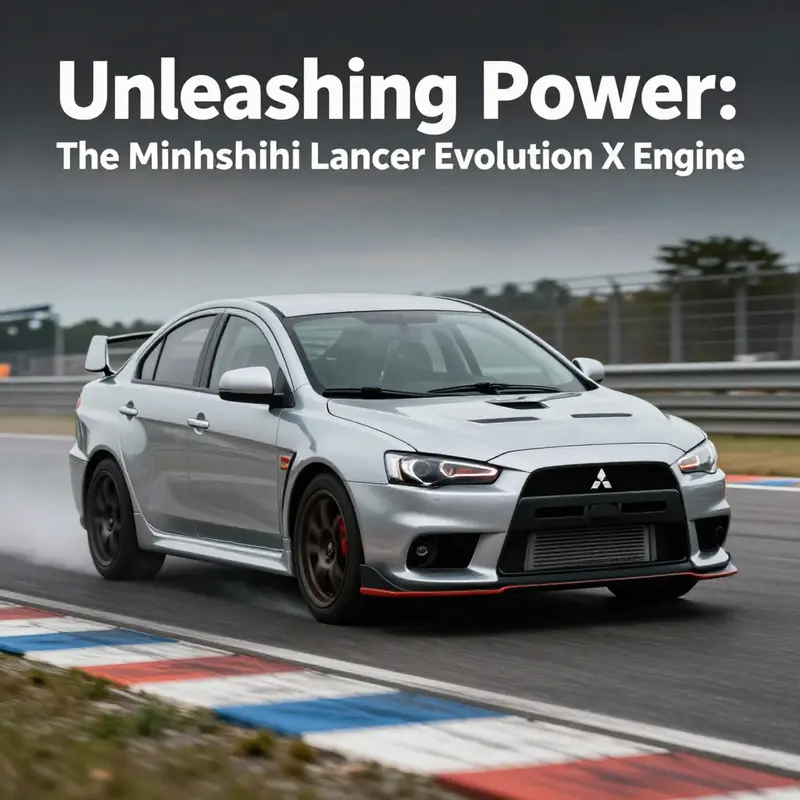

Power and torque figures tell the first part of the story. In production trim the common GSR specification produces roughly 276 horsepower (280 PS) at 6,500 rpm and around 350 N·m (258 lb-ft) of torque at 3,500 rpm. These figures reflect a deliberately tuned output curve that favors tractable midrange torque and high-rev responsiveness. Special editions and dealer-tuned variants pushed those limits. Factory-backed and aftermarket calibrations, including those applied to limited runs, raise peak output substantially; some tuned versions approach or exceed 320 horsepower. The Final Edition models further sharpened peak figures, with horsepower and torque raised via exhaust and intake optimization, among other changes.

Acceleration and top speed metrics show how that power is used on the road. Official 0–100 km/h (0–62 mph) times are typically quoted at 5.5 seconds, yet independent testing often recorded quicker runs, down to near 5.1 seconds under ideal conditions. Those variations reveal the importance of traction, gearing, and driver technique when extracting acceleration from an all-wheel-drive performance sedan. The top speed is governed by an electronic limiter set at 250 km/h (155 mph), a common restriction for high-performance cars of this class.

Transmission choice plays a decisive role in usable performance. The car was offered with a six-speed manual and a dual-clutch automatic labeled SST. The manual preserves the traditional driver-operated interface, while the SST delivers near-instant shifts and programmable shift maps. The SST’s dual-clutch design minimizes torque interruption during upshifts, improving measured acceleration. Conversely, the manual can offer tighter launch control when paired with skilled drivers and aftermarket modifications. Both gearboxes have trade-offs: the SST gives repeatable, fast shifts suited to track and daily usability, while the manual rewards coordination and offers a direct mechanical feel some drivers prefer.

The drivetrain architecture is central to the Evolution X’s lap times. The Super All-Wheel Control system integrates active center differential control, active yaw control, and ABS into a single electronic strategy. Rather than a simple torque split, S-AWC actively modulates torque distribution between axles and side-to-side at the rear. That control changes under braking, corner entry, and throttle application to resist understeer and improve rotation. On fast corners, AYC applies yaw moments to tuck the rear end in, allowing higher entry speeds. The active center differential shifts torque to the axle that can use it best. Because electronic modulation happens quickly, drivers perceive a composed, neutral balance that helps them push harder without surprising behavior.

Braking and suspension components complement the powertrain. High-performance calipers and vented discs give consistent stopping power and fade resistance, both critical to extracting repeated laps or hard road runs. Suspension geometry and spring/damper tuning were targeted to preserve composure under load while allowing the front end to maintain bite. Those chassis decisions let the 4B11T’s torque be applied without upsetting balance, keeping tire contact patches optimized during transitions.

Thermal and mechanical considerations constrain how long sustained performance can be hovered at peak levels. The aluminum block reduces mass, improving responsiveness and handling balance, but it requires careful attention to head gasket and cooling system design under high boost and temperature. The 4B11T benefits from a robust intercooling path and tuned boost controls to keep intake temperatures in check. Engine management calibrations limit boost or adjust timing when temperatures climb, protecting internals and ensuring safe operation. For owners who push the envelope, common upgrades include stronger internals and improved cooling, including uprated intercoolers and oil cooling solutions; some even explore billet components to increase block rigidity for high-power builds, as detailed in the discussion on the 4B11T billet block.

Turbocharger behavior defines much of the driving character. The stock turbo is sized to deliver usable spool without excessive lag, preserving midrange punch while allowing high-rpm build. Tuners often trade a bit more lag for greater top-end flow with larger turbos. The result changes the car’s powerband shape and requires recalibrated fueling, boost control, and sometimes transmission mapping to align with the altered torque curve. Because the vehicle’s electronic control systems manage traction and torque distribution, they help smooth the transition when higher outputs arrive abruptly, making high-power conversions more tractable than they otherwise would be.

Electronic intervention extends beyond torque routing. Traction and stability management systems include launch strategies and boost control schemes that influence real-world sprint times. Launch control, when engaged, coordinates clutch engagement or clutch packs in the SST and wheel slip thresholds to minimize wheelspin. This coordination is why independent test runs sometimes beat the official 0–100 time—the internal calibrations and an ideal surface combine to produce quicker launches than the nominal factory measurement, which is often conservatively stated.

Measuring effectiveness requires looking beyond peak numbers to usable delivery. A 320-horsepower headline is impressive, but if torque arrives in a narrow band, it can be harder to exploit on mixed-surface roads. The 4B11T’s MIVEC variable valve timing broadens the usable range, smoothing torque delivery and improving throttle response across rpm. That technical choice emphasizes everyday drivability and spirited road use over a single peak power figure, which explains why the Evolution X often outpaces rivals with similar peak claims in real driving.

Finally, the Evolution X’s engineering is a systems story: motor, turbo, cooling, transmission, brakes, suspension, and electronics work together. Upgrades that ignore this integration can unveil weak links—brakes may fade before added power is usable, or transmission tolerances may be exceeded by greater torque. Owners and tuners therefore approach performance with a systems mindset, reinforcing cooling, strengthening rotating assemblies, and recalibrating electronic controls to maintain harmony.

For those exploring deeper mechanical modifications, a common resource covers upgrades and strengthened components, including information on a 4B11T billet block. That reference provides context for how builders address block rigidity and strength when pursuing high-power targets.

External reference: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution_X

The Pulse of Rally Precision: Inside the Evolution X’s 4B11T Powertrain

At the core of the Lancer Evolution X lies a compact, purpose-built heartbeat: a 2.0-liter, aluminum inline-four that wears the code 4B11T and wears turbocharging as a badge of intent. This engine isn’t merely about peak numbers; it is about how those numbers translate into an experience that feels both race-bred and controllable on everyday roads. The configuration—16 valves, double overhead camshafts, and a twin-scroll turbocharger fed by an intercooler—defines a power delivery that is as much about how you feel the surge as about how much it roars. Officially, the standard variant of this motor makes close to 291 horsepower (217 kW) with a torque peak around 366 Newton-meters. Those figures, impressive on their own, are part of a broader story: the engine’s real strength lies in how it breathes and where the torque comes on song, not merely in the ceiling it reaches. The real engineering nuance emerges through Mitsubishi’s MIVEC system—Mitsubishi Innovative Valve timing Electronic Control—which choreographs the intake and exhaust timing to flatten and widen the torque curve. In practice, this means power arrives more smoothly and linearly from roughly 3,000 rpm upward, giving the car a sense of readiness and responsiveness that feels continuous rather than peaky. The effect is most obvious when you hold a steady road speed in a midrange gear and reach a bend where torque comes on gradually; the throttle response stays predictable, your steering steadies, and the chassis begins to articulate its intent without surprise. It is a refinement that balances the raw appetite for speed with the discipline needed to stay composed through twisty sections. Within the same family, Mitsubishi offered evolutions of the motor, culminating in what many enthusiasts regard as the apex of the line: a Final Edition that is tuned for even more aggressive output, where horsepower nudges past 300, and torque climbs to the high 400s. This refinement isn’t simply about a higher ceiling; it reflects a broader tuning philosophy—the engine, the exhaust, and the turbocharger all align to maximize efficiency at the edge of grip. The engine’s charge is harnessed and delivered through a companion transmission that is as much a performance instrument as the motor itself. The six-speed TC-SST twin-clutch sportronic sequential transmission provides ultra-fast gear changes, with the added allure of paddle shifters for manual control. The virtues of this setup are not only the precision of the shifts but also the way power is staggered and released during aggressive acceleration. In real-world terms, the car can sprint from rest to 100 km/h in under five seconds, a demonstration of how a well-tuned turbocharged inline-four, when paired with a smart, speed-oriented transmission, can deliver both thrilling bursts and a sense of control that remains reassuring to the driver. The integration of the engine with the chassis demonstrates a philosophy that has guided performance cars for decades: power must be delivered where the driver can use it, not merely at the highest revs. To that end, the Evolution X’s drive-line architecture is more than a collection of high numbers. It is a system designed to manage the complexity of high-velocity road dynamics—torque distribution, yaw management, and stability control—all in a way that keeps the car predictable yet exciting. The centerpiece of that system is S-AWC, the Super All-Wheel Control, which unifies several subsystems into a cohesive road-science mosaic. The Active Center Differential channels torque to each axle with precision, but it is the Active Yaw Control and the stability control that dominate when the car learns a circuit’s rhythm. As you approach a corner with a straight line of mid-corner acceleration, S-AWC reads grip and weight transfer, modulating torque not just front to rear but left to right across the axle. The result is a vehicle that leans into the apex with a sense that the car knows the intent long before the driver does. The brakes, too, play a vital role in that choreography. A high-performance setup—often featuring Brembo-race-inspired calipers—provides the necessary stopping power that matches the engine’s readiness. It’s a careful balance: the car can brake late and pick its line, or it can maintain a stable flow through a tighter sequence with input from the stability systems. The chassis and suspension architecture reinforces this philosophy. The Evolution X uses a rigid, lightweight body with a longer wheelbase that measures roughly 2,650 millimeters, and wider tracks at both ends. Those dimensions contribute to a stable platform that feels planted when the road begins to bend, while the wheel choice—18-inch forged units—minimizes unsprung mass to sharpen steering response and grip. Inside, the cabin continues the focus on driver engagement with minimal distraction, aided by supportive seats that hold you through cornering without compromising comfort on longer drives. Even the interior’s audio treatment borrows a mood of high-end clarity without stealing attention from the road, preserving a balanced sense of purpose. The powertrain’s interface with the driver is not merely mechanical; it is a narrative of feedback. You feel the engine’s torque curve, hear the turbo’s whistle, and sense the car’s stance as you apply force through the steering and pedals. The engine’s legitimacy comes from how that feedback translates into confidence—confidence to push deeper into a corner, to throttle through a straight, or to select a new gear as you manage a dynamic balance. This is essential because the Evolution X is, above all, a vehicle that trains the driver to become more precise. And that precision extends beyond the track. The one-stop chassis system, with its integrated wonder—S-AWC—offers a resilience that makes everyday driving feel more controlled, even when you are not chasing lap times. The MIVEC-powered engine, while a modern interpretation of turbocharged performance, does not depend on mechanical drama to be compelling. It uses timing and intake management to craft an experience that is both accessible at the daily commute and exhilarating on a back road. In this sense, the Evolution X translates rally-derived DNA into a sophisticated, rideable balance of power, balance, and feedback. It is not merely the sum of numbers; it is the sum of careful engineering decisions that allow a driver to interpret what the road asks in real time. For readers who want to see how the chassis and powertrain live in a broader ecosystem, the lightweight but rigid structure supports the engine’s demands without sacrificing daily usability. Its weight distribution, suspension geometry, and steering geometry are all tuned to maintain lines that feel intuitive rather than contrived, so that the car’s behavior remains predictable as grip changes or as temperature and road surfaces vary. As a result, the Evolution X embodies a performance ethos that blends rally heritage with the pragmatism of a modern, road-going sedan. The Final Edition’s upgraded output—over 300 horsepower and torque climbing beyond 400 Newton-meters—illustrates how far this philosophy can push a powertrain if the entire system is aligned to a unified objective: to deliver power through manners that reward precise control rather than raw aggression. In practice, drivers can appreciate the turbo’s responsiveness in midrange and the way the clutching of the TC-SST and the all-wheel-drive system work in concert to distribute grip where it is most needed. If you are curious about practical accessories that complement this combination of lightness and strength, a carbon-fiber bonnet is a striking option that reduces weight and enhances stiffness. For an example of how such components are sourced, see this carbon-fiber bonnet option for the Lancer Evolution X. carbon-fiber bonnet for the Lancer Evo X. The overall result is a machine that feels engineered for the long haul of a race weekend and the long arc of a road trip alike, a rare blend of track-ready fidelity and road-car restraint. For readers who want to cross-check the official technical ledger, the Evolution X’s specifications exist in a broader framework that captures the intended performance envelope across versions, including the standard and final-edition variants. These figures—from horsepower to torque to the practical 0–100 km/h timing—map the engine’s evolution as the chassis and control systems mature alongside it. And while the numbers may shift a little with market and version, the underlying philosophy remains consistent: deliver a connected, confident, and exhilarating experience through a powertrain and drive architecture designed to be felt, understood, and trusted on every road you choose to conquer. For a detailed, official snapshot of the model’s broader specs, see the external resource linked here. https://www.mitsubishi-motors.com/evolutionx/specs.html

Power, Precision, and Traction: Driving Dynamics of the Evolution X’s Turbocharged Inline-Four

The Mitsubishi Lancer Evolution X is defined as much by what lies beneath its sculpted hood as by the way it meets the road. At its core sits a compact, all-aluminum, turbocharged inline-four that delivers immediacy and responsiveness, transforming ordinary street driving into a focused, track-ready experience. The engine translates throttle input into a surge of torque that presses the car forward with a clean, linear rhythm. While numbers tell part of the story, the true character emerges when the power is paired with the drivetrain philosophy: the chassis choreographs the engine’s force, ensuring the thrust becomes confidence rather than chaos, and that traction translates into precision rather than twitchy handling.

The powertrain character is inseparable from how the vehicle prosecutes grip across all four wheels. The engine’s torque curve, the responsiveness of its turbo delivery, and the control logic that distributes torque are the hinge points of the Evolution X’s driving dynamics. The engine’s ability to deliver broad, usable torque at mid-range revs makes it forgiving for spirited street driving while still capable of thrustful, track-appropriate performance when the throttle is planted. This is not about raw peak numbers alone; it is about how the engine keeps pulling through the mid-to-upper end of the rev band and how smoothly it responds to a demanding pedal.

The all-wheel-drive system is the mechanism that translates power into expected, repeatable grip. Instead of a fixed distribution, the system continually evaluates wheel speed, steering angle, yaw rate, and lateral acceleration to decide how much torque to push to each axle and to each rear wheel. This real-time torque orchestration keeps the car predictable as you enter a corner, dampens understeer before it becomes tangible, and guides the rear toward a balanced, composed exit. The result is an agility that feels tactile; the chassis seems to negotiate the turn with you rather than fight you.

Behind that practicality is a triad of dynamic control that acts as a running conversation between car and driver. First, an adaptive center differential channels torque between the front and rear axles to stabilize grip as conditions change. Second, a rear-wheel torque balance system fine-tunes how much drive the left and right rear wheels receive to sharpen cornering. Third, a stability-oriented program watches speed, steering input, yaw, and lateral acceleration, making micro-adjustments to torque and braking to keep the vehicle on a stable trajectory. The integration of these elements rewards clean, precise inputs and translates small corrections into meaningful changes in attitude.

On track and road, the practical expression of these dynamics is evident in steering response, throttle timing, and braking stability. On circuit corners, the front wheels bite, the rear settles, and the body stays composed with minimal yaw. The mid-range pull allows you to maintain velocity through apexes, with torque continuing to feed you on the exit. The adaptive torque distribution helps keep the car balanced as weight shifts, preserving a line that respects entry and exit radii. On public roads, the same system delivers quick, confident responses to changing surfaces or evasive demands. The Evo X feels poised, almost intuitive, because the drivetrain and chassis continually interpret and deliver what you intend, rather than forcing you to compensate for grip shortfalls.

Power delivery, handling, and braking form a triad that defines the Evolution X’s character as much as the engine itself. The braking system provides bite and precision matched to the chassis’s poise, assuring controlled deceleration and preserved steering feel. Braking input remains predictable at the limit, reinforcing the idea that speed comes from disciplined technique as much as from horsepower. The chassis’s rigidity, balanced weight distribution, and tuned suspension contribute to a sense of connection: the driver can feel throttle changes, steering angle, and braking inputs as the tires respond to the road. In this sense, the engine is not merely an aggressor but a partner that, when managed well by the drivetrain and chassis, elevates the driving experience to something urgent, controlled, and communicative.

External reading and deeper theory on all-wheel-drive control systems can further illuminate how grip and handling are shaped across performance platforms. See official overviews of the system’s principles for context and comparison.

Heart of Speed: The 4B11T Turbo Engine and the Driving Soul of the Lancer Evolution X

The Lancer Evolution X stands as a culminating statement of Mitsubishi’s track-inspired engineering on the street. At its core sits a compact turbocharged 2.0-liter inline-four that balanced top-end ability with midrange vitality. This aluminum-block, four-valve-per-cylinder engine breathed through a turbo and a carefully tuned intake, designed not just for peak horsepower but for usable, linear torque across the rev range. The power figures varied across markets and model years, but the goal remained constant: a responsive surge that complemented the chassis and all-wheel-drive system, rewarding skillful throttle modulation and precise gearwork. The engine’s variable valve timing helped maintain broad torque across midrange while sustaining high-end power, a trait that allowed the Evo X to feel eager rather than abrupt. In production form, the engine delivered horsepower in the high two-hundreds with torque in the mid-to-upper hundreds of Newton-meters, offering a balance of tractability in daily use and velocity on track. The Final Edition refined intake, exhaust, and turbo characteristics to extract more usable power and sharpen response, while preserving the car’s accessible nature. The Evo X’s drivetrain married the engine to a sophisticated all-wheel-drive system that distributed torque to the wheels to maintain momentum through corners and deliver controlled, predictable acceleration on exit. The chassis and suspension, tuned to convey the engine’s intent through steering feel and seat feedback, allowed drivers to push with confidence, knowing the powertrain and dynamics would respond in a measured, communicative way. Inside, the cockpit emphasized driver engagement: a digital cluster, supportive seats, and a layout that rewarded precise input and sustained focus on the driving task. Over the car’s life, the Evo X became a symbol of balance—an engine that could fuel an enthusiast’s pace without overwhelming daily usability. Its run ended with broader market trends but its memory endures in the way it paired a small, responsive turbo with a drivetrain and chassis tuned for both pace and control. Today, the Evolution X remains a reference for how a compact engine, when paired with a capable drive system and a communicative chassis, can deliver track-ready performance without sacrificing everyday tractability.

Final thoughts

The Mitsubishi Lancer Evolution X represents a combination of innovative engineering, raw power, and precise control, making it a hallmark in performance automotive history. Its 4B11T motor not only sets the bar for engine specifications but also highlights technological advancements that influence the automotive industry. As we have explored, the Evo X’s remarkable performance metrics and driving dynamics position it as a benchmark for future designs. Understanding its evolution equips business owners with invaluable insights into automotive trends and consumer expectations for high-performance vehicles.