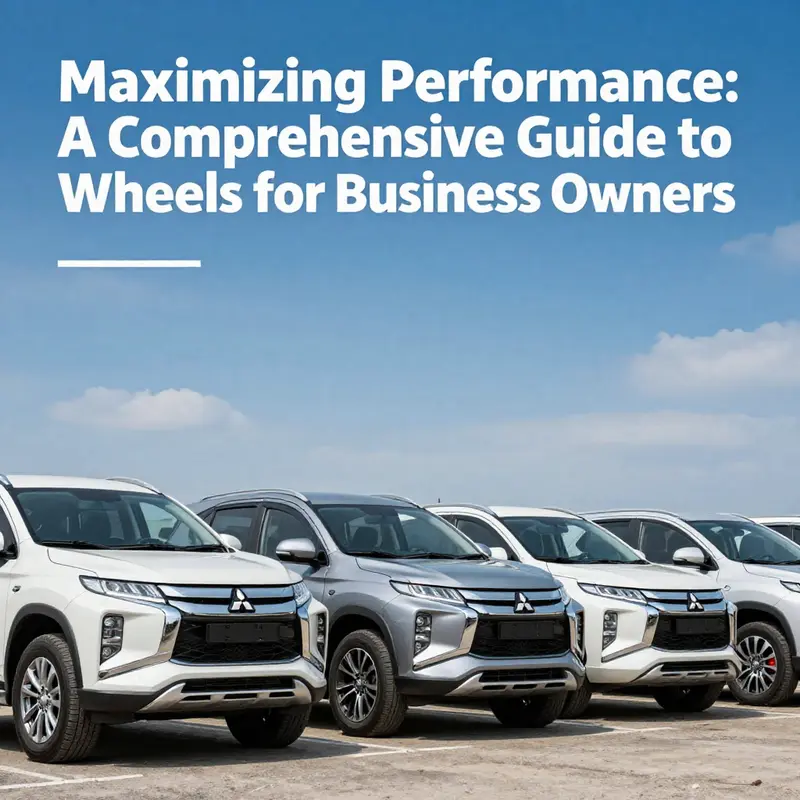

For business owners, investing in the right vehicles can greatly influence operational efficiency and cost-effectiveness. Mitsubishi, known for its reliable and versatile vehicles, offers a variety of wheel types designed for different applications and performance requirements. Understanding these wheels—ranging from standard wheel lock keys to specialized commercial truck wheels—can help you make informed decisions that enhance both safety and functionality. This article will delve into standard wheel lock keys crucial for security, the various steering wheel options enhancing driver comfort, and the commercial truck wheels ideal for heavy-duty applications. By the end, you’ll have a holistic view of Mitsubishi wheels relevant to your business operations.

Secure Spins: Understanding and Managing Standard Wheel Lock Keys for Mitsubishi Wheels

Secure Spins: Why Mitsubishi Wheel Lock Keys Matter and How to Manage Them

Wheel locks are a small component with an outsized role. On Mitsubishi vehicles they act as a physical deterrent against unauthorized wheel removal. Standard wheel lock keys are the matching tool that lets you remove and reinstall those locking lug nuts. Because the key and lock share a precise tooth pattern, only the correct key will turn the lock. That precision is the source of security and frustration alike. When the key is present, it makes wheel theft harder. When the key is lost, routine tire service can become complicated.

At first glance, a wheel lock key looks simple. It is a compact socket with an internal spline or groove pattern. That internal pattern mates with the lock nut installed on the wheel. The pattern is manufacturer-specific and typically stamped with an identifying code. Mitsubishi uses standard types that fit multiple models, but there is no universal key. The lack of a universal fit is intentional. Each unique pattern reduces the chance that a would-be thief can improvise a remover. It also means owners must track the exact pattern for replacement.

Understanding compatibility begins with the key code. Most keys and lock nuts carry a small stamped code, often a short alphanumeric sequence. Technicians and parts departments use that code to match replacements. When you order a replacement key, providing the code shortens the process and reduces guesswork. If the code is absent, obtaining a proper match may require removing a lock nut for inspection, or consulting an authorized dealer who can cross-reference model and production data.

There are practical steps that reduce the risks of losing access to your wheels. First, always store the original key in a predictable, secure place. A small padded pouch inside the spare tire compartment works well. Some owners snap the key into a pouch under the trunk lining, while others keep it in the glove box with the vehicle manual. The goal is consistent placement, not expensiveness. Second, make a durable record of the key code. Photograph the code or write it down and keep the note with other vehicle documents. Third, consider ordering a duplicate key when the vehicle is new. A spare key provides immediate insurance and simple peace of mind.

When replacement is required, options vary. The most reliable source is an authorized dealership or an official parts retailer. They can match the code to the correct pattern and supply a factory-compatible key. Reputable aftermarket parts suppliers also offer matched keys, but they must be chosen carefully. Some third-party keys are high-quality and fit correctly. Others replicate generic patterns that do not match factory locks and thus prove useless. Verifying the seller and requesting a clear return policy helps avoid problems.

Replacement requires attention to fit and finish. A properly matched key should seat fully on the lock nut with no play. When turning a matched key, the engagement should feel positive, without slipping or grinding. If you sense wobble, misfit, or resistance beyond expected torque, stop. Forcing a misfit key risks damaging the lock nut or the wheel. Damaged lock nuts complicate removal and may require drilling or professional extraction.

Routine maintenance of the key and the lock nut pays dividends. Clean both components periodically to remove grit, road salt, and brake dust. A light application of anti-seize compound on the lock nut threads helps prevent corrosion and makes future removal easier. However, avoid heavy lubricants inside the key’s spline, as they can attract dirt. Keep the key dry and inspect it for worn splines. Worn or rounded splines indicate it is time for a replacement before a breakdown occurs.

Tire shops and mobile technicians commonly encounter wheel locks during service. If the key is available, removal and reinstalling is routine. If it is not, technicians will follow an extraction protocol. That protocol starts with attempting to identify the pattern visually. If the pattern is recognized, they may use a matched aftermarket key. If not, careful mechanical removal follows. Specialists use extraction sockets designed to bite into the damaged lock and back it out. Drilling is a last resort and requires expertise to avoid harming the wheel. Because these procedures can damage lock nuts and sometimes wheels, they can be costly.

For owners of custom wheels or aftermarket rims, wheel locks deserve particular attention. Many aftermarket wheels use different lock nut profiles. Some require a proprietary key from the wheel manufacturer. When changing wheels or rims, always request the matching lock key and record the pattern. If you are fitting a new set of rims to a Mitsubishi, plan for how the lock keys will be integrated. Exchange the information with the installer and store the key with other wheel accessories. This practice prevents surprises during seasonal tire swaps.

The security benefit of wheel locks should be viewed realistically. Wheel locks raise the barrier to theft. They do not make wheels impossible to steal. A motivated and well-equipped thief can defeat wheel locks given time and opportunity. The primary value is deterrence and delay. For many owners, a visible lock nut, a keyed lug pattern, and common-sense parking choices are enough to discourage opportunistic theft. For high-value wheels, combining locks with other measures—surveillance, secure parking, and wheel identification marks—produces stronger protection.

When ordering replacement wheel locks or keys, gather the right details. Note the vehicle model, year, wheel type, and any stamping on the original components. If the lock nut remains installed and carries a code, photograph it and include the image with your inquiry. Confirm whether the replacement key is an original-equipment match or a compatible aftermarket option. Ask about return policies and warranties, and seek explicit statements about interchangeability. When in doubt, choose the proven route: an authorized parts source or dealer.

There are sensible emergencies where access to wheels is urgent. A roadside flat tire requires a fast solution. If you cannot find the wheel lock key, a few steps help. First, check common storage spots in the vehicle, including the spare area. Second, contact roadside assistance or a local dealership for a mobile key retrieval. Third, if time and safety permit, arrange transport to a tire shop with extraction tools. Avoid improvised removals that risk damaging the wheel or axle components. If a temporary solution is necessary, document the process and seek professional follow-up to replace damaged components.

Owners replacing wheels for performance or aesthetic reasons must integrate wheel locks into the upgrade plan. High-performance forged or alloy wheels often pair with specific lock profiles. When selecting rims, verify the lock nut type needed. If the new wheel requires a different lock, plan to obtain the matching key before the install. This avoids situations where the shop installs wheels but cannot reseat the lock nuts because the key is absent. A small logistical step up front saves hours and expense later.

A growing number of owners prefer to keep key information digital. Photograph the key code and store it in a secure cloud folder. Back up the image to a vehicle maintenance app or an encrypted note. Digital storage is convenient, particularly during travel. However, always maintain a physical backup as well. Electronic devices fail, batteries die, and service access can be limited. A laminated paper copy kept with the vehicle’s title or manual provides redundancy.

There are legal and practical considerations when dealing with lost or damaged lock nuts. In some regions, the replacement or removal of wheel locks by non-dealers may impact certain warranties or service agreements. Check your vehicle’s documentation and the parts seller’s terms. If extraction is required, use certified technicians who document the process. Proper documentation helps with insurance claims or warranty questions that may arise from wheel damage during forced removal.

Finally, treat the wheel lock system as a simple part of wider wheel care. Pair locks with regular inspections of lug nuts, wheel bearings, and hub components. When you change tires or rotate them, confirm the torque settings of all lug nuts, including the locks. Proper torque ensures safe seating and prevents loosening over time. Combine that mechanical attention with careful storage of the key and a clear plan for replacements. The result is a balanced approach: effective theft deterrence without unnecessary risk of being stranded.

For practical reference, one helpful guide outlines types, key features, and engineering applications for wheel lock key replacement. It explains identification methods and best practices for matching keys and locks. Consult that resource for technical diagrams, pattern examples, and step-by-step procedures. https://www.mitsubishiparts.com/tech/wheel-lock-key-replacement-guide

If you upgrade or swap wheels on a Mitsubishi, remember that rims and wheel locks are a matched system. For guidance on rims that fit specific models, consult available fitment resources. For example, see information about fitting 17-inch rims for Eclipse wheels to confirm compatibility and planning during wheel upgrades: 17-inch rims fit Mitsubishi Eclipse wheels (2018–2023).

Mindful management of wheel lock keys keeps your Mitsubishi wheels protected and accessible. The steps are straightforward: document the code, store the key securely, purchase a duplicate, and prefer matched replacements from trusted sources. Regular maintenance and a clear emergency plan reduce the chances of unexpected costs. When chosen and managed well, standard wheel lock keys offer a quiet but effective layer of security for your wheels.

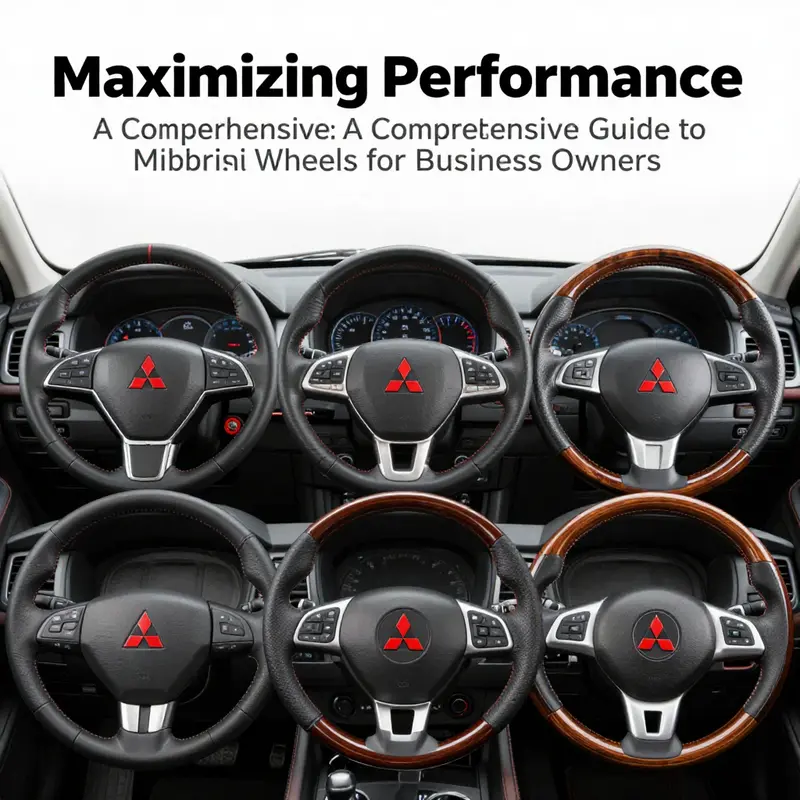

The Handprint of Performance: Steering Wheels in Mitsubishi Interiors

In a Mitsubishi, the steering wheel is the primary interface between driver and road, a tactile link that communicates mood and intent before a single turn is made. The wheel’s diameter, thickness, material, and texture influence grip, leverage, and feedback, shaping how the car feels at speed or in stop-and-go traffic. Across the lineup, Mitsubishi offers a range of wheel options designed to match different driving preferences, trims, and safety considerations. Leather-wrapped wheels provide luxury and grip; sport wheels offer a flatter profile and quicker response; wood-grain accents convey a classic or premium cabin tone. Each choice affects not only aesthetics but also ergonomics, steering effort, and tactile feedback that informs the driver’s sense of connection with the road. The integration of steering wheel controls further enhances this relationship, letting you adjust audio, cruise, and phone without lifting a hand from the rim.

Maintenance and care for each style matter as heat, sun exposure, and sweat can influence grip and longevity. Leather may benefit from conditioning to maintain suppleness; sport wheels call for periodic cleaning to preserve texture; wood-grain surfaces reward gentle cleaning to protect finish. Beyond texture and finish, compatibility with airbags and steering-column hardware remains essential. A properly matched wheel supports safe deployment of the airbag and preserves steering geometry, while aftermarket options should be evaluated for fitment and safety implications.

Ultimately, selecting a wheel in a Mitsubishi is about comfort, control, and compatibility with the vehicle’s safety systems. The right wheel should feel natural in the hands, be appropriate for the model and trim, and reinforce confidence on every road, from daily commutes to spirited back-road sessions.

Rolling Reliability: How Mitsubishi’s Commercial Truck Wheels Power Fleet Performance

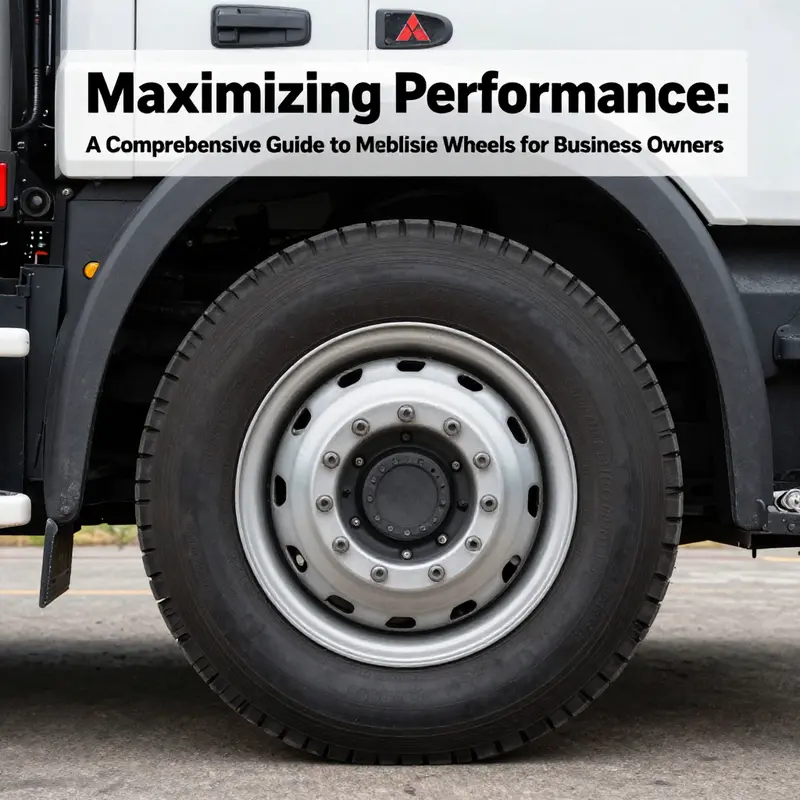

Wheels are more than circular add-ons to a heavy machine; in the world of commercial fleets, they are critical components that directly influence uptime, safety, and the bottom line. When fleets move goods through crowded urban corridors, across rough construction sites, or along long-haul corridors, the choice of wheel type, material, size, and accompanying hubs becomes a strategic decision. For a brand with a long history of industrial strength, the commercial segment has always balanced durability with efficiency. The wheel is the interface between the vehicle and the road, translating power into momentum, traction, and control. In Mitsubishi’s commercial truck segment, this balance is achieved through a deliberate pairing of steel and alloy wheels, a range of sizes tailored to payload and terrain, and engineering that tightly couples wheel design with driveline performance. The emphasis is not merely on carrying heavy loads; it is on sustaining performance over the vehicle’s entire life, under diverse conditions, with predictable maintenance intervals and minimal downtime. In this context, wheels become a fulcrum around which fleet reliability pivots, with every material choice and size selection carrying implications for fuel economy, wear patterns, and the resilience of the entire chassis and drivetrain system.

Steel wheels have long been the workhorse of industrial fleets. They are prized for robustness, cost-effectiveness, and straightforward maintenance. In environments where machinery endures harsh treatment—from vibration-filled construction sites to gritty urban routes—steel wheels stand up to the rigors with a resilience that keeps a fleet rolling. Their simple construction makes them less susceptible to cosmetic damage that might complicate downtime and maintenance decisions. For operations where the priority is predictable performance at a predictable cost, steel wheels offer a reliable baseline. They also play well with the heavier duties that come with urban delivery fleets, where curb impacts and loading cycles can accumulate quickly. The trade-off is clear: while steel wheels provide durability and value, they are heavier and less efficient in terms of weight savings, which can influence fuel consumption and handling at the edge of payload capacity. In fleets where the payload is consistently heavy and the route profile demands rugged reliability, steel wheels remain a prudent choice.

Alloy wheels introduce a different calculus. Lighter weight translates to a reduction in unsprung mass, which can improve handling, steering response, and ride quality. In environments where smooth operation and lower noise are valued—such as fleets making frequent urban stops or operating in noise-sensitive zones—alloy wheels can contribute to a perceptible improvement in ride comfort and driver fatigue. Alloy wheels also tend to resist corrosion more effectively than basic steel in many climates, which helps reduce maintenance overhead and keeps wheels looking professional for longer periods. The downside is cost and, in some cases, the potential for higher repair costs if damage occurs in demanding service conditions. Therefore, choosing alloy wheels often signals a fleet’s commitment to improving efficiency and driver experience, provided that the operational profile includes routes where weight savings and noise reduction translate into meaningful gains in fuel economy and turnover.

The spectrum of wheel options across Mitsubishi’s commercial lineup reflects a practical acknowledgment that one size does not fit all. Fleet managers face a spectrum of decisions that must align with payload requirements, terrain, and service cycles. A front axle that carries a different load profile from the rear, or a vehicle operating on uneven surfaces with frequent starts and stops, benefits from wheel configurations that balance strength with weight optimization. The sizes chosen for front and rear wheel positions are not arbitrary; they are matched to the tire specifications, brake cooling, steering geometry, and suspension tuning that define how a truck behaves under load. In real-world operations, these decisions manifest in numbers that drivers encounter every day. Front wheels configured at 7.50R16 and rear wheels at 8.25R16, for example, reflect a deliberate division of labor between steering performance, traction, and payload capacity. Such configurations support a high payload while maintaining a favorable turning radius and predictable handling in urban delivery routes or on challenging rural roads. The result is a wheel system that works in harmony with the rest of the vehicle, rather than a set of parts that merely occupies space on the chassis.

Beyond the basic material distinction, the engineering of wheel systems integrates tightly with the powertrain and gear ratios. The wheel is not a passive recipient of engine torque; it is an active participant in how power is transmitted and how efficiently it is consumed. In heavy-duty and long-haul scenarios, pairing wheel design with drivetrain gearing can yield meaningful gains in fuel economy and drivability. Higher gear ratios correlate with better highway efficiency, allowing engines to operate at lower rpm while maintaining road speed, which reduces fuel consumption and wear over long distances. Conversely, lower gear ratios are advantageous for incline regimes or heavy lifting on slopes, where torque delivery must be robust enough to maintain momentum and prevent stalling. This synergy between wheel size, axle spacing, and gearing reduces drivetrain stress, minimizes tire wear, and helps ensure consistent performance through varying loads and conditions. When a fleet transitions to a mix of urban routes and highway runs, the ability of the wheel-drivetrain pairing to adapt becomes a strategic asset, decreasing maintenance cycles and improving predictability in service schedules.

The wheel’s role in handling and traction extends to the relationship between wheel hubs and the rest of the steering and drivetrain assembly. Front hubs are designed for smooth rotation and precise steering input, especially critical in tight urban corridors where steering response translates directly into operational safety. Rear hubs are integrated with the differential, enabling the wheels to rotate at different speeds during turns. This functional separation reduces tire scrub and uneven wear, which can be a common problem in fleets that encounter frequent cornering in mixed driving conditions. The hub design supports consistent traction across axles, which is essential when heavy loads shift during cornering or when road surfaces vary. A well-executed hub system contributes to a smoother ride for the driver, less vibration transferred into the cab, and longer tire life—factors that relate directly to uptime and maintenance costs. In practical terms, fleets that operate in urban centers with frequent stop-and-go conditions benefit from hub configurations that minimize tire wear and maximize grip in both dry and wet conditions.

Wheel caps, while often perceived as cosmetic, perform functional roles that matter for fleets. Factory-installed caps ensure a precise fit and maintain the original appearance, while aftermarket options can provide additional design flexibility. The right wheel cap can shield critical components from dirt and moisture, reducing corrosion and helping maintain brake and hub performance over time. In a fleet context, the decision to use factory caps or aftermarket variants is typically guided by maintenance schedules, the likelihood of curb damage, and the value placed on aesthetics in customer-facing operations. Yet the material and design of the cap also influence how easily technicians can inspect the wheel area for damage or wear during routine maintenance checks. A cap that facilitates quick inspection without compromising protection contributes to faster service times and better overall fleet reliability.

Security considerations intersect with wheel design and maintenance in a way that often goes overlooked in discussions of performance. The introduction of wheel locks and lock keys to prevent unauthorized wheel removal underlines a fundamental truth: security and serviceability must coexist. For fleets operating across multiple sites or in locations with variable security levels, the need for compatible keys and the possibility of lock replacement are practical realities. While these mechanisms add a layer of protection against theft, they also introduce maintenance considerations—lost keys or damaged locks require careful replacement to avoid delays, which can affect route adherence and uptime. The best practice for this dimension of wheel management is to maintain a compact, well-documented inventory of wheel-lock keys and to ensure that any replacements match the original tooth pattern precisely. In the best-run fleets, security does not become a bottleneck; it is harmonized with ease of access for maintenance and tire service, so the wheels remain a reliable anchor rather than a point of friction.

In some fleets, the wheel equation extends into specialized industrial applications where equipment needs to be ready for rapid deployment and variable workloads. For example, hydraulic power take-off systems enable remote operation of auxiliary devices such as cranes, pumps, and snow-removal equipment. In such contexts, wheels must not only bear heavy loads but also interface with power delivery systems that demand stable, predictable performance. The integration of hydraulic PTOs with wheel systems emphasizes precision engineering: precise gear ratios, robust hubs, and reliable mounting hardware all contribute to a system that can deliver hydraulic energy where it is needed, with minimal friction losses and consistent response times. While such configurations are more common in industrial settings and utility fleets, they illustrate how wheel technology sits at the heart of broader mission capabilities. The wheel is a gatekeeper of performance; it governs not only how a truck moves but how it supports a suite of tools and operations that extend the vehicle’s usefulness on the job site.

For fleets considering aftermarket or premium options, the world of wheel design demonstrates a spectrum of trade-offs between durability, weight, aesthetics, and cost. It is not simply about choosing the lightest wheel or the most rugged one. It is about aligning wheel characteristics with the fleet’s duty cycle, average payload, route profile, and maintenance philosophy. In the realm of heavy-duty service, where the primary goal is predictable uptime and safe operation under heavy load, steel wheels can provide unambiguous reliability. In lighter duty routes or fleets seeking improved ride quality and marginal improvements in fuel economy, alloy wheels may offer advantages, provided the operational conditions justify the upfront investment. The key is understanding that each wheel type interacts with tires, brakes, suspension, and driveline in a way that shapes rolling resistance, steering effort, heat generation, and ultimately the vehicle’s life cycle costs. Decision-makers who map these interdependencies tend to optimize both performance and reliability, translating engineering choices into measurable fleet metrics over months and years of service.

To illustrate how a wheel choice resonates through a fleet’s daily routine, consider the interplay between wheel sizes, payload, and turning radius in a busy urban setting. A configuration that supports a high payload without compromising agility is essential for last-mile delivery or service vehicles that operate in dense city streets. The numbers matter: the front wheels might be sized to optimize steering response while the rear wheels are sized to support heavy loads and maintain traction on varied surfaces. A tight turning radius—such as a few meters in compact urban blocks—reduces maneuver time and fuel consumption, while also reducing tire wear caused by repeated tight turns. When wheel choice aligns with suspension tuning and braking performance, fleets experience smoother operation, longer tire life, and fewer maintenance interruptions. Each mile traveled in such a configuration is an accumulation of tiny efficiencies—less energy wasted in dragging weight, less time lost to tire replacements, and fewer unscheduled maintenance events that disrupt routes.

The overarching narrative here is that Mitsubishi’s commercial wheel strategy embodies a pragmatic balance. It is a strategy designed for reliability, durability, and efficiency across a spectrum of job sites—from urban fleets to remote work sites—while accommodating the realities of maintenance programs and the realities of operating budgets. The dual-track approach—robust steel for durability and lighter alloys for efficiency—allows fleets to tailor wheel configurations to specific routes, loads, and climates. It also acknowledges that wheels are part of a larger ecosystem: tires, hubs, suspensions, brakes, and drivetrains all operate in concert to deliver predictable performance. In practice, this means fleets can select wheel configurations that minimize downtime, maximize uptime, and deliver the steady cadence of service that customers and end users expect. It also means that the wheel choice made today will ripple through maintenance schedules, fuel bills, and driver satisfaction for years to come, underscoring the wheel’s role as a strategic asset rather than a mundane component.

For readers who want to explore related topics beyond core wheel configurations, the world of Mitsubishi’s wheel ecosystem offers several avenues. Specifically, premium aftermarket alloy options for certain passenger segments illustrate how advanced wheel design translates into performance benefits in a lighter vehicle class. This broader context helps fleet managers see how the principles of wheel selection—durability, weight, fit, and compatibility with the driveline—apply across the spectrum of Mitsubishi’s vehicles, from work trucks to service vans. To broaden the view further, consider the practical example of a fleet that weighs strategic upgrade decisions against the total cost of ownership, factoring in maintenance intervals, tire wear patterns, and replacement cycles. When a fleet aligns its wheel choices with maintenance planning and driver training, it unlocks smoother operations and more reliable service delivery across all routes. The wheel, in this sense, becomes a compass for fleet performance, guiding decisions that preserve uptime and keep customers satisfied across the road network.

Internal reference for further context on premium wheel options is available here: brand-new original BBS rims set of 4 R18 rims for Lancer sedans. While this example focuses on a different vehicle segment, it helps illustrate how high-quality alloy rims can influence performance characteristics such as weight, heat dissipation, and wear resistance, which are relevant to any fleet considering upgrades within the wheel family. The principle remains consistent: the best wheel choice is one that harmonizes with the vehicle’s overall design, the duty cycle, and the maintenance strategy to deliver reliable, efficient operation over the long haul.

External reference: https://www.mitsubishifuso.com/

Final thoughts

Understanding the various types of wheels associated with Mitsubishi vehicles equips business owners with the knowledge to make sound decisions regarding safety, comfort, and performance. From standard wheel lock keys that protect your investment to specialized steering wheels that enhance driver experience and robust commercial truck wheels designed for heavy applications, each component plays a vital role in business operations. By choosing the right wheels, business owners can ensure a safer, more efficient, and stylish fleet, ultimately translating to better productivity and profitability.