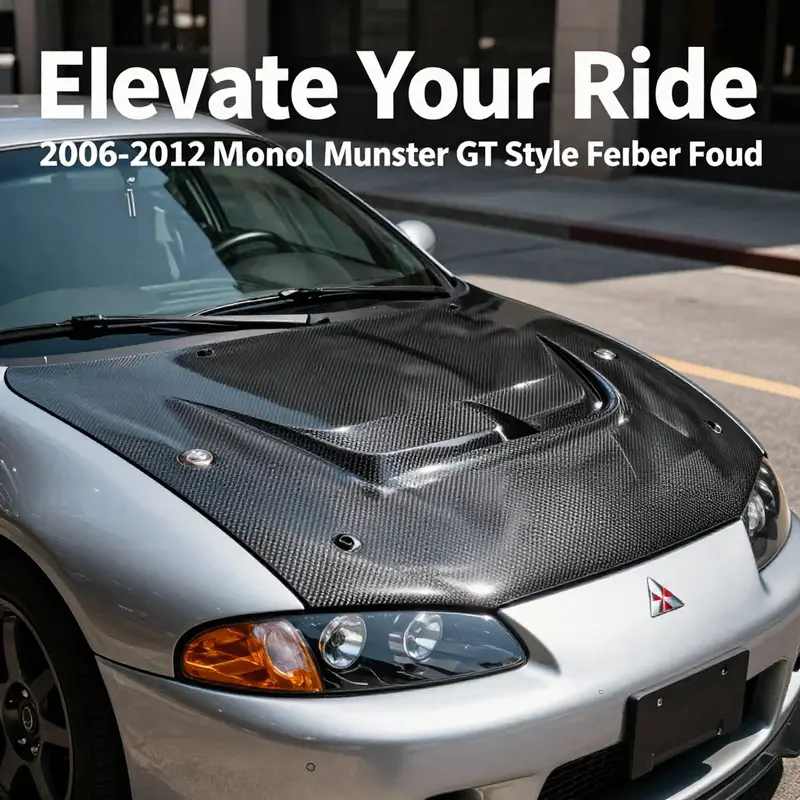

The 2006-2012 Mitsubishi Eclipse Monster GT Style Carbon Fiber Hood is more than just an aftermarket component; it’s a gateway for enthusiasts looking to enhance the performance and styling of their vehicles. Designed specifically for two-door variants of the Mitsubishi Eclipse, this carbon fiber hood offers a blend of lightweight construction and aggressive aesthetics, making it essential for business owners in the automotive aftermarket sector. This article delves into its standout features, explores performance enhancements that can attract discerning customers, and provides essential maintenance and installation tips, giving you the insight needed to discuss and promote this product effectively.

Weight, Heat, and Attitude: How a Carbon Fiber Hood Transforms a Mid-2000s Two-Door Sport Coupe

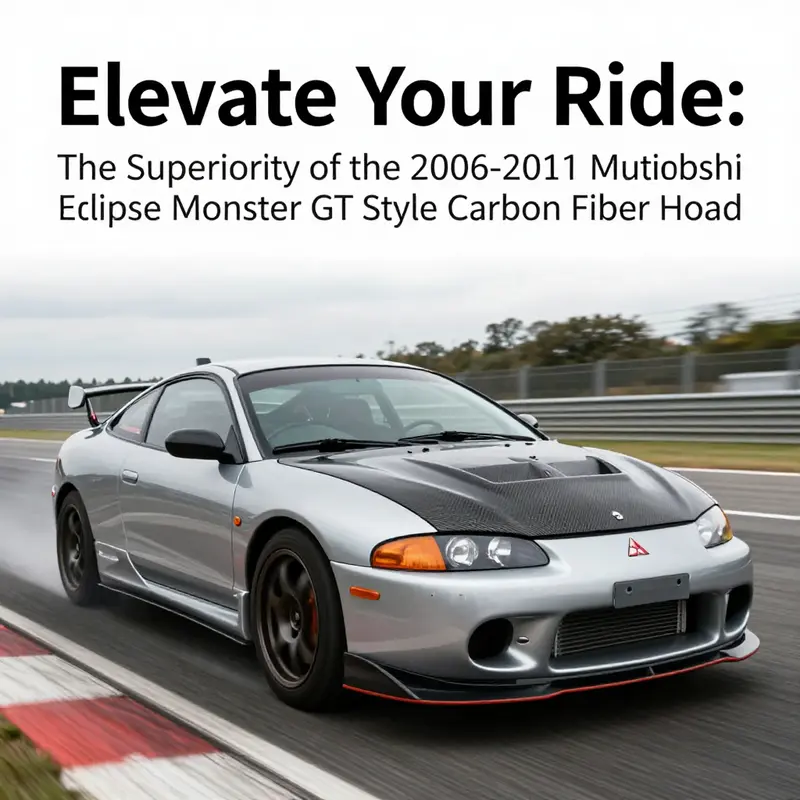

In the world of late-2000s and early-2010s automotive culture, the two-door sport coupe became a canvas for engineering ideas and personal expression. Enthusiasts sought every possible edge, from suspension tuning to exhaust notes, but few upgrades embodied both performance intention and visual impact as directly as a carbon fiber hood. This is not merely a weight-saving bolt-on; it is a deliberate rethinking of the vehicle’s front-end identity. The material itself is a quiet revolution. Carbon fiber, the same material that graces high-performance race cars and luxury supercars, brings a weight penalty that is nearly half of a conventional steel hood. When you consider the job of a hood—from shielding the engine bay to shaping the car’s front-end aerodynamics—the reduction in mass translates to tangible performance benefits. The chassis feels freer, the steering is more responsive, and even the tires wear a little differently once the unsprung weight is trimmed. In practical terms, the acceleration you feel when you roll onto the accelerator is more immediate, and the braking system benefits from a reduced rotational inertia that helps the car settle more quickly into a straight line under heavy deceleration. These changes, while subtle in daily driving, accumulate into a more confident, composed, and engaging driving experience on a winding road or a smooth race surface. The incremental gains compound with other performance modifications, creating a synergistic effect that makes the car feel lighter on its feet and more willing to respond to driver input.

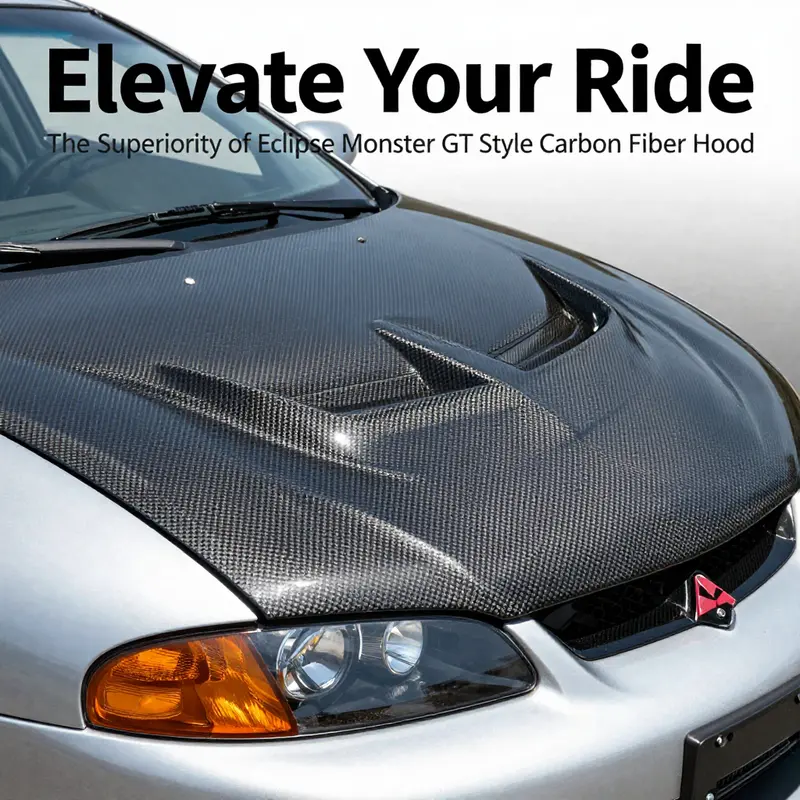

The appeal of carbon fiber goes beyond the scale. The material’s inherent strength-to-weight ratio offers structural advantages that matter at the limits of grip. In the context of a mid-2000s two-door sports coupe, the hood must contend with heat generated by a turbocharged or naturally aspirated engine, the demands of aggressive driving, and the structural needs of a forward-mounted bay. A carbon fiber hood can be engineered with scalloped air intake openings, raised lines, and sculpted contours that not only accommodate larger heat exchanges but also guide airflow in a way that reduces stagnation over the engine bay. The result is a cooler engine and a more stable front-end attitude during hard cornering. Even if the car isn’t on a race track every weekend, the improved heat management can extend the life of performance components by maintaining consistent temperatures during spirited drives and repeated power applications.

From a design perspective, the aesthetic intent mirrors the performance goals. The look is inherently race-inspired, with exaggerated lines that communicate purpose. Aggressive air openings, sharp edges, and well-defined creases give the front of the car a more confrontational stance, signaling capability even when the engine bay is closed. This is a styling language that aligns with the history of performance tuning—where function and form reinforce each other. The surface treatment on these carbon fiber hoods adds another layer of durability. A common specification is a scratch- and dent-resistant finish that protects the exposed weave from routine road hazards, wash cycles, and the occasional brush with a garage wall. That protective layer helps preserve the visual integrity of the carbon fiber’s distinctive weave, allowing the hood to remain visually striking without demanding constant refinishing. The combination of lighter weight, heat resistance, and protected aesthetics makes the hood a compelling upgrade for drivers who want their car to look as fast as it feels, even when stalled in traffic.

A crucial consideration for any aftermarket hood is fitment. The best products in this category offer a precise, direct-fit installation that minimizes or eliminates the need for bodywork or invasive modifications. The term often used to describe this is “vehicle-specific compatibility,” and it matters as much as the material itself. When a hood is engineered to align with the factory hinges, latching points, and hood supports, the installation becomes more than a simple swap. It becomes a reliable upgrade you can perform with common hand tools in a driveway or garage, without the fear of misaligned gaps or muffled hood latches. In practice, this translates into confidence for the owner. The hood sits flush against the fenders, the hood line aligns with the character line of the roof, and the resulting silhouette looks intentional rather than tacked-on. Even the small details, such as the curl of the leading edge and the precision of the radii around the wheel arches, contribute to an overall impression of quality. Those details matter because a carbon fiber hood is more than a component; it is the visible manifestation of a broader performance mindset.

The market for carbon fiber aftermarket hoods in this segment has, over time, matured into a resource for enthusiasts who want more than a cosmetic upgrade. The material’s properties—stiffness,耐 heat resistance, and the potential for dramatic styling—make it a compelling choice for cars that attract attention at car shows and on the street alike. The combination of weight savings and heat management aligns with the broader goals of performance modification: reduce parasitic drag and mechanical load while increasing throttle response and steering fidelity. For many drivers, this is a holistic upgrade, not just a single enhancement. The hood becomes a focal point in the car’s narrative about capability and drive character. It invites curiosity about what lies beneath the surface and why the car feels different when the engine is exposed to air and movement through the wind tunnel of everyday traffic. In that sense, the hood is both instrument and artifact—an engineered part that communicates a philosophy of speed and control.

In exploring the technical promise of carbon fiber hoods, it’s important to acknowledge the real-world questions that often accompany upgrades. How does the hood perform under repeated heat cycles? Will the latch system, hood dampers, and surrounding hardware wear at the same rate as stock components? The answer, when the hood is produced with automotive-grade certified carbon fiber and a robust resin matrix, is generally affirmative. The material’s durability under high-stress driving conditions is a key factor in its appeal. A well-made carbon fiber hood resists common issues such as delamination at the edges, micro-cracking along the weave, or rapid dulling of the surface finish after exposure to sun, road debris, and car wash cycles. The protective treatment helps ensure that the hood remains visually engaging even after months of exposure to the elements, a common concern for owners who drive their cars year-round. Meanwhile, the heat management advantage is not merely about preventing engine bay temps from rising; it also supports the longevity of nearby components. Electronic sensors, heat-sensitive wiring, and performance-oriented hardware can benefit from cooler operating environments, reducing the risk of heat-induced fatigue and maintaining consistent performance during sustained use.

The audience for this kind of upgrade tends to be driven by a blend of practical and aspirational motives. Performance tuners see the weight reduction as a lever to improve acceleration, braking, and handling characteristics, even when measured against other chassis modifications. Show car builders view the hood as a centerpiece, a visual statement that communicates depth of investment and dedication to quality. Daily drivers, too, might appreciate the cosmetic upgrade and the improved airflow management, provided they understand the maintenance and care required to keep the carbon weave pristine. The conversations that arise around this kind of product often touch on the balance between performance gains and price. Carbon fiber remains a premium material, with costs that reflect the manufacturing complexity and quality control needed to achieve a consistent weave, precise layup, and reliable surface finish. Yet for many enthusiasts, the perceived value—reduction in weight, improved aesthetics, and the potential for better track readiness—justifies the investment.

Beyond the immediate specifications, it’s helpful to place this upgrade within a larger narrative about how performance culture has evolved in the mid-2000s to early 2010s. This era bridged a period of growing accessibility for aftermarket enhancements with an increasing emphasis on engineering rigor and material science. Carbon fiber, once a symbol of exclusive, high-cost performance, gradually found its way into mainstream tuning shops and reputable aftermarket lines. The result was a more diverse ecosystem of parts that offered meaningful, measurable benefits without requiring a complete revamp of the vehicle’s architecture. In this context, a well-designed carbon fiber hood becomes a strategic element. It signals a willingness to optimize weight distribution, improve engine bay ventilation, and refine the vehicle’s stance, all while staying true to the driver’s sensory experience of speed and precision.

To round out the picture, consider how this specific hood aligns with the broader ecosystem of aftermarket improvements. A wheel upgrade, for example, changes the stance and the contact patch with the road, complementing the weight savings in the front of the car. A properly matched set of wheels can further reduce unsprung mass and improve rotational inertia, enhancing the effect of a lighter hood on overall performance. Yet the hood remains distinct in its immediate impact: it touches the heart of the car’s front-end aerodynamics, the engine’s heat management, and the vehicle’s visual storytelling. For the curious reader who wants to see how this narrative connects to other parts of the modifying journey, the linked exploration of historic carbon fiber hood design from adjacent platforms offers a comparative perspective on how different marques approached similar challenges. See 1994-1999 mitsubishi-3000gt-pit-fighter-carbon-fiber-hood for a related lineage of performance-focused carbon fiber engineering across generations.

In practice, the installation experience is often described as straightforward when the panel is engineered for direct bolt-on compatibility. The process of unbolting the stock hood and fastening the carbon fiber part in its place is a familiar rite of passage for enthusiasts who have added or replaced aftermarket components before. The effort is rewarded by a more coherent front-end silhouette, a sense of immediacy in the car’s communication of intent, and a front-end that feels lighter and more responsive in both straight-line drive and cornering. While some steps require careful alignment and an eye for detail, the payoff is immediate in how the vehicle communicates its performance character to the world. It is this combination of immediate feedback and long-term benefits that keeps carbon fiber hoods a steady presence in the tuning community.

As this chapter unfolds within the broader article, the story remains anchored in a single, clear proposition: replacing a steel hood with a carbon fiber counterpart yields a multi-dimensional upgrade. It’s not simply about reducing weight; it’s about sharpening the car’s personality, improving heat management, and delivering a front-end look that communicates readiness for competition—whether on a track, a show field, or a fast morning commute. The result is a vehicle that feels more connected to the driver’s inputs, with a front end that responds with greater immediacy and confidence. In that sense, the carbon fiber hood functions as a catalyst for a more holistic driving experience, one that rewards not just the time spent under the hood but the time spent behind the wheel.

For readers who want to explore this area further, there is a lineage of performance-focused carbon fiber components that provide context for what makes a hood of this type a meaningful upgrade. The evolution across generations demonstrates how heat management, weight distribution, and front-end aerodynamics are interdependent aspects of car tuning. It also shows how a carefully engineered component can integrate with existing hardware to minimize maintenance complexity while maximizing the driver’s sense of connection to the machine. This is the core argument behind choosing a high-quality carbon fiber hood: it aligns engineering intent with the thrill of driving, offering a tangible path from concept to connection. And as with all parts in the aftermarket ecosystem, the quality of the material, the rigor of manufacturing, and the precision of fitment ultimately determine whether the upgrade delivers on its promise over time.

If you are curious about the broader ecosystem and want to see how dedicated sources discuss similar components, you can explore related transitions in carbon fiber hood design in surrounding platforms. See the linked historical reference to a comparable carbon fiber hood from another generation here: 1994-1999 mitsubishi-3000gt-pit-fighter-carbon-fiber-hood. This connection offers a sense of how design language and engineering priorities evolve while maintaining a consistent thread of performance improvement through carbon fiber technology.

As the conversation continues across chapters, the narrative will extend to how owners balance the benefits of weight reduction with the realities of daily use. It will consider maintenance considerations, such as how to protect the weave from UV exposure, how to clean the surface without compromising the resin and coating, and how to assess the long-term durability of bonding agents or mounting hardware when subjected to temperature swings and road conditions. The aspiration remains clear: a carbon fiber hood should not feel like a fragile accessory but rather like a purposeful upgrade that remains practical, reliable, and visually compelling across seasons and miles. With any aftermarket modification, the decision rests on aligning personal driving goals with the part’s engineering promise. When that alignment occurs, the result is not only a better-looking car but a more intentional, engaging, and capable driving experience.

External reference for further context and product detail can be found here: https://www.amazon.com/dp/B07Z5JFQ8K

null

null

Fitting the Aggressive Carbon Fiber Hood on a 2006–2012 Eclipse: Precision, Performance, and Preservation

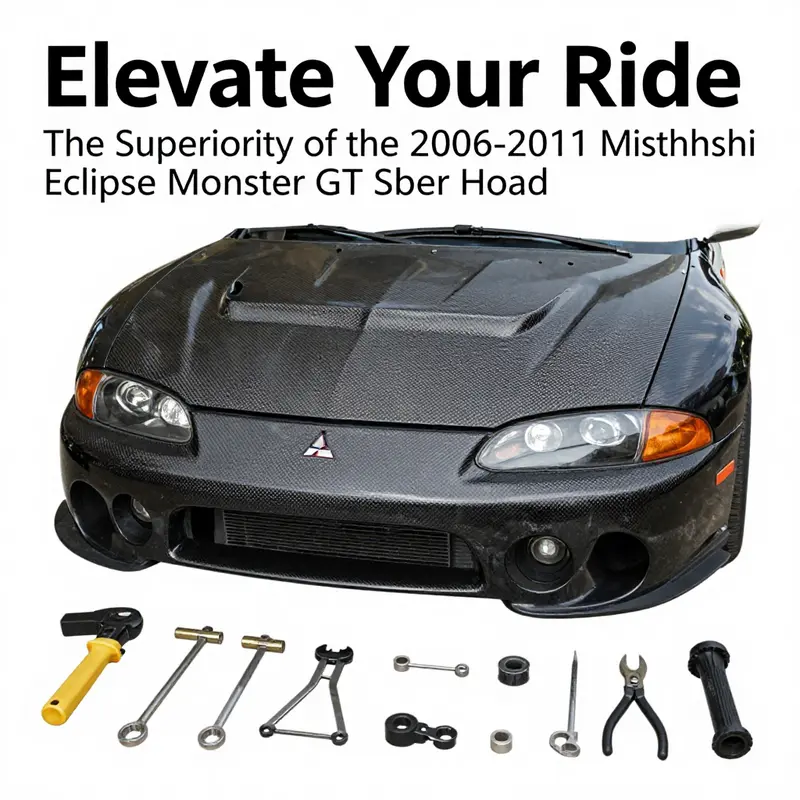

The decision to install a high‑performance carbon fiber hood on a mid‑2000s Mitsubishi Eclipse is more than a cosmetic upgrade. It is a deliberate statement about weight reduction, airflow management, and how a car communicates with the road. The hood brings an aggressive silhouette to the car’s profile and signals a driver who values speed and control. Yet the appeal rests not only in the new look but in potential performance gains from a lighter skin over the engine bay. This chapter traces a practical, integrated path through the installation experience, the realities of alignment and modification, and the long‑term maintenance that preserves both form and function. From the outset, aftermarket carbon fiber components demand respect for the engineering boundaries of the vehicle. The Eclipse chassis for this generation is designed around specific hood geometry, hinge lines, latch mechanisms, and the underside interaction with adjacent panels. Upgrading to a panel with a different contour or altered weight distribution can require more than bolt‑in steps; it often calls for measured preparation and precise alignment to avoid introducing new stress points that ripple through fenders, the windshield area, or other front‑end components. This is not merely about drilling holes or reattaching a latch; it is about rehoming the hood to respect the car’s overall geometry and the engine bay’s clearance.

The pre‑fit phase sets expectations. Technicians inspect factory mounting points, hinges, and latch alignment, then compare these with the hood’s mounting pattern. Carbon fiber is rigid and strong, but its surface finish and edging require mindful handling to avoid micro‑cracking or edge deflection that could alter fit if stressed during installation. The process begins with careful removal of the stock hood. The hood must come off with the engine off, the vehicle chocked, and hood supports stowed to prevent movement. Any connected hoses or wiring harnesses near the front of the engine bay should be unplugged or relocated to clear the path for the new panel. The new hood is then brought into position on the hinges to test basic alignment. The perimeter edge should align with fender contours, headlight cutouts should sit in a plane with surrounding metal, and engine bay components must not interfere with underside clearance.

A common reality is that some OEM parts may still be present or require modification to accommodate the hood’s contour. Alignment cannot be rushed; installation should proceed in small, deliberate steps. Initial hinge mounting reveals whether the hood sits too high or too low, whether the edge is parallel to the fender line, or whether there is misalignment that would cause binding when opening and closing. If misalignment is detected, it is usually addressed by adjusting hinge position or trimming small amounts to equalize gaps. For carbon fiber, even a slight misfit can be felt as a wobble, making final alignment critical for aesthetics and function. The hood latch mechanism and safety catch must be checked to ensure secure operation during driving while still allowing easy release.

Hardware considerations matter. The carbon fiber panel, even at half the weight of a steel hood, can alter loading characteristics at mounting points. Stainless or coated fasteners are typically advised to resist corrosion and keep torque stable. The installer confirms no interference with latch mechanics and hood struts, and may remove or revise the OEM latch or release cables if they cause binding. The goal is a hood that sits flush against surrounding bodywork, with a clean line from windshield to grille and a dramatic profile under daylight and street lamps. The final look should respect the car’s aerodynamic intent while presenting a confident stance.

Finish and protection deserve equal attention. Carbon fiber surfaces reveal imperfections, and the protective clear coat should be free of micro‑cracking and resin ridges. A light polish can restore uniformity, but care must be taken not to burn through the clear coat or abrade the weave. After final fit, gaps, seams, and reflections should be checked for any misalignment or moisture intrusion risk. The hood’s distinctive lines, vents, and ridges communicate purpose even when the car is stationary. A routine maintenance cycle should include periodic checks of latch alignment and edge clearance, as well as a seal around the radiator opening to maintain airflow and moisture protection.

Beyond the fit, upgrades affect cooling, electricals, and overall vehicle balance. Front‑end airflow components such as radiators and ducts may require minor repositioning or sealing to maintain optimal airflow with the new hood geometry. The installation should consider mass distribution changes and how they influence suspension geometry and brake balance, even down to pedestrian safety features. Maintenance includes periodic protection of the finish with a UV‑resistant sealant or wax, and regular inspection for micro‑cracks or chips that could propagate under temperature changes. Protecting the clear coat extends the life of the weave and preserves aesthetics as the car ages.

For readers planning broader front‑end modernization, a coordinated package that echoes the hood’s lines can help preserve aerodynamic balance and visual cohesion. Related content on wheel choices and suspension alignment may provide valuable context for forming a complete upgrade strategy. See guides focused on wheel sizing, offsets, and how those choices influence stance and handling. See also resources on component compatibility and community discussions that share practical, experience‑based guidance. External references may include supplier sites and automotive forums that document real‑world fitment experiences.

Final thoughts

In summary, the 2006-2012 Mitsubishi Eclipse Monster GT Style Carbon Fiber Hood stands out as a superior choice for vehicle enthusiasts, combining style, performance, and quality. Its lightweight design not only enhances the vehicle’s aesthetics but also contributes to significant performance improvements, making it an attractive option for customers looking to upgrade their vehicles. Additionally, understanding how to install and maintain this high-quality component allows automotive businesses to provide exceptional value and service. By positioning this hood in your inventory, you not only offer an appealing product but also empower your customers to elevate their driving experience.