The Mitsubishi Lancer Evolution, revered for its rally pedigree, embodies the spirit of performance and innovation. Among its many engine configurations, the 4G63 short block engine stands out, especially the variant with part number 1000B075, designed to enhance the driving experience across Evo IV to Evo IX models. This article delves deep into the characteristics, technical specifications, motorsport applications, economic implications, and community perspectives surrounding this iconic engine. Each chapter contributes to a comprehensive understanding of how this engine fosters business opportunities and fuels automotive passion.

Foundations of Power: The 4G63 Short Block and the Evolution IV–IX Turbo Legacy

The Mitsubishi Lancer Evolution line is built on a core belief: the heart of a race-bred sedan is a proven bottom end capable of surviving the rigors of forced induction and high-velocity cornering. In the story of Evo IV through Evo IX, the 4G63 short block acts as the dependable base upon which power is scaled, torque curves are sculpted, and reliability under stress is earned. The part number 1000B075 represents a universal short-block assembly intended for the 4G63 family, a formal acknowledgment that in the world of hardcore turbo performance, the bottom end does not merely support the engine; it defines its resilience. This chapter follows that logic, tracing how a robust short block connects the Evo’s sophisticated chassis, dynamic all-wheel drive, and turbocharged heritage into a coherent whole that enthusiasts return to again and again when they plan a rebuild, a rebuild-and-upgrade, or a measured increase in horsepower.

To understand the appeal of a short block like 1000B075, it helps to recall what the Evo IV was asking of its engine. The 4G63T—a turbocharged four with its roots in the late 1980s and refined through continuous development—delivered a formidable 280 horsepower at 6,500 rpm and about 353 Nm of torque at 3,000 rpm. Those numbers, respectable in any era, become a different proposition once you consider the Evo’s 4WD chassis, its multi-link rear suspension, and the active torque distribution offered by the optional Active Yaw Control. In short, the car demanded a bottom end that could sustain high boost, rapid throttle response, and the precision required to translate torque to momentum without letting the drivetrain break traction. The short block is where the plan starts—the platform that keeps the rotating assembly aligned, oiling consistent under duress, and compression reliable as boost climbs.

The Evo IV’s engineering also introduces a few distinctive design choices that influence how a short block behaves in service. The engine orientation, a notable feature of the Evolution platform, is rotated roughly 180 degrees to optimize weight distribution and reduce torque steer. This arrangement has practical consequences for the oiling system, pickup geometry, and the overall health of the bottom end when the car sits at the edge of its grip on a racetrack or a spirited back-road blast. When a builder sources a universal short block like 1000B075 for a 4G63-based project spanning Evo IV to IX, the goal is to preserve the fundamental architecture—still a robust iron block with prepared oil galleries and a capably hardened main and thrust bearing setup—while allowing room for source parts, pistons, rings, and a rotating assembly tuned to boosted performance.

But a short block is more than a mere container for pistons and crank. It is the stage on which turbocharged destiny plays out. Turbo engines demand more than simply an increase in bore and stroke; they require a block that supports higher piston speeds, improved oiling for elevated bearing loads, and a revised deck height compatibility with forged components if the power target climbs. The 4G63 family has a storied reputation for durability when properly prepared, and the 1000B075 short block is positioned as a versatile foundation for builds that approach the limit of the stock bottom end’s endurance. A rebuild using this type of short block is not just a refresh; it is a careful recalibration of clearances, material strength, and lubrication pathways designed to handle sustained boost, peak RPM, and the heat that comes with aggressive turbocharger economics.

Across Evo IV to IX, the remnant appeal of the 4G63 engine lies in its balance of torque, response, and the ability to revisit an older platform with modern tuning sensibilities. Even as Mitsubishi’s lineup moved through generations, the underlying philosophy remained consistent: a strong, adaptable bottom end paired with a capable turbocharged charge-cooling system could deliver a thrilling, endearing driving experience. The short block is the anchor in that philosophy. It holds the crank and connecting rods in precise alignment, keeps the pistons and rings in ring-compressing tango with the cylinder walls, and establishes the foundational oiling regimen that keeps bearings spinning with minimal wear under load. When an owner orders a universal short block like 1000B075, they are choosing a part designed to address a spectrum of service conditions—from street tuning to serious track work—while maintaining compatibility with the broader engine architecture that defined the Evo era.

Enthusiasts often weigh the short block against a suite of supporting upgrades. A typical approach is to couple the block with forged or high-strength pistons, upgraded connecting rods, and reinforced main bearing caps to accommodate higher boost and extended redline operation. The 4G63T’s healthy bottom end can respond well to forged internals, especially when paired with appropriate oiling upgrades, a tighter oil clearance strategy, and a beefier main cap arrangement. Yet even with a robust block in hand, a high-performance Evo build must manage heat, boost, and lubrication in a coordinated manner. The short block interacts with the rest of the engine’s internal relationships—the crankshaft’s journal diameters, the rod bearing oil clearances, and the piston-ring package—all of which must be calibrated to the chosen boost target. In this light, a universal short block is not a one-size-fits-all solution but a versatile platform that a skilled engine builder can tailor to an intended use, whether that use is daily driving with occasional track days or a more aggressive, competition-ready configuration.

Another layer of consideration is the practical compatibility with other Evo components. The Evo IV’s suspension, brakes, and chassis innovations were designed around a particular balance of weight distribution, grip, and rigidity. A bottom-end upgrade, while fundamentally a mechanical decision, reverberates through the car’s performance envelope. If the engine’s rotating assembly is tuned for higher boost, the drivetrain geometry, the differential’s torque handling, and the braking system’s thermal capacity all become elements of a larger equation. The short block cannot operate in isolation; it must be integrated with an appropriate head, a matching turbocharger setup, intercooling, an engine management strategy, and a cooling system that keeps boost-fed temperatures within the engine’s tolerances. In the Evo IV’s lineage, where 16-inch and 15-inch brake hardware, a high-mounted rear wing, and clever aerodynamics were part of the performance equation, the bottom end upgrade must be harmonized with these features to preserve the car’s intended balance.

The practical realities of sourcing and fitting a universal short block like 1000B075 include attention to OEM compatibility and maintenance philosophy. The idea of using original equipment manufacturer (OEM) parts for critical components—such as the suspension, brakes, and engine auxiliaries—remains relevant even as power levels rise. OEM parts, with their calibrated tolerances and proven reliability under high-load conditions, help preserve the Evo’s intended handling and safety characteristics. While aftermarket options may offer advantages in weight or styling, OEM parts tend to deliver consistent performance under the kinds of repeated stress that a high-performance 4G63 build will encounter on the road or track. It is this blend of a robust bottom end, thoughtful tuning, and careful component matching that underpins durable, repeatable performance.

From a historical perspective, the Evo IV’s position as a benchmark in the Evolution line adds cultural weight to a decision to use a universal 4G63 short block across generations. The car’s engineering heritage—rotated engine orientation, optional Active Yaw Control, and the standard limited-slip differential—exemplifies the philosophy that performance is a system, not a single component. The short block is a crucial thread in that system, a mechanical foundation that supports the synergy between power, grip, and steering feel. When builders reflect on the 4G63’s ability to fulfill developmental demands across multiple Evo generations, the short block becomes a touchstone for reliability under boost, a predictable platform that makes the act of tuning a more controlled craft rather than a leap of faith.

For those who want to explore the more extreme end of the spectrum, a billet-block option represents a different path. A billet alternative, such as the 4b11t billet block, is mentioned here as a comparative point of reference for builders eyeing even higher levels of performance. While the 4G63’s legacy rests on robust casting and established maintenance procedures, a billet block offers a different set of attributes—stability under extreme pressures, potential weight considerations, and a distinct path for future upgrades. If you are considering this direction, you can learn more about that specialized route through a dedicated resource, and you can compare how a billet block might change the heat management, oiling strategy, and overall mass distribution of an Evo-inspired machine.

In the end, the 4G63 short block, part number 1000B075, embodies a pragmatic, performance-oriented philosophy. It is a building block designed to endure, to accommodate, and to empower the user to extract measurable, repeatable gains from a platform steeped in rally heritage and circuit-ready DNA. The Evo IV’s engineering choices—the 180-degree engine orientation, the available AYC, the locked or optional LSD—are not mere footnotes. They are the living context in which a short block operates. The bottom end is where torque becomes velocity, where boost translates into pace, and where the car’s most fundamental stability originates. When a builder threads together an Evo IV–IX project, that bottom end is the shared language, a common thread that ties together chassis dynamics, turbocharging strategies, and the user’s broader goals for performance and reliability.

External reference: For a contemporary evaluation of the Evo IV’s engineering and real-world driving experience, see Car and Driver’s profile on the Mitsubishi Lancer Evolution IV: https://www.caranddriver.com/mitsubishi/lancer-evolution-iv

Internal reference: For enthusiasts considering alternative block options within the Mitsubishi performance landscape, a billet-block option is discussed here: https://mitsubishiautopartsshop.com/4b11t-billet-block/

The Core of Power: Unraveling the 4G63 Short Block Across Evolution IV to IX and the Enigmatic 1000B075

The short block is the quiet workhorse of any high-performance engine, the section of metal and precision that bears the torque and feeds the rhythm of a turbocharged four. In the context of Mitsubishi’s Lancer Evolution lineage, the 4G63 short block becomes more than a base—it is the foundational heart that must endure the abuse of high boost, rapid throttle response, and the relentless demands of all-wheel-drive traction. When enthusiasts speak of builds for the Evolution IV through IX, the short block often emerges as a focal point: a component that must balance rigidity with weight, oiling with reliability, and compatibility with head, turbo, and ECU that together define a whole. Within this framework, a part number like 1000B075 sits at an intriguing intersection of sourcing reality and performance mythology. The literature gathered around this identifier is sparse; it hints at a universal short-block assembly designed for the 4G63 family, intended for the Evo IV through Evo IX. Yet the specifics—crankshaft configuration, bore and stroke details, cylinder liner design, and associated fasteners—are not laid out in the general databases consulted. Still, the story of the short block in these cars is coherent and worth tracing, because it illuminates why this component matters so much to the way an Evolution behaves on the road and on the track.

To appreciate the place of a short block in the Evo’s engineering, it helps to recall the engine’s core as it appeared in Evo IV. The 4G63 is a 2.0-liter, DOHC, 16-valve turbocharged inline-four, a configuration that produced about 250 PS at 6000 rpm and roughly 299 Nm of torque at about 3000 rpm in stock form. The compression ratio sat around 8.8:1, a figure chosen to support higher boost without detonation while preserving reasonable fuel efficiency in street driving. The engine was paired with a five-speed manual transmission and a full-time all-wheel-drive system with a viscous coupling unit and a limited-slip differential. The weight of the vehicle hovered around the mid-1300 kilogram range, a balance that allowed the powertrain to deliver remarkable acceleration without becoming unwieldy. These specifications define not just performance numbers but the operating envelope within which the short block must perform.

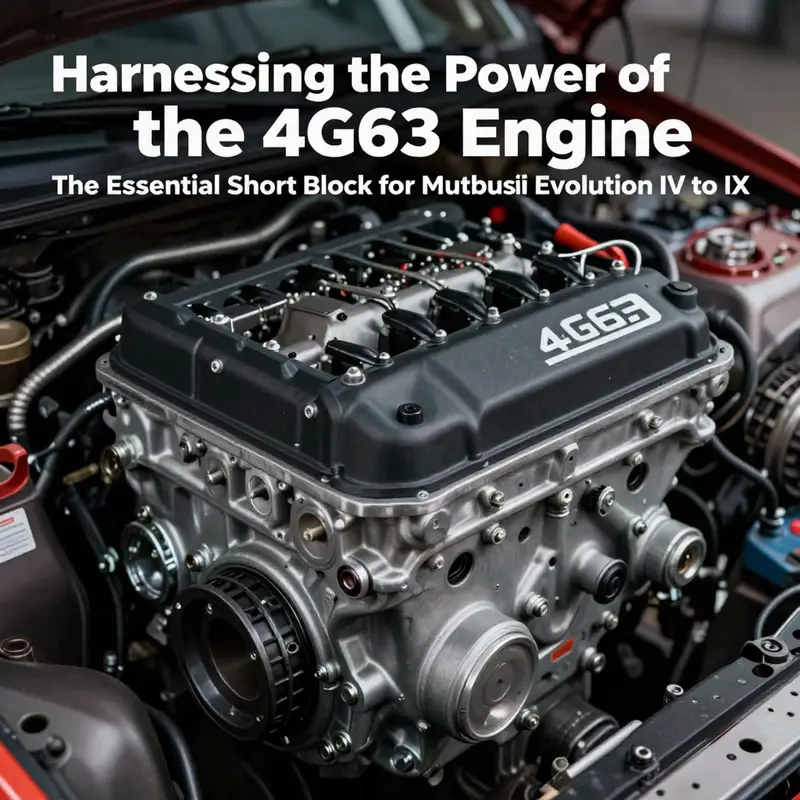

A short block, by definition, contains the lower end of the engine: the crankshaft, main bearings, pistons, connecting rods, block casting, and the associated oiling galleries and seals. It excludes the cylinder head, camshafts, rocker arms, intake and exhaust manifolds, turbocharger, fuel delivery hardware, and the transmission. In practice, a short block like the purported 1000B075 is intended as a rebuild or replacement core that can be dropped into an Evo IV or later model chassis with the right matching components. The practical value of such a part lies in its potential to provide a fresh, robust bottom end for a high-boost build, a remanufactured core that can withstand the stresses of sustained operation at elevated horsepower. The caveat, however, is real: even when a short block is described as “universal” within a model family, the actual fitment must be verified against OEM tolerances, main journal sizes, bore diameters, oil passages, and the compatibility of crank fillets and pistons from the intended build.

In the Evo IV’s context, and extending through Evo IX, the 4G63 family shared enough constancy for a short-block approach to be plausible. Yet the evolutions within the line—improvements in head design, variations in turbo sizing, and refinements to intake and exhaust flow—also altered the load paths and dynamic demands on the bottom end. A short block that is compatible with the Evo IV’s crank and main bearing arrangement could still be mismatched with a later model’s revised oiling passages or altered bore centers if not paired with correct pistons, rings, and a crankshaft that meet the same tolerances. This is why the stated universality in sources often comes with a heavy caveat: verify the block’s bore size, stroke, and deck height, confirm that the main journals align with the crankshaft you plan to use, and ensure that the oil galleries, oil pan interfaces, and windage tray provisions will play nicely with your chosen head, turbo, and exhaust system.

One thread that ties together the Evo IV’s powertrain philosophy with the concept of a universal short block is the balancing act between rigidity and mass. A robust bottom end supports higher cylinder pressures, enables more aggressive rod and piston designs, and helps preserve oil pressure at elevated RPMs under boost. This is particularly important in a car with all-wheel-drive and a viscous coupling unit, where transient loads can be quite complex as traction changes under cornering and throttle transitions. In practice, a well-chosen short block becomes the anchor around which a high-performance build revolves. It must endure boost pressure, sustain proper clearances, and maintain a reliable oiling system that can feed the crank, rod bearings, and pistons even as the engine breathes wider and spools larger turbochargers.

Given the uncertainty surrounding the exact specifications of 1000B075 in public databases, many builders approach it as an enabler rather than a fixed blueprint. They consider it a ready-made foundation that can be tailored with carefully selected pistons and rods, a crankshaft tuned for the target power level, and a gasket set designed to seal a high-boost environment. In this approach, the short block becomes a chassis member of sorts: the platform that must stay true and square while the head, intake, and exhaust choreography do the heavy lifting of airflow. This mindset often leads enthusiasts to search for compatible components that can be mated with the 4G63 bottom end without forcing drastic alterations to the engine bay or the four-wheel-drive architecture. It is here that the broader ecosystem of aftermarket options becomes relevant. Upgrading the bottom end often involves ancillary choices—oil cooling strategies, upgraded oil pump components, and windage baffles—that collectively ensure reliability when the engine is pushed beyond stock parameters.

Among the options that enthusiasts might explore for strengthening the engine core is the role of alternative block designs, including billet or premium cast blocks. A billet block, for instance, can offer improved strength and precise tolerances at high boost, an attractive proposition for someone planning sustained high-load runs. This relevance of block design naturally dovetails with experiences from the broader Mitsubishi performance community, where the interplay between block rigidity, crank alignment, and oiling reliability is a recurring theme. When contemplating a project based around a short-block assembly for the 4G63 family, a builder may weigh the cost, weight, and durability benefits of a billet-block path against the practicality of refurbishing a reliable OEM or aftermarket cast block. Either approach will demand meticulous attention to bearing clearances, piston-to-wall clearance, and deck height consistency, because even small deviations can magnify under boost and high rpm in a car that depends on precise timing and robust engine management.

The practical journey from concept to in-car performance begins with clarity about what the short block is intended to support. If the goal is a street-oriented Evo with respectable track capability, the short block must supply a stable foundation for a moderate boost level, a tuned fuel system, and efficient intercooling. If the objective is a more extreme track-focused build, the bottom end must tolerate aggressive piston profiles, upgraded rod kits, and a high-flow oiling regime. In both cases, the bottom end’s resilience directly influences the engine’s ability to sustain power and to recover from heat soak during long sessions on a demanding circuit. The Evo’s drivetrain and chassis respond to the engine’s behavior in subtle, telling ways: throttle response remains crisp, turbo lag is managed by the turbo system and intake design, and tire dynamics reveal the reliability of the internal components when the car is pushed to the edge of grip. A robust short block supports all of these interdependent aspects by ensuring that the core mechanical integrity remains intact under load.

Within the information landscape around 1000B075, the absence of a detailed public specification invites a practical discipline. It reinforces the principle that any high-performance build relies on cross-checking alignments with official manuals and trusted suppliers. The presence of competing resources—ranging from official Mitsubishi service literature to dedicated databases and aftermarket catalogs—means the builder must do due diligence to confirm bore, stroke, deck height, main journal diameters, and oil passages before committing to a specific short-block exchange. In a world where performance hardware often travels across multiple Evo generations, the ability to verify compatibility becomes as crucial as the performance gains promised by a higher displacement, better pistons, or a stronger crankshaft. For this reason, the chapter’s discussion remains anchored in the Evo IV baseline while acknowledging that what works well on Evo IV can be adapted across the family, provided careful match-ups are made between the long block, head, and turbocharging ensemble.

As part of the broader ecosystem of parts and upgrades, this narrative nods to options that enthusiasts sometimes explore to reinforce the bottom end. A block upgrade, such as a billet alternative, can be attractive for strict performance builds where ultimate rigidity is prized. The link to a billet block option—presented here as a reference point for readers exploring the landscape of high-end bottom-end solutions—illustrates how builders approach the problem of easing the bottlenecks that come with higher boost and higher RPM operation. The bottom line is that the short block is not a standalone solution; it is the keystone that requires thoughtful integration with every other system of the engine. Sourcing, matching, and validating components across the entire powertrain are the steps that convert a universal-sounding part number into a dependable foundation for sustained performance.

For readers who want to explore additional perspectives on block design and Evolution performance, a broader inquiry into the lineage and evolution of the 4G63-powered cars provides helpful context. Contemporary discussions from the community note how the 4G63’s architecture supported a wide range of tuning strategies—from restrained street setups to aggressive drag and circuit configurations. The engine’s enduring popularity is a testament to its versatility and adaptability, a trait that makes the short block a compelling focus for anyone considering a build around the Evo IV through IX. In the end, the precise specification of the 1000B075 may remain elusive within the public domain, but the practical implications for builders are clear: a well-chosen short block is the anchor for reliability, a platform for tuning, and a gateway to the performance potential that defines Mitsubishi’s Evolution legend.

For readers seeking a deeper dive into related hardware, the broader ecosystem offers tangible options that can complement a 4G63 short-block project. A practical example is the availability of upgraded block options that cater to high-performance, high-boost applications, which can help secure the engine’s core against the stresses of enhanced airflow and fueling. Such options are often part of a holistic upgrade path, where the bottom end, head, turbo, and cooling systems are harmonized to deliver power with consistency. As always, the path from concept to road-ready performance should be paved with careful measurements, cross-checking specifications, and adherence to manufacturer guidance as reflected in official service documentation and trusted catalogs. In short, while the public record around 1000B075 may not present a complete blueprint, the underlying engineering principles and practical build strategies remain consistent across the Evolution family: choose a robust, well-matched bottom end; ensure compatibility with the head and turbo system; and verify the details with authoritative sources before committing to the installation.

Internal link: 4b11t billet block offers a context for enthusiasts curious about high-strength, high-precision alternatives when planning a serious performance build around the 4G63 platform. External reference: for a broader historical and technical overview of the Evolution lineage, see https://en.wikipedia.org/wiki/MitsubishiLancerEvolution.

Shocks, Short Blocks, and Speed: Tracing the 4G63 Short-Block’s Motorsport Footprint Across Evolution IV to IX

The phrase short block rarely lands in a rally diary the way a turbo map or a tire compound does, but in the world of performance engines it anchors a practical truth: the bottom end of an engine can define how far a car travels between service intervals, how consistently power is delivered, and how easily teams adapt a base design to different racing demands. In the broader lineage of the Evolution line, the discussion around a shock, a short block, and a complete 4G63 assembly sits at a crossroads between design philosophy and the realities of racing schedules. The 4G63 family has a long history of modular construction, with the short block emerging as a flexible core that teams could refresh, rebuild, or reconfigure without discarding the entire long-block architecture. The part number associated with a widely used short-block assembly—1000B075—points to a design intention that transcends a single generation. It is a reference point for a class of bottom-end components designed to support rapid rebuilds and reliable endurance across multiple Evolution models, most notably the range from the fourth to the ninth generation.

In the mid‑1990s, the fourth generation of this lineage was developed with motorsport as a core objective. The Evo IV became a direct showpiece on rally stages, where the combination of a turbocharged four-cylinder and an all‑wheel drivetrain demanded both peak performance and durability under harsh, varied conditions. Its powerplant—while high in torque and strong in response—originally leaned on a traditional long-block approach. Yet the racing environment quickly highlighted a practical truth: teams benefit from a robust, modular bottom end that can be serviced quickly between events, tuned in the paddock, and reassembled with precision on the transmission bench. That mindset seeded the broader adoption of short-block configurations as a portable, flexible platform for competition engines across the later generations.

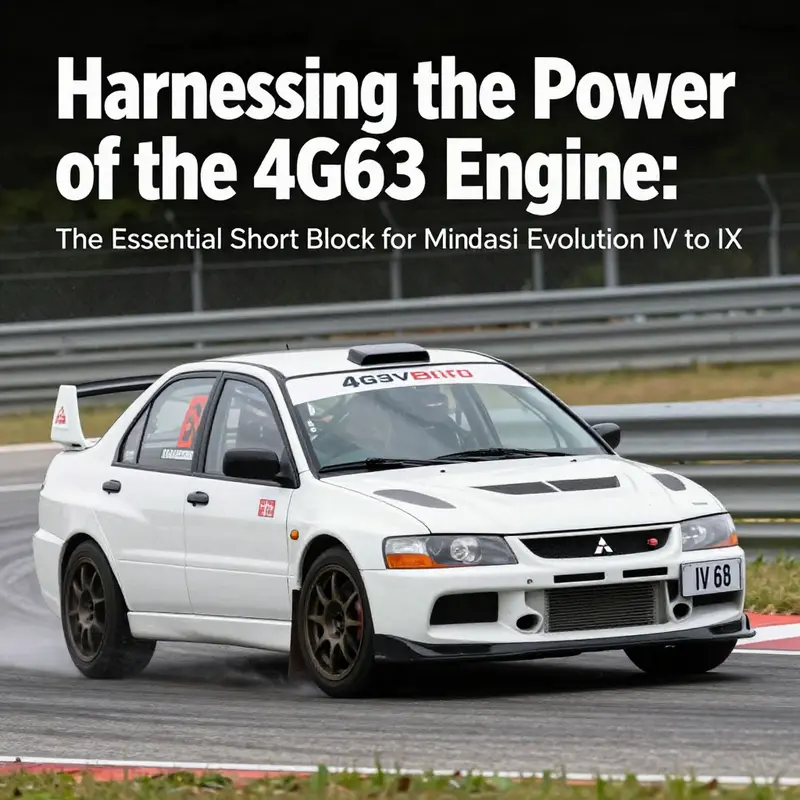

The Evo IV’s rally duties are well chronicled in the annals of motorsport history. In the World Rally Championship arenas of the mid‑1990s, the car competed against other turbocharged four‑cylinder rivals with an emphasis on stable power delivery, sophisticated aero, and a chassis that could hold high loads through rough gravel and tight tarmac sections. The engine’s 280 PS output, coupled with a sophisticated all‑wheel drive system and a stiffened chassis, enabled drivers to extract maximum traction with measured throttle control. That combination—not unlike the DNA that future short-block configurations would leverage—proved effective in both the WRC and regional rally events. The Evo IV’s success helped Mitsubishi secure a string of podium finishes and contributed to a growing understanding that the bottom end of the engine could be as important to race strategy as the turbocharger, intercooler, or ECU calibration.

If the Evo IV established the rallyer’s creed, the later Evolutions moved toward a more modular, rebuild-friendly approach to the engine. The 4G63 engine family is a flexible blueprint, and the short-block concept—whether referred to in forums as a compact block assembly or a dedicated bottom end—was shaped by the need for speed in preparation, durability in the face of heat and vibration, and the ability to adapt to an increasingly diverse catalog of racing rules and track layouts. Across Evolutions IV, V, VI, VII, VIII, and IX, teams conceptualized the engine as a system that could be refreshed without rewriting the entire block. The 4G63 short block that found its way into many high-performing builds served as a practical heartbeat for the car, providing a platform where high-performance pistons, crankshafts, connecting rods, bearings, and oiling pathways could be optimized with a minimum of downtime.

This modular mindset aligns with the broader engineering trend toward bottom-end reliability in high-stress conditions. In rally, every gram of weight, every moment of heat buildup, and every drop of oil pressure matters. The short block—by focusing maintenance and upgrades on the lower end—reduced risk during long, grueling events and allowed teams to push the rest of the drivetrain harder without compromising endurance. The Evolution IX’s redesigned 4G63 block, a refined iteration of that lineage, embodies this evolution: a bottom end that can stand up to more aggressive tuning while maintaining engine reliability across a wider set of competition formats. The shift from a traditional long-block to a more modular short-block philosophy did not erase the original architecture; it extended the architecture’s life by creating a pathway for continual improvement without wholesale redesigns.

In the paddocks where time attacks and circuit racing began to carve out their own niche for these cars, the same principles applied. The Evo IV’s initial success translated into a fertile ground for experimentation: the bottom end would tolerate upgraded bearings and stronger crank throws, the oiling system would be tuned for higher G‑loads, and the cooling strategy would be adjusted to keep the engine stable at high RPM for longer stints on track. Enthusiasts and professional teams alike discovered that the short-block approach offered a practical route to higher torque delivery and more predictable power curves. This was exactly what time attack competitors needed—an engine core that could be tuned aggressively for speed on the clock while staying reliable enough to last through a full qualifying and final session. Drifting—another arena in which these cars found a dedicated following—benefited as well. The rearward torque bias and balanced weight distribution of the Evolution chassis, combined with a robust bottom end, made the platform an appealing base for drivers seeking precise, controllable oversteer and consistent power delivery through corner entries.

What binds these applications together is a design philosophy that treats the engine block not as a single disposable component, but as a modular platform capable of evolving with the rules and the demands of the circuit and the rally stage. The 1000B075 short-block designation serves as a reminder that there is a universal bottom-end kit in the lineage that teams could source, assemble, and adapt for use across generations. While the Evo IV did not bring a dedicated short-block in the strict sense to its race program, the broader practice of using a modular bottom end matured in parallel with the evolution of the platform. It is this maturation that made the later generations more approachable in professional competition, where reliability and repeatability are as valuable as peak power. The engineering advantage lay in the ability to swap or refresh the bottom end, aligning internal clearances, oil passages, and crank geometry with upgraded turbo hardware or revised intake systems without rebuilding the entire engine around a different block family.

From a technical vantage point, the bottom end is a linchpin. The crankshaft’s bearing surfaces, the connecting rods’ strength, the pistons’ lightness and heat resistance, and the oiling and cooling pathways all interplay to determine how much of the turbocharged surge the engine can sustain before a detonation event or oil-starved moment interrupts the clock. The short-block approach helps manage these risks by isolating assembly tolerances and enabling more precise control over the bottom-end tolerances. In motorsport environments, such precision translates into reproducible performance across sessions and events. It also supports a broader ecosystem of aftermarket and factory-enhanced configurations, where the block becomes not simply a foundation but a platform for experimentation with materials, machining strategies, and surface finishes that improve durability under stress. The result is a vehicle that can maintain grip and balance as the driver explores the limits of traction, while the mechanics can push the envelope of tuning without sacrificing reliability.

In this sense, the short-block concept embodies the practical spirit of the Evolution project: make the core architecture more adaptable, more service-friendly, and more capable of sustaining aggressive performance over the course of a championship calendar. It is easy to romanticize the idea of a single, perfect engine, yet the reality is more collaborative. Designers and engineers from all corners of the competition world contributed through experience: rally engineers who learned what a bottom end could endure on gravel and ice; circuit engineers who needed stability under sustained high RPM; and tuners who expanded the envelope of what power could be produced without compromising engine life. The end result is a lineage that can be traced from the Evo IV’s rally heritage toward the more refined, rebuildable blocks seen in the later generations. The 4G63 short-block concept, as embodied in part numbers like 1000B075, is a representative thread in that tapestry—less a single achievement and more a method that allowed the platform to adapt, survive, and thrive under shifting regulations and evolving competition formats.

For readers curious about how such blocks fit into modern restoration or performance builds, the parallel between factory intent and aftermarket adaptability remains instructive. A practical entry point is to consider a billet-block upgrade that preserves the same core geometry while offering enhanced strength and bore stability. A notable example in the community is the 4B11T billet block, which illustrates how builders translate the same principle of modular bottom-end design into a more robust, race-ready foundation. The idea is not to replace the entire engine, but to reinforce the very heart of the machine so that power delivery remains linear and predictable even as horsepower and torque rise. In practice, this means pairing the short-block with precision machining, high-quality bearings, upgraded oil pump geometry, and tailored cooling paths so that the engine behaves consistently through a wide operating range. The result is a platform that remains faithful to its motorsport roots while offering the reliability demanded by modern racing programs. 4b11t billet block serves as a concrete example of how the philosophy translates into tangible components that teams can source and integrate.

As this lineage unfolds, the chapter’s wider arc becomes clear. The Evolution’s motorsport story is not a single narrative about a peak number of horsepower or a singular triumph. It is a chronicle of how engineers and teams learned to treat the engine as a living system, capable of adaptation across eras and disciplines. The short-block concept is a pragmatic thread that ties the different generations together. It enabled rapid service, allowed proactive durability improvements, and supported aggressive tuning regimes across rally, time attack, and drifting disciplines. The Evo IV set the stage with a competitive, technically rich platform; the later Generations IX and beyond refined that platform into a more modular, serviceable, and track-friendly package. The result is a lineage that remains a touchstone for engineers who value reliability as a force multiplier in high-stakes competition. The bottom end, properly understood and properly engineered, can unlock the full potential of the entire engine, ensuring that the car remains a faithful instrument of the driver’s intent across a season, a weekend, or a single high-g lap.

For readers looking to anchor this discussion in a broader historical context, the official archives illuminate the Evolution lineage and its motorsport milestones, underscoring how the philosophy of modularity and durability evolved in parallel with rule changes and competition formats. External resources provide a frame for how these machines were perceived and celebrated in the years that defined modern rally and performance driving. As a practical takeaway, the ongoing relevance of short-block design in contemporary builds speaks to the enduring wisdom of engineering for serviceability and resilience without sacrificing performance. The chapter closes with a reminder that the story of the Evolution is as much about the mechanics beneath the hood as it is about the drivers who pushed them to the edge—and that the bottom end, when given thoughtful design and careful maintenance, can remain the engine room’s quiet engine of progress across generations.

External resource for further context on the Evolution’s motorsport heritage: https://www.mitsubishi-motors.com/en/evolution/history/

The Quiet Engine of Value: The 4G63 Short Block Across Evo IV to IX

Across Evo IV to IX, the 4G63 short block is more than a component; it is a fulcrum of value for builders, owners, and shops. It represents the portion of the engine that remains after removing the head and cams, and it anchors budgets, schedules, and performance goals. The economic reality begins with supply: OEM availability wanes as models age, driving up the appeal of remanufactured cores, refurbished blocks, or billet replacements. The choice among these options carries different price signals, lead times, and reliability expectations.

In the market, the short block functions as a focal point for cost planning. Core condition, machinist work to true bores and alignments, and compatibility with bearings, pistons, and the oiling system all shape the total bill. The longer a project sits in the shop, the more cost increases through labor, dyno work, and potential re-tuning. These financial friction points push buyers toward bundles that include warranties, or toward more conservative upgrades if budget is tight.

The aftermarket ecosystem around the Evo 4G63 is robust and diverse. Standard remanufactured blocks offer dependable performance, while sleeves, honing services, and precision machining open doors to specific bore sizes and power targets. At the high end lie billet or engineered blocks designed for stiffness, cooling, and sustained high boost. Each option conveys a different value proposition: budget-friendly reliability, targeted performance, or advanced durability.

Practical decision making centers on balance: how much reliability is required, what power level is pursued, and how long the car must stay in service between rebuilds. The short block also interacts with engine management, fuel, cooling, and lubrication systems, so the total cost of ownership reflects more than the block itself. In global markets and online marketplaces, information symmetry has improved, enabling buyers to compare cores, warranties, and delivery windows more effectively.

Ultimately the 4G63 short block mirrors the Evo’s broader story: a legacy platform sustained by a community that values precision, documentation, and steady investment. The block may be a single piece of hardware, but its economic footprint reverberates through every upgrade, every rebuild, and every track day.

null

null

Final thoughts

The Mitsubishi 4G63 short block engine, part number 1000B075, serves as a cornerstone for the performance capabilities of the Evolution series. Its proven design cemented its role in motorsports, driving innovation and community engagement. Through an exploration of its specifications, applications, and economic impact, this engine emerges not only as a mechanical marvel but also as a catalyst for business opportunities within the automotive sector. Embracing the 4G63 engine is essential for those aiming to optimize performance while ensuring customer satisfaction.