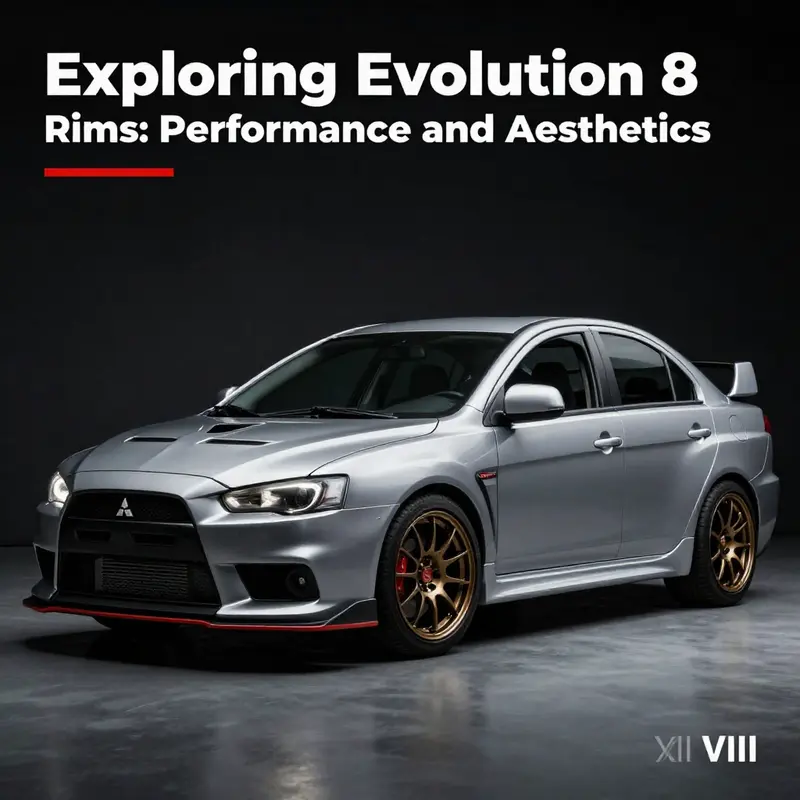

The Mitsubishi Lancer Evolution VIII is a pinnacle of performance in the world of motorsports, merging engineering excellence with style and functionality. Essential to this performance narrative are the wheels—specifically, the standard Enkei wheels and the high-performance BBS wheels that define this model. Understanding the differences between these rim options can help business owners in the automotive industry enhance their service offerings, increase customer satisfaction, and seize opportunities in the aftermarket. Proceeding deeper, we will analyze the standard Enkei wheels, investigate the high-performance alternatives, delve into technological innovations, and highlight vibrant aftermarket options that collectively shape the landscape of Evolution 8 rims.

Standard Enkei 17-Inch R17 Rims: The Quiet Cornerstone of Evolution VIII’s Handling and Identity

In the lineage of Mitsubishi’s Lancer Evolution, the Evolution VIII sits at a peak where engineering clarity meets brutal drive-ability. The wheels, often overlooked in the glare of bigger turbo numbers and rally-derived chassis tricks, play a quieter but essential role in shaping how the car feels, accelerates, and communicates with the road. The standard configuration for the EVO VIII’s GSR and RS trims centers on 17-inch Enkei wheels, a choice that speaks to a deliberate balancing act. At first glance, 17 inches may appear modest in a modern context crowded with larger diameters and gaudier spokes. Yet this size is the hinge point that preserves acceleration, steering response, and ride comfort, while still delivering brisk turn-in, stable mid-corner poise, and a tactile connection through the steering wheel. The Enkei R17 wheels fitted to the Lancer Evolution VIII are not just a package component; they are a foundational element of the car’s dynamic character, a frame within which the chassis and powertrain sing in harmony. The 17-inch diameter narrows the gap between raw grip and controllable load transfer, letting the driver feel the tire’s grip limit before the car’s stability controls intervene, and it does so without adding excessive unsprung mass that would dull feedback or complicate turn-in. The standard size, time-tested for both street and track use, remains a point of reference for enthusiasts who trace the EVO’s handling fingerprint across generations.

The dimensions of the standard wheels—17 inches in diameter, with a width of 8.0 inches and an offset (ET) of 45 millimeters—are precisely chosen to optimize the Lancer Evolution VIII’s geometry. An 8-inch width provides a broad canvas for the tire to maintain contact with the road under lateral load, supporting a stable footprint during aggressive cornering. The ET45 offset keeps the wheel’s mounting surface in a position that preserves the intended scrub radius, steering feel, and suspension geometry. In practice, this means predictable turn-in, consistent tire contact through mid-corner load, and a chassis balance that favors even, linear grip growth as you ride the edge. The Enkei R17 wheel is recognized for its lightweight construction, a trait that matters little in isolation but hugely when multiplied across unsprung mass, rotational inertia, and the tire’s own inertia. Lightweight rims mean the car responds more briskly to steering input and rotates more readily on the throttle, with less energy required to change direction. The effect on lap times, street responsiveness, and overall ride quality is subtle yet meaningful, especially in a car designed to be both a daily driver and a capable performer on winding roads or a back-road circuit.

Enkei’s reputation for high-performance alloy wheels factors into why the EVO VIII settled on the R17 as the standard. The brand’s emphasis on balance between strength, stiffness, and weight translates into a wheel that can endure the rigors of spirited driving without carrying unnecessary mass. In the context of the Evolution VIII, where the powertrain, suspension, and chassis are tuned to work in concert, the Enkei wheel acts as a conduit for the car’s handling philosophy. It is not merely a cosmetic accessory; it is a component that preserves the delicate triad of grip, feedback, and compliance. When you look at the standard 17×8 Enkei wheel on the EVO VIII, you are seeing a deliberate design choice: a wheel that preserves the car’s agility while still communicating the tires’ adherence to the road with a crisp, planted feel. The wheel’s design also contributes to the car’s iconic appearance. The 17-inch diameter is not only a performance choice but a visual one. It preserves the EVO VIII’s compact, athletic stance and ensures the body’s lines remain balanced with the wheel wells, a factor that contributes to the car’s distinctive silhouette even when parked and viewed head-on.

From a practical perspective, the Enkei R17 wheel’s weight savings translate into improved actuation of the suspension system and better braking feel. With a lighter wheel, the unsprung mass—the portion of the vehicle not supported by the springs—drops, allowing the suspension to react more quickly to road irregularities. This manifests as more immediate tire contact during cornering and better steering precision as the tire carcass maintains grip under dynamic loads. In street use, that translates to a more predictable steering response and a more confident, communicative chassis. On track, the benefits compound: reduced rotational inertia aids in quicker direction changes, and the brake system can more readily shed heat and maintain consistent pedal feel when the tires are pushed to the limit. The standard Enkei wheels thereby underscore a core principle of the EVO VIII: a chassis that rewards precise inputs and consistent tire contact with a wheel design that reinforces those traits without demanding compromises elsewhere in the package.

The distinction between the standard Enkei wheels and the higher-performance MR variants underscores a broader ethos within the Evolution family. The MR’s shift to BBS wheels marks a step up in perceived performance, with the wheels serving as both an aesthetic and functional upgrade—lighter weight, stronger construction, and a more aggressive stance to echo the MR’s aluminum roof, Bilstein dampers, and front limited-slip differential. Yet the EVO VIII’s standard wheel remains a benchmark—a reference point against which changes in ride, handling, and visual tone can be measured. When the MR wheels arrived as part of a broader Performance package, the car’s dynamic envelope shifted subtly toward sharper handling limits and more immediate feedback, but the standard Enkei wheels sustain their relevance. They represent the baseline that keeps the driving experience approachable, particularly for enthusiasts who use the car both on the street and in occasional track days. This baseline is invaluable; it provides a stable platform for evaluating upgrades, tire choices, and alignment settings without the interpretive layer of a heavier, more aggressive wheel. It also preserves OEM balance and the car’s original handling character, which is a critical reference for purists who value the EVO VIII’s era-specific tuning and restraint.

The broader conversation around OEM wheels often doubles as a meditation on what drivers prioritize when they choose to keep or upgrade. For many EVO VIII owners, the Enkei R17s are a trusted starting point. They offer a compelling mix of lightness, strength, and a clean, sport-leaning aesthetic that suits the car’s compact dimensions and forward-weighted weight distribution. The wheels contribute to the car’s overall vision: a machine that invites engagement, rewards precise line discipline, and delivers a connected feel at the limit without demanding a steep learning curve. The wheel’s finish and style complement the EVO VIII’s front end and side profile, reinforcing the sedan-like centering of the chassis’s mass while hinting at the car’s rally heritage. In this way, the standard Enkei wheels function as a design and performance anchor, shaping how the Lancer Evolution VIII is experienced on a daily basis and on the course.

For readers who want to explore related wheel options that retain the spirit of this original setup, there is a tangible avenue to explore beyond the Enkei profile. A related wheel family includes high-quality BBS rims that have historically accompanied the EVO’s more extreme performance packages. For a reference to an alternative wheel option within the same brand family, you can view the following page, which discusses a set of BBS rims for Lancer variants: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans. This link offers context on how engineers and designers calibrate weight, strength, and brake clearance across the Mitsubishi wheel ecosystem, while still honoring the EVO VIII’s chassis geometry and the driver’s need for responsive handling. The Enkei standard remains the reference point, a baseline that helps frame the perceived gains when upgrading to a lighter or more aggressively engineered wheel in future projects.

The chapter’s historical thread is inseparable from the car’s broader story. The EVO VIII’s standard wheel choice—the 17-inch Enkei R17 with an 8.0-inch width and ET45—exemplifies a period when performance and practicality intertwined. It is a wheel that supported the EVO VIII’s balanced performance envelope: quick steering, steady mid-corner grip, and a ride that could absorb road imperfections without surrendering the vehicle’s agile personality. It is also a reminder that aftermarket upgrades are not merely about shaving seconds from a lap time; they are about preserving or enhancing the driving virtues that first drew enthusiasts to the car. The Enkei wheel’s role in this narrative is quietly foundational, a chassis partner that helps keep the Evolution VIII’s spirit intact as it evolves in the hands of new generations of drivers and collectors who seek to understand what made this machine compelling in the first place.

For those who want to dive deeper into wheel design and its implications for performance, Enkei’s official materials emphasize the union of weight, strength, and stiffness in a way that mirrors the EVO VIII’s ethos. The practical implications—improved acceleration responses, crisper steering, and better ride compliance—are not merely theoretical; they translate into on-road feel that a driver can recognize with just a few minutes behind the wheel. In the end, the standard Enkei R17 wheels on the Evolution VIII are more than a size or a model name. They are a crucial component that supports and reveals the car’s character, creating a platform where power, chassis tuning, and driver input converge into a coherent and engaging driving experience.

External resource for further reading: https://www.enkei.com/en/products/rim/17inch/

High-Performance BBS Wheels on Evolution 8 Rims

The Mitsubishi Evolution VIII has long stood as a benchmark for rally-inspired engineering, where every component is tuned to deliver a balance of raw grip, quickness, and precision under pressure. Among these components, the wheels do more than merely fill the arches; they define how the car responds to a sweep of corners, a dip in a straight, or a late braking maneuver into a hairpin. In the EVO 8’s lineage, the jump from standard 17-inch rims on the GSR and RS models to the higher-performance, factory-fitted variants on the MR range marks a turning point not just in looks, but in fundamental dynamics. The shift from a lightweight Enkei setup to a more stringent, performance-focused wheel design signals a broader philosophy: that pursuing speed at the limit begins with minimizing inertia, maximizing stiffness, and maintaining harmony with the car’s suspension, steering, and braking geometry. When you listen to enthusiasts describe the EVO 8, they often begin with the wheel, because a wheel is the first link between the tire and the road, and between the car’s intent and what the tires actually do on the pavement. The story of these rims is therefore a story of balance—between weight and strength, between rigid attachment and compliant ride, and between traditional engineering practice and the demands of modern performance thresholds.

The performance core of these wheels rests on the material and the manufacturing process. Forged wheels, the method commonly favored for high-end OEM configurations on performance cars of this era, deliver a superior strength-to-weight ratio compared with typical cast wheels. In practice, this means reduced unsprung mass. When the wheel and tire assembly has less mass riding on the suspension, the system can respond more quickly to road input. The suspension can follow the ground with less lag, and the tires can change slip angles more rapidly, improving grip during aggressive cornering and reducing the inertia that can hinder steering feedback at the limit. Forging does more than shave grams; it densifies the metal structure, yielding a wheel that resists deformation under high lateral loads and braking forces. That resistance is not merely about longevity; it translates directly into steering fidelity, more precise turn-in, and more linear weight transfer during aggressive maneuvers. In a car designed for rapid direction changes and high-speed cornering, those subtle gains accumulate into a tangible, track-ready feel.

The Evolution’s MR variants were set apart not only by chassis refinements such as the aluminum roof or Bilstein dampers, but also by the wheels that spoke to an ethos of Mitsubishi Racing. A high-performance wheel is more than a cosmetic upgrade; it is a tuned partner to the car’s brakes, suspension geometry, and transmission of torque. The 17-inch diameter is a deliberate choice, a compromise between the available tire technology of the era and the car’s suspension calibration. Larger diameters can clear bigger brakes but often at the cost of additional unsprung weight or altered steering feel. The EVO 8’s MR package solved that dilemma by adopting a wheel design that could preserve or improve response while accommodating the front LSD and the more aggressive dampers. The result is a wheel culture that values crisp, immediate response as much as visual impact. The rims themselves tend toward a clean, multi-spoke silhouette that emphasizes stiffness and even load distribution, projecting a stance that matches the EVO’s aggressive lines and rally heritage.

For enthusiasts, the visual language of these wheels is inseparable from the technical language. A forged wheel with a dark or black finish can sharply contrast with the car’s high-contrast body lines, underscoring a performance identity that feels authentic rather than fashion-driven. The wheel’s spoke pattern, thickness, and hub design communicate cues about rigidity and load paths. A well-designed forged wheel distributes forces evenly through the spoke network, reducing local stress concentrations that could otherwise compromise braking performance or cornering stability under load. In the EVO 8’s context, maintaining optimal brake rotor temperatures and ensuring even damping across the wheel’s circumference are important considerations. Lighter wheels reduce gyroscopic effects and improve brake response, while a well-chosen spoke configuration helps maintain stiffness as heat builds up in the brake assemblies during a demanding session. Even tire selection, often a deliberate pairing with the wheel’s width and offset, is tuned to complement the wheel’s mass and inertia. It becomes a closed loop where tire compound, tire profile, wheel weight, and suspension tuning converge to deliver a cohesive, controllable feel through the steering wheel.

The practical realities of owning Evolution VIII wheels extend into the realm of authenticity and maintenance. For many collectors and drivers, the appeal of the forged OEM setup lies in its proven fit and its integration with the car’s braking and suspension geometry. Authentic, OEM-grade forged rims are designed to be hub-centric, meaning their center bore matches the hub precisely, minimizing runout and ensuring even load transfer. When wheels are sourced second-hand, as is common for these cars, minor imperfections may accompany the many miles that a dedicated EVO has logged. Curb rash, scratches, or slight bending near the bead seat can be contained with careful refurbishment, but there is a line between feasible restoration and compromised integrity. Verifying authenticity is not simply about lineage or surface appearance; it is about ensuring the wheel’s forging lineage and material properties remain intact, because the weight distribution and brake interaction depend on those properties in ways that are not always visible at first glance.

From a practical standpoint, installation is a nuanced process. Tire mounting, alignment, and proper balancing are essential for preserving the wheel’s intended interaction with the EVO 8’s suspension. The hub bore, offset, and centerline alignment must be matched to the car’s specs to preserve steering feel and front-to-rear balance. A misaligned wheel or one with a slightly different offset can alter steering geometry enough to change bite and turn-in behavior, especially in a vehicle built for high-speed cornering. Attention to torque values for lug nuts, the use of appropriate hub-centric rings if needed, and ensuring true concentricity are all part of a responsible upgrade or restoration routine. In the MR configuration, where the front axle contributes to the car’s overall steering feel, even a modest deviation can be noticeable behind the wheel. The interplay with the car’s braking system is another critical axis. Lighter wheels improve the rate of brake heat dissipation by reducing the mass that must be slowed down and cooled, while the wheel’s diameter and width influence the surface area available for tire contact and, by extension, grip under braking. When paired with a high-performance rubber compound, the combination of forged 17-inch rims and a thoughtfully chosen tire can yield more predictable pedal feel and shorter stopping distances under demanding conditions.

Beyond the mechanical and cosmetic appeal, there is a deeper narrative about sourcing and preserving the EVO 8’s heritage. Enthusiasts frequently pursue authentic OEM forged wheels either as a complete set or as individual components relocated from other well-preserved EVOs. The search is as much about provenance as it is about performance. Sets removed from earlier evolutions can surface in marketplaces and online communities, sometimes with minor imperfections that reflect years of rally-inspired driving. A careful inspection focuses on the integrity of the bead area, the absence of hairline cracks around the lug seats, and the overall uniformity of weight across the wheel. The owner’s diligence in confirming the wheel’s origin contributes to a safer, more reliable upgrade path and helps preserve the car’s balance and handling characteristics over time.

For readers seeking practical guidance on this journey, a careful, informed approach to the wheel’s origin is essential. When considering any upgrade, the objective is to preserve the EVO 8’s chassis harmony while extracting the performance benefits that forged rims can provide. The wheel’s interaction with the front differential and the MR-specific suspension tuning is part of a larger system, where improved inertia characteristics can unlock more precise feedback through the steering wheel and more immediate throttle response in tight corners. The aesthetics should complement the EVO’s aggressive stance without appearing disconnected from its rally-bred DNA. The result is not merely a more attractive car; it is a more confident machine, capable of delivering the exact, repeatable behavior a driver expects when pushing toward the limit on a winding back road or a damp, high-speed sector of a track.

For readers drawn to the technical depth behind these rims, the broader engineering literature and OEM documentation emphasize that forging processes yield material properties that support high-load scenarios. The wheel’s architecture—its hub interface, spoke topology, and rim bed—plays a critical role in how the vehicle accelerates, brakes, and corners. A robust forged wheel helps maintain tire contact with the road under abrupt weight transfer and mitigates energy losses that could otherwise degrade roadholding. This is precisely the kind of performance refinement that makes the Evolution VIII a benchmark in its segment. The upshot is that, in the EVO 8 MR configuration, the combination of lighter, stiffer wheels and carefully tuned dampers translates to sharper response, more precise cornering, and a more confident brake-in phase as road conditions demand every fraction of a second’s decision.

In reflecting on the journey from standard Enkei wheels to the high-performance, forged rims that characterize the MR variants, one witnesses a philosophy that treats wheels as a core performance element rather than a mere cosmetic upgrade. The practical steps—from authentic sourcing to careful installation and ongoing maintenance—affirm that the wheel is not an afterthought but an enabler of the EVO 8’s rally-bred capabilities. As owners look to both preserve and enhance the car’s dynamic potential, the wheel becomes a focal point in a broader pursuit of balance, speed, and control. For deeper insights into the specific characteristics and testing approaches used to guide these high-performance wheels, see the detailed technical guide offered by the brand’s engineering documentation and the community-driven technical summaries that accompany it. And for real-world examples of how such rims perform in practical settings, a curated reference on the subject provides a window into the nuances of fitment, weight, and response that shape everyday driving as well as high-speed, controlled exploration of limits. brand-new-original-bbs-rims for Lancer sedans.

External reference: to explore the formal technical discourse surrounding forged, high-performance wheel design and their implications for braking, handling, and overall vehicle dynamics, consult the detailed guide available at https://www.bbs-racing.com/en/technical-guides/super-rs-wheels-guide/.

Forging Speed: The Tech-Driven Evolution of EVO VIII Rims

Rims do more than dress the wheel arches of the Evolution 8; they encode a philosophy of balance between lightness, strength, and braking discipline.

The EVO VIII sits at a crossroads where chassis tuning, weight distribution, and tire contact all hinge on the choices made for the wheelset.

The 17-inch diameter became a defining standard across its variants, a pragmatic compromise between highway comfort, track capability, and the car’s compact, nimble character. In the basic GSR and RS models, a factory wheel package emphasizes efficiency and agility. These wheels are designed to shrink unsprung mass just enough to sharpen steering response without sacrificing daily drivability. Their forged alloy construction is quietly essential; it provides a high strength-to-weight ratio that reduces the rotational inertia the engine must manage during takeoff, cornering, and braking. The result, in practical terms, is a car that feels more willing to react to driver input, with crisper turn-in and more immediate acceleration behavior. The interplay between wheel design and the EVO VIII’s immediate mechanical DNA is subtle but unmistakable.

The MR versions—our high-performance brethren of the Evolution 8 lineage—push the wheel story further. In these variants, the 17-inch wheels are not merely larger versions of a standard package; they are engineered to complement a broader performance package. The MR’s approach to weight distribution, grip, and chassis rigidity is reinforced by wheels that prioritize rigidity under load and lighter mass at the rim. Forging, as a manufacturing principle, becomes a central theme: forged rims offer a combination of strength and reduced weight that cast wheels rarely match. This performance edge is not just theoretical. It translates into tangible handling benefits: faster turn-in, more precise mid-corner adjustments, and more consistent brake performance under demanding conditions. When a car’s roof and chassis are already tuned for performance—an aluminum roof to reduce mass, advanced shock damping to manage tire compliance, and a front limited-slip differential to modulate grip—the wheel becomes the final tuning element that can make the difference between a good lap and a great one.

The choice of 17 inches across EVO VIII variants is a testament to the car’s design philosophy. A larger wheel diameter often means a heavier wheel, which can blunt a car’s responsiveness and increase unsprung mass. Yet the EVO VIII, in its standard form, negotiates that trade-off with a focus on efficiency and balance. The standard 17-inch forged alloy wheels satisfy the bite required by the stock brakes and the suspension geometry, enabling predictable, linear behavior that is crucial for daily drivability and club-level track sessions alike. For enthusiasts who push the car harder, the MR’s upgraded wheels become a new baseline. The combination of a stiffer wheel with reinforced spokes and material choices reduces flex under heavy cornering and increases the stiffness of the wheel-brake interface. This is more than a matter of fashion; it’s about reliability and repeatability when the tires are loaded with lateral forces and the driver demands precise steering corrections.

Design and engineering converge in how these wheels interact with brake calipers, rotors, and the vehicle’s aerodynamic profile. The EVO VIII’s 17-inch wheel well isn’t a blank canvas; it’s a carefully measured space that must accommodate caliper size, rotor diameter, and heat dissipation, all while maintaining a clean, unobstructed brake-in heat path. Forged rims, with their streamlined cross-sections and optimized spoke patterns, enable ample brake clearance without sacrificing wheel strength. The spoke design, though not always visible to the casual observer, is a quiet act of aerodynamics and thermal management. A well-designed spoke arrangement helps shed heat from the brakes during repeated hard braking, reducing the risk of brake fade on a tight, winding road or a short, aggressive track session. In the MR’s context, where heat buildup can be more aggressive due to the overall performance tuning, this thermal performance becomes a practical advantage that drivers can feel in the pedal’s firmness and the consistency of stopping power.

Aesthetics cannot be divorced from function in this narrative. The EVO VIII’s wheel styling, whether on a GSR, RS, MR GSR, or MR RS, contributes to the car’s visual stance and its perceived performance. The GSR/RS standard wheels favor a clean, muscular silhouette that matches the compact proportions of the Lancer Evolution’s chassis. The MR variants push for a more aggressive profile—a look that signals performance while also supporting the underlying engineering aims: stiffer front-end behavior, improved brake caliper clearance, and a wheel presentation that complements the car’s aerodynamic cues. The visual language of the wheels—like the way light catches the rim’s edge or how the spokes create subtle shadows in the wheel well—echoes the broader design ethos of the Evolution VIII: efficiency, precision, and a fidelity to the road that rewards skilled driving.

Beyond the immediate mechanical considerations, there is a broader historical thread to the Evolution 8’s wheel story. In the early 2000s, wheel technology was transitioning from simpler, robust cast designs toward forged and hybrid constructions that offered a meaningful reduction in weight without compromising strength. This shift aligned with Mitsubishi’s racing-inspired engineering ethos, whereby every component was scrutinized for performance gains. The Evolution 8’s wheel choices reflect that mindset: a 17-inch diameter that remains relevant even as modern performance cars push into larger diameters, often at the expense of unsprung mass. It’s a reminder that success in high-performance road cars often hinges on a nuanced balance rather than a single bold specification. The wheels are the last millimeter of tuning in a carefully engineered system.

To the collector and the everyday enthusiast alike, the EVO VIII’s wheel story is inseparable from the vehicle’s broader performance identity. The standard wheels offer a baseline of efficiency and handling that suits spirited street driving. The MR wheels, with their emphasis on strength and lightness, extend the car’s capability into committed driving scenarios. The 17-inch size remains a constant thread through this evolution, a reliable reference point that keeps the car’s geometry coherent as other performance parts are upgraded. In practice, this means that upgrades or maintenance involving the rims must respect the wheel’s role in the car’s dynamics. The choice of offset, width, and spoke pattern—while often invisible to the untrained eye—can significantly alter steering feel, grip balance, and even tire wear patterns. The EVO VIII’s wheel architecture demonstrates that even a single component, when thoughtfully engineered, can influence the entire vehicle’s behavior on the road and on the track.

For readers looking to explore the practical side of applying this knowledge, the wheel cataloging culture that supports Mitsubishi chassis families often shows a cohesive approach to 17-inch rims across various models. In practice, this means that a wheel upgrade or replacement for the Evolution 8 can benefit from cross-model compatibility considerations, ensuring that brake clearance and hub fitment align with the car’s tuned geometry. The idea is not to chase the flash of a particular brand or a flashy spoke pattern, but to secure a wheel that preserves the intended brake feel, steering response, and suspension harmony. This is the subtle art of rim selection: a decision that, behind the scenes, preserves the car’s driving character while enabling a touch more discipline under load.

For those who want to delve deeper into contemporary discussions about Evolution 8 rims and racing-inspired wheel design, there is an active thread that examines how technological innovations in wheel design have influenced handling and braking across generations. This community conversation provides a practical, experience-based complement to the technical narrative, offering anecdotes about fitment, clearance, and real-world performance that extend beyond factory specifications. If you are curious about how designers and engineers balance weight, strength, and heat management in a forged 17-inch wheel, this forum thread can be a valuable resource and a source of perspective from drivers who push their EVO VIII to the edge of its capabilities. See the discussion here: https://www.rimworld.com/forums/evolution-8-rims-design-innovations-discussion-t20456.html. For convenience in exploring related wheel options that are commonly compatible with performance-focused Mitsubishi platforms, you can also browse catalog entries that discuss rims compatible with a range of Eclipse-era models, which often share the same sizing logic and brake clearance considerations as the Evolution 8. rims-fit-mitsubishi-eclipse-wheels-2018-2019-2020-2021-2022-2023-17×7-5-new. This link is a practical reminder that the wheel ecosystem for Mitsubishi performance cars is interconnected, with sizing and offset practices that help ensure reliable fitment and predictable performance across models.

In summary, the wheel story of the Evolution 8 transcends simple aesthetics; it is a narrative of engineering discipline. The 17-inch size anchors the car’s performance envelope, while the choice between standard and MR wheels reflects a wider commitment to weight management, structural rigidity, and heat integrity. Forged rims illustrate the industry’s move toward components that can withstand the demands of spirited driving without compromising daily reliability. The EVO VIII’s wheel design is a microcosm of its broader engineering philosophy: keep the mass as low as possible where it matters, preserve the stiffness and balance essential for precise handling, and let the wheel serve as a bridge between the car’s mechanical heart and the driver’s skill.

External resources can provide a broader perspective on wheel design innovations that inform these choices and help enthusiasts understand how forged wheels contribute to modern performance. For a broader view of the ongoing conversations about evolution-era rims and design innovations, see the forum discussion linked above. The dialogue among enthusiasts and professionals alike continues to illuminate how these decisions translate into real-world performance, longevity, and driving enjoyment.

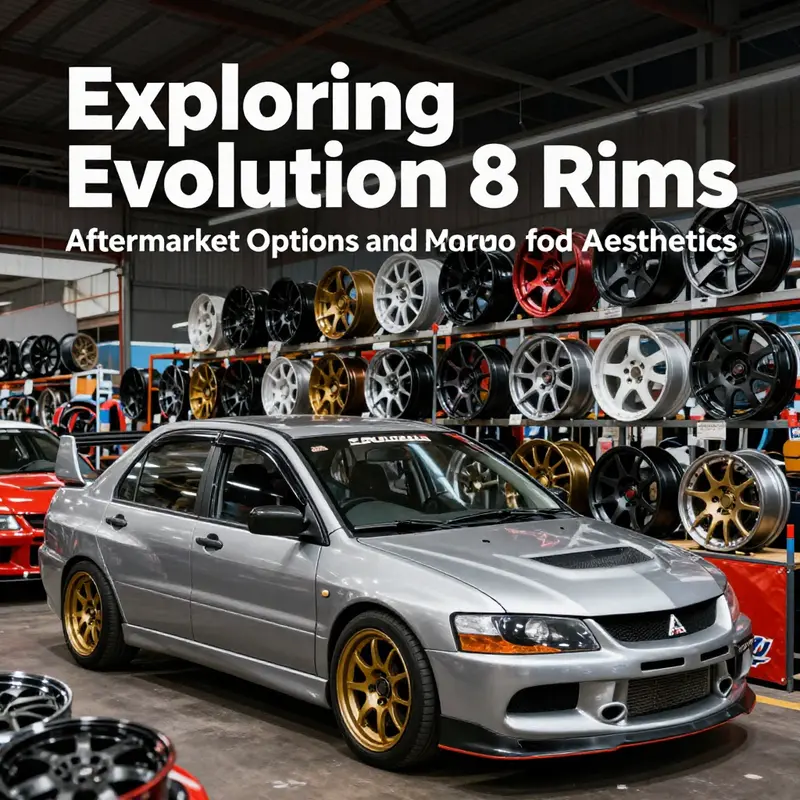

Forged, Cast, and Carbon: Navigating the Aftermarket Market for Evolution 8 Rims

Aftermarket Evolution 8 Rims: A Single Roadmap for Performance and Style

The aftermarket for Evolution 8 rims blends engineering, aesthetics, and real-world fitment. Owners want wheels that improve handling, reduce unsprung weight, and amplify the car’s aggressive stance. For the Evo 8, the wheel conversation starts with the familiar 17-inch baseline. From there, choices branch toward forged alloys for track duty, cast wheels for daily driving, and exotic composites for show and weight savings. Each path carries trade-offs in cost, durability, and fitment complexity. Understanding those trade-offs prevents wasted expense and poor handling outcomes.

Forged wheels dominate conversations among drivers chasing the best strength-to-weight ratio. The forging process compresses metal under extreme pressure. This eliminates internal porosity and aligns grain structures. The result is a lighter wheel with greater tensile strength. For an engine that delivers strong midrange torque, the reduction in rotational mass translates to faster throttle response and lower rotational inertia. Forged wheels also withstand repeated track stresses with less deformation than cast options. They are often offered with precise offsets and bespoke widths. That makes them ideal for wide, low-offset setups that improve grip without rubbing. Forged wheels, however, demand a premium price. They also require careful inspection for curb damage, as that can compromise the structure despite the material strength.

Cast aluminum wheels remain a practical upgrade. Modern casting techniques produce wheels that balance cost and structural integrity. Precision molds and flow-controlled casting yield lighter, stronger parts than older cast designs. These wheels suit spirited street driving and occasional track days. Their lower price allows owners to choose attractive, complex designs without breaking the bank. With proper sizing and offset, cast wheels can replicate the aggressive look of more expensive options. They also make it easier to experiment with staggered setups or deeper concave profiles. When choosing cast wheels, seek reputable manufacturers with load ratings and independent testing. A well-made cast wheel will perform reliably under daily abuse and spirited cornering.

Carbon fiber and composite wheels represent the cutting edge in both weight savings and visual impact. Carbon fiber rims significantly reduce unsprung and rotational mass. The result is crisper steering and quicker acceleration. Composite wheels also allow designers to sculpt deep concave faces and intricate spoke patterns impossible in traditional metal. However, carbon wheels cost considerably more. They require careful scrutiny for impacts and are sensitive to road debris. Repairs are possible but complex and expensive. For many Evo 8 owners, carbon options are reserved for show cars and high-budget builds. Yet the aesthetic and performance rewards can be transformative when the application justifies the expense.

Fitment considerations are just as important as material choice. The Evo 8 has specific hub bore dimensions, lug patterns, and brake clearance needs. Selecting wheel diameter, width, and offset affects tire sidewall height and suspension geometry. Going wider increases contact patch and grip, but it can also change scrub radius and steering feel. Higher offsets push the wheel inboard, clearing fenders but narrowing the track. Lower offsets push the wheel out, widening the track but risking fender contact. Tire choice must match the wheel width. Low-profile tires reduce sidewall flex, improving response, but they transmit more road shock. For those modifying suspension, including larger brakes or coilovers, wheel selection must account for caliper clearance and negative camber potential. A balanced approach preserves the Evo’s predictable handling.

Design trends influence buyer preferences. Deep concave faces remain popular because they emphasize wheel depth and aggression. Multi-piece and split designs offer modular repair options and unique finishes. Split rims can make mounting simpler and allow for component replacement after damage. Yet they are less common on passenger cars than on commercial or classic setups. Many owners adopt staggered dimensions—wider rear wheels to enhance traction—while keeping fronts narrower for steering precision. Concavity and spoke count also affect brake cooling and airflow. Open-spoke designs encourage brake heat dissipation. Solid or fewer-spoke styles may look clean but require attention to brake temperatures if the car sees track use.

Durability and maintenance are practical concerns. Salt, brake dust, and road chemicals can degrade wheel finishes. Protective coatings and periodic cleaning extend aesthetic life. Powder coating and ceramic clear coats resist chipping and corrosion. For wheels exposed to track use, regular inspection for hairline cracks or buckling is essential. Repairability differs by construction. Cast wheels are often repairable after minor bends. Forged wheels can be straightened if the damage is limited, but severe cracks necessitate replacement. Carbon wheels require specialist evaluation for structural issues. When buying used wheels, request proof of no structural damage and verify bolt pattern and hub fitment. A visually perfect wheel can hide problems in its unseen structure.

Market dynamics shape availability and pricing. The Evo 8’s continuing popularity keeps demand steady. OEM wheels built for higher-spec trims are sought after for their period-correct look. Many owners prefer wheels that echo the car’s original performance character. At the same time, the international tuner scene drives variety. Suppliers across regions offer custom offsets and finishes tailored to local tastes. That ensures a wide range of options for owners in different markets. Price tiers reflect manufacturing complexity and material costs. From budget-friendly cast designs to boutique forged and carbon sets, choices exist for any budget.

Purchasing strategy matters. Start with a clear goal—track performance, street comfort, or show appearance. Set a realistic budget and research wheels that match that intent. Cross-reference wheel measurements with the Evo 8’s hub, lug pattern, and brake clearances. When possible, test-fit wheels before completing a purchase. Many sellers offer mock-up services to verify fender clearance and center bore alignment. Consider tire costs too; wider wheels often require pricier tires. Factor in potential suspension adjustments like increased negative camber or ride-height changes. For many owners, the best path is incremental: choose a reliable cast or entry-level forged set first. Then move to specialized forged or composite wheels when the build direction is locked in.

The used market plays a major role in the Evo 8 wheel ecosystem. OEM and specialty rims circulate frequently among enthusiasts. Because these cars are often modified and then sold, owners regularly list high-quality wheels at reasonable prices. When buying used, prioritize structural integrity and authenticity. Counterfeit or misrepresented wheels pose risk. Verify any claims about forging or proprietary manufacturing. Ask for documentation like torque plates, certifications, and manufacturing stamps. Refinish options can renew older wheels affordably. A trusted refinisher can correct curb rash and restore coatings, making a used set like-new at a fraction of new cost.

A final note on community and resale: wheel choices influence resale value and buyer interest. Period-correct or tasteful performance wheels often attract more buyers. Extreme or overly trend-focused styles can limit appeal. Engage with local communities and forums before final decisions. Other Evo 8 owners can share fitment tables, offsets, and setup photos. Peer feedback highlights common pitfalls and successful combinations. For direct purchases, look for sellers with return policies and verified fitment support. And if authenticity matters, confirm origin and certification. A smart wheel choice improves looks and handling, and preserves value for future owners.

For those who want to explore OEM style options and availability, see this OEM BBS rim listing for reference. For a look at custom carbon fiber wheel possibilities, visit the product page linked below.

https://www.alibaba.com/product-detail/Mitsubishi-Evo-8-Wheels-Custom-Carbon-Fiber-More_1600493725345.html?spm=a2700.gallery-merchant.0.0.7d7a7e1cXWqkxT

Final thoughts

In sum, the rims of the Mitsubishi Lancer Evolution VIII are not merely functional aspects; they represent a fusion of innovation, performance, and branding essential for any automotive business. By understanding the distinctions between the standard Enkei and high-performance BBS wheels, as well as recognizing the importance of technological advancements and aftermarket prospects, business owners can better position themselves in a competitive market. Investing in the right options for your customers can elevate the overall driving experience and enhance performance, reflecting a commitment to quality and excellence.