The Mitsubishi Lancer EVO X stands as a symbol of performance and innovation in the automotive world. A crucial yet often overlooked component, the side skirts, enhances the vehicle’s aerodynamic efficiency and aesthetic appeal. Understanding these elements is essential for business owners involved in automotive customization or parts sales, as it can significantly inform product offerings and customer engagement. This article delves into three core aspects: the technical specifications that make these side skirts critical, the current marketplaces influencing their sale, and insights into manufacturers that ensure quality and durability. Each chapter builds a comprehensive narrative that empowers business owners to make informed decisions in this competitive market.

Engineered Edges: The Technical Anatomy and Performance of Lancer EVO X Side Skirts

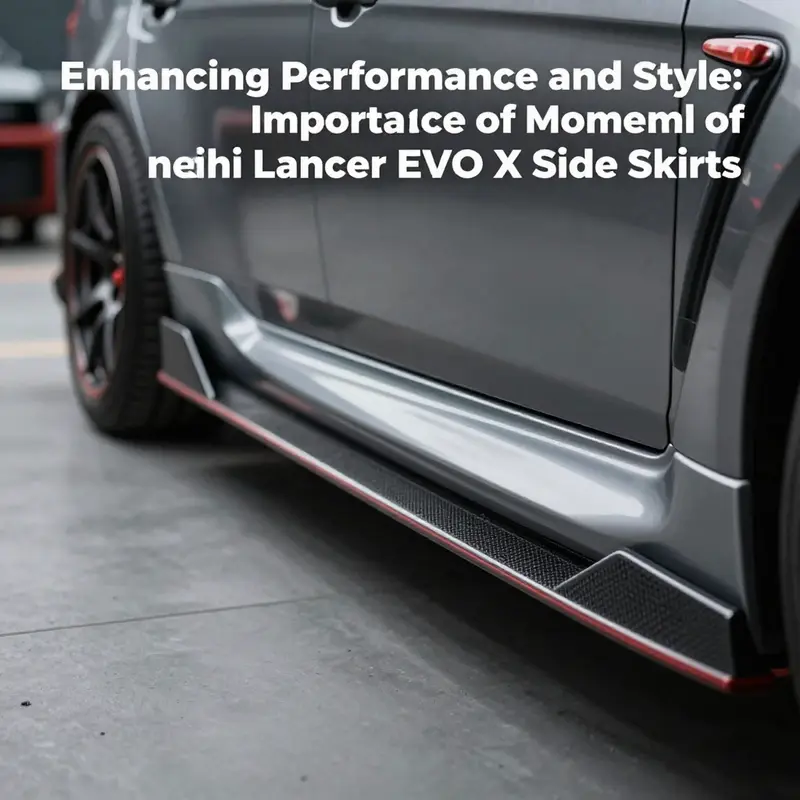

The side skirts on the Lancer Evolution X do more than clip a line under the car’s silhouette; they shape the vehicle’s behavior at speed. In performance tuning, they sit at the intersection of aesthetics, aerodynamics, and durability. A well-chosen set tightens the lower envelope, guiding air along the flank and away from the underbody, where chaotic flow can generate lift and drag. The EVO X, with its rally-inspired stance, relies on this subtle control of airflow to sustain stability as speeds climb. This chapter examines the material choices, mounting realities, dimensional logic, and the standards that govern modern automotive manufacturing. The aim is to illuminate how side skirts function, what differentiates an ordinary set from a performance-minded kit, and how buyers can align their choice with their car’s overall intent.

Material composition anchors the conversation. The most common substrates are ABS plastic, polyurethane, and carbon fiber. ABS offers a time-tested balance of stiffness, impact resistance, and light weight. It resists cracking under minor impacts and holds shape across weather cycles. PU offers a touch more flexibility, translating into better fatigue resistance when subjected to road debris and temperature swings. Carbon fiber provides a high strength-to-weight ratio and superior heat resistance; in racing contexts carbon skirts can offer a lighter footprint and a rigid geometry that preserves aerodynamic profile under duress. Yet premium price and variable mass-market quality mean buyers weigh performance gains against durability and cost. Across this spectrum the core idea remains: the material must resist weathering, maintain a smooth surface, and preserve its shape under dynamic loads.

Fitment precision is central. For the EVO X, side skirts are engineered via CAD/CAM workflows that translate a blueprint into a one-piece or modular geometry designed to hug the rocker panel with consistent radii and line continuity. The aim is precise alignment with factory mounting points while accommodating common modifications. The result is a kit that remains robust under pothole hits, speed bumps, and curb encounters. In best examples, mounting points align with factory bosses, and fasteners engage with tolerances that minimize vibration and noise at highway speeds. Rubber grommets and stainless-steel bolts are typical details that reduce resonance, turning an undercarriage edge into a quiet, predictable boundary layer that behaves as an extension of the chassis.

Dimensions tell a story of balance. Standard lengths per side typically fall in a range that keeps the lower line coherent with the wheelbase and stance, often around 1.2 to 1.4 meters. Width variability typically 15 to 25 centimeters, signaling design intent: flush-fit skirts emphasize svelte lines, while more aggressive kits add subtle flares or lips to carve air along a widened profile. These numbers reflect aerodynamics, ground clearance, and fitment realities with common wheel-and-tire configurations. The geometry must also cooperate with front lips, rear diffusers, and side canards to maintain a coherent aero family. The result is a silhouette that looks integrated rather than tacked on.

Surface finish has a practical effect. The top coat provides UV resistance to slow pigment fade. A smooth finish reduces dirt adhesion and makes cleaning easier. Matte and glossy black are common options, each with care regimes: matte tends to mask minor imperfections, while gloss can emphasize lines and depth. Regardless of finish, coatings should resist cracking, chalking, and yellowing under sun and temperature swings. Finish is part of durability and maintaining a clean appearance.

Mounting systems are the backbone of a side-skirt setup. High-quality kits use factory-style mounting points compatible with EVO X hardware. This typically involves a combination of pressed-in fasteners and brackets that attach to the rocker panel or sill area, supported by grommets and stainless-steel bolts. Rubber grommets dampen vibrations, reducing noise transmission at speed. A secure mounting system resists aerodynamic loads that can cause flutter. For enthusiasts with more extreme setups, some third-party systems add mounting points or adjustable hardware; such choices should be evaluated for compatibility with suspension travel, bumper geometry, and wheel widening.

Aerodynamics sit at the heart of function. Side skirts aim to minimize underbody turbulence and guide air smoothly along the sides. Properly designed skirts reduce drag and help maintain stable flow with the rest of the aero package—the front lip, rear diffuser, and undertray—creating a coherent stream. The result is a firmer feel in cornering, a more predictable response to gusts, and a modest top-end stability gain. The key is consistent geometry, clean transitions, and materials that resist heat or strain.

Compliance and standards guide production reality. Reputable manufacturers aim to meet automotive-quality benchmarks, including IATF 16949, signaling process consistency, traceability, and continuous improvement. Suppliers that emphasize calibration, repeatable mold accuracy, and testing provide assurance that each batch maintains fitment and performance characteristics. In regions with advanced mold engineering, such as parts of China, a robust ecosystem delivers UV-stable materials, dimensional tolerances, and documented test results verifying durability under impact and temperature variance. This illustrates a broader market trend: performance-oriented components manufactured with modern supply chains, sold with documentation supporting street use and track development.

Beyond theory, the real-world data sketch a nuanced picture. OEM-equivalent options aim to preserve factory look with authentic fit and finish. Aftermarket choices offer broader styling and performance. Some enthusiasts pursue carbon fiber for race-ready lightness and rigidity, accepting premium price and maintenance of a high-gloss surface. Others favor UV-stable ABS or PU for durability and cost efficiency, trading some stiffness for budget-friendliness. Width and lip designs influence ground clearance and interaction with lowered setups. The best installations respect suspension geometry, ensure consistent clearance, and avoid interference with side steps or protective coatings. Fitment hinges on careful measurement, preparation of mounting surfaces, and adherence to installation procedures to minimize vibration and misalignment. When aligned, side skirts feel like a natural extension of the car, contributing to a coherent performance narrative.

Maintenance and care form the ongoing part of ownership. Longevity depends on more than initial install. Regular cleaning removes grit and road salt to preserve finish and postpone micro-scratching. If UV-stable coating is chosen, reapplication may be minimal, but periodic inspection is prudent to catch micro-cracks or loose fasteners. In sunny climates, a wax or sealant helps sustain gloss and reduce micro-pitting on glossy surfaces. For aggressive setups with wide wheels or sharpened suspension, maintenance includes ensuring attachment hardware remains tight and that there is no rub between skirts and tires at full lock. The joy of a well-fitted kit is the confidence it will persist under many miles.

The broader narrative is the producer’s craft and the buyer’s purpose. A basic sturdy replacement restores lines and protects the rocker; a high-end engineered variant can contribute measurable stability and aero precision. The EVO X design language rewards seamless integration: a line from front fender across the sill to a refined edge that mirrors the car’s aggression without shouting. The skill in selecting a set lies in aligning material choice with intended use, fitment with wheel and suspension, and finish with the car’s aesthetic. The market shows an active ecosystem of OEM-equivalent and aftermarket options, a spectrum of materials, and a supply chain capable of delivering consistent, tested products, even for older models. The chapter remains grounded in modification as craft, not shortcut, with the goal of enhancing the vehicle’s performance envelope without compromising integrity.

For readers curious about related chassis components that complement side skirts, an OEM-style reference provides a useful frame: it shows how a stone-guard approach to styling can harmonize with rocker panels and a broader body kit. This connected view helps frame the side skirt choice within a larger exterior-modification strategy, ensuring alignment of aesthetic and aero goals. The next layer of refinement then looks at high-end engineered systems that push aero performance further, with a representative example from specialized manufacturers illustrating precise molding and tuned profiles. Links to external resources offer deeper insight into how design intent translates into a complete aero package, including front, sides, and rear elements that work in concert for track-ready performance.

Edges in Motion: Sourcing and Significance of the Mitsubishi Lancer EVO X Side Skirts Across Global Markets

The Mitsubishi Lancer Evolution X sits at the crossroads of performance engineering and aggressive styling, and nowhere is that tension more visible than in the side skirts. These components do more than frame the car’s silhouette; they influence how air travels around the car at speed, guiding the flow away from the underbody and contributing to a balanced aero profile that supports grip during high-velocity cornering. For EVO X owners, side skirts are a practical upgrade as well as a visual statement, signaling a turn toward more purposeful, race-inspired aesthetics. The market surrounding these parts reflects that dual purpose, drawing in enthusiasts who want factory authenticity, shops seeking scalable supply, and hobbyists chasing affordable, high-performance alternatives. To understand this marketplace, it helps to look at how the EVO X’s design language translates into a demand for replacement and upgrade pieces, and how buyers navigate the landscape of OEM versus aftermarket, new versus used, and domestic versus international sourcing.

From a design standpoint, the EVO X uses side skirts to shape the lower character line and to skirt the transitional zone between the rocker panels and the front and rear fenders. The effect is not merely cosmetic; the side skirts contribute to a more controlled airflow beneath the car. Original equipment manufacturers deliver a version built to endure the car’s rally heritage, with materials selected for impact resistance and UV stability. Typical OEM implementations lean on high-impact resistant ABS plastics or fiberglass-reinforced polymers, chosen for their balance of rigidity, weight, and cost. In practice, these materials hold up under daily driving and weekend track sessions, but true performance-minded builders also explore carbon fiber options. Carbon fiber surfaces can shave weight, add stiffness, and deliver a distinctive weave that appeals to enthusiasts who value both performance metrics and the aesthetics of advanced composites. The market, therefore, accommodates a spectrum of choices, from close-to-OEM appearances to high-tech, carbon fiber upgrades that demand more careful fitment and handling during installation.

On a global scale, the marketplaces for Lancer EVO X side skirts reveal two distinct but complementary dynamics: bulk industrial sourcing and consumer-level resale. Alibaba.com captures the wholesale end of the spectrum, where the emphasis is on volume, consistency, and the capacity to outfit shops or distributors with carbon fiber or carbon-fiber-inspired options. The example of “In Stock Evo X Side Skirt Half Carbon Fiber, Durable | Alibaba.com” signals a product category aimed at professional installers and automotive businesses. Prices in this arena—roughly around $887 per unit—underscore how carbon fiber variants have become economically viable for more than boutique projects. The value proposition here centers on repeatable quality and a predictable supply chain, suitable for professional tuning shops, body shops, and small distributors who need to stock multiple units across a fleet of vehicles or a service bay that handles EVO X restorations and performance builds.

In contrast, eBay functions as the more accessible marketplace for individual buyers, restorers, and DIY enthusiasts pursuing OEM-specified parts or budget-conscious upgrades. Listings such as the OEM side skirts paired as factory rocker panels for the EVO X CZ4A illustrate how the platform enables the acquisition of authentic factory components at reachable price points. A listing price of about $400 for a pair highlights the appeal of sourcing genuine parts in pre-owned or salvage-grade conditions, especially for restorations or builds that emphasize factory look and fitment without the premium of new OEM inventory. This channel also introduces buyers to regional pricing variations and seller-informed nuances like wear, UV damage to the finish, and the possibility of minor restoration work before installation. The dichotomy between Alibaba’s bulk pricing and eBay’s individual-access approach helps explain why buyers often triangulate between platforms: a wholesale order for a shop’s inventory, paired with a few individual pieces sourced on the side for precise fitment or a specific color/finish match.

Beyond these two giants, the evolution of niche automotive e-commerce sites and forums signals a broader ecosystem in which side skirts, like many EVO X components, are discussed in depth. Consumers can access installation guides, DIY tutorials, and peer reviews that illuminate fitment concerns for different trims, paint finishes, or trim levels within the CZ4A family. This crowd-sourced knowledge helps reduce the uncertainty that often accompanies aftermarket parts. Yet with this expansion comes heightened vigilance. The offset between OEM accuracy and aftermarket substitutes can be substantial, particularly when a product is marketed as carbon fiber or UV-stable for long-term exposure. Buyers increasingly seek documentation of material composition, thickness, and resin systems, in addition to mold accuracy and wind-tunnel or track-tested claims. That trend aligns with a broader demand for reliability and traceability in automotive parts, especially when a project leans heavily on performance upgrades and the potential for repeated track use.

Quality, in this context, is not a single attribute but a fabric of interconnected expectations. For OEM side skirts, the emphasis is on fidelity to the CZ4A Evo X’s geometry and the seamless integration with rocker panel contours. For aftermarket carbon fiber variants, the considerations expand to nominal weight reduction, surface finish, weave pattern alignment, and the endurance of the clear coat against UV exposure and road hazards. The research materials point to the existence of manufacturers in China—particularly in Changzhou and Zhejiang—that specialize in high-precision mold engineering, UV-resistant finishes, and material science designed to thrive under harsh conditions. These operations typically strive to meet IATF 16949 quality standards, a reminder that even performance-oriented parts must ride within an emerging framework of process control and supplier accountability. The result is a spectrum of products that can meet varied expectations: factory-fit looks, weight-optimized performance, and durable finishes that resist the marathon of daily driving and the sporadic intensity of track days.

For buyers, the decision often starts with intent. Are you restoring an EVO X CZ4A to its original condition, with factory look and matching wear patterns? Or are you chasing a weight-saving, visually aggressive upgrade that signals intent from the curb? Do you prefer a meticulously installed, closely matched OEM pair, or are you comfortable with a carbon-fiber alternative that requires a careful check of mold seams, paint compatibility, and edge finish? These questions shape the shopping path. They also influence where a buyer chooses to shop and how much they invest in the marginal gains of aero efficiency. The market supports both routes, and the best choice often hinges on the broader project goals, including paint color, overall weight distribution, and the car’s intended use on the street or track.

In many ways, the EVO X side skirt conversation mirrors the evolution of automotive sourcing itself. It illustrates how the car community values the authenticity of OEM parts while embracing the innovations of advanced composites. It underscores a practical logic: for a shop or a dedicated enthusiast working on a limited budget, pairing a lower-cost, OEM-equivalent option sourced through a regional marketplace with a few carefully chosen carbon fiber accents can deliver a compelling balance of performance and aesthetics. For a boutique builder or a professional tuner, the calculus often expands to include explicit adherence to manufacturing standards, traceable material composition, and the potential for scale. The market’s design is not simply about what parts exist, but how buyers perceive value, risk, and the certainty that a purchase will translate into predictable fitment, durable finish, and reliable service after installation.

To illustrate how this ecosystem can extend into related areas of carbon fiber optimization, consider broader composite component sourcing beyond side skirts. For example, high-end carbon fiber bonnets and hoods are part of the same conversation, where the emphasis on weight reduction and rigidity often prompts a deeper dive into resin systems, weave orientation, and protective coatings. For readers who want to explore related components, a related example exists in the broader carbon fiber component marketplace, which includes a range of parts designed to complement the EVO X’s aero profile. If you’re curious about rotating into that ecosystem, you can explore a component of the carbon fiber family here: brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

Putting this marketplace into a practical frame, it is helpful to think about who participates in these purchases and how their transactions unfold. Professional installers and performance shops often initiate bulk procurements through Alibaba, leveraging the platform’s breadth to secure multiple units and create a turnkey upgrade path for customers who demand carbon fiber or UV-resistant finishes in quantity. These buyers value consistent specs, known lead times, and the scalability of the supply chain. Independent enthusiasts, on the other hand, typically search for better prices, clearer condition descriptions, and verifiable fitment for their specific EVO X configuration. The appeal of a used OEM set on a site like eBay lies not only in cost savings but in the chance to preserve factory geometry and panel fitment, which can reduce the risk of misalignment after paint and install. The tension between these purchase modalities reflects a wider truth about the EVO X aftermarket: the market rewards choices that align with a buyer’s priorities—authenticity, performance, affordability, and confidence in fitment.

But even as the market expands, buyers must navigate a landscape where not all carbon fiber looks are created equal. Misrepresentations, weak finishes, or mismatched mold lines can mar an otherwise strong upgrade. This is why the narrative around side skirts also embraces due diligence: researching a seller’s track record, understanding material certifications, and inspecting installation guidelines can help buyers avoid costly missteps. The EVO X’s relatively compact dimensions and the rocker-panel integration mean that even small deviations in panel curvature or edge thickness can show up as misalignment, gaps, or paint cracking after a few seasons of use. In this sense, the marketplaces function as a filter: for every list that promises a performance edge, there are accompanying requirements for fit, finish, and reliability that buyers learn to demand, either through direct questions to sellers or by relying on the experience shared across forums and retailer catalogs.

The market, then, is a living map of how EVO X enthusiasts leverage both established channels and peer knowledge to source side skirts that meet their goals. It is a map that shows the difference between sourcing in bulk for a shop, with attention to consistency and lead times, and sourcing for a personal project, guided by a budget, a color match, and a readiness to accept minor imperfections that do not affect performance. It also reveals how the community values genuine OEM integrity while embracing modern composites that push the potential of the EVO X’s aero stance forward. In this way, the side skirt market is a microcosm of the car culture’s wider shift toward combining proven engineering with innovative materials, a shift that continues to shape how owners select, install, and enjoy their upgrades on both the street and the track.

As sourcing strategies evolve, the practical takeaway remains straightforward: understand the project’s goals, verify fitment for the exact EVO X variant (CZ4A, versus other EVO X regional specs), and balance cost against the expectations for durability, finish, and weight. Whether you’re chasing a factory-accurate look or a lighter, more aggressive carbon fiber profile, the market supports a spectrum of paths. Buyers who approach this with a clear sense of their needs—whether it’s bulk supply for a shop, a single OEM pair for a resto project, or a carbon-fiber upgrade that saves weight and enhances aesthetics—can navigate the options with greater confidence. The EVO X side skirt conversation thus becomes a broader reflection of how a modern automotive aftermarket thrives on a mix of authentic parts, high-tech materials, scalable sourcing, and the shared knowledge of a dedicated community. External resource: https://www.alibaba.com

From Mold to Road: Crafting the Perfect Lancer EVO X Side Skirt through Global Manufacture and Quality

The side skirts on a Mitsubishi Lancer EVO X do more than frame the car’s lower profile. They are a quiet conversation between form and function, a line that orients the eye toward speed while quietly guiding air. In the world of high-performance tuning, a set of side skirts is rarely a single idea drawn on a drawing board. It is the result of a long chain of decisions—from where the parts are made to how they are checked for fit, weather, and track life. The EVO X side skirt exists at the intersection of aesthetics, aerodynamics, and manufacturability. Its success depends on both the discipline of engineering and the realities of a global supply chain that must deliver consistent parts at a range of scales. In this landscape, three geography-led pillars emerge as decisive: Guangdong in the south, Zhejiang in the east, and Jiangsu in the center. Each region contributes something distinct to the final product, and together they deliver a package that can satisfy both a showroom dweller and a race-day technician who needs reproducible results across dozens of vehicles.

In Guangdong, the industrial ecosystem is remarkably integrated. The factories here excel at high-impact ABS plastic formulations and composite body kit assemblies through injection molding and related processes. This is where the standard aftermarket kits often take shape, echoing OEM specifications while preserving the ability to scale production. The advantages go beyond material behavior; proximity to major ports around Shenzhen and Hong Kong translates into speed and reliability for international shipments. For buyers who need steady supply chains—whether a small shop stocking a handful of EVO X builds or a larger distributor serving a network of customers—this regional strength reduces lead times and improves consistency in surface finish. The result is parts that can match the visual cues of the original yet accommodate the customization tastes of a diverse owner base.

Moving east to Zhejiang, the emphasis shifts toward precision and durability under real-world conditions. Wenzhou-area suppliers frequently work with materials that balance rigidity and resilience, such as UV-resistant polymers reinforced with fiberglass or carbon-reinforced composites. This is where the aerodynamic load path of the side skirt can be tuned for trust under high-speed airflow and for longevity in sun-drenched climates. The craftsmanship here often centers on the interface between the skirt and the vehicle’s rocker panel, a critical junction where tolerances determine how well a side skirt aligns with the rest of the body lines. The use of CNC tooling and precision machining in Zhejiang ensures that mounting points, clip pits, and mounting flanges stay true to the intended geometry, even as the part undergoes painting or curing. For performance-oriented builds, this translates to a higher likelihood that the skirt will sit flush, resist delamination, and retain its shape even when the vehicle is pitched aggressively at the edge of adhesion and control.

In Jiangsu, particularly Changzhou, the emphasis is on process discipline and traceability. Here, factories lean on advanced die-casting, sheet metal forming, and related forming technologies to create skirts with consistent surface finishes and dimensional accuracy. This is the linchpin for buyers who demand evidence of repeatable quality. The presence of robust quality systems, often aligned with IATF 16949 and ISO/TS 16949 standards, provides a backbone for parts that must withstand rigorous testing and real-world use. The result is a pathway from raw materials to finished product that is auditable at every step. Full traceability—from material lot numbers to mold IDs and inspection reports—becomes not a luxury but a standard, a feature that reduces risk for workshops and manufacturers that treat side skirts as fixed durability components rather than disposable adornments.

Beyond geography, the material choices themselves shape performance and durability. ABS plastic remains the workhorse for many standard aftermarket skirts, balancing impact resistance with paint adhesion and cost. It tolerates the daily grind of road debris, curb contact, and washed surfaces while delivering a reasonable surface finish that can be color-matched to the EVO X’s styling cues. For those who seek a different balance of flexibility and crash absorption, polyurethane offers a bit more give. Its resilience helps when the car sits lower for aggressive setups or when the skirt must endure occasional ground contact without cracks propagating. Yet for the most exacting applications—where weight, stiffness, and a minimal cosmetic footprint matter—carbon fiber reinforced polymer represents the upper tier. CFRP skirts deliver a superior strength-to-weight ratio and a distinctive, performance-oriented aesthetic. They respond well to high-speed aerodynamic demands and the rigors of track testing, though they come with higher costs and longer lead times. Across these materials, the selection is more than a matter of preference; it is a careful balancing act between the intended use, the vehicle’s geometry, and the owner’s tolerance for maintenance and expense.

In practical terms, this material mosaic feeds into a broader manufacturing philosophy that increasingly relies on smart process control. Modern suppliers integrate real-time inspection systems, including laser scanning and three-dimensional coordinate measurement, to confirm that every produced skirt matches its nominal design within tight tolerances. Rather than only relying on post-production sampling, these systems provide live feedback during molding, trimming, and finishing. The early catching of deviations reduces waste, shortens rework loops, and ensures that a batch of skirts will align with a fleet of EVO Xs without bespoke adjustments for each installation. The digital thread here matters as much as the physical part: digital twin models of molds allow validation of fit and function before a single part is produced, enabling virtuous cycles of improvement. In a market where a small misalignment can cause scraping or uneven paint uptake, this capability translates into tangible reliability that a technician can trust when prepping a set for installation on a car that already has performance upgrades.

The conversation about quality is never complete without attention to standards and verification. Internationally recognized frameworks such as IATF 16949 and ISO 9001 form the backbone of supplier qualification. For procurement managers and performance shops alike, these certifications signal more than a glossy certificate—they indicate a measurable commitment to process consistency. Parts sourced from facilities that operate under these standards typically come with documented test results, process capability indices, and traceability records that reassure buyers about long-term reliability. In the EVO X ecosystem, where a side skirt must retain its geometry across a spectrum of temperatures, moisture levels, and mechanical loads, that assurance matters. The best suppliers will pair such certifications with practical, vehicle-relevant testing: abrasion resistance in paint, adhesion tests for the chosen coating system, load-bearing compatibility at mounting points, and resilience to vibrational stress that mirrors real-world use. The sum of these tests is not merely compliance; it is a signal that the skirt’s performance will endure both the showroom moment and the car’s more demanding days on the road or the track.

The market’s reality is that many enthusiasts source side skirts from a global pool of manufacturers, and the available options range from factory-accurate OEM replacements to aggressively styled aftermarket pieces. The appeal of a well-made SKU rests on more than the surface finish. It rests on fitment accuracy, compatibility with a range of rocker panel configurations, and the ability to withstand the environment of spirited driving without warping or paint failure. Even as some buyers pursue a factory look, the reality of aftermarket ecosystems is that differences in mounting points, panel gaps, and underbody clearance can become noticeable only after installation. For this reason, the best practice is to prioritize suppliers with solid process controls, robust material selection, and verifiable testing histories. This is how a side skirt becomes a durable, repeatable component that adds to the EVO X’s aggressive silhouette without introducing new points of failure into the chassis or the protective undertray.

An important practical note for buyers and builders is the ongoing trade-off between cost and quality. The most economical skirts, particularly those sourced through large-volume production channels, can deliver comparable aesthetics but may require additional fettling or on-car adjustments to achieve ideal fit. Conversely, premium CFRP or multi-material systems may offer superior stiffness and lighter weight, but the economics of such parts demand a higher upfront investment and longer lead times. The right choice depends on the project’s aims: a daily-driven EVO X that seeks durable, consistent appearance and performance, or a race-focused build where every gram and every micro-inch of clearance matters. In either case, the path to success is clear when the supplier can demonstrate a cohesive capability story—from resin chemistry and molding discipline to precise finishing and documented testing—rather than a single standout feature.

Across geography and materials, what ultimately matters is the alignment between a part’s intended use and the factory floor that makes it. The Guangdong plants’ scalability, the Zhejiang shops’ precision, and the Jiangsu facilities’ traceability each contribute to a larger system that can deliver consistent side skirts for EVO X owners around the world. The interplay of these elements—material choice, processing accuracy, inspection rigor, and certification discipline—shapes the quality the buyer experiences when they bolt a skirt to a rocker panel and push the car toward a corner at speed. It is a reminder that even a component as seemingly simple as a side skirt carries a technical heritage. Its lineage traces back to the mold and the metal, to the careful calibration of a factory line and the meticulous documentation that supports every finished piece. In the hands of a driver, that heritage translates into confidence: the ability to commit to a corner, knowing the piece beneath the doors is doing its job as designed.

For readers who want to explore more about supplier capabilities and the standards that govern modern automotive composites and plastics, a broader industry overview offers valuable context. External resources illuminate how manufacturers structure their quality programs and how buyers evaluate supplier performance across the globe. This lens helps explain why some EVO X side skirts are perceived as “factory-like” in their precision while others convey a strong sense of aftermarket character. The shared thread is a commitment to repeatable quality, traceability, and an end product that performs as a cohesive part of the vehicle’s dynamic system.

External resource for further reading: https://www.b2bchina.com/supplier-guide-lancer-evo-x-side-skirts-china-manufacturers-2026

Final thoughts

In conclusion, the Mitsubishi Lancer EVO X side skirts are not merely aesthetic add-ons; they play an integral role in performance optimization and vehicle stability. For business owners, understanding the technical specifications can enhance product offerings, while knowledge of marketplace dynamics helps in strategic positioning. Additionally, partnering with reputable manufacturers guarantees quality, catering to the demands of a discerning clientele. By embracing these insights, businesses in the automotive sector can better meet customer needs and foster long-term relationships with enthusiasts of this iconic vehicle.