The Mitsubishi Lancer rear wing spoiler is not just an attractive aesthetic feature; it plays a crucial role in vehicle performance and aerodynamics. For business owners in the automotive industry, understanding the nuances of rear wing spoilers can lead to better product offerings, improved customer satisfaction, and enhanced market competitiveness. This article delves into various aspects of Lancer rear wing spoilers, including their aerodynamic benefits, materials used, customization trends, performance impact, and market availability. By exploring these chapters, business owners can gain valuable insights into how to effectively incorporate Lancer spoilers into their offerings, thus catering to the needs of automotive enthusiasts and casual consumers alike.

Shaping Stability: How the Lancer Rear Wing Transforms Aerodynamics

Shaping Stability: How the Lancer Rear Wing Transforms Aerodynamics

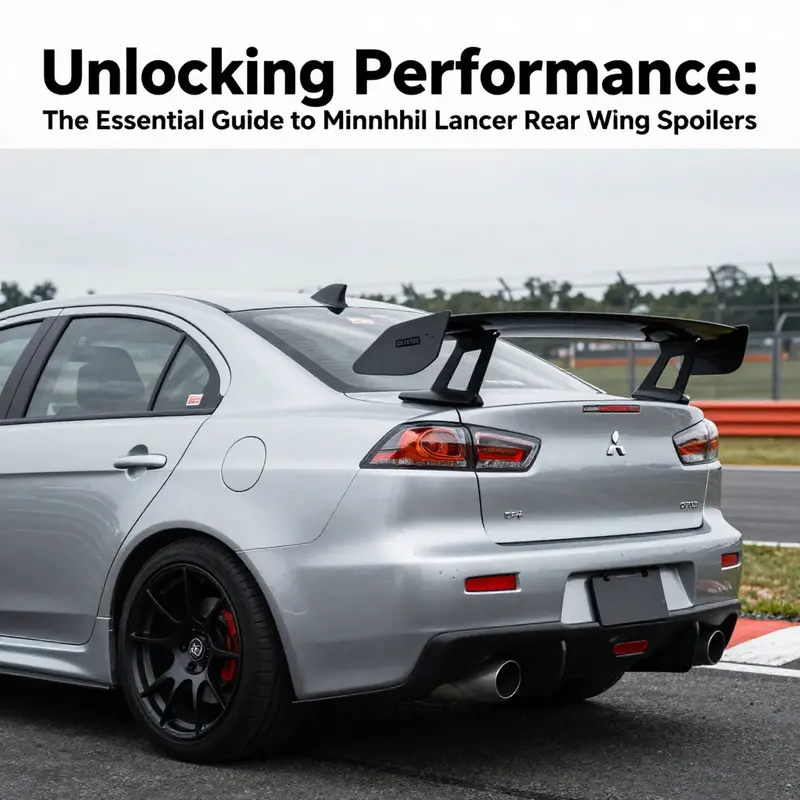

A rear wing spoiler is more than an aesthetic flourish on the trunk lid. For the Lancer, it is a deliberate aerodynamic device that reshapes airflow, trades lift for downforce, and refines the car’s behavior at speed. When tuned correctly, the wing improves rear traction, steadies the chassis through fast corners, and helps the driver place the car with confidence. The story begins with the way air meets the car, and ends with how contact patches respond under load.

At highway speeds, the flow of air over the roof and rear deck creates pressure differences. If left unmanaged, that flow can separate and form turbulent, low-pressure zones behind the car. Those zones act like suction, producing lift at the rear axle. Lift reduces tire load, undermining grip and steering stability. The wing interrupts that process by redirecting and energizing the flow. Its surfaces are profiled to generate downward force on the rear of the car. In practical terms, that means more weight on the rear tires without adding mass to the vehicle.

A wing’s effect depends on shape, size, and placement. A high-mounted, multi-element wing produces strong downforce with relatively low interference to the vehicle’s base pressure. Lower, subtler spoilers—sometimes called lips—reduce drag and tame small vortices. On the Lancer platform, full-height wings commonly seen on high-performance variants balance visible performance with measurable handling benefits. They act over a larger vertical distance, targeting the wake and creating a controlled pressure gradient that reduces separation.

Materials matter. Lightweight composites allow the wing to exert force without creating a heavy pendulum at the rear. Reinforced polymers and carbon fiber provide the stiffness required to hold an aero profile under load. Stiffer structures keep the designed angle of attack stable during high-speed runs and sudden cornering. Plastic-based materials like ABS and fiberglass are common for everyday use. They offer a compromise of durability, cost, and weight for street-focused drivers. Carbon fiber and advanced composites are favored where every fraction of performance counts.

A critical feature for drivers intent on maximizing performance is adjustability. An adjustable wing lets the driver alter the angle of attack to match conditions. Increase the angle for more downforce during track sessions. Back it off to lower drag for long straights or economy-minded driving. Each incremental change affects both downforce and drag, so adjustments are a trade-off. Higher angles increase rear grip but also increase aerodynamic resistance and alter balance. The challenge is to preserve predictable behavior through the entire envelope.

Precision fit plays a powerful role in aerodynamic success. A spoiler that fits the factory flange and follows the trunk contour preserves the intended flow lines. Wide aftermarket wings and universal-fit pieces that require adapters or fillers can introduce gaps and abrupt transitions. Those interruptions seed turbulence, which reduces the wing’s efficiency. For Lancer owners, components designed for the platform typically yield smoother integration and more reliable results.

Integration with other aerodynamic elements amplifies overall performance. A rear wing works best when the front end, underbody, and diffuser cooperate. A front lip or splitter manages the airflow entering beneath the car, controlling pressure distribution over the chassis. A rear diffuser recovers energy from the underbody flow and helps maintain attached air at the aft. When these pieces are designed together, the vehicle develops a coherent aero balance that improves cornering and straight-line stability. For reference on how rear underbody parts complement wings, consider the carbon rear diffuser V-style for Mitsubishi Lancer and Evo 10.

Wind tunnel testing and computational fluid dynamics (CFD) are the tools engineers use to refine wing geometry. Wind tunnels reveal how pressure contours form along the deck, and CFD visualizes flow separation zones. Together they guide changes in flap curvature, endplate design, and mounting height. Endplates, vertical surfaces at the wing tips, reduce spanwise flow and limit vortices that bleed away lift. They also encourage a more uniform pressure distribution across the wing. On a tuned Lancer, modest endplates often make a measurable difference in stability without adding much drag.

Real-world effects vary with speed and load. At low city speeds, a wing has negligible aerodynamic impact. Its influence only becomes meaningful as airspeed rises and dynamic pressure increases. On a tight mountain road, the added rear downforce allows drivers to carry speed into mid-corner and maintain throttle sooner through the exit. On the track, a properly set wing reduces rear-end snap and makes the car more predictable at threshold. For everyday driving, the payoff is often more confidence under spirited inputs, even if absolute lap-time gains are modest.

The tuning process should be methodical. Begin with a neutral baseline setting. Test with a consistent fuel load and tire pressures. Make small angle changes, one at a time, and record the vehicle’s behavior. Look for changes in understeer or oversteer and note the speeds where those shifts occur. Remember that rear downforce affects balance: too much can increase understeer, while too little may leave the tail light and lively. Align wing adjustments with suspension setup for a cohesive result.

Installation and durability considerations are practical but essential. Proper mounting distributes loads into the trunk structure rather than thin sheet metal. Reinforcement plates and secure hardware prevent fatigue and rattles. Waterproof seals around mounts protect against corrosion. Surface finishes matter too. UV-stable coatings preserve composite integrity and appearance. A well-installed wing should endure daily use and seasonal exposure without warping or losing alignment.

There are trade-offs. Downforce comes at a cost in drag. For drivers focused on long-range fuel economy or light commuting, an aggressive wing may be counterproductive. Urban drivers rarely exploit high-speed benefits. For enthusiasts who spend time on twisty roads or circuits, the handling improvements often outweigh the fuel penalty. The optimal compromise depends on intended use, with adjustable solutions offering flexible middle ground.

Beyond raw numbers, a rear wing communicates intent. It signals that the car’s setup prioritizes dynamic control. But visual cues must be backed by function. A wing that looks race-ready but lacks correct geometry can mislead and disappoint. Conversely, subtle, well-engineered spoilers provide discreet improvements that reward drivers without dominating aesthetics.

Maintenance is straightforward but valuable. Regular checks of fasteners and mounts prevent loosening. Inspect composite surfaces for cracks after hard use. Clean aerodynamic surfaces gently to avoid abrasive damage. If an adjustable wing sits outside, occasional lubrication of pivot points keeps operation smooth.

In the end, the Lancer rear wing spoiler is a tool. When properly selected, fitted, and tuned, it reshapes airflow to favor contact and predictability. It links the invisible physics of air to the tangible sensation of grip. That linkage is the essence of aerodynamic value: making the car behave the way the driver expects, even at the edge.

For a deeper technical exploration of rear wing design standards and applications, see this comprehensive guide: https://www.carinterior.com/guides/understanding-rear-wing-track-spoiler-complete-guide-to-standards-properties-and-industrial-applications/

From ABS to Carbon Fiber: The Materials that Shape the Lancer’s Rear Wing Spoilers

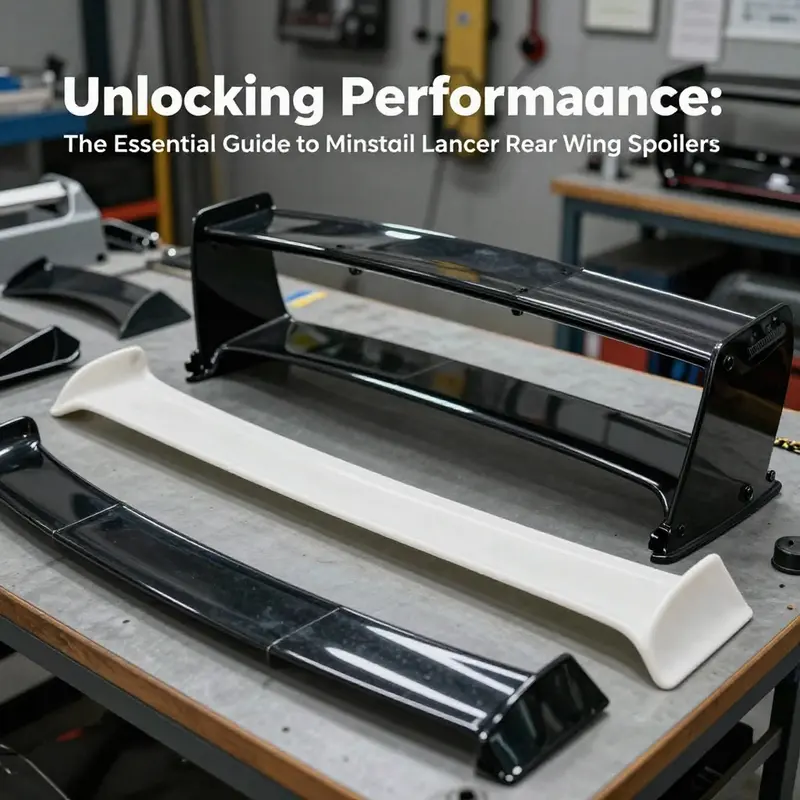

Choosing a rear wing spoiler for a Mitsubishi Lancer is a decision that blends science with style. The material you select not only affects how the spoiler looks but also how it behaves in the air, how it wears over time, and how much you will pay to achieve your desired balance of speed, stability, and personality. In the world of aftermarket wings, four materials dominate the conversation: ABS plastic, carbon fiber, fiberglass, and polyurethane. Each offers a unique mix of stiffness, weight, durability, and cost, shaping not just performance but the entire driving experience behind the Lancer. For enthusiasts, the material choice is a conversation about how air, gravity, and grit meet the curb and the corner alike, and it anchors the spoiler’s role within the broader aero package that accompanies the car.

ABS plastic serves as the practical starting point for most Lancer owners who want a reliable, affordable upgrade. It delivers a lightweight shell that resists impact and weathering, which makes it well suited to daily driving and variable climates. The molding process for ABS is mature, so designers can craft complex rear contouring that fits a range of Lancer generations without excessive tooling costs. A high-quality ABS spoiler is typically easy to paint to match the body color, and the material accepts automotive coatings that resist weathering and UV exposure over several seasons. This ease of customization is a major reason ABS remains the default choice for many street-driven builds.

Color matching and finishes are not merely cosmetic concerns. They influence how the spoiler complements the car’s silhouette and how visible the aero element remains in everyday use. ABS takes modern paints well, with good gloss retention when a protective clearcoat is applied. Its flexibility also matters in the mounting phase; a little give can ease alignment with the trunk lid and reduce the risk of micro-cracks if the panel flexes during operation. Yet that same flexibility can be a drawback at high speed if the spoiler relies on insufficient backing or undersized mounting points. In such cases, the spoiler can exhibit a slight flutter or wobble, which is more about installation and support than the material itself. A careful fit coupled with proper hardware is essential to preserve both aero performance and the visual integrity of the car.

For a different flavor of performance, carbon fiber stands out as the premium option. It brings an almost mythical stiffness-to-weight ratio, a quality that translates into a more rigid aero surface under airflow and less intrusive flex at high speeds. The result can be a more predictable downforce profile and steadier rear traction through sweeping bends and aggressive exits. Visually, carbon fiber has a distinctive weave and sheen that many owners find compelling, especially when paired with other carbon components in a complete aero kit. However, carbon fiber is not a universal cure-all. The material carries a premium price, and the engineering behind a carbon spoiler must ensure the load paths and mounting points can tolerate the greater stiffness and potential stiffness-induced loading on the trunk lid. Proper backing structures, precise alignment, and compatible hardware become even more critical when carbon fiber is chosen.

The manufacturing reality of carbon fiber adds another layer of consideration. True carbon fiber spoilers often involve hand-laid layers or carefully controlled resin systems, which contribute to a high-strength, low-weight product but also to higher costs and longer lead times. The surface may require meticulous finishing to highlight the weave and to protect against environmental exposure. Resin-rich surfaces must be sealed to prevent UV degradation, and care is needed to avoid surface microcracks, especially after impact events. While carbon fiber delivers impressive rigidity and a premium look, the owner should be prepared for a higher upfront investment and a more involved installation process to fully realize its performance potential.

Fiberglass represents a robust middle ground between ABS and carbon fiber. It is widely used in performance body kits because it can be molded into aggressive shapes without the higher price tag of carbon fiber. Fiberglass is typically stiffer than ABS and can be reinforced to improve rigidity, helping the spoiler maintain its aero profile under tougher conditions. The trade-off is weight: fiberglass is heavier than carbon fiber, though still lighter than many solid metal components. It can withstand moderate impacts and offers good durability for enthusiasts who want a bold look and reliable performance without breaking the bank. With proper gel coat protection and sealing, fiberglass spoilers can resist road exposure and maintain a strong, consistent surface over time.

Polyurethane, while less common for full rear wings, has a niche role where flexibility is advantageous. PU’s elasticity helps absorb minor impacts and prevent cracks in areas prone to slight deformation. In rear spoilers, polyurethane is more often seen in endplates or small extensions rather than the entire wing because full rigidity is typically desired for predictable aero behavior. When PU is used for a spoiler, it must be designed to avoid sag and excessive flex over the spoiler’s length, ensuring that the trailing edge remains consistent with the car’s airflow. PU can be a sensible compromise in severe driving environments where some give is preferable to a brittle defect.

The material you pick is a reflection of what you value most in the car’s personality. If you prioritize budget and straightforward installation, a high-quality ABS spoiler provides a sensible balance of price, strength, and paintability. If you want to maximize downforce while minimizing weight, carbon fiber becomes compelling—especially when the rest of the aero system is tuned for stability at speed. If you seek a robust, aggressive look and are willing to trade a bit more weight for price control, fiberglass offers a solid middle path. And if your use-case includes frequent minor impacts or a desire for flexible components that still look integrated, polyurethane has some appeal in specific, carefully engineered details.

Beyond the material properties, fitment and aging matter just as much as the raw composition. The Lancer’s rear end has evolved across generations, with trunk lines and tail panel geometries that influence how a spoiler seals and aligns with the body. A spoiler designed for one generation may require modifications to fit another, and the mounting approach matters as much as the material itself. Solid alignment, uniform base contact, and a reliable seal against moisture protect the interior layers and maintain a consistent aero surface. When a spoiler sits flush with the trunk line, airflow follows the contour smoothly, reducing the risk of drag-induced noise or vibration and preserving rear stability at the limit. For readers curious about how rear-end components intertwine with spoilers and other aero elements, a broader look at the rear area of the Lancer can be illuminating: 2008-2015-mitsubishi-lancer-evo-x-rear-bumpers.

Maintenance and care also reflect the material choice. ABS offers straightforward cleaning and a simple repaint process if chips occur. A protective clear coat helps preserve gloss and resist UV fading, which keeps the spoiler looking sharp through many sunlit seasons. Carbon fiber requires careful surface care to protect the weave’s appearance; light polishing and a UV-safe coating preserve both the look and the structural integrity of the surface. Fiberglass benefits from vigilant inspection for gel coat cracks and moisture intrusion, with timely repairs to prevent deeper damage. In each case, routine checks of seams, mounting hardware, and the seal with the trunk are essential to sustaining performance and appearance. A properly maintained spoiler supports consistent airflow and reduces the chance of edge separation or flutter in spirited driving.

In practice, the choice of material becomes a broader expression of how the owner wants the car to behave and feel. ABS is a cost-effective, reliable baseline that keeps the rear end visually integrated. Carbon fiber elevates the experience with a premium weight saving and stiffness, but at a cost and complexity that may exceed what some drivers need. Fiberglass offers a bold look with robust performance at a more accessible price point, while polyurethane provides flexibility in targeted areas where some give is desirable. These options reflect a community of enthusiasts who value both the function and the form of the Lancer’s rear end, recognizing that a spoiler is not merely a cosmetic accent but a carefully engineered element that interacts with the entire aerodynamics of the vehicle.

For those who want to pursue more informed research and practical guidance, there are comprehensive resources that discuss how to choose and install a Mitsubishi Lancer rear spoiler. A reliable external resource provides a detailed overview of selection criteria, installation steps, and maintenance considerations, which can help readers align their goals with the appropriate material choice. External resource: https://www.carinterior.com/how-to-choose-and-install-a-mitsubishi-lancer-rear-spoiler

Shaping Speed and Style: Contemporary Customization of Lancer Rear Wing Spoilers

Shaping Speed and Style: Contemporary Customization of Lancer Rear Wing Spoilers

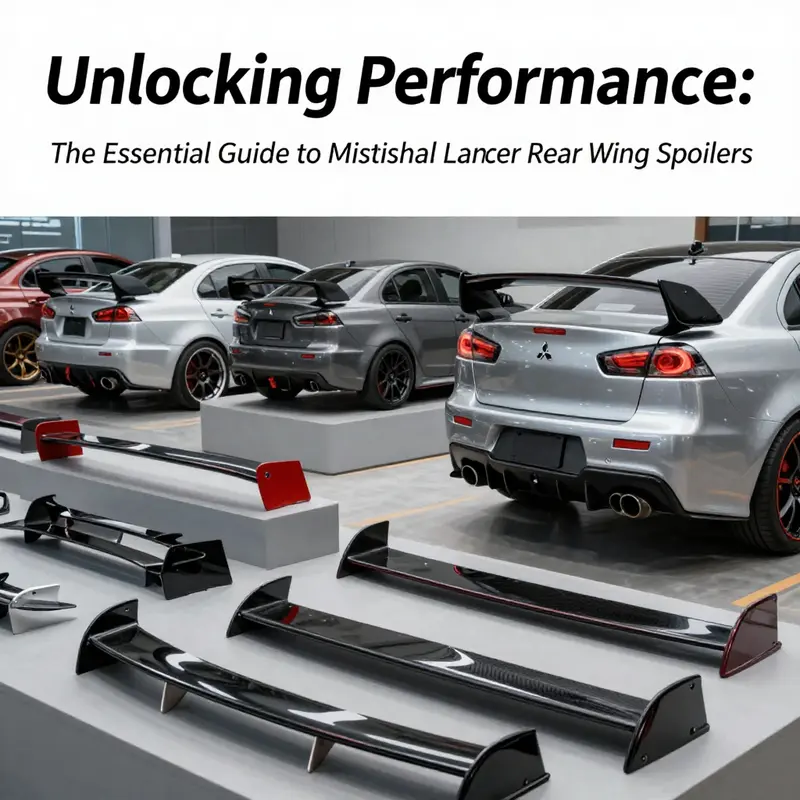

Customization of the Mitsubishi Lancer rear wing spoiler sits at the intersection of performance engineering and personal expression. Owners no longer accept a one-size-fits-all approach. Instead, they choose spoilers that reflect how they drive and how they want their car to be seen. This chapter follows the current trends in spoiler customization, and explains why each trend matters for handling, fitment, and visual harmony.

A dominant direction is the adoption of race-inspired wing profiles scaled for street cars. These designs borrow the silhouette of GT racing wings. They use elevated mounts, broad endplates, and adjustable blades to influence airflow at the rear. When tuned properly, these wings reduce lift and increase rear downforce at speed. That increases traction during high-speed cornering and helps maintain composure under braking. Enthusiasts who value track performance choose wings with real aerodynamic purpose. Others pick the same shape for the aggressive stance it lends their car.

Customization today balances extremes. On one hand, subtlety is sought by daily drivers who want an OEM-plus look. On the other, dramatic pedestal-mounted wings appeal to those who want a track-ready appearance. The available spectrum ranges from delicate lip spoilers that sit flush with the trunk edge, to tall, multi-piece wings that dramatically alter the car’s profile. Each choice carries trade-offs. Smaller lips preserve hatch access and reduce the chance of wind noise. Larger wings offer measurable aerodynamic benefit when the vehicle sees higher speeds or track use. Understanding these trade-offs is now essential before buying and fitting a spoiler.

Material choice drives both durability and cost. Modern spoilers commonly use impact-resistant plastics and reinforced composites. Thermoplastic blends provide flexibility and lower cost, and they resist damage from minor impacts. Fiberglass remains popular for its stiffness and ease of repair, though it is heavier and can be brittle on impact. For those prioritizing weight savings, carbon fiber and composite layups deliver the best strength-to-weight ratio. However, they are more costly and often require careful maintenance to avoid surface damage. Buyers weigh these factors against intended use: daily commuting, spirited street driving, or dedicated laps on a circuit.

Fitment precision is a rising expectation. Aftermarket suppliers now offer spoilers tailored to specific model years and trims. That reduces trimming and adjustment during installation. Proper fitment prevents gaps, reduces unwanted vibration, and ensures the spoiler complements the vehicle’s proportions. Many modern options are molded to match trunk curvature, tail light geometry, and factory mounting points. For owners considering wider body modifications, designers often recommend coordinating spoiler size with bumper and diffuser treatments, creating an integrated aerodynamic package for balanced performance.

Aesthetic integration has grown more sophisticated. Designers focus on a spoiler’s ability to accentuate a car’s lines rather than merely adding a bolt-on element. This means paying attention to the interplay between roofline, trunk angle, and rear fascia. Subtle contours, matched surface transitions, and color-matched finishes turn a spoiler into a coherent design element. Paint-matched bases and wrapped or textured surfaces help a wing appear intentional rather than aftermarket. The goal is a unified look where the spoiler appears to have been considered at the same time as the rest of the car’s design.

Customization is not only about form. Many builders combine spoilers with complementary aero parts. Rear diffusers, side skirts, and front splitters create a full aerodynamic suite that manages airflow from front to back. When these pieces are developed together, they create coherent pressure zones that improve stability. A rear wing without attention to the underbody and diffuser can give uneven results. For people looking for an assembled look, pairing a spoiler with an appropriately shaped diffuser keeps the rear balanced and reduces the chance of unpredictable handling.

Practical considerations influence the choice as much as aesthetics. Large pedestal wings can interfere with hatch operation. Some wings require drilling into the trunk floor for secure mounting, which can complicate hatch seals and wiring routed through the trunk. Improper installation can introduce wind noise and vibration, especially at highway speeds. Buyers are increasingly turning to professional installers or verified fit kits to avoid these issues. The smart approach is to factor in installation details before buying, rather than retrofitting a wing to a car not prepared for it.

Color and finish trends reflect a blend of subtlety and contrast. Many owners prefer paint-matched wings for a seamless factory look. Others choose exposed-finish styles, such as raw-weave composites or matte textures, to signal bespoke modification. Some finishes emphasize longevity, using UV-stable paints and protective clear coats. Others favor wrapped surfaces that can be changed seasonally or replaced with less expense than repainting. These choices affect resale value and visual impact, so they are planned with both short-term tastes and long-term ownership in mind.

The debate between factory and aftermarket remains active. Factory spoilers provide a clean fit and do not usually affect warranty coverage. They suit owners who seek mild sportiness without trade-offs. Aftermarket options win on variety. They let owners pursue unique themes, from understated lips to competitive wing geometries. The aftermarket permits customization of mount height, blade angle, endplate design, and even adjustability. Yet aftermarket parts demand more attention to quality and fit. Poorly matched items can introduce noise, rust through improper drilling, or hamper hatch function. The trend is toward vetted designs and reinforced mounting kits that minimize these risks.

Community influence shapes many decisions. Enthusiasts often draw inspiration from performance models and specialized builds. That drives replication of certain wing styles across year ranges and body types. At the same time, social platforms and galleries show how different wings change the car’s personality. This visual feedback helps buyers make choices that match their aesthetic goals. The most successful builds consider how the wing interacts with wheel fitment, ride height, and body lines, producing a cohesive result rather than a single dramatic element.

Maintenance and longevity are practical trends that matter to owners. Spoilers exposed to road debris, salt, and UV need appropriate care. Regular inspection of mounting hardware, seal integrity, and finish condition prevents larger failures. For those who track their cars, modular wings that allow easy removal and transport are increasingly popular. That reduces the risk of damage during everyday use and keeps the spoiler’s condition optimal for both show and performance.

Choosing the right spoiler for a Lancer requires balancing goals: aerodynamic performance, visual intent, material priorities, and installation realities. When those factors align, the rear wing becomes more than an accessory. It enhances stability, defines the car’s character, and integrates with the broader set of desired modifications. For owners planning a fuller aero transformation, pairing the wing with compatible rear diffusers and bumpers completes the approach; see this resource on a carbon rear diffuser for Lancer and Evo 10 for an example of how components work together: carbon rear diffuser for Lancer and Evo 10.

For a deeper technical overview of bodykit standards and the industrial design considerations that influence spoiler development, consult a detailed guide on bodykit standards and industrial use: https://www.motortrend.com/cars/mitsubishi-lancer/2023-mitsubishi-lancer-6-bodykit-standards-composition-industrial-use/.

Anchoring the Lancer: How a Rear Wing Spoiler Shapes Stability and Cornering

Anchoring the Lancer: How a Rear Wing Spoiler Shapes Stability and Cornering

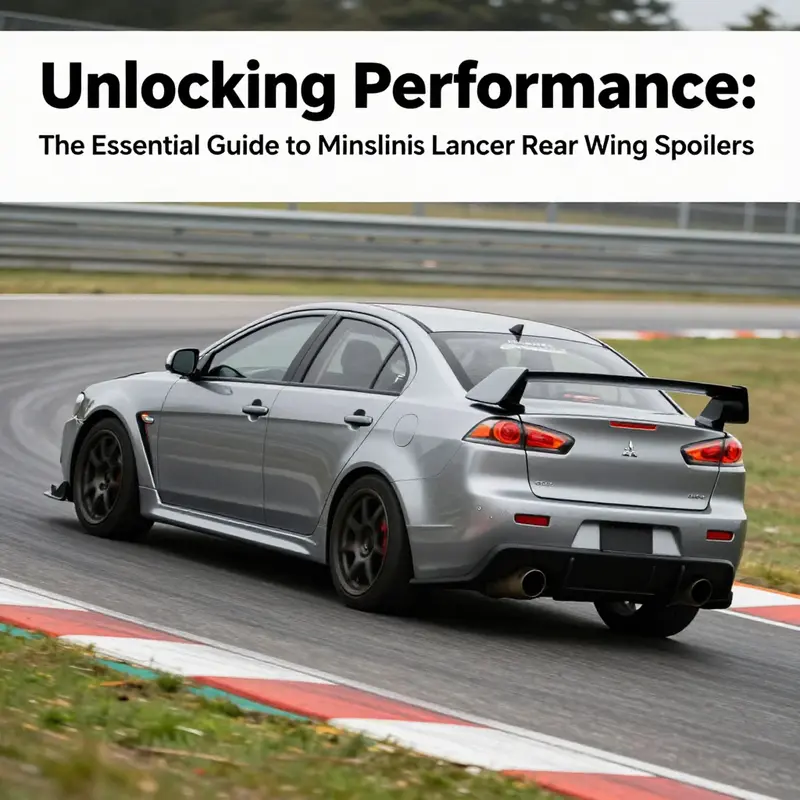

A rear wing spoiler on a Lancer does more than dress the trunk. It is an aerodynamic tool that shifts how the car interacts with air. At speed, air behaves like a moving surface beneath and above the car. A properly designed spoiler modifies that air, trading lift for downforce and turning an uncertain rear end into a planted platform. The result affects straight-line stability, turn-in confidence, and tire load distribution.

Downforce is the central concept. As the car accelerates, airflow over the roof and trunk creates pressure differences. Without intervention, this can generate lift at the rear axle, reducing traction. A wing-shaped spoiler forces air to change direction and speed. That change produces a downward force on the trunk lid, increasing vertical load on the rear tires. More load increases lateral and longitudinal grip, allowing the driver to carry higher speeds through corners and maintain composure under heavy throttle.

This effect is speed-dependent. At city speeds, the aerodynamic forces are small. On a highway or a track, the forces grow quickly with speed. Because aerodynamic forces scale roughly with the square of speed, a small increase in velocity yields a much larger increase in downforce. That is why a spoiler that seems ornamental around town can become functionally significant on a sweep or straight.

Design details determine how much downforce appears and at what cost. Wing profile, chord length, and the angle of attack set the balance between extra grip and added drag. A higher angle usually increases downforce but also increases drag and can reduce top speed or fuel efficiency. Multiple-element designs can achieve better lift-to-drag ratios, but they add complexity and weight. Materials matter too: rigid, lightweight materials help the wing hold shape under load. If a spoiler flexes, its intended aerodynamic shape changes, and performance declines.

Beyond the wing itself, integration with the car’s overall aero package amplifies gains. When a rear wing works in concert with front splitters, side skirts, and underbody components, airflow becomes more coherent. A front-mounted element reduces lift at the nose and helps distribute aerodynamic balance front-to-rear. When designers manage airflow under the car and through diffusers, the rear wing operates on cleaner, more useful air, enhancing stability while keeping drag in check.

Practical integration is not only about parts. Suspension setup, ride height, and tire choice interact with aero changes. Adding rear downforce shifts weight distribution toward the back. If the suspension remains unchanged, handling balance may move toward understeer or oversteer depending on front grip. Tuners often alter spring rates, anti-roll bars, and damper settings to restore a predictable balance after fitting a wing. Tire pressures might need fine-tuning too; the added vertical load changes contact patch behavior under cornering.

Testing matters. Static bolting and visual fitment reveal little about aerodynamic effect. Real gains are measured in lap times, braking stability, and driver confidence. Wind tunnel data offers precise metrics. Track testing provides real-world feedback. Simple on-road tests—such as timed pulls or slalom runs—can demonstrate differences in stability and responsiveness. For owners without access to a track, highway runs at legal speeds still allow a sense of reduced twitchiness and more stable lane changes.

Not every spoiler delivers meaningful performance. Cosmetic designs often prioritize shape and finish over airflow management. These pieces can look aggressive and enhance presence, but their aero contribution is limited. Performance spoilers have specific profiles, mounting positions, and, sometimes, adjustability. Adjustable mounts allow drivers to tweak angle of attack to suit conditions, trading downforce for lower drag when needed. That adaptability is valuable for a car used both on road and track.

Material selection impacts both function and durability. Lightweight composites maintain profile under load and reduce added mass. Rigid plastics with reinforcement offer a balance between cost and structural integrity. Heavier materials can still be effective but may alter vehicle dynamics through increased trunk mass. Corrosion-resistant mounts and strong attachment points ensure the wing transmits aerodynamic loads safely to the chassis without flexing or loosening.

Fitment precision is a practical point often overlooked. Gaps, misalignment, or poor sealing where the spoiler attaches can create turbulent flow that undermines downforce and increases drag. A spoiler engineered for precise fitment to a specific trunk or hatch shape will perform better than a generic item adapted to fit. Proper installation also preserves trunk weatherproofing and prevents rattles or vibration under load.

A wing’s role changes with driving context. On the street, modest downforce may simply make high-speed cruising feel more secure. On the circuit, the same wing can transform lap times by enabling higher exit speeds and later braking. Drivers notice improved rotation mid-corner when rear traction is more consistent. The confidence to apply throttle earlier often equals tangible time saved.

Integration with rear-end components enhances effect. Elements like diffusers and splitters manage the air before it reaches the wing or after it leaves the car. A diffuser accelerates air underneath, reducing pressure and contributing to net downforce at the rear. When matched with a properly tuned wing, this system improves balance and reduces drag penalties compared to a mismatched setup. For owners considering a full aerodynamic strategy, pairing a rear wing with a compatible diffuser is a logical step; see an example of a carbon rear diffuser V-style for Mitsubishi Lancer and Evo-10 for reference.https://mitsubishiautopartsshop.com/carbon-rear-diffuser-v-style-mitsubishi-lancer-and-evo-10/

Maintenance is straightforward but important. Inspect mounting hardware regularly. Check for cracks or delamination in composite parts. Ensure adjusters remain tight and corrosion-free. Small repairs or reinforcements can prolong life and maintain performance. When replacing a wing, prioritize parts that maintain original mounting geometry and structural load paths to avoid introducing unwanted flex.

Finally, consider measurable goals before fitting a spoiler. Are you seeking a visual upgrade, more highway composure, or lap time reductions? If the aim is performance, prioritize an aerodynamically validated design and prepare to adjust suspension and tires. If the goal is style, accept that aerodynamic benefits may be minimal. In either case, fitment quality and materials influence how the wing behaves across conditions.

For deeper background on how vehicle aerodynamics create lift and downforce, consult a technical overview of road vehicle aerodynamics: https://en.wikipedia.org/wiki/Aerodynamicsofroad_vehicles

A rear wing spoiler is not a magic fix. It is an aerodynamic tool that, when matched to a car and a driver’s goals, can markedly improve stability and cornering. The best results come from coherent design, precise fitment, and complementary suspension tuning. For a Lancer owner, a thoughtfully chosen spoiler can change how the car communicates and behaves, turning fast driving into a more controllable, confident experience.

Where to Find Lancer Rear Wings: Availability, Pricing Tiers, and Buying Strategy

Market reality for Lancer rear wing spoilers combines variety and clear trade-offs. Buyers choose between convenience, exact fit, cost, and performance. The right decision balances style, materials, and intended use. This chapter walks through what’s available, typical price brackets, and practical advice to help you find the best rear wing for your Lancer.

The market splits into three broad channels: genuine factory parts, branded aftermarket offerings, and bulk or budget wholesale imports. Each channel serves different priorities. Genuine factory parts deliver fit and finish tuned to original specifications. They usually cost more, because they match factory mounting points and paint options. Aftermarket parts aim to blend appearance and added functions. They often offer sportier shapes, built-in lighting, or integrated diffusers. Wholesale imports cater to budget buyers and installers who need many units. These are often basic in finish and may need modification for a perfect fit.

Materials and construction explain much of the pricing range. Common materials include ABS plastic, fiberglass, and higher-end composites. ABS is lightweight, inexpensive, and resistant to everyday impacts and weather. Fiberglass is stiffer and can carry sharper shapes. It also often requires finishing work after delivery. Premium composite options offer superior strength and weight savings. They also command higher prices. When assessing a listing, look for clear material descriptions. Sellers who list thickness, reinforcement methods, and curing processes usually provide more reliable parts.

Price tiers are straightforward. Entry-level wings for common Lancer models can be found in the low hundreds, under $130 on many online auction platforms. These units tend to be simple ABS pieces. Mid-tier options run toward the upper hundreds. They include branded aftermarket spoilers with integrated features and finer surface finish. Top-tier aftermarket and genuine parts approach or exceed the high two-hundred dollar range. These include refined fitment, better coatings, and sometimes lighting integration.

OEM pieces often sit at the high end of that band. Their premium derives from guaranteed fit, finish, and paint matching. They may also come with part numbers and documentation that support warranty claims. For owners who value authenticity, OEM parts are worth the extra cost. For tuners or budget restorers, a high-quality aftermarket wing can deliver similar visual impact at a lower price.

Availability varies with the Lancer generation. Popular performance models typically have the widest offerings. Early-generation sedans and later compact models both enjoy a steady aftermarket supply. However, exact-fit wings for specific year ranges sometimes sell out faster. When you want a part built for a narrow production window, watch listings regularly and consider trusted suppliers who stock compatible options.

Geography affects buying choices as well. North American and Australian markets both host vibrant aftermarket scenes. Online marketplaces and regional distributors make shipping common. But shipping costs and import duties influence the final price. Bulk suppliers from overseas offer attractive unit prices. But buyer beware: low upfront costs can be offset by customs fees, long transit times, and possible return complications. For a one-off replacement, a domestic supplier may save time and hassle, even at a slightly higher price.

Retailers beyond auction sites provide additional benefits. Some sellers offer installation kits, matching hardware, and finished paint. Others include warranty coverage. When comparing price tags, factor in these extras. A more expensive listing with included hardware and a short warranty can be better value than a cheaper listing that lacks bolts, tape, or paint-ready finishing.

Quality indicators help separate good buys from poor ones. Clear photos from multiple angles show attachment points and underside structure. Seller-provided measurements and templates reduce risk. Listings that mention reinforced mounting plates and pre-drilled holes usually require less trimming during installation. Also consider return policies. Reputable sellers allow returns within a reasonable window. They often describe their shipping protections and packaging methods. These details matter with brittle finishes or large fiberglass parts.

If you plan on painting the wing to match your car, check whether the part arrives primed or raw. Some parts ship in primer for easier painting. Others ship in finished paint. A finished paint job avoids immediate paintwork. But it might not perfectly match your vehicle’s factory shade. Primered wings allow custom paint matching. Budget import wings may need substantial sanding and filler to achieve a smooth finish.

Performance-minded buyers should weigh aerodynamic claims against verified fitment. Many aftermarket wings improve stability at higher speeds. However, small cosmetic pieces rarely change handling in a meaningful way for daily driving. Look for wings with documented downforce benefits or those used by track communities. If you aim to enhance cornering traction, consider professional fitting and alignment after installation. Correct mounting height and angle matter for aerodynamics.

Installation complexity affects total cost. Some wings bolt directly to factory holes. Others need drilling, adhesives, or custom brackets. If you lack fabrication tools, budget for a professional installation. Labor costs vary. A straightforward bolt-on usually takes one to two hours. Custom mounts and paint matching add time and expense. Keep this in mind when comparing cheap listings against slightly pricier, ready-to-install parts.

Resale and value retention come into play too. A well-matched OEM wing can preserve a vehicle’s resale appeal. A poorly fitted or ill-painted aftermarket unit may reduce appeal. If you plan to sell the car, document the parts and keep receipts. Buyers often value original parts or high-quality aftermarket upgrades.

For resellers and shops buying in volume, wholesale platforms offer the most attractive margins. Bulk orders reduce unit prices significantly. But verify quality before committing to large purchases. Request samples and inspect fitment on a test vehicle. Establish relationships with suppliers who can meet color, material, and lead-time expectations.

When negotiating price, use clear comparisons. Show listings with similar items and better terms. Ask sellers about combined shipping, discounts for multiple purchases, or custom packaging. A polite and informed approach often yields a better deal.

Warranty and customer support separate confident sellers from questionable ones. A short warranty on paint or fitment signals seller confidence. Some sellers provide follow-up support, including installation guidance. Always save communication records and warranty information. They protect you if a fitment issue arises.

Practical buying steps include measuring your trunk and mounting points, confirming model-year compatibility, and requesting close-up photos of the underside. If possible, test-fit before final finishing. A dry-fit ensures alignment and reveals hidden obstacles. For painted parts, order paint codes or request spot-matching before shipping.

Finally, consider complementary components. A rear wing often works best with related aero pieces, such as diffusers or bumpers. Combining purchases from the same supplier can streamline finish matching and reduce freight costs. For Evo X owners and those upgrading performance bumpers, exploring coordinated rear bumper and wing options can create a cohesive look. See an example of coordinated rear bumper offerings for related context.

For a practical listing and reference on availability, see this auction listing: https://www.ebay.com/itm/267449064625

Final thoughts

Understanding the role of the Mitsubishi Lancer rear wing spoiler is essential for business owners looking to cater to the performance and aesthetic needs of their customers. As highlighted throughout this article, these spoilers not only enhance the vehicle’s aerodynamic properties but also provide a canvas for customization and bolster overall performance dynamics. With diverse material options and market accessibility, integrating quality Lancer rear wing spoilers into product offerings can significantly attract both automotive enthusiasts and those seeking practical enhancements for their daily drives. Investing in expert knowledge on these components will give business owners the edge required to thrive in a competitive automotive market.